Broken yella terra ultralite rocker arm :(

#21

Hundreds, perhaps thousands, of sets of these rockers (3rd Gen design) have shipped over the last four years.....each set with 16 rocker arms.....do the math. How many various stock failures have you seen (even some with aftermarket/upgrade bearing kits) in that same time frame.....more than that.

Im sending Alex a rocker arm on Monday from my own inventory to get him on the road again. I would have sent something today but Im on the east coast at the moment and will handle it as soon as I return.

I would never, ever consider a stock rocker arm in a performance application such as this....twice the spring pressure....twice the cam lobe intensity....more cam lift and RPM....this is not what they were designed for and the wipe geometry is horrible. Do they work....yes...of course they will function (and occasionally fail) but the poor geometry will scrub and side load the guides reducing the service life of your heads by a significant amount even with powdered metal guides (faster with bronze). Check the scrub/wipe pattern of a factory rocker with .625 lift.....its a square covering 2/3 of the tip of the valve versus a roller wheel which glides over a much more narrow portion of the tip leaving a small rectangular patch instead (ideal).

Guys....I can sell anything and recommend and use anything I want. If a rocker existed that did a better job I would be using it but you have to understand how critical it is to have a lightweight rocker arm in an HR application if your hoping to achieve perfect valve control at 7000 or more RPM. You cant use a heavier rocker arm more designed for solid roller applications....it will never give you the valve control in an HR application and it will cost you power as soon as your valvetrain shows signs of unhappiness and instability (valve float being a severe case of this).

