Lifters

#21

sorry...it moves .078....Measured many times.....

and think about it...

GM says that you should be anywhere from 1/4 turn to 1-3/4 turns....

stock LS1 lifter allows for .160... 2 turns would be almost .160

if it were only .049...they would allow for up to 3 turns....

the numbers make sense at .078, and again.. I have measured at roughly .078 many times

anyways...not going to get into this argument in this thread...its about lifters anyways...not the preload associated with them..

personally, I prefer to run about .025 of preload...keeps things quieter, and allows for higher rpm's because you arent fighting the lifter pressure...I also run a set of Jesel Adjustable rockers...so I can set preload on each rocker individually and I can set it to the value I desire...

and think about it...

GM says that you should be anywhere from 1/4 turn to 1-3/4 turns....

stock LS1 lifter allows for .160... 2 turns would be almost .160

if it were only .049...they would allow for up to 3 turns....

the numbers make sense at .078, and again.. I have measured at roughly .078 many times

anyways...not going to get into this argument in this thread...its about lifters anyways...not the preload associated with them..

personally, I prefer to run about .025 of preload...keeps things quieter, and allows for higher rpm's because you arent fighting the lifter pressure...I also run a set of Jesel Adjustable rockers...so I can set preload on each rocker individually and I can set it to the value I desire...

#22

Its not an argument. Since these are pedestal mount, they simply do not move like SBC rockers. Once seated they don't move. Torque them to 50 ftlbs and they won't move anymore. I have no idea what you are measuring. Best way is to get an adjustable pushrod, set to 0 lash then add desired preload. The turn method is goofy with the ls1 because of the limited bolt travel.

#24

Its not an argument. Since these are pedestal mount, they simply do not move like SBC rockers. Once seated they don't move. Torque them to 50 ftlbs and they won't move anymore. I have no idea what you are measuring. Best way is to get an adjustable pushrod, set to 0 lash then add desired preload. The turn method is goofy with the ls1 because of the limited bolt travel.

Last edited by KCS; 12-30-2013 at 11:39 AM.

#25

Its not an argument. Since these are pedestal mount, they simply do not move like SBC rockers. Once seated they don't move. Torque them to 50 ftlbs and they won't move anymore. I have no idea what you are measuring. Best way is to get an adjustable pushrod, set to 0 lash then add desired preload. The turn method is goofy with the ls1 because of the limited bolt travel.

and agreed...best way is an adjustable pushrod...

crank down the rocker, adjust the adjustable pushrod to zero lash, and add the desired preload to that length, order pushrods cut to your exact length.

#26

LS7 lifters work well in moderate valvetrain setups. Aggressive lobes, heavy valves, and weak springs can cause the valvetrain to become unstable and destroy any lifter. A large duration doesn't necessarily mean an aggressive lobe either. Some of Comp's softest shelf lobes are 230 degrees minimum.

#28

I'm not so sure what the math you are trying to do there is...

but its not 1/3 of a turn from zero lash to rocker snug....

0 lash, is zero lash...

once the rocker is snug, you get .078 every turn

if you get something different, then your measurement is flawed somewhere.

that must have been somebodys measurement on their own setup, and like I said...somewhere, their math is flawed

but its not 1/3 of a turn from zero lash to rocker snug....

0 lash, is zero lash...

once the rocker is snug, you get .078 every turn

if you get something different, then your measurement is flawed somewhere.

that must have been somebodys measurement on their own setup, and like I said...somewhere, their math is flawed

#30

The term "0 lash" can be different depending on the method.

If you use the turn method, "0 lash" is when the bolt has been tightened down enough to take out the slop in the system, but the rocker may or may not be seated on the stand.

If you use the turn method, "0 lash" is when the bolt has been tightened down enough to take out the slop in the system, but the rocker may or may not be seated on the stand.

#31

I measured zero lash after I torqued to 22 ft lbs then added my preload to the equation

#32

then you torque to 22ft lbs...

the distance it moves between 0 lash and 22 ft/lbs is your preload amount.

#33

For LS7 lifters, there's enough movement that it doesn't matter the exact preload. The range from .050" to .100" would work. For something like the Comp or Johnson short travel or Morels, you have a much smaller window for preload.

Last edited by JakeFusion; 12-30-2013 at 01:04 PM.

#34

it makes no difference where the rocker is at that point with a fixed rocker

if you were to get the rocker to touch the stand before you got to zero lash, you would never get to zero lash...meaning you have too short of a pushrod.

with a fixed rocker, it should always contact the pushrod before the rocker seats on the stand, otherwise, as just stated, you have too short of a pushrod and zero preload on the lifter

if you are using an adjustable rocker, then you have to bring the rocker adjuster down to meet the pushrod for zero lash and add in your desired amount...but zero lash is still that point where you can no longer move the pushrod by hand

I measured zero lash after I torqued to 22 ft lbs then added my preload to the equation

put an adjustable pushrod in, torque down the rocker to spec, turn adjustable pushrod until you experience zero lash, and add your desired preload to the measurement.

you will get exactly the preload you added to your measurement assuming you measured correctly.

also, we are not measuring total valve lash with an LS1....there should be zero valve lash with a hydraulic lifter

if you have a solid lifter, you have to have a pretty exact pushrod length and you set your lash with shims or spacers to get the rocker to sit so you have a predetermined amount of "lash" or slack between the rocker and the pushrod..usually in the order of .010 to .015, sometimes smaller after the engine heats up and things expand.

if you dont measure, and just slap in a random set of what you have been told is the correct pushrod...

once you find zero lash...you can count the turns to get an approximate amount of total preload that your system has...

again, 1 full turn is .078...and you can only measure as accurately as you can estimate by eye.....example...1/2 turn.....are you really at exactly 180* or are you at 175* from where you started...?

