0.650" lift on stock rockers, pictures!!!

#1

Well now that you are here to see the carnage, let me show it to you.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

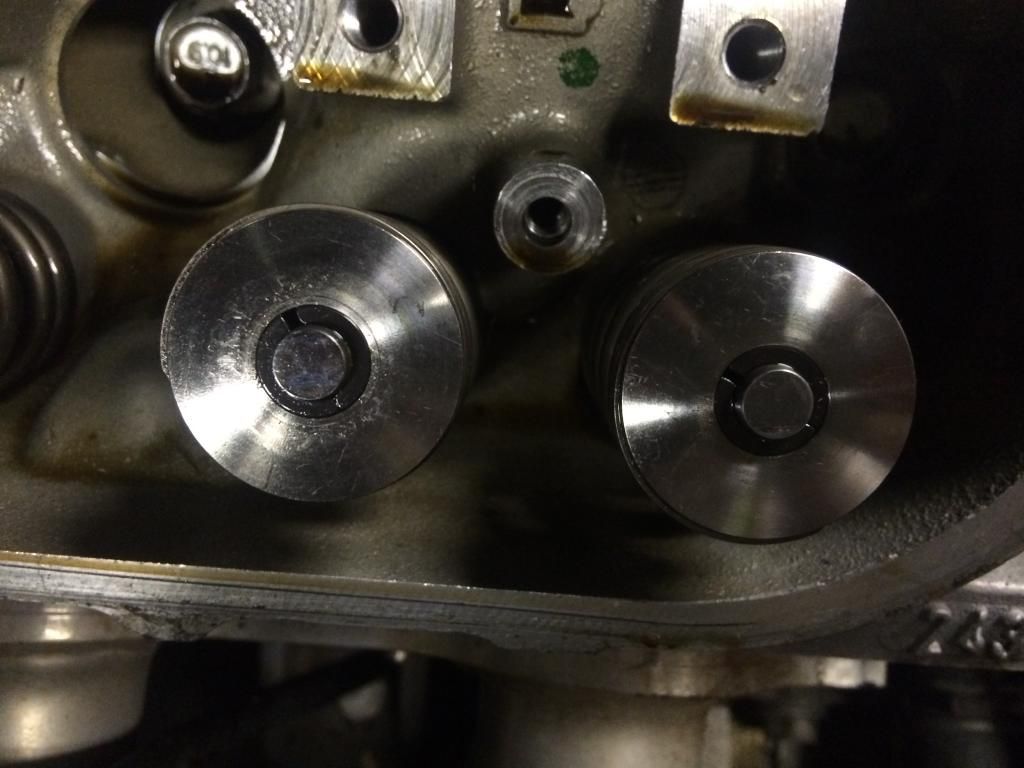

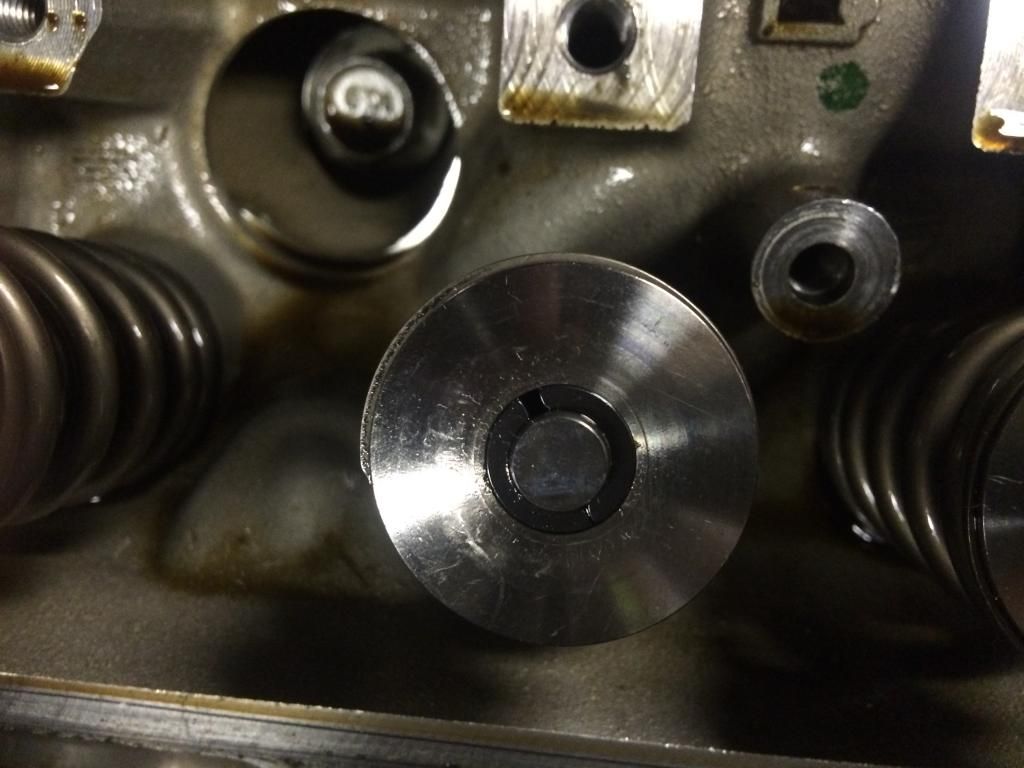

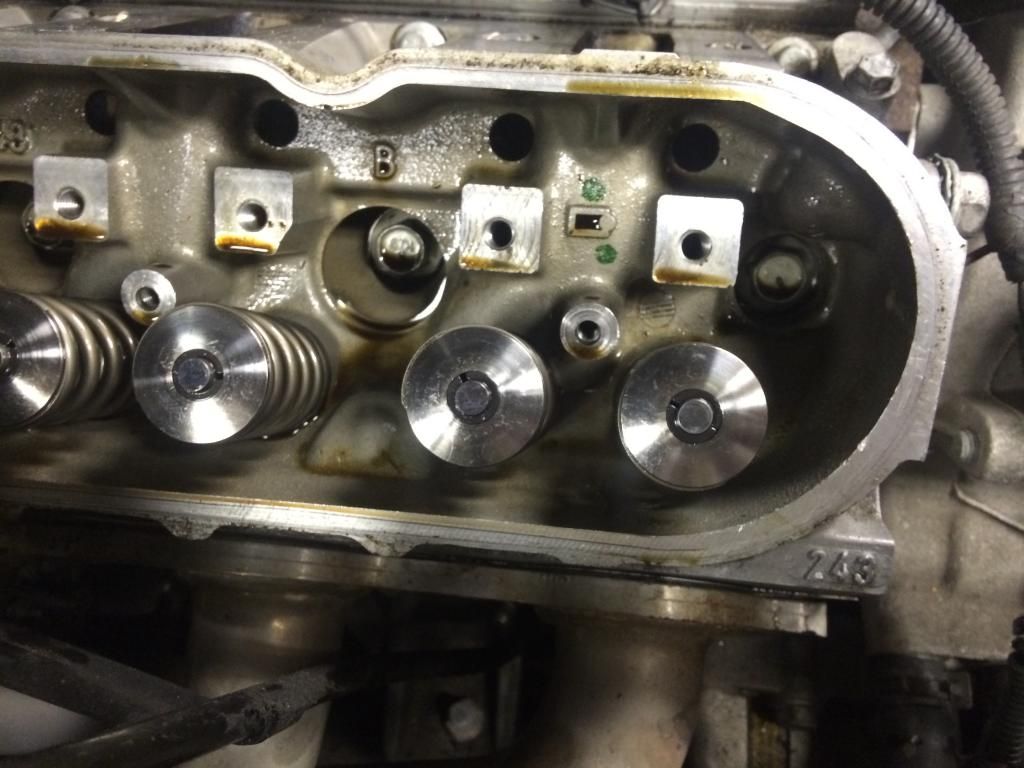

