View Poll Results: Can it Be Saved?

Yes

25

83.33%

Nope, it's scrap.

5

16.67%

Voters: 30. You may not vote on this poll

Can This Block Be Saved? 4.250" Stroke LQ9 Build Thread

#61

TECH Veteran

I don't see how a 4.250 stroker crank is going to be used due to the LQ motors having the shortest sleeve in the LS engine family...

#63

Quick update, it looks like the pistons may have shipped.

The rings came in. Instead of Total Seal .9/.9/2.0mm rings, I had to use Mahle 1.0/1.0/2.0mm rings instead. No big deal, still a very nice reduction in internal friction and reciprocating weight. Should seal better too.

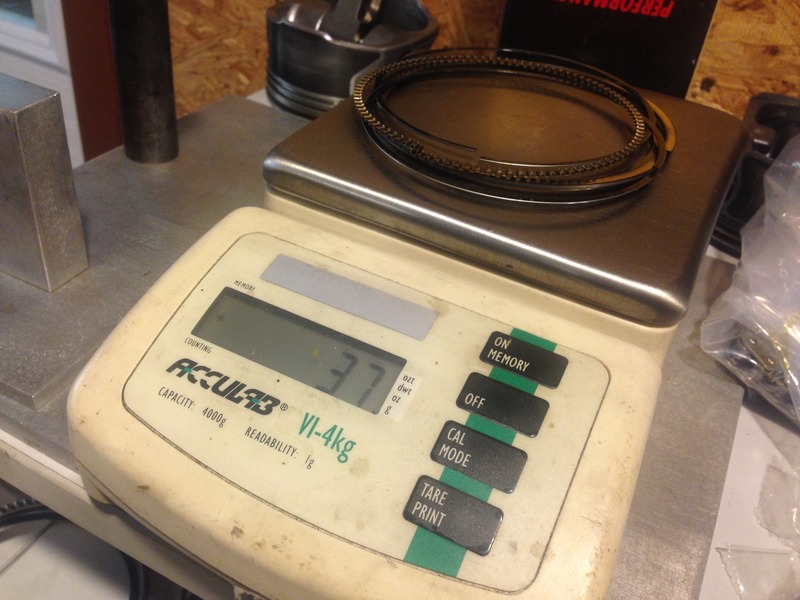

Stock LS3 rings weigh 37 grams:

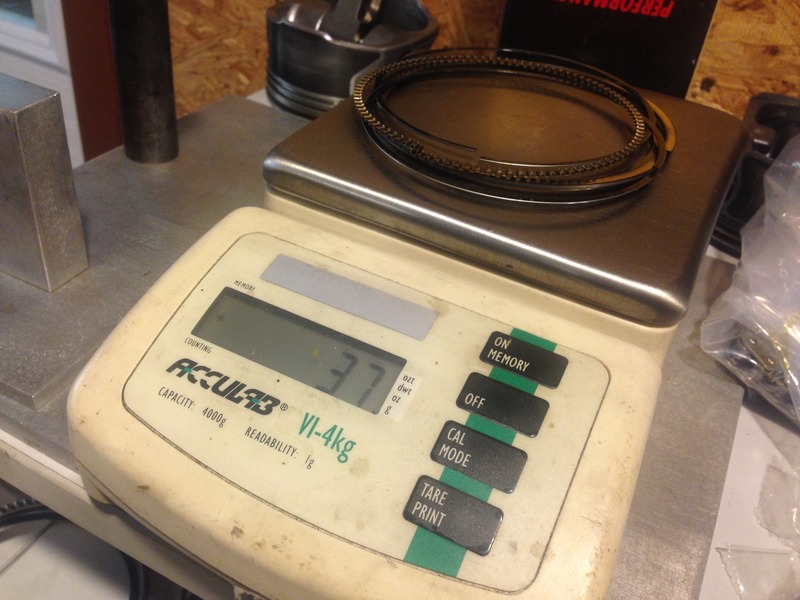

Mahle rings weigh 22 grams:

Also, I'm considering having my TFS as cast heads and Holley Hi-Ram sent off to be ported since my engine grew 70 cubic inches from the original plan with the LS2. I'm reluctant to sink anymore money into them though since I really think a set of small bore LS7 heads would be more appropriate.