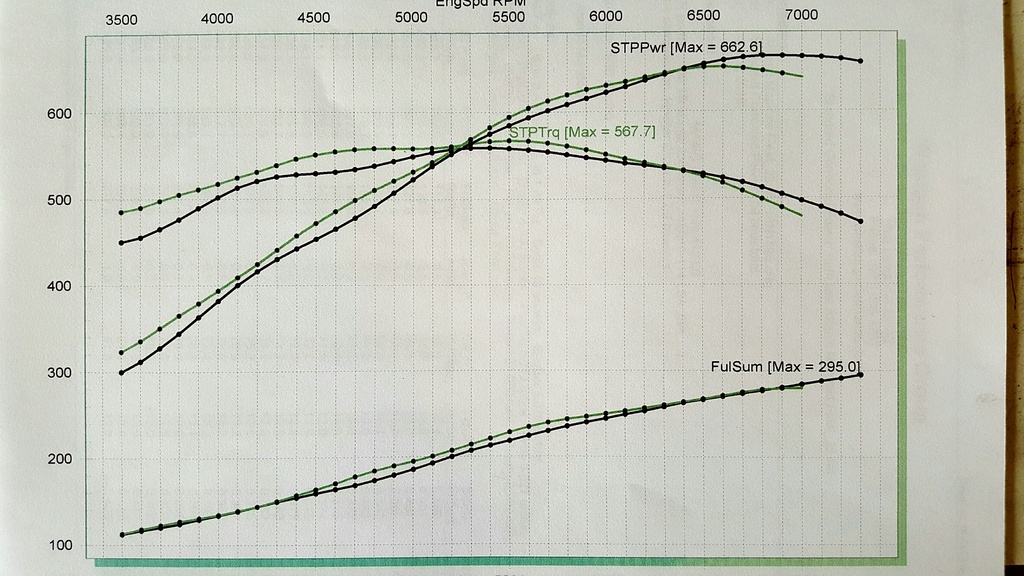

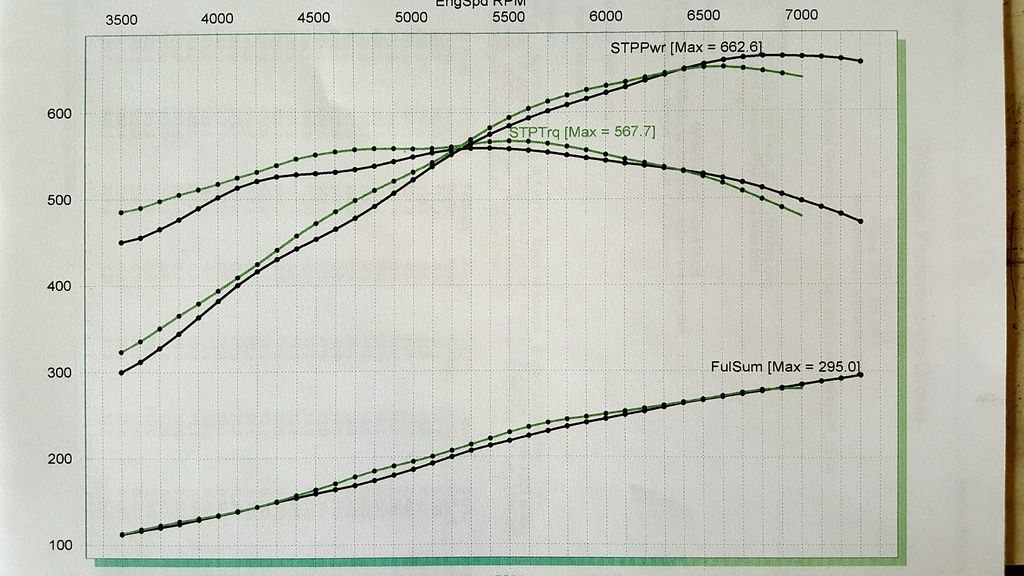

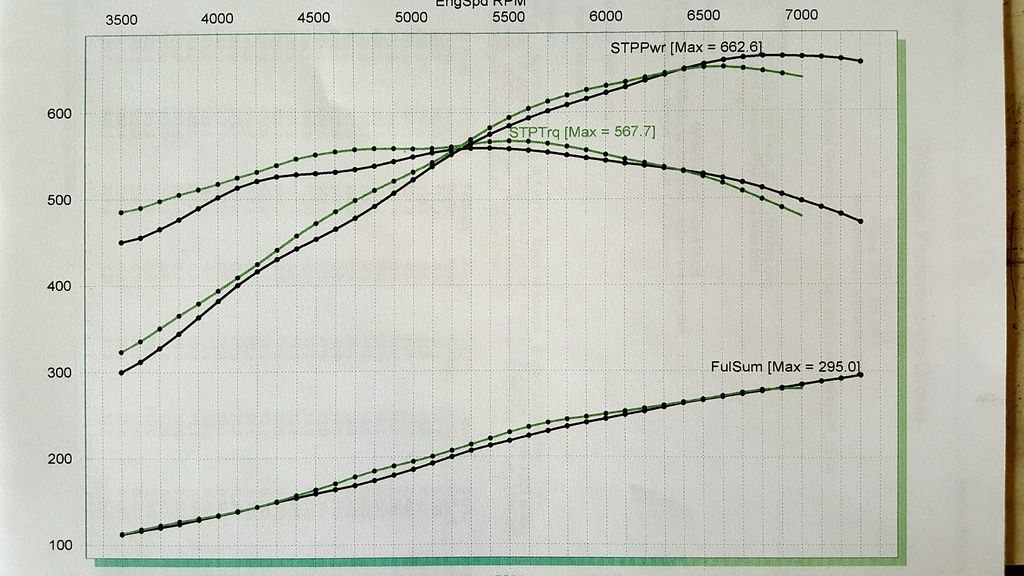

Here is an engine I recently built and did some engine dyno testing with earlier this week....this had a 1.8 ratio YT rocker (one of my 10mm units) and it looked like a solid roller was installed with perfect valve control to 7300 RPM where we terminated the pull. This had .662 lift also...same lifters, same pushrods as the OP of this thread. Clearly the valvetrain set-up in this engine is working extremely well (more on this test in a thread I started drafting and haven't posted yet btw).

Bottom line the YT Ultralite design is a purpose built rocker....it is the right tool for the job but excess weight was removed everywhere it could be and I think the Gen 3 design is the best compromise of reliability and function. It would be easy for Yella Terra to add a bunch of aluminum and weight to make them more "unbreakable" but that would hurt the functionality of what it was intended to do.

I get that it sucks if you are one of the unlucky that experiences a remote failure, I really do, but until I see an epidemic of failures I will continue to support and use this product. I run them on my personal vehicles....in fact my 2009 CTSV makes about 700 RWHP and I have put over 24000 miles on that modded engine with the YT Ultralite rockers and it runs like a top.

Personally I would rather be inconvenienced by a rocker arm failure then experience valve float and a serious loss in performance with other brands of (heavier) aftermarket rockers and I would never run a stock rocker period due to all the previous things already mentioned. Valve guides shaped like an hour glass due to to all the side loading is not very ideal....ultimately you start consuming oil and your valves wont seat properly on the head because of the wear and excessive guide clearance. I would rather get a triple A ride home and swap a broken rocker arm than knowingly install a rocker arm unsuited for my application that will reduce the service life of a very expensive set of heads.