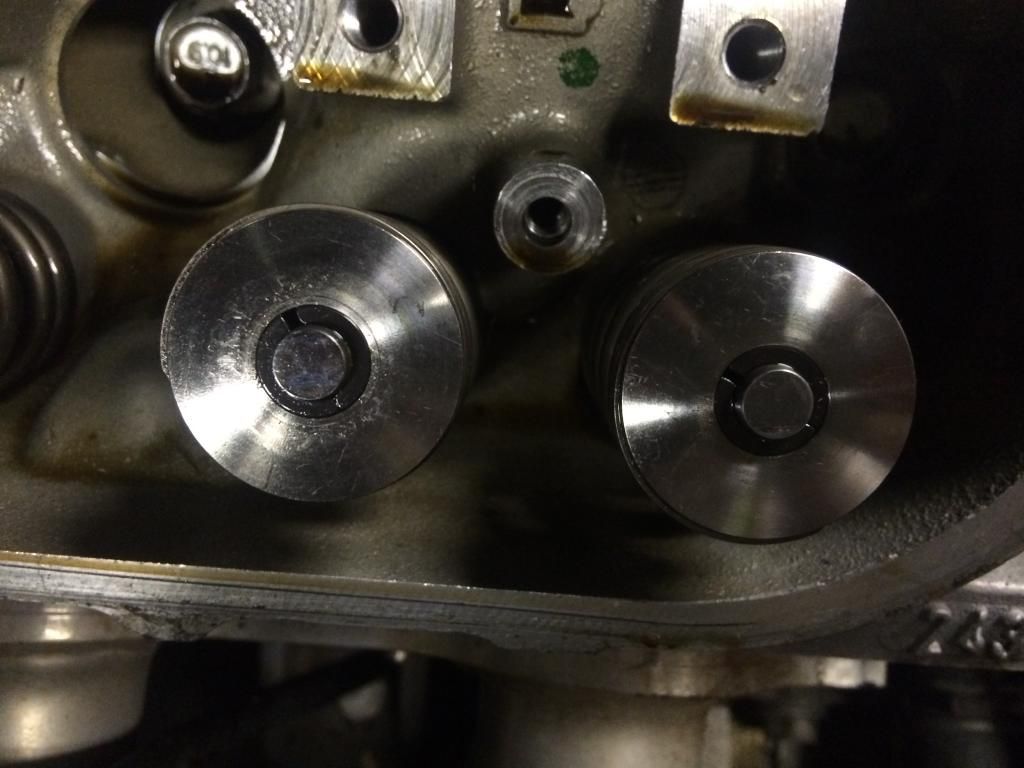

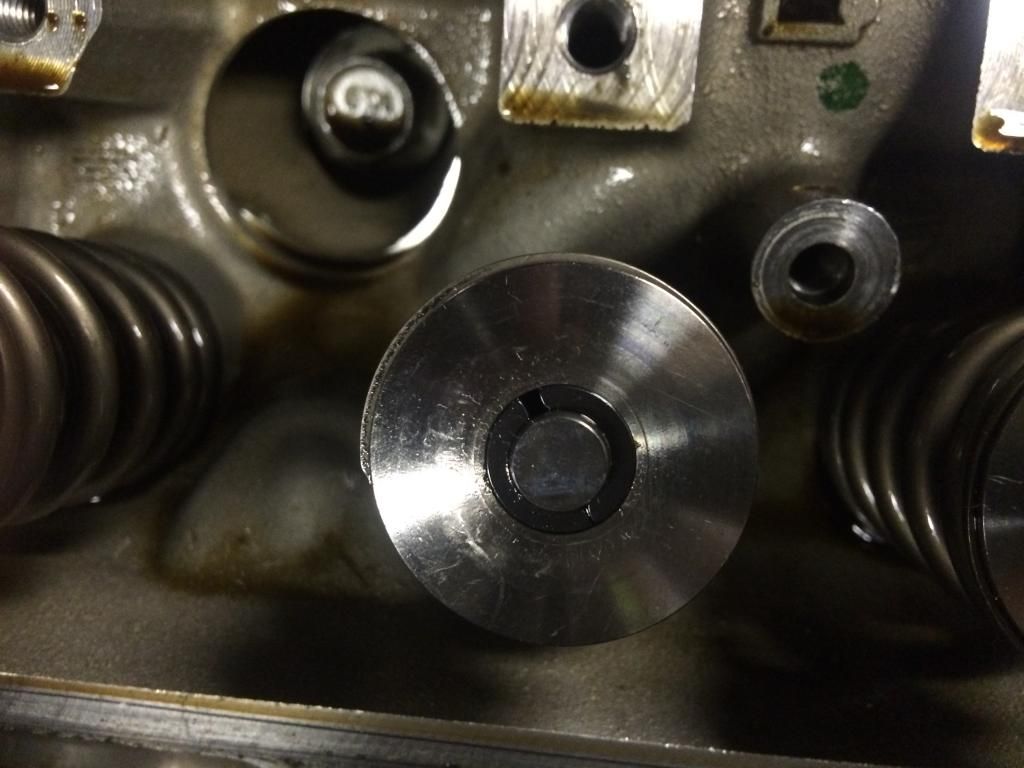

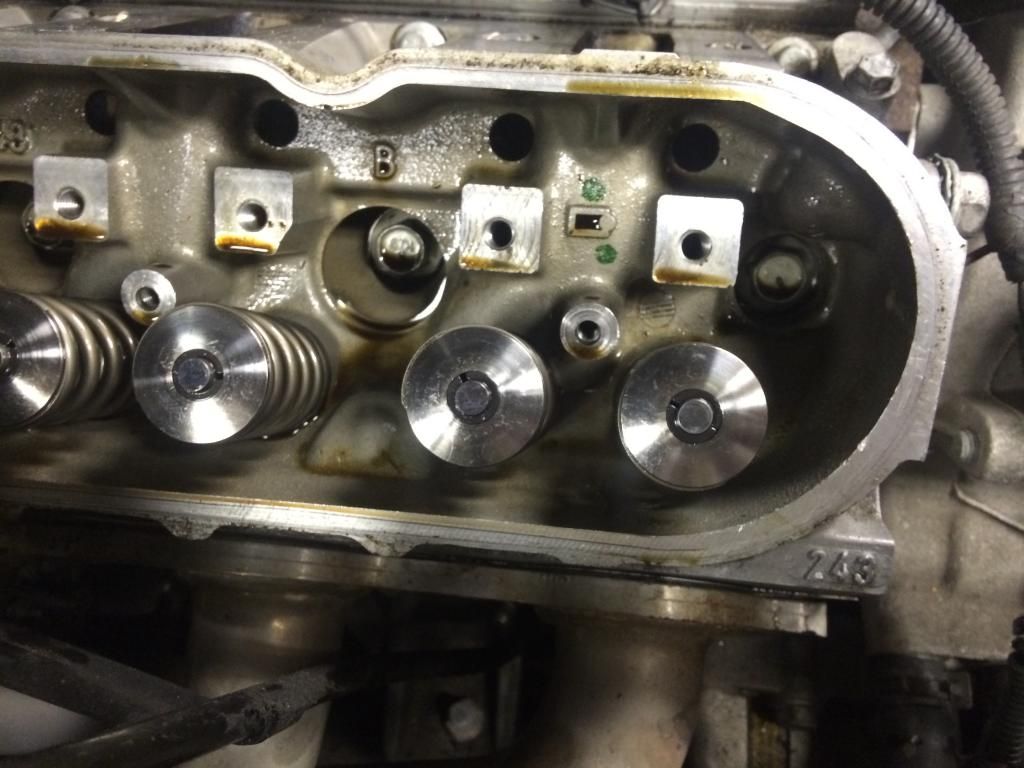

These are valve tips after 15K of hard daily driven miles. Lots of 6,800 RPM shift, hitting the rev limiter and prolonged Idle in Detroit traffic. As you can clearly see these tips look fantastic. So now that we have addressed the theory of anything over .630" lift will destroy the rockers and valves, letís go to loads.

I run a PAC-1206X on my combo. They install at 145lbs on the seat and open is a tick over 410lbs. May I add that these are .150" thou from coil bind too. So there is another debunked myth of 0.050" from bind always, every time, no exception, well the box said so........ I can tell you now that some engines require 0.020" from bind, other require 0.150" from bind, this is all out max effort race engine I am talking about, not street stuff. So if an all out varies that much, how can a street car be so temperamental?????

