LM7 questions regarding refresh/rebuild

#1

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

Hi Guys, it's been a while since I've done anything car related after selling my old Camaro. I decided to get back into the game starting with a turbo motor build. I decided to go the 5.3L junkyard route (01 Suburban). I must admit I don't know too much about rebuilding engines but this is a good inexpensive place to start.

Goal 1: Get the engine down to just the short block.

Goal 2: Tear down the short block

Goal 3: Clean up the block/parts

Goal 4: Add new main/rod bearings, piston rings (gapped for boost).

Goal 5: Reassemble the short block (re-using stock crank, rods, pistons)

This is what I'm focusing on for now.

Goal 4/5 has me worried because it seems everything is about clearances, measuring, and thousandths of inches. Anybody have any tips on the best way to go about this?

Goal 1: Get the engine down to just the short block.

Goal 2: Tear down the short block

Goal 3: Clean up the block/parts

Goal 4: Add new main/rod bearings, piston rings (gapped for boost).

Goal 5: Reassemble the short block (re-using stock crank, rods, pistons)

This is what I'm focusing on for now.

Goal 4/5 has me worried because it seems everything is about clearances, measuring, and thousandths of inches. Anybody have any tips on the best way to go about this?

Last edited by C_Rules; 08-28-2015 at 02:49 PM.

#2

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

Removed the front accessory drive, it was pretty straight forward. Not all that difficult. Will try to post some pics. Still worried about the actual internals build. I'm questioning if I should just leave it alone even though it has 164k. Watching all these videos about using micrometers and bore gauges has more worried. Plus I would have to buy all those tools I don't have.

#3

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

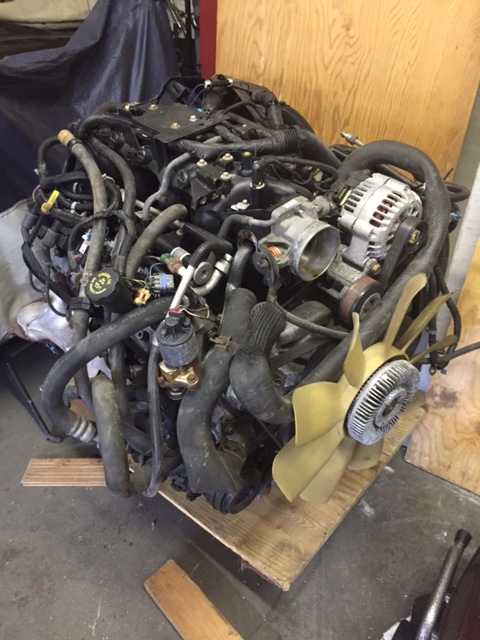

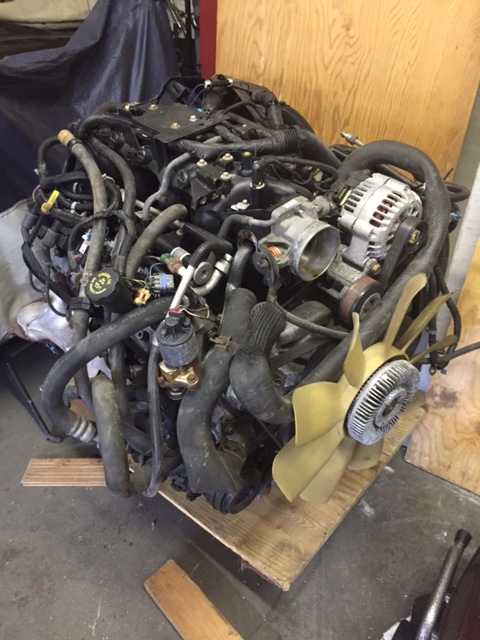

Started with this

After removing most of the top end stuff was left with this

After removing first head (passenger side) instant

Cleaned out the water/sludge and this is what it looked like

After some cleaning

The cylinder is rough in that spot but no scratches and nothing gets caught when rubbing against it. Will have to tear it down to the bare block then take it to the machine shop. Might have to bore the block to 3.79 and throw in some wiseco forged slugs in there.

Sending the stock heads to be ported.

How it sits now

After removing most of the top end stuff was left with this

After removing first head (passenger side) instant

Cleaned out the water/sludge and this is what it looked like

After some cleaning

The cylinder is rough in that spot but no scratches and nothing gets caught when rubbing against it. Will have to tear it down to the bare block then take it to the machine shop. Might have to bore the block to 3.79 and throw in some wiseco forged slugs in there.

