what is causing the need for shorter pushrods?

#1

Hey everyone I have a quick question. If I have undecked heads, block, factory cam, factory head gaskets, factory lifters, and factory rockers. Why are my srock 7.400" (measured closer to 7.395") pushrods way too long. When I put a cylinder to tdc and torque the rocker to 22 ft lbs both valve springs compress well over 1/8".

I understand when I do things that will change the distance between the rocker tip and the can base circle but I have not. I have a adjustable pushrod checked coming so should know soon what size I need just confused as to what is throwing off the measurement.

Thanks

Shane

I understand when I do things that will change the distance between the rocker tip and the can base circle but I have not. I have a adjustable pushrod checked coming so should know soon what size I need just confused as to what is throwing off the measurement.

Thanks

Shane

#2

TECH Apprentice

Hey everyone I have a quick question. If I have undecked heads, block, factory cam, factory head gaskets, factory lifters, and factory rockers. Why are my srock 7.400" (measured closer to 7.395") pushrods way too long. When I put a cylinder to tdc and torque the rocker to 22 ft lbs both valve springs compress well over 1/8".

I understand when I do things that will change the distance between the rocker tip and the can base circle but I have not. I have a adjustable pushrod checked coming so should know soon what size I need just confused as to what is throwing off the measurement.

Thanks

Shane

I understand when I do things that will change the distance between the rocker tip and the can base circle but I have not. I have a adjustable pushrod checked coming so should know soon what size I need just confused as to what is throwing off the measurement.

Thanks

Shane

#3

TECH Senior Member

iTrader: (4)

Also, do they initially compress and then the valves close or do they stay open? When you first torque the rockers in place, they will open the valves a bit until the lifter bleeds down. That may be what you are seeing assuming you are doing this by the correct procedure, i.e., both lifters are on the base circle of the cam.

#4

Both valves are closed. Confirmed with a dial indicator on the top of the spring retainer. If I torque the rockers down all the way if I turn the motor over very slowly by hand it stops on the compression stroke of that cylinder. Assuming its hitting the valves cause they are open. When I back the rockers off so the valves are closed engine turns over no issues.

#5

Also, do they initially compress and then the valves close or do they stay open? When you first torque the rockers in place, they will open the valves a bit until the lifter bleeds down. That may be what you are seeing assuming you are doing this by the correct procedure, i.e., both lifters are on the base circle of the cam.

#6

Teching In

iTrader: (3)

Like vettenuts said, I've seen valves open about an 1/8" and then close when the lifters bleed down. Seems to take a good 15-20 minutes for the lifters to bleed down. This is assuming you're working with used lifters and haven't taken them apart to remove the oil. When you tighten the rocker can you also see the pushrod moving down a bit?

#7

TECH Fanatic

iTrader: (2)

Both valves are closed. Confirmed with a dial indicator on the top of the spring retainer. If I torque the rockers down all the way if I turn the motor over very slowly by hand it stops on the compression stroke of that cylinder. Assuming its hitting the valves cause they are open. When I back the rockers off so the valves are closed engine turns over no issues.

Trending Topics

#8

I am concerned because I have stated multiple times that the cam is on the base circle. When I checked. I just don't see what about my combo would cause this.

#9

TECH Fanatic

iTrader: (2)

#10

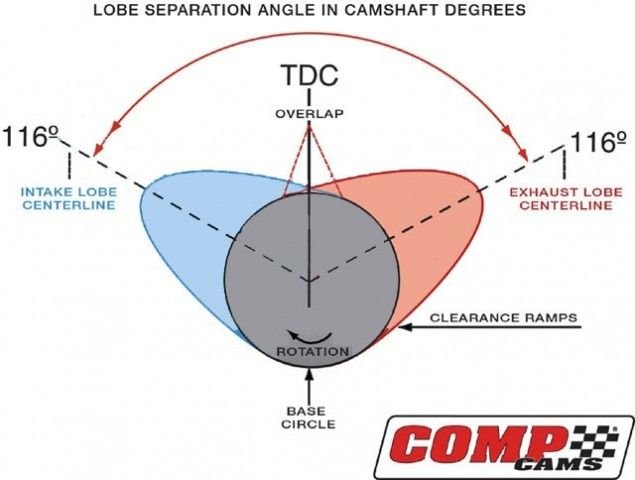

I'm not sure what you're actual goal is, but the valves are not going to be closed at TDC. You're going to be in the middle of the overlap between the intake and exhaust lobes. Therefore, you're not on the base circle of the cam when you're making your pushrod measurement.

#12

#16

TECH Senior Member

iTrader: (4)

How did you determine the cylinder was at TDC firing stroke? Also, please don't find this insulting but it has happened before to a few good people who had a similar problem, are the stock aluminum rocker stands in place?

If using the dots on the sprockets, the cam dot must be at 12 o'clock for cylinder #1 and not at 6 o'clock.

If using the dots on the sprockets, the cam dot must be at 12 o'clock for cylinder #1 and not at 6 o'clock.

#17

10 Second Club

iTrader: (37)

Easy way to do this is to rotate the crank until the intake valve is open all the way on cly 1 and check the exhaust pushrod on the same cylinder. Then rotate crank until cylinder 1 exhaust valve is open all the way and check the intake pushrod on the same cylinder. Start on another cylinder of choice and repeat until all 8 cylinders are done. You might need different length pushrods on intake and exhaust.

#18

How did you determine the cylinder was at TDC firing stroke? Also, please don't find this insulting but it has happened before to a few good people who had a similar problem, are the stock aluminum rocker stands in place?

If using the dots on the sprockets, the cam dot must be at 12 o'clock for cylinder #1 and not at 6 o'clock.

If using the dots on the sprockets, the cam dot must be at 12 o'clock for cylinder #1 and not at 6 o'clock.

I am just confused what is throwing this off. Everything in this combo tells me that the factory length pushords should work since it is a factory setup and nothing has been changed that would change the distance between the center of the cam and the pushrod cup in the rocker arm.

#19

Teching In

iTrader: (3)

I am just confused what is throwing this off. Everything in this combo tells me that the factory length pushords should work since it is a factory setup and nothing has been changed that would change the distance between the center of the cam and the pushrod cup in the rocker arm.

#20

Could the lifters be messed up? At TDC between compression and power strokes I can see the pushrod for the intake is much higher than the exhaust one and I have swapped both pushrods and rocker assemblies. #1 exhaust measured fine...... I have only been checking #1 intake. #6 exhaust is fine. #6 intake is not