Point I am making is talk to an engine builder, not someone who knows someone who knows someone. There is not one set rule across the board for anything.

If anyone here ever has any questions on springs feel free to ask me.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]These are valve tips after 15K of hard daily driven miles. Lots of 6,800 RPM shift, hitting the rev limiter and prolonged Idle in Detroit traffic. As you can clearly see these tips look fantastic. So now that we have addressed the theory of anything over .630" lift will destroy the rockers and valves, letís go to loads.

I run a PAC-1206X on my combo. They install at 145lbs on the seat and open is a tick over 410lbs. May I add that these are .150" thou from coil bind too. So there is another debunked myth of 0.050" from bind always, every time, no exception, well the box said so........ I can tell you now that some engines require 0.020" from bind, other require 0.150" from bind, this is all out max effort race engine I am talking about, not street stuff. So if an all out varies that much, how can a street car be so temperamental?????

Point I am making is talk to an engine builder, not someone who knows someone who knows someone. There is not one set rule across the board for anything.

If anyone here ever has any questions on springs feel free to ask me.

#2

What do you believe the result would have been if you were using an even stronger spring, such as the PRC EHTs?

148# Closed.

450# @ .650 lift

I've got a set of stock rockers, ready for trunions.

A set of Harland Sharp currently running.

A new set of PRC Stg 2.5 317 Heads with the PRC EHT's .675" lift springs installed. I didn't do my homework before, and just ordered these springs because they advertise "Longer Life". Not knowing about the high load pressure on the seats. Not sure what to do, and I also have a New TICK cam in the .630/.615 range AND, I'm really wanting to get the COMP Ultra Pro Magnum rockers but they have the 1:7.5 ratio. Which would put my max lift right at .650 like yours.

What would you do out of curiosity?

148# Closed.

450# @ .650 lift

I've got a set of stock rockers, ready for trunions.

A set of Harland Sharp currently running.

A new set of PRC Stg 2.5 317 Heads with the PRC EHT's .675" lift springs installed. I didn't do my homework before, and just ordered these springs because they advertise "Longer Life". Not knowing about the high load pressure on the seats. Not sure what to do, and I also have a New TICK cam in the .630/.615 range AND, I'm really wanting to get the COMP Ultra Pro Magnum rockers but they have the 1:7.5 ratio. Which would put my max lift right at .650 like yours.

What would you do out of curiosity?

#6

What do you believe the result would have been if you were using an even stronger spring, such as the PRC EHTs?

148# Closed.

450# @ .650 lift

I've got a set of stock rockers, ready for trunions.

A set of Harland Sharp currently running.

A new set of PRC Stg 2.5 317 Heads with the PRC EHT's .675" lift springs installed. I didn't do my homework before, and just ordered these springs because they advertise "Longer Life". Not knowing about the high load pressure on the seats. Not sure what to do, and I also have a New TICK cam in the .630/.615 range AND, I'm really wanting to get the COMP Ultra Pro Magnum rockers but they have the 1:7.5 ratio. Which would put my max lift right at .650 like yours.

What would you do out of curiosity?

148# Closed.

450# @ .650 lift

I've got a set of stock rockers, ready for trunions.

A set of Harland Sharp currently running.

A new set of PRC Stg 2.5 317 Heads with the PRC EHT's .675" lift springs installed. I didn't do my homework before, and just ordered these springs because they advertise "Longer Life". Not knowing about the high load pressure on the seats. Not sure what to do, and I also have a New TICK cam in the .630/.615 range AND, I'm really wanting to get the COMP Ultra Pro Magnum rockers but they have the 1:7.5 ratio. Which would put my max lift right at .650 like yours.

What would you do out of curiosity?

I have seen a setup that had a stock cam with roller rockers bleed down the stock lifters due to the extra mass and spring pressures required with the rockers. We switched the setup to a short travel lifter and the combo was stable to 7K. With stock lifters we couldn't keep valve train control past 6K on the spintron.