The rings came in. Instead of Total Seal .9/.9/2.0mm rings, I had to use Mahle 1.0/1.0/2.0mm rings instead. No big deal, still a very nice reduction in internal friction and reciprocating weight. Should seal better too.

Stock LS3 rings weigh 37 grams:

Mahle rings weigh 22 grams:

Also, I'm considering having my TFS as cast heads and Holley Hi-Ram sent off to be ported since my engine grew 70 cubic inches from the original plan with the LS2. I'm reluctant to sink anymore money into them though since I really think a set of small bore LS7 heads would be more appropriate.

#65

I have read about at least one guy who's pilot bearing bore was a little loose on his K1 crank. I haven't checked mine yet but that was the first I've heard of a problem from a K1 product.

I got a smoking deal on this crank so really I can't complain even if it needed to be touched up, but I think it's a nice piece. I wouldn't hesitate to buy another crank from them if I were to build another engine.

#68

TECH Apprentice

iTrader: (2)

Join Date: Oct 2012

Location: Akron, Ohio

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

It's looks pretty good from the naked eye. The journals all seem to be pretty straight and round when I mic'd them and there's only about +/- .0001" variation from one journal to another. However, there is a really good crank grinder local to me that has some very expensive equipment which would really be able to tell how good the machine work is. He has told me that most of the crank he sees aren't up to his standards anyways.

I have read about at least one guy who's pilot bearing bore was a little loose on his K1 crank. I haven't checked mine yet but that was the first I've heard of a problem from a K1 product.

I got a smoking deal on this crank so really I can't complain even if it needed to be touched up, but I think it's a nice piece. I wouldn't hesitate to buy another crank from them if I were to build another engine.

I have read about at least one guy who's pilot bearing bore was a little loose on his K1 crank. I haven't checked mine yet but that was the first I've heard of a problem from a K1 product.

I got a smoking deal on this crank so really I can't complain even if it needed to be touched up, but I think it's a nice piece. I wouldn't hesitate to buy another crank from them if I were to build another engine.

#69

Quick update, it looks like the pistons may have shipped.

The rings came in. Instead of Total Seal .9/.9/2.0mm rings, I had to use Mahle 1.0/1.0/2.0mm rings instead. No big deal, still a very nice reduction in internal friction and reciprocating weight. Should seal better too.

Stock LS3 rings weigh 37 grams:

Mahle rings weigh 22 grams:

Also, I'm considering having my TFS as cast heads and Holley Hi-Ram sent off to be ported since my engine grew 70 cubic inches from the original plan with the LS2. I'm reluctant to sink anymore money into them though since I really think a set of small bore LS7 heads would be more appropriate.

The rings came in. Instead of Total Seal .9/.9/2.0mm rings, I had to use Mahle 1.0/1.0/2.0mm rings instead. No big deal, still a very nice reduction in internal friction and reciprocating weight. Should seal better too.

Stock LS3 rings weigh 37 grams:

Mahle rings weigh 22 grams:

Also, I'm considering having my TFS as cast heads and Holley Hi-Ram sent off to be ported since my engine grew 70 cubic inches from the original plan with the LS2. I'm reluctant to sink anymore money into them though since I really think a set of small bore LS7 heads would be more appropriate.

#70

Yeah I don't doubt it, but I don't know how they will line up with the valve releifs in the pistons. The OEM valve locations in the LS7 head are a lot different than in a cathedral or LS3 head. I think the small bore heads would fit better but I wouldn't want to have to cut new valve releifs in a piston like this where everything is tight already.

As a quick update, I'm making some progress on the shortblock. I'll be working on the block tonight to get the bottom of the cylinders notched to clear the rod bolts, file fit the rings, and set the rod bearing clearance. I'll post some pics tomorrow.