Sorry for the long post but there is alot to consider here....we don't live in a perfect world....high performance modded engines in general are never as reliable as lower powered stock applications for obvious reasons but we do our best to achieve higher levels of performance using parts that will go the distance. In some cases overbuilding the part is the simple answer but this part (the rocker arm) is a very delicate balance to get the results we want and that's what you guys need to understand

I hope some of you reading this found what I wrote here helpful and hopefully provided you a different perspective on this situation. Also, if any of you need some assistance with a Yella Terra product (whether you purchased them from me or not) don't hesitate to reach out. Alex, your rocker arm will be in the mail on Monday as soon as I return from my trip.

Regards,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 06-04-2016 at 04:24 PM.

#22

I was unaware there was a trade-off buying these rocker arms, pretty disappointed...I did not compromise on this build, went all out with everything...I would expect these things to outperform and maybe even outlast the stockers for the price you pay, not just be 1000mile disposable...guess it don't work that way with these...would be a big pain to go back to stockers as I'll most likely need to measure for a new set of pushrods as well, which weren't cheap either Mamo will be sending me a new arm shortly, so I'm assuming it was actually just the rocker that failed and it's common...guess I'll know right away when I fire it up, if she's nice n quiet, safe to assume lifters are good....just kinda sucks now, gonna feel like I'm just waiting for the one or few to go

I also don't think 1k miles is ok, or even 10k miles.

Seems pretty hit or miss with the random failures

#25

Honestly, that's exactly what this is....everything and anything can break. This is only the 2nd failure of a 3rd Gen rocker that I know of and the Internet makes it pretty easy these days to spread information (good and bad).

Hundreds, perhaps thousands, of sets of these rockers (3rd Gen design) have shipped over the last four years.....each set with 16 rocker arms.....do the math. How many various stock failures have you seen (even some with aftermarket/upgrade bearing kits) in that same time frame.....more than that.

Im sending Alex a rocker arm on Monday from my own inventory to get him on the road again. I would have sent something today but Im on the east coast at the moment and will handle it as soon as I return.

I would never, ever consider a stock rocker arm in a performance application such as this....twice the spring pressure....twice the cam lobe intensity....more cam lift and RPM....this is not what they were designed for and the wipe geometry is horrible. Do they work....yes...of course they will function (and occasionally fail) but the poor geometry will scrub and side load the guides reducing the service life of your heads by a significant amount even with powdered metal guides (faster with bronze). Check the scrub/wipe pattern of a factory rocker with .625 lift.....its a square covering 2/3 of the tip of the valve versus a roller wheel which glides over a much more narrow portion of the tip leaving a small rectangular patch instead (ideal).

Guys....I can sell anything and recommend and use anything I want. If a rocker existed that did a better job I would be using it but you have to understand how critical it is to have a lightweight rocker arm in an HR application if your hoping to achieve perfect valve control at 7000 or more RPM. You cant use a heavier rocker arm more designed for solid roller applications....it will never give you the valve control in an HR application and it will cost you power as soon as your valvetrain shows signs of unhappiness and instability (valve float being a severe case of this).

Here is an engine I recently built and did some engine dyno testing with earlier this week....this had a 1.8 ratio YT rocker (one of my 10mm units) and it looked like a solid roller was installed with perfect valve control to 7300 RPM where we terminated the pull. This had .662 lift also...same lifters, same pushrods as the OP of this thread. Clearly the valvetrain set-up in this engine is working extremely well (more on this test in a thread I started drafting and haven't posted yet btw).

Bottom line the YT Ultralite design is a purpose built rocker....it is the right tool for the job but excess weight was removed everywhere it could be and I think the Gen 3 design is the best compromise of reliability and function. It would be easy for Yella Terra to add a bunch of aluminum and weight to make them more "unbreakable" but that would hurt the functionality of what it was intended to do.

I get that it sucks if you are one of the unlucky that experiences a remote failure, I really do, but until I see an epidemic of failures I will continue to support and use this product. I run them on my personal vehicles....in fact my 2009 CTSV makes about 700 RWHP and I have put over 24000 miles on that modded engine with the YT Ultralite rockers and it runs like a top.

