UK based LQ9 build advice please

#1

I'm just starting out on building an LQ9 motor to drop into my 79/80 Camaro. Can't remember ever seeing another LQ in the UK, but there are a few LS motors knocking around. But very few indeed - you can count them on one hand even at big car shows.

I currently have a 425hp small block fitted - already running on MS3 ECU, 4L80E transmission and 3200rpm stall converter. 4.11 rear gears in a 12 bolt.

I picked up a heap of parts, but a lot of major components are missing. But I mainly wanted the heads and block anyway.

I've built a fair few motors in my time and made good power with them, but this is my first Gen III motor.

I'd really like to achieve at least 600hp at the crank, naturally aspirated. The car is only a weekend/fun car and will see a bit of track use as well. Having been reading around this seems like an achievable target? I'd rather not spray it if I can get away with it.

I've got a lot of planning to do and a few questions for those more knowledgeable than me with the LS/LQ motors. I'd rather build it right first time, so I'd like to just run a few things past you guys..

Here's what I have to start with:

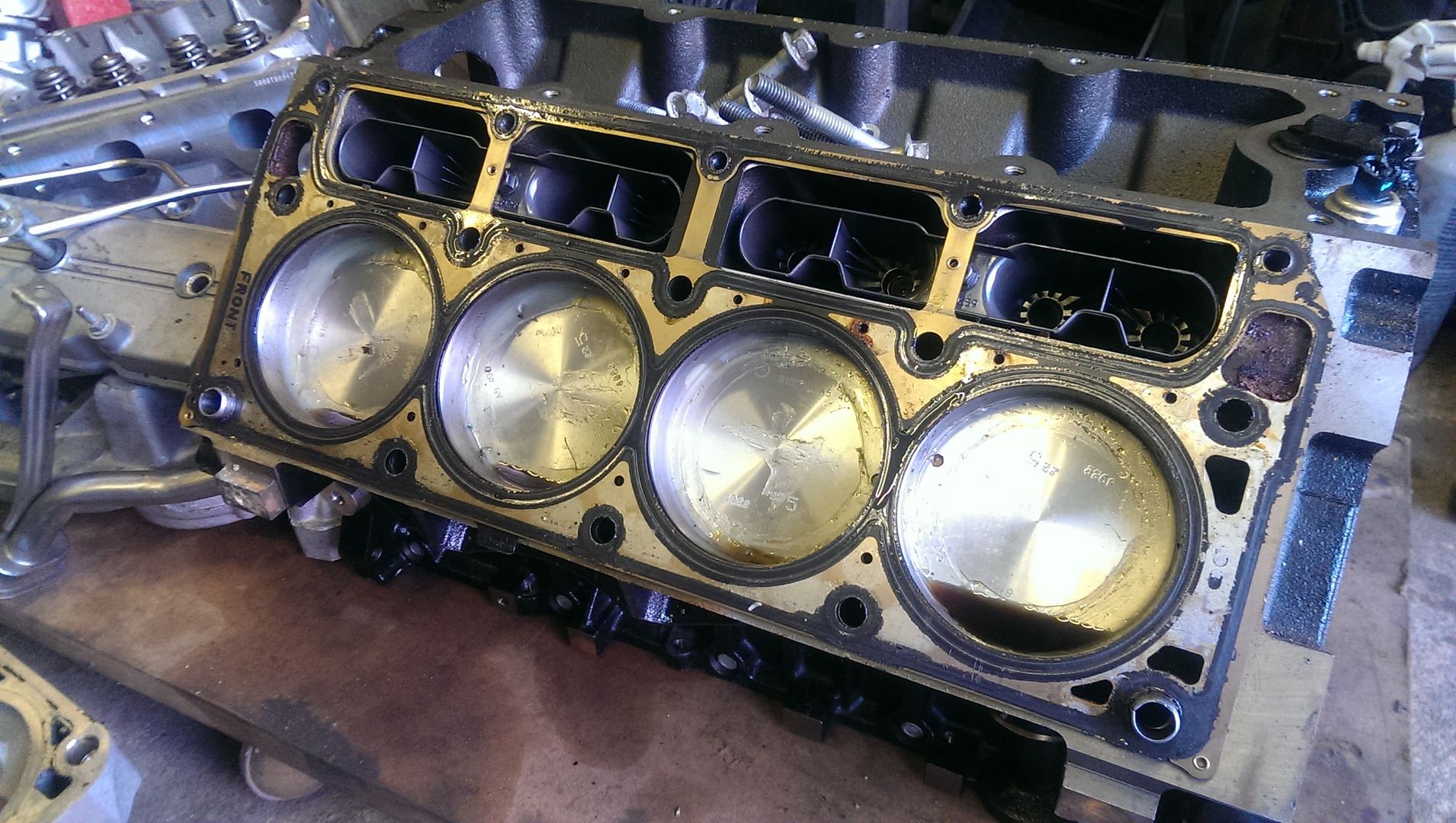

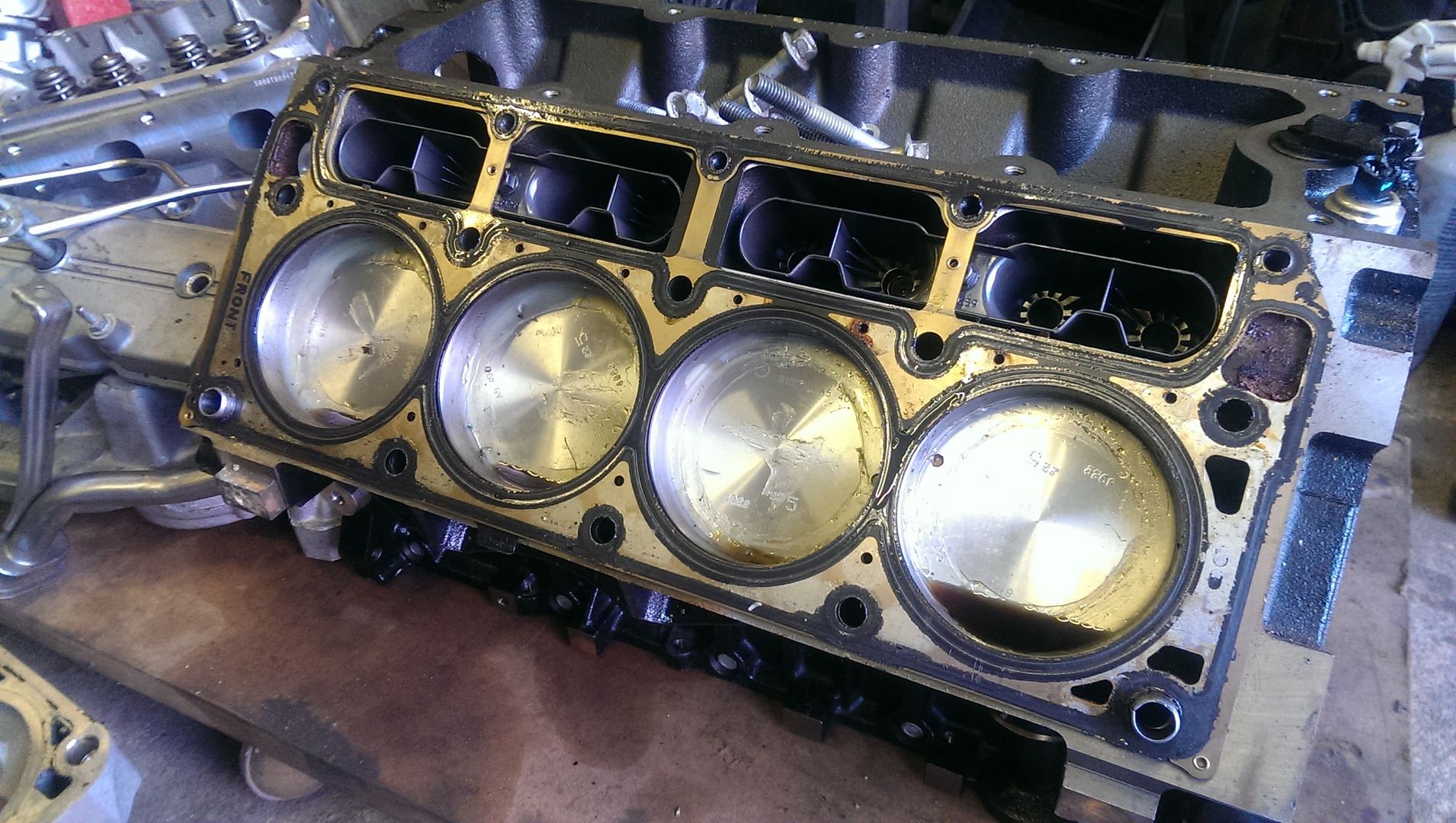

Brand new LQ9 block - stock bore

New LQ9 pistons and stock rods (floating pins)