As a quick update, I'm making some progress on the shortblock. I'll be working on the block tonight to get the bottom of the cylinders notched to clear the rod bolts, file fit the rings, and set the rod bearing clearance. I'll post some pics tomorrow.

#72

Made some more progress the last few days. Upon my first attempt at setting the main hearing clearance, I found out that the main housing bores were way out of round. They were tighter at the parting line causing a pretty significant decrease in clearance there. I ended up having to line hone the block to get the bores round again. Also, I was able to get the rotating assembly mocked up, deck height checked, and deck cut for the pistons to sit slightly out of the hole at TDC.

Custom Wiseco pistons sitting at TDC:

Rocking the piston to measure how far the piston sat in the hole. Repeated on both sides of the piston in all four corner cylinders (#1, 7, 2, & 8).

All four corner cylinders were within +/- .001" of eachother so I didn't have to do much with the surfacer to correct the deck. I just cut off about .012" which should put the pistons just slightly above the deck.

Bottom view of the piston at BDC. Before anyone says "OMG the piston is pulled too far down," please keep reading.

I measured the piston rock at BDC using an extension for the deck bridge. The dial indicator read .010" when rocked downwards and .050" when rocked upwards, equating to .040" of piston rock.

A 408 with Wiseco pistons and a 4" stroke crank I measured last week rocked .045" at BDC. The needle started at .000" when rocked upwards and ended up at .055" when rocked downwards.

So yeah. With a 4.250" crank, the piston rocks LESS than a 4" crank at BDC.

Custom Wiseco pistons sitting at TDC:

Rocking the piston to measure how far the piston sat in the hole. Repeated on both sides of the piston in all four corner cylinders (#1, 7, 2, & 8).

All four corner cylinders were within +/- .001" of eachother so I didn't have to do much with the surfacer to correct the deck. I just cut off about .012" which should put the pistons just slightly above the deck.

Bottom view of the piston at BDC. Before anyone says "OMG the piston is pulled too far down," please keep reading.

I measured the piston rock at BDC using an extension for the deck bridge. The dial indicator read .010" when rocked downwards and .050" when rocked upwards, equating to .040" of piston rock.

A 408 with Wiseco pistons and a 4" stroke crank I measured last week rocked .045" at BDC. The needle started at .000" when rocked upwards and ended up at .055" when rocked downwards.

So yeah. With a 4.250" crank, the piston rocks LESS than a 4" crank at BDC.

Last edited by KCS; 05-09-2016 at 12:43 PM.

The following users liked this post:

Godsmercy81 (08-10-2020)

#78

I like Comp. I've been using their cams for years and never really had a problem with them. I know several people on here don't like to use them because of that "whine" issue, but out of the hundreds of Comp cams I've installed, I've never had that problem.

#80

I'm getting close now! I got the block washed and brought it in the assembly room to start getting it ready for final assembly. I started with the main bearing clearance by putting standard size bearings in the #1 cap to see if I'm in the ball park before putting all the other caps on.

