View Poll Results: Can it Be Saved?

Yes

25

83.33%

Nope, it's scrap.

5

16.67%

Voters: 30. You may not vote on this poll

Can This Block Be Saved? 4.250" Stroke LQ9 Build Thread

#82

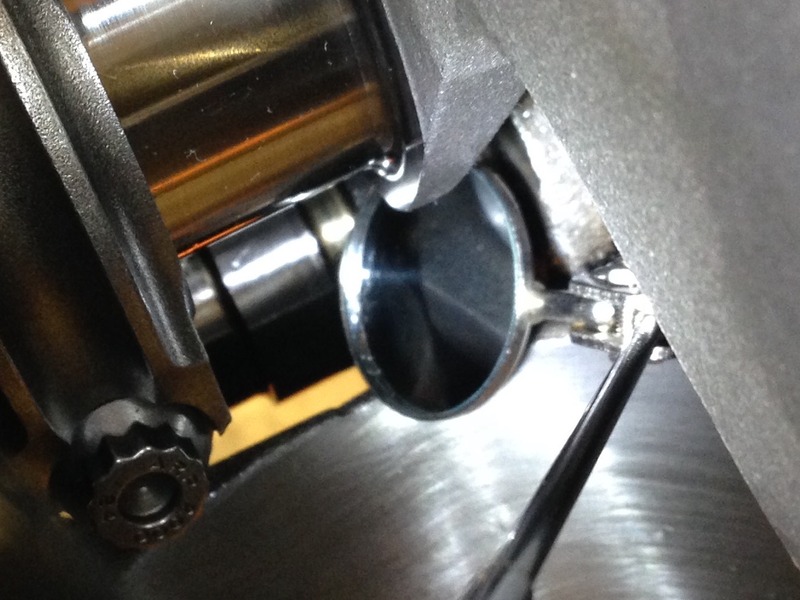

The #8 piston just barely hit the reluctor at bottom dead center. That was fixed after about 15 minutes in the end mill as only about .015-.020" was faced off the pin boss. There's still .100" of material in front of the groove for the spirolocks.

The rod bearing clearances are set. With standard bearings, the clearance is .0028"-.0030" which is a little looser than what I was shooting for. However, with half standard and half .001" under, I'm getting .0022"-.0024" which is a little tighter than I wanted, but it will still work just fine.

After setting the bearing clearances, it think it's worth mentioning that the journal diameters on the K1 crank are all on the low side of the tolerances. For example, the rod journals are supposed to be 2.0990"-2.1000", and the K1 journals were all right at 2.0992". This is probably pretty smart, IMO, since you're pretty much forced to run a looser clearance which is usually needed in a performance engine.

#85

TECH Apprentice

iTrader: (2)

Join Date: Oct 2012

Location: Akron, Ohio

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

The rod bearing clearances are set. With standard bearings, the clearance is .0028"-.0030" which is a little looser than what I was shooting for. However, with half standard and half .001" under, I'm getting .0022"-.0024" which is a little tighter than I wanted, but it will still work just fine.

After setting the bearing clearances, it think it's worth mentioning that the journal diameters on the K1 crank are all on the low side of the tolerances. For example, the rod journals are supposed to be 2.0990"-2.1000", and the K1 journals were all right at 2.0992". This is probably pretty smart, IMO, since you're pretty much forced to run a looser clearance which is usually needed in a performance engine.[/QUOTE]

Looks like the K1 crank is a decent crank for the money.

Couldn't you coat the standard rod bearings like you did the mains to close it up?

After setting the bearing clearances, it think it's worth mentioning that the journal diameters on the K1 crank are all on the low side of the tolerances. For example, the rod journals are supposed to be 2.0990"-2.1000", and the K1 journals were all right at 2.0992". This is probably pretty smart, IMO, since you're pretty much forced to run a looser clearance which is usually needed in a performance engine.[/QUOTE]

Looks like the K1 crank is a decent crank for the money.

Couldn't you coat the standard rod bearings like you did the mains to close it up?

#86

I could always work on the heads in the meantime.

#93

#94

TECH Regular

Join Date: Dec 2003

Location: Cherry Hill, New Jersey State

Posts: 486

Received 0 Likes

on

0 Posts

Impressive detailed work

Did you mill all the pistons boss in the same manner to have equal pistons mass weight to have an equal acting mass forces on the crankshaft?

With this modification, this will require to re-balance the rotating assembly.

Did you mill all the pistons boss in the same manner to have equal pistons mass weight to have an equal acting mass forces on the crankshaft?

With this modification, this will require to re-balance the rotating assembly.

#96

So I ended up swapping out the Compstar rods for K1 rods. The weight was close enough that the crank didn't need to be rebalanced either. Whats interesting about the K1 rods is that they don't give you a torque value for the 7/16" ARP 2000 rod bolts. Instead they give you a stretch value and a torque-to-angle value. These rod bolts go to 30ft-lbs plus 50 degrees, which ended up being about 85ft-lbs. With a set of coated Federal Mogul rod bearings, I ended up with .0026" clearance.

After final cleaning everything, I oiled up the cylinders and finally assembled the shortblock.

After final cleaning everything, I oiled up the cylinders and finally assembled the shortblock.

Last edited by KCS; 07-02-2016 at 03:00 PM.

#98

The K1 and Compstar rods were both at about .0009" which will work on most street car builds. The Scat's were closer to what a stock engine has at about .0005", which IMO, is too tight for a performance application. With the long stroke and the potential to see 7500-8000 RPM, I opened them up a little further to .0012".

#100

TECH Apprentice

iTrader: (2)

Join Date: Oct 2012

Location: Akron, Ohio

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

The K1 and Compstar rods were both at about .0009" which will work on most street car builds. The Scat's were closer to what a stock engine has at about .0005", which IMO, is too tight for a performance application. With the long stroke and the potential to see 7500-8000 RPM, I opened them up a little further to .0012".