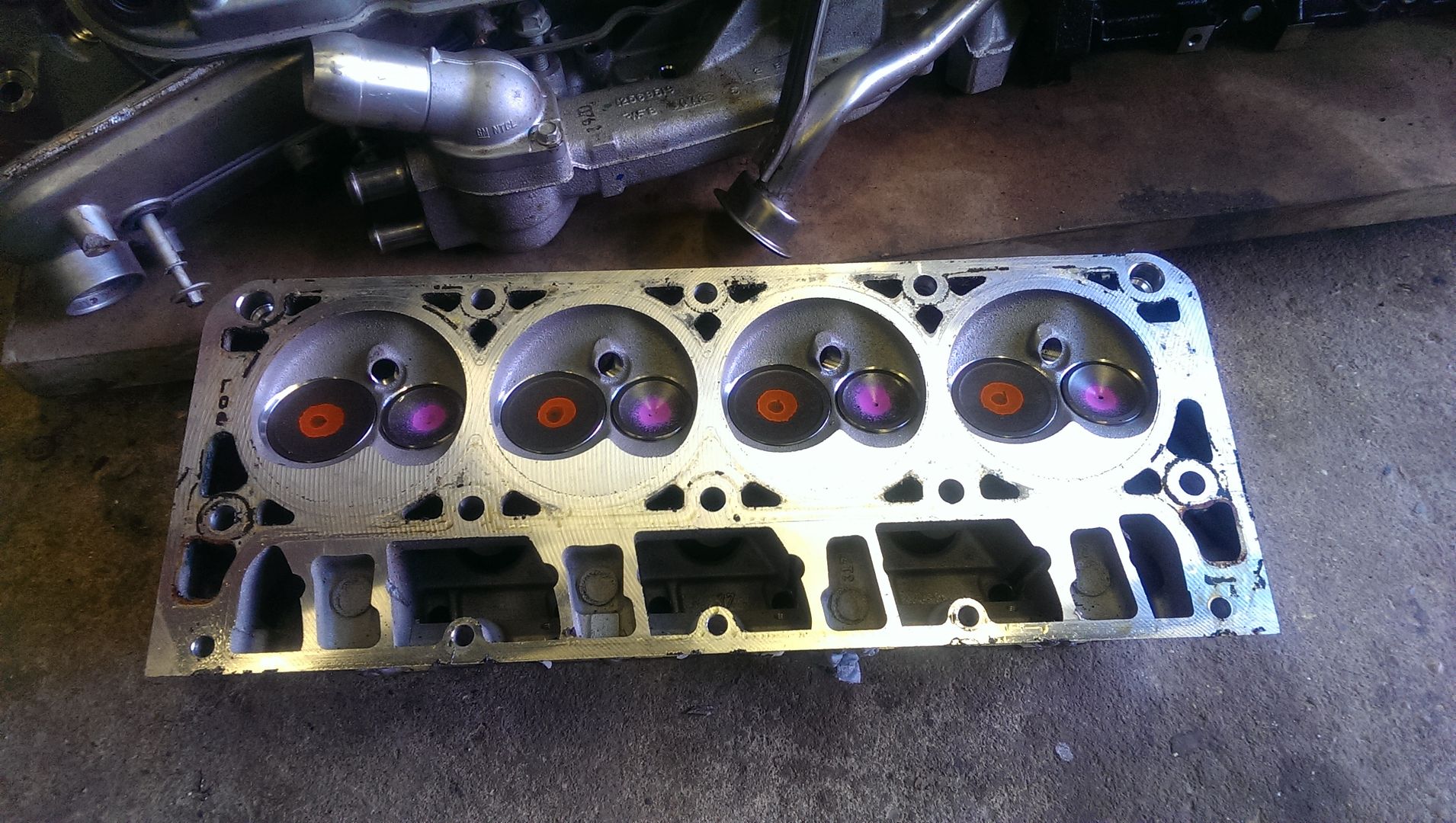

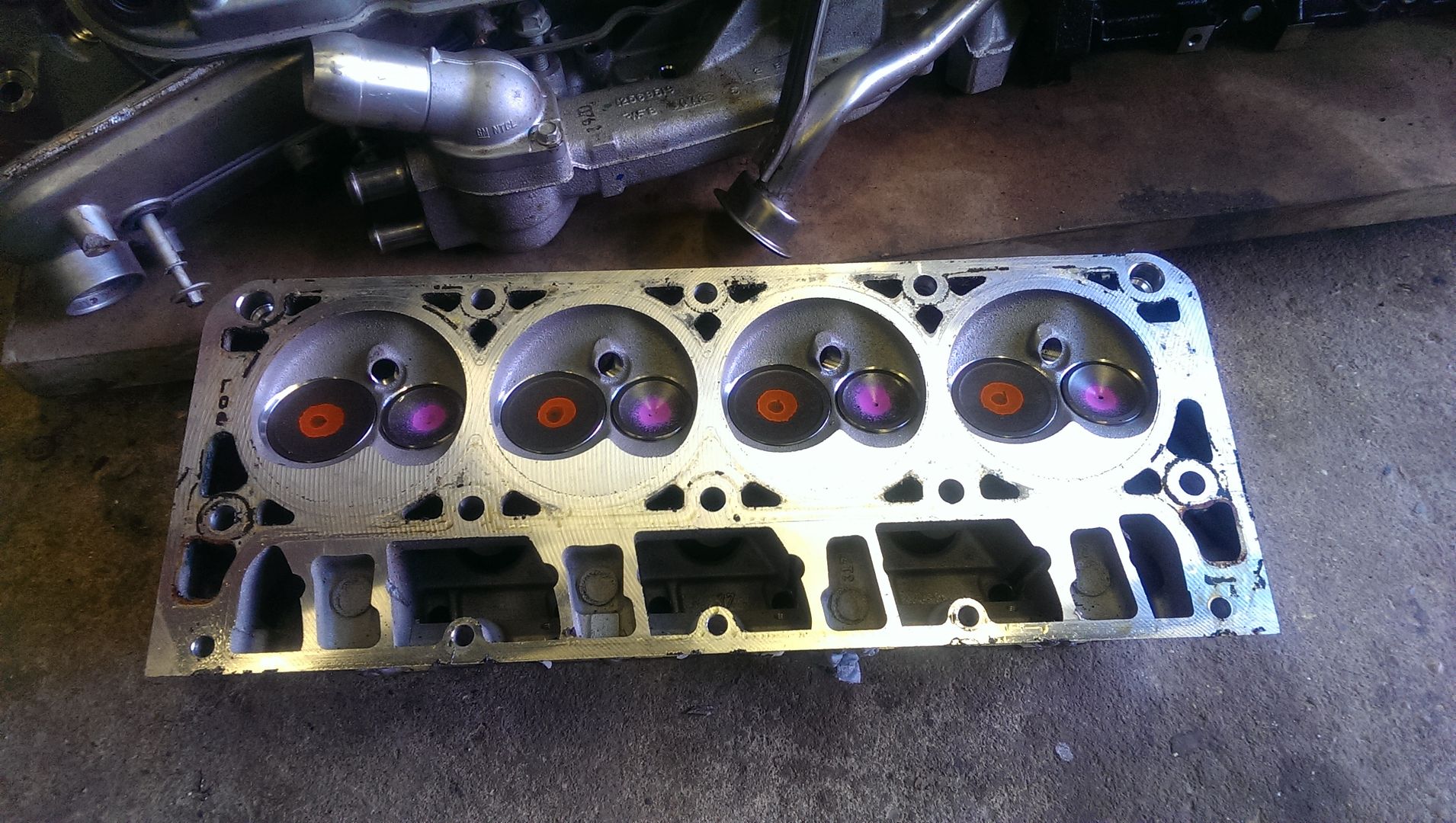

New 317 heads with valves and springs - plus 1 scrap head for some port testing.

Escalade sump - will be modifying this.

New water pump

I need to get everything else.

Bottom end

My intention for the bottom end was to source a stock crank, and fit ARP bolts to the stock rods, re-size the bores and fit oversize OD bearings. Use the stock LQ9 pistons and notch them for the valves if needed.

Would this bottom end be OK for a 7000 rpm limit?

Cam

Probably end up with a custom grind. I don't need anything too streetable to be honest and already have that high stall converter. Thinking around .6" lift and ~240 duration.

Is this reasonable or too much cam?

Top end

Skim the heads to increase CR to around 10.6-10.8:1. Get a decent porting job done. Replace stock springs to suit cam. Roller rockers.