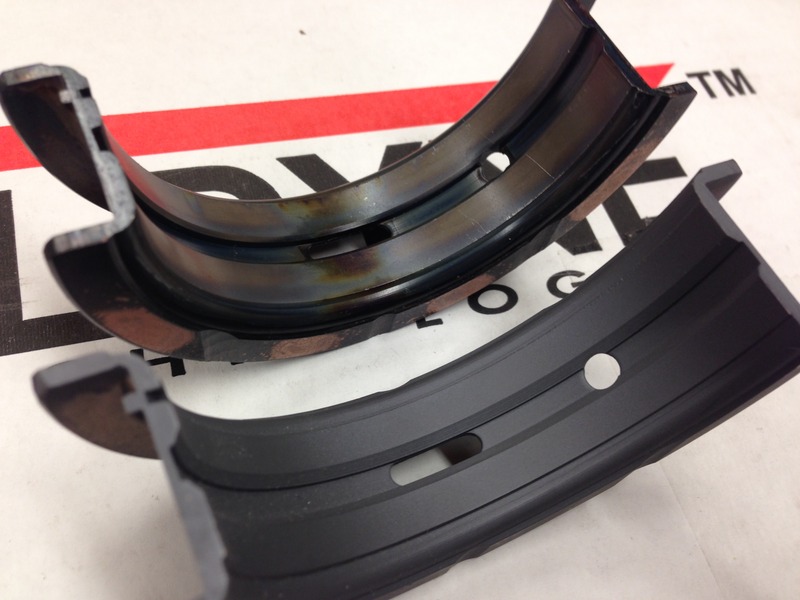

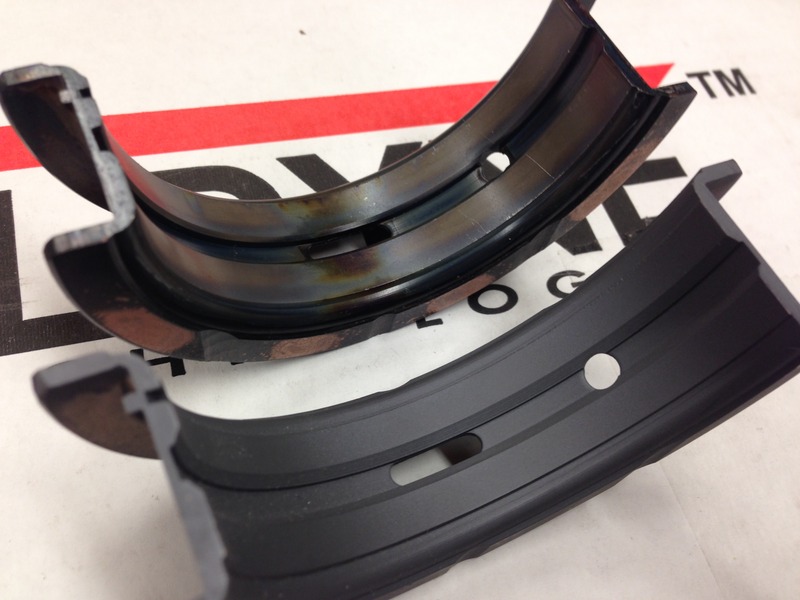

The bearing clearance on #1 came out to .0024", which is right where I want to be so I put in the rest of the bearings and got .0022" on the #3 cap and .0024-.0026" everywhere else. I'm using Federal Mogul bearings with a coating by PolyDyne here in Houston, TX. The coating allows you to run your clearance a little tighter, but if something bad happens, the coating can be wiped away without hurting the engine or the bearing itself. It's great for power adder applications where the customer says he'll be on "low boost" and ends up making 1000hp at the wheels. The bearing on top is a standard uncoated bearing and underneath is a PolyDyne coated bearing.

Next I went ahead and filed the rings with .018" gap on the top ring and .022" on the second rings. I make a habit of checking the oil rails too. They should have at least .011" gap but I've found a couple sets over the years that had less than .006". These were fine as an .011" feeler gauge dropped right in.

The bearing clearance on #1 came out to .0024", which is right where I want to be so I put in the rest of the bearings and got .0022" on the #3 cap and .0024-.0026" everywhere else. I'm using Federal Mogul bearings with a coating by PolyDyne here in Houston, TX. The coating allows you to run your clearance a little tighter, but if something bad happens, the coating can be wiped away without hurting the engine or the bearing itself. It's great for power adder applications where the customer says he'll be on "low boost" and ends up making 1000hp at the wheels. The bearing on top is a standard uncoated bearing and underneath is a PolyDyne coated bearing.

Next I went ahead and filed the rings with .018" gap on the top ring and .022" on the second rings. I make a habit of checking the oil rails too. They should have at least .011" gap but I've found a couple sets over the years that had less than .006". These were fine as an .011" feeler gauge dropped right in.