#35

I didn't torque down to 22ft-lbs before I measured. I doubt it makes much difference. It torques almost immediately to 22 without any preload.

I measured 7.52x" across my valves (just holding them with my finger - and setting the adjustable to 0 lash) and ordered 7.557 for ~.035-.040" preload. I got 3/4 a turn or so (measured the degree with my torque wrench - 260-330 degrees across the valves). I only have .058" of travel. And I had 7.572 pushrods before, and they meaured out to 370-420 degrees across the board). If they had been wayy too long, the valves would have opened. The measurement was .048-.054" preload.

Again, I didn't measure 0 lash at 22 ft-lbs. I kind of wish I did. I would have probably been slightly shorter across the range and would have ordered something closer to a 7.550" pushrod. But I'll lose .010" of preload anyway at temp.

I measured 7.52x" across my valves (just holding them with my finger - and setting the adjustable to 0 lash) and ordered 7.557 for ~.035-.040" preload. I got 3/4 a turn or so (measured the degree with my torque wrench - 260-330 degrees across the valves). I only have .058" of travel. And I had 7.572 pushrods before, and they meaured out to 370-420 degrees across the board). If they had been wayy too long, the valves would have opened. The measurement was .048-.054" preload.

Again, I didn't measure 0 lash at 22 ft-lbs. I kind of wish I did. I would have probably been slightly shorter across the range and would have ordered something closer to a 7.550" pushrod. But I'll lose .010" of preload anyway at temp.

#36

zero lash is always when you can no longer move the pushrod by hand either up or down or by spinning it.. there is no other definition

it makes no difference where the rocker is at that point with a fixed rocker

if you were to get the rocker to touch the stand before you got to zero lash, you would never get to zero lash...meaning you have too short of a pushrod.

with a fixed rocker, it should always contact the pushrod before the rocker seats on the stand, otherwise, as just stated, you have too short of a pushrod and zero preload on the lifter

if you are using an adjustable rocker, then you have to bring the rocker adjuster down to meet the pushrod for zero lash and add in your desired amount...but zero lash is still that point where you can no longer move the pushrod by hand.

it makes no difference where the rocker is at that point with a fixed rocker

if you were to get the rocker to touch the stand before you got to zero lash, you would never get to zero lash...meaning you have too short of a pushrod.

with a fixed rocker, it should always contact the pushrod before the rocker seats on the stand, otherwise, as just stated, you have too short of a pushrod and zero preload on the lifter

if you are using an adjustable rocker, then you have to bring the rocker adjuster down to meet the pushrod for zero lash and add in your desired amount...but zero lash is still that point where you can no longer move the pushrod by hand.

Like I said, "0 lash" is when the slop is taken out of the system, but depending on the method, it can be different. Using the turn method, like you just explained, the rocker shouldn't seat when you reach "0 lash". It can, but shouldn't. Using the other method with an adjustable pushrod, the rocker should be seated when you reach "0 lash".

#38

I'm not so sure what the math you are trying to do there is...

but its not 1/3 of a turn from zero lash to rocker snug....

0 lash, is zero lash...

once the rocker is snug, you get .078 every turn

if you get something different, then your measurement is flawed somewhere.

that must have been somebodys measurement on their own setup, and like I said...somewhere, their math is flawed

but its not 1/3 of a turn from zero lash to rocker snug....

0 lash, is zero lash...

once the rocker is snug, you get .078 every turn

if you get something different, then your measurement is flawed somewhere.

that must have been somebodys measurement on their own setup, and like I said...somewhere, their math is flawed

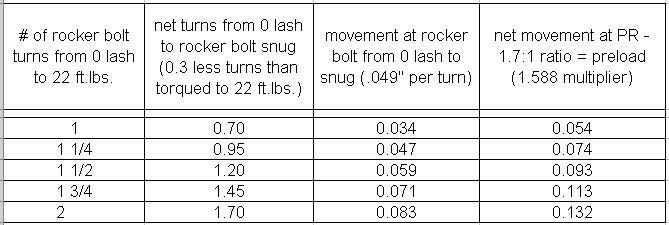

If you had 1.3 turns from 0 lash to 22 ft.lbs. (.3 of that turn is used up stretching the rocker bolt to get to 22 ft. lbs.) so only 1 turn is used up applying lifter preload. 1 x .049 = .049" movement at the rocker bolt, .049" x 1.588 = .078" lifter preload.

The chart is intended to provide a ballpark preload figure if you're using the "number of turns" method to check preload.

I agree, that you get .078" preload per turn of the rocker bolt, unless the bolt is being torqued in which case the rocker & pushrod aren't moving.

#39

from tight to 22 ft-lbs is not .3 of a turn.....

not even close.....

maybe .1 of a turn.....bit not a whole 1/3 of a turn

if you get .3 of a turn from 0-22 ft/lbs...you weren't all the way down to begin with

not even close.....

maybe .1 of a turn.....bit not a whole 1/3 of a turn

if you get .3 of a turn from 0-22 ft/lbs...you weren't all the way down to begin with