4150 style intake manifold with 1200cfm throttle body, 70lb injectors.

I know there are a lot more other parts needed. Any feedback or advice welcome at this stage!

I currently have a 425hp small block fitted - already running on MS3 ECU, 4L80E transmission and 3200rpm stall converter. 4.11 rear gears in a 12 bolt.

I picked up a heap of parts, but a lot of major components are missing. But I mainly wanted the heads and block anyway.

I've built a fair few motors in my time and made good power with them, but this is my first Gen III motor.

I'd really like to achieve at least 600hp at the crank, naturally aspirated. The car is only a weekend/fun car and will see a bit of track use as well. Having been reading around this seems like an achievable target? I'd rather not spray it if I can get away with it.

I've got a lot of planning to do and a few questions for those more knowledgeable than me with the LS/LQ motors. I'd rather build it right first time, so I'd like to just run a few things past you guys..

Here's what I have to start with:

Brand new LQ9 block - stock bore

New LQ9 pistons and stock rods (floating pins)

New 317 heads with valves and springs - plus 1 scrap head for some port testing.

Escalade sump - will be modifying this.

New water pump

I need to get everything else.

Bottom end

My intention for the bottom end was to source a stock crank, and fit ARP bolts to the stock rods, re-size the bores and fit oversize OD bearings. Use the stock LQ9 pistons and notch them for the valves if needed.

Would this bottom end be OK for a 7000 rpm limit?

Cam

Probably end up with a custom grind. I don't need anything too streetable to be honest and already have that high stall converter. Thinking around .6" lift and ~240 duration.

Is this reasonable or too much cam?

Top end

Skim the heads to increase CR to around 10.6-10.8:1. Get a decent porting job done. Replace stock springs to suit cam. Roller rockers.

4150 style intake manifold with 1200cfm throttle body, 70lb injectors.

I know there are a lot more other parts needed. Any feedback or advice welcome at this stage!

#2

Don't know what your resources are like but you may want to rethink the 317 heads, 243/799's would do a lot more for your compression and still have good flow. Better yet, a set of ported 243's. To get 600 engine HP you'll need good heads, the right cam, an unrestrictive exhaust and a good intake manifold with a good tune with the fuel you're going to run.

#4

Don't know what your resources are like but you may want to rethink the 317 heads, 243/799's would do a lot more for your compression and still have good flow. Better yet, a set of ported 243's. To get 600 engine HP you'll need good heads, the right cam, an unrestrictive exhaust and a good intake manifold with a good tune with the fuel you're going to run.

I was under the impression (probably incorrectly?) that the 317 and 243 heads were the same with the exception of the combustion chamber volume? Same valve and port sizes. All parts for these motors are very hard to find in the UK, and expensive too. The heads I have came with the other motor parts bundle and are new.

I plan on running 1 7/8" mid length headers - possibly Hooker 2472. The rest of my exhaust is currently 2.5" tube with x pipe.

#5

[QUOTE=gothic_sera;18737794]Thanks

I was under the impression (probably incorrectly?) that the 317 and 243 heads were the same with the exception of the combustion chamber volume? Same valve and port sizes. All parts for these motors are very hard to find in the UK, and expensive too. The heads I have came with the other motor parts bundle and are new.

I plan on running 1 7/8" mid length headers - possibly Hooker 2472. The rest of my exhaust is currently 2.5" tube with x pipe.[/QUOTE

You've got a lot of milling to do on a 317 to get anywhere close to the volume of a 799/243. Compression is the cheapest form of torque and HP if you're building an NA motor.

I was under the impression (probably incorrectly?) that the 317 and 243 heads were the same with the exception of the combustion chamber volume? Same valve and port sizes. All parts for these motors are very hard to find in the UK, and expensive too. The heads I have came with the other motor parts bundle and are new.

I plan on running 1 7/8" mid length headers - possibly Hooker 2472. The rest of my exhaust is currently 2.5" tube with x pipe.[/QUOTE

You've got a lot of milling to do on a 317 to get anywhere close to the volume of a 799/243. Compression is the cheapest form of torque and HP if you're building an NA motor.

Last edited by 64post; 04-11-2015 at 12:15 PM.

#6

Based on a bit of reading, milling the 317's 0.030 should get me to a 66cc chamber and around 10.6:1. I think I could go more but might run into other problems after that. I would also consider running a thinner head gasket which would bump it up a bit more.