Trending Topics

#10

10 Second Club

iTrader: (8)

I run roller rockers on my ls6. Only way to go. You will notice a smoother running engine at high rpms. I ran 1.7 harland sharp rocker on the stock ls6 spring to 7000 rpm. I run 1.8's now on a set of psi beehive springs......to 7000rpm and I may turn it 7200.

one of the first mods should be chucking the stock rockers.

one of the first mods should be chucking the stock rockers.

#14

TECH Fanatic

iTrader: (34)

Join Date: Jun 2004

Location: lancaster,pa

Posts: 1,625

Likes: 0

Received 0 Likes

on

0 Posts

I don't want to speak for Matt but the car was put together by me. I actually came to you for advice through pm's when I was setting up the rockers. I used a dial indicator with the head off and a checker spring. I ended up milling the stands .050 iirc

#15

The Scammer Hammer

iTrader: (49)

I caught wind of something similar on FaceBook the other day... LOTS of big name guys all chiming in on it. The "rule" of don't go over .630 lift on stock rockers is nothing more than folklore.

Another guy was WELL over .650 and had over 50k miles without issue as well.

Another guy was WELL over .650 and had over 50k miles without issue as well.

#16

Was looking @ that the other day. Stock rockers produce a wide contact patch. Looking @ the bottom photo where the camera is further from the valve tip, the pattern looks centered.

#17

TECH Senior Member

iTrader: (26)

I run roller rockers on my ls6. Only way to go. You will notice a smoother running engine at high rpms. I ran 1.7 harland sharp rocker on the stock ls6 spring to 7000 rpm. I run 1.8's now on a set of psi beehive springs......to 7000rpm and I may turn it 7200.

one of the first mods should be chucking the stock rockers.

one of the first mods should be chucking the stock rockers.

#18

TECH Resident

iTrader: (24)

I run roller rockers on my ls6. Only way to go. You will notice a smoother running engine at high rpms. I ran 1.7 harland sharp rocker on the stock ls6 spring to 7000 rpm. I run 1.8's now on a set of psi beehive springs......to 7000rpm and I may turn it 7200.

one of the first mods should be chucking the stock rockers.

one of the first mods should be chucking the stock rockers.

#19

10 Second Club

iTrader: (8)

IDK....no experience with those. But I don't think they have a roller tip so I would not buy them.

Sure....and they have done a good job.

But the advantages of a roller tip is to great to me. Just relieving the stress on the valve is piece of mind. I have not had my stuff apart in a while. besides it has run the stock rockers, HS 1.7's and HS 1.8's....so you probably couldn't tell ****. But it has gave me the experience about how the car feels. And roller rockers feel much smoother at higher rpm.........it's actually very noticeable. Now keep in mind that's on just a bolt-on ls6.

Besides no one would ever not run roller rockers on a old school sbc with .600 lift cam. They usually go to rollers long before that........just a example

But the advantages of a roller tip is to great to me. Just relieving the stress on the valve is piece of mind. I have not had my stuff apart in a while. besides it has run the stock rockers, HS 1.7's and HS 1.8's....so you probably couldn't tell ****. But it has gave me the experience about how the car feels. And roller rockers feel much smoother at higher rpm.........it's actually very noticeable. Now keep in mind that's on just a bolt-on ls6.

Besides no one would ever not run roller rockers on a old school sbc with .600 lift cam. They usually go to rollers long before that........just a example

#20

Super Hulk Smash

iTrader: (7)

The problem with roller rockers and aftermarket lobes is they are a pain in the *** to control. Whereas you experience smoothness in the upper RPM with mild stock lobes, a lot of folks experience valvetrain instability. The solution is to continue throwing more and more spring pressure at it to control the weight and jerk characteristics of the combo, and at some point, you either stress the rocker, pushrod, or lifter too much and end up creating friction issues from excess spring pressure or something breaks (like the rocker).

The solution is of course a well-engineered combo. But most folks throw tiny pushrods, LS7 lifters, and heavy roller rockers at something with LSL or LSK lobes and hope for the best...

The solution is of course a well-engineered combo. But most folks throw tiny pushrods, LS7 lifters, and heavy roller rockers at something with LSL or LSK lobes and hope for the best...