Sending the stock heads to be ported.

How it sits now

Last edited by C_Rules; 10-26-2015 at 12:01 PM.

#4

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

Since I'll have to bore the block I'll need new pistons. The only boost friendly dish size for a stock rod is -10.7 (not looking to buy aftermarket rods). After the heads are worked the combustion chamber size will can be anywhere from 60-64cc. Depending on the porter i decide to go with. The 64cc combustion chamber leaves my compression ratio below 9:1. Since this build is for a car that will mostly see street duty I'd like to go keep the compression at the stock level of 9.5:1 for low rpm enjoyment. Now they're a number of ways to raise the compression without buying any additional parts that i won't already need:

1) Custom pistons with a smaller dish

2) Custom MLS head gasket

3) Mill the heads

4) Deck the block

It looks like the easiest and most cost effective solution is a custom MLS head gasket with a compressed thickness of .030. What are some of the pros and cons of each of these methods? Any I should stay away from?

1) Custom pistons with a smaller dish

2) Custom MLS head gasket

3) Mill the heads

4) Deck the block

It looks like the easiest and most cost effective solution is a custom MLS head gasket with a compressed thickness of .030. What are some of the pros and cons of each of these methods? Any I should stay away from?

#5

TECH Addict

The best way to raise compression is with pistons. But... Since you are already getting the heads ported, I would just have them decked to give you a 10:1 compression ratio.

That spot in the cylinder may smooth out with a simple hone, so you may not have to over bore it at all.

Don't be afraid of putting it together yourself. Either buy or rent the proper tools. Make sure everything is clean and organized. And have a notebook handy to take notes, write down measurements, and label things.

You're clearly smart enough to establish steps for your rebuild, so now make sub-steps for those. Keep making checklists. Keep it as straightforward as possible. And try maintain some semblance of organization.

That spot in the cylinder may smooth out with a simple hone, so you may not have to over bore it at all.

Don't be afraid of putting it together yourself. Either buy or rent the proper tools. Make sure everything is clean and organized. And have a notebook handy to take notes, write down measurements, and label things.

You're clearly smart enough to establish steps for your rebuild, so now make sub-steps for those. Keep making checklists. Keep it as straightforward as possible. And try maintain some semblance of organization.

#7

TECH Addict

Gaskets are wear items. They get replaced. Replacing custom parts can prove to be a dubious task, especially in unfavorable circumstances.

Milling the heads is a one time affair, and it allows you to use off the shelf gaskets.

Milling the heads is a one time affair, and it allows you to use off the shelf gaskets.

Trending Topics

#9

TECH Addict

Changing your pushrods immediately found its way on to your to-do list as soon as you said "gapped for boost" in reference to your piston rings in post #1.

Boost needs heavy duty valve springs. Heavy duty valve springs need heavy duty pushrods.

I still think that milling the heads for a 59-60c combustion chamber while you are already having them ported is the best way to address raising compression.

Or, maybe find a good set of GenIV 5.3 rods and flat-top pistons and throw them in there, assuming that the block doesn't need to be over bored. Even with flat tops, I would still mill the heads, for 11:1 compression, but that's just me.

Boost needs heavy duty valve springs. Heavy duty valve springs need heavy duty pushrods.

I still think that milling the heads for a 59-60c combustion chamber while you are already having them ported is the best way to address raising compression.

Or, maybe find a good set of GenIV 5.3 rods and flat-top pistons and throw them in there, assuming that the block doesn't need to be over bored. Even with flat tops, I would still mill the heads, for 11:1 compression, but that's just me.

#11

Launching!

Join Date: Oct 2010

Location: Houston, TX

Posts: 227

Likes: 0

Received 0 Likes

on

0 Posts

imo flat top 4.8l pistons and 64cc chamber heads = 10:1 compression with stock gasket. now you need to know what cam your going with to figure out the dynamic compression.

as for milling heads or thinner gasket you need to research about quench and squish.

would also get that block checked out and see if its ok for boost.

as for milling heads or thinner gasket you need to research about quench and squish.

would also get that block checked out and see if its ok for boost.

#12

TECH Addict

11-12:1 isn't too much static compression for 15# of boost. Your tune just has to be closer to perfect than with 9-10:1 compression.

The days of intentionally dropping compression for boost are behind us.

The days of intentionally dropping compression for boost are behind us.