I am not going to rule out either forced induction or nitrous in the future... but I know that will need more upgrades in other areas of the motor. I'm sticking with the plan of an NA motor for now.

Finding any other heads in the UK will be a nightmare, and shipping a set from the USA is prohibitively expensive. So while the 317's might not be ideal, they are the best I have got.

In terms of other areas of the engine based on the 600hp goal:

Are the stock main bearing bolts up to the job?

Stock head bolts?

Is a .6" ~240 duration cam in the right ballpark?

I am not going to rule out either forced induction or nitrous in the future... but I know that will need more upgrades in other areas of the motor. I'm sticking with the plan of an NA motor for now.

Finding any other heads in the UK will be a nightmare, and shipping a set from the USA is prohibitively expensive. So while the 317's might not be ideal, they are the best I have got.

In terms of other areas of the engine based on the 600hp goal:

Are the stock main bearing bolts up to the job?

Stock head bolts?

Is a .6" ~240 duration cam in the right ballpark?

#7

Do you think 10.6 CR static is enough to make 600 HP? I don't. Most people building a NA motor are looking for 11:1 plus. By all means YES, run the thinnest head gasket you can but starting with 59-62cc chambers will get you closer to your goal, not to mention the torque that would provide and make your car much more fun to drive, just saying.

Trending Topics

#8

I'm not really sure, that's why I was asking the questions that I did. I've built loads of engines in the past but I know each is different in terms of what works and doesn't.

In thinking a bit further ahead - I'm willing to forgo a little bit of NA power and compression in order to leave a bit of headroom for possibly running a small amount of boost in the future. If I left it at around 10.5:1 then is that then too high to be thinking of running a few PSI of boost?

In thinking a bit further ahead - I'm willing to forgo a little bit of NA power and compression in order to leave a bit of headroom for possibly running a small amount of boost in the future. If I left it at around 10.5:1 then is that then too high to be thinking of running a few PSI of boost?

#9

I'm not really sure, that's why I was asking the questions that I did. I've built loads of engines in the past but I know each is different in terms of what works and doesn't.

In thinking a bit further ahead - I'm willing to forgo a little bit of NA power and compression in order to leave a bit of headroom for possibly running a small amount of boost in the future. If I left it at around 10.5:1 then is that then too high to be thinking of running a few PSI of boost?

In thinking a bit further ahead - I'm willing to forgo a little bit of NA power and compression in order to leave a bit of headroom for possibly running a small amount of boost in the future. If I left it at around 10.5:1 then is that then too high to be thinking of running a few PSI of boost?

#10

I'm really in 2 minds what to do.

I can build the motor with the right internals for some mild boost in the future and suffer with less NA power in the interim couple of years - or I can build it to be NA from the outset and then have to do a complete rebuild and replace all of the internals, cam and heads at the same time as and when I stick a turbo on it.

If I wanted to run say 5-6psi of boost, is a static compression of around 10-10.5 going to be too high on an LS motor? I've built other engines in the past with 10:1 static and 14psi of boost with no detonation issues - but this wasn't an LS motor!

I can build the motor with the right internals for some mild boost in the future and suffer with less NA power in the interim couple of years - or I can build it to be NA from the outset and then have to do a complete rebuild and replace all of the internals, cam and heads at the same time as and when I stick a turbo on it.

If I wanted to run say 5-6psi of boost, is a static compression of around 10-10.5 going to be too high on an LS motor? I've built other engines in the past with 10:1 static and 14psi of boost with no detonation issues - but this wasn't an LS motor!

#11

I'd quite like a pair of 317 heads but I've got quite a lot of work to get done on my heads before it would be worth your while swapping.

If you are considering boosting it, I'd build it for boost and put up with it til then, I'm don't have any real experience with boosted LS's yet but 10:1 should be fine for 5-6psi and probably more, meth injections always a pretty cheap option if you want to go higher. I'm sure there are plenty of people with more knowledge on the subject who could confirm though.

If you are considering boosting it, I'd build it for boost and put up with it til then, I'm don't have any real experience with boosted LS's yet but 10:1 should be fine for 5-6psi and probably more, meth injections always a pretty cheap option if you want to go higher. I'm sure there are plenty of people with more knowledge on the subject who could confirm though.

Last edited by dobergoose; 04-11-2015 at 08:06 AM.