#13

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

So I finally got the motor down to where I want it. Was going to take it down to the bare block but decided to take it to the machine shop with the crank still in it. It's going to be a while before I take but it's ready to go. Heads got to TEA this days ago, but I haven't been able to contact them even though I've called a bunch of times, left a message, and sent a few emails  . Not sure what the reason is but i hope all is ok.

. Not sure what the reason is but i hope all is ok.

Below are some pics of what it looks like now.

. Not sure what the reason is but i hope all is ok.

. Not sure what the reason is but i hope all is ok.Below are some pics of what it looks like now.

Last edited by C_Rules; 10-26-2015 at 12:03 PM.

#14

TECH Addict

Once the block is assembled, you will measure for quench/squish and that determines your head gasket thickness.

Decking the heads makes the combustion chamber smaller, raising compression regardless of quench.

Decking the heads makes the combustion chamber smaller, raising compression regardless of quench.

#15

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

After the head work is done i'll end up with a final combustion chamber of 64cc. I'm just going to run a piston with a custom dish to get the compression just where I want it.

#16

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

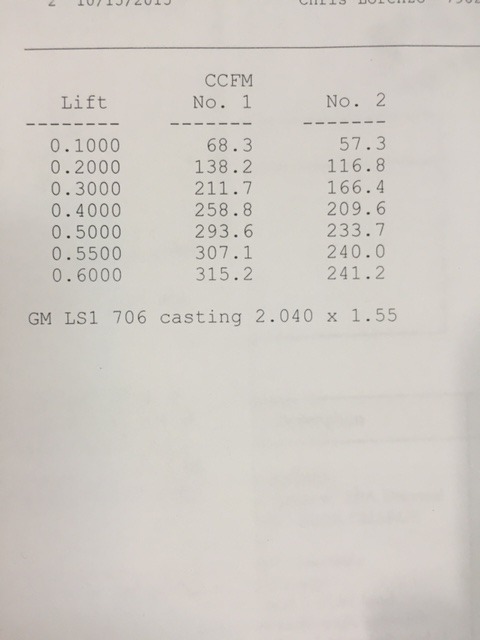

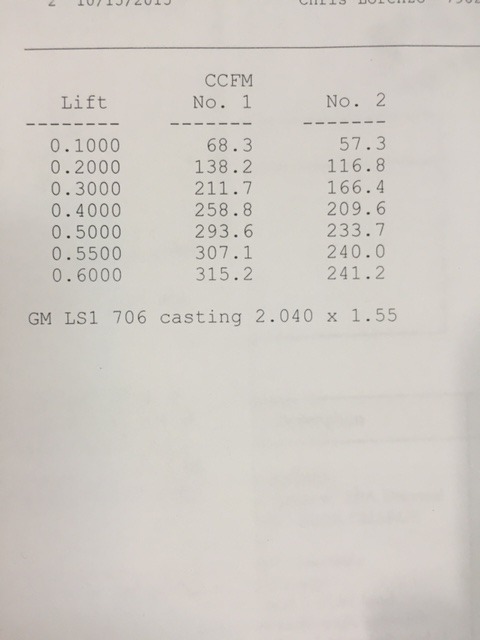

Ok got my heads back from TEA. I didn't hear from them for about a week while Gregg was on vacation but once he came back he was super quick to answer all questions. Even before I sent my heads he was quick to answer any question. Really good customer service and quick turnaround. Would definitely use them again. Here some pics of how they came out.

#17

what machine work did you have done to your block?

Im going to bring my lm7 block to the shop and im trying to figure out what all i should have done to the block.

I want to retain as much factory specs as i can. Just wondering what all people normally have done to their block and crank.

Im going to bring my lm7 block to the shop and im trying to figure out what all i should have done to the block.

I want to retain as much factory specs as i can. Just wondering what all people normally have done to their block and crank.

#18

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

what machine work did you have done to your block?

Im going to bring my lm7 block to the shop and im trying to figure out what all i should have done to the block.

I want to retain as much factory specs as i can. Just wondering what all people normally have done to their block and crank.

Im going to bring my lm7 block to the shop and im trying to figure out what all i should have done to the block.

I want to retain as much factory specs as i can. Just wondering what all people normally have done to their block and crank.

You can have the machine shop check the tolerances and if all is good put some new bearings in and put it back together with the stock rotating aseembly and new rings.

#20

12 Second Club

Thread Starter

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

Thanks. Good question on the bore size. I'll find out. I believe they're based on a a bore size closer to an LS1 3.898 or slightly larger 3.9.

Last edited by C_Rules; 10-24-2015 at 08:31 AM.