Personally I would rather be inconvenienced by a rocker arm failure then experience valve float and a serious loss in performance with other brands of (heavier) aftermarket rockers and I would never run a stock rocker period due to all the previous things already mentioned. Valve guides shaped like an hour glass due to to all the side loading is not very ideal....ultimately you start consuming oil and your valves wont seat properly on the head because of the wear and excessive guide clearance. I would rather get a triple A ride home and swap a broken rocker arm than knowingly install a rocker arm unsuited for my application that will reduce the service life of a very expensive set of heads.

Sorry for the long post but there is alot to consider here....we don't live in a perfect world....high performance modded engines in general are never as reliable as lower powered stock applications for obvious reasons but we do our best to achieve higher levels of performance using parts that will go the distance. In some cases overbuilding the part is the simple answer but this part (the rocker arm) is a very delicate balance to get the results we want and that's what you guys need to understand

I hope some of you reading this found what I wrote here helpful and hopefully provided you a different perspective on this situation. Also, if any of you need some assistance with a Yella Terra product (whether you purchased them from me or not) don't hesitate to reach out. Alex, your rocker arm will be in the mail on Monday as soon as I return from my trip.

Regards,

Tony

Hundreds, perhaps thousands, of sets of these rockers (3rd Gen design) have shipped over the last four years.....each set with 16 rocker arms.....do the math. How many various stock failures have you seen (even some with aftermarket/upgrade bearing kits) in that same time frame.....more than that.

Im sending Alex a rocker arm on Monday from my own inventory to get him on the road again. I would have sent something today but Im on the east coast at the moment and will handle it as soon as I return.

I would never, ever consider a stock rocker arm in a performance application such as this....twice the spring pressure....twice the cam lobe intensity....more cam lift and RPM....this is not what they were designed for and the wipe geometry is horrible. Do they work....yes...of course they will function (and occasionally fail) but the poor geometry will scrub and side load the guides reducing the service life of your heads by a significant amount even with powdered metal guides (faster with bronze). Check the scrub/wipe pattern of a factory rocker with .625 lift.....its a square covering 2/3 of the tip of the valve versus a roller wheel which glides over a much more narrow portion of the tip leaving a small rectangular patch instead (ideal).

Guys....I can sell anything and recommend and use anything I want. If a rocker existed that did a better job I would be using it but you have to understand how critical it is to have a lightweight rocker arm in an HR application if your hoping to achieve perfect valve control at 7000 or more RPM. You cant use a heavier rocker arm more designed for solid roller applications....it will never give you the valve control in an HR application and it will cost you power as soon as your valvetrain shows signs of unhappiness and instability (valve float being a severe case of this).

Here is an engine I recently built and did some engine dyno testing with earlier this week....this had a 1.8 ratio YT rocker (one of my 10mm units) and it looked like a solid roller was installed with perfect valve control to 7300 RPM where we terminated the pull. This had .662 lift also...same lifters, same pushrods as the OP of this thread. Clearly the valvetrain set-up in this engine is working extremely well (more on this test in a thread I started drafting and haven't posted yet btw).

Bottom line the YT Ultralite design is a purpose built rocker....it is the right tool for the job but excess weight was removed everywhere it could be and I think the Gen 3 design is the best compromise of reliability and function. It would be easy for Yella Terra to add a bunch of aluminum and weight to make them more "unbreakable" but that would hurt the functionality of what it was intended to do.

I get that it sucks if you are one of the unlucky that experiences a remote failure, I really do, but until I see an epidemic of failures I will continue to support and use this product. I run them on my personal vehicles....in fact my 2009 CTSV makes about 700 RWHP and I have put over 24000 miles on that modded engine with the YT Ultralite rockers and it runs like a top.

Personally I would rather be inconvenienced by a rocker arm failure then experience valve float and a serious loss in performance with other brands of (heavier) aftermarket rockers and I would never run a stock rocker period due to all the previous things already mentioned. Valve guides shaped like an hour glass due to to all the side loading is not very ideal....ultimately you start consuming oil and your valves wont seat properly on the head because of the wear and excessive guide clearance. I would rather get a triple A ride home and swap a broken rocker arm than knowingly install a rocker arm unsuited for my application that will reduce the service life of a very expensive set of heads.

Sorry for the long post but there is alot to consider here....we don't live in a perfect world....high performance modded engines in general are never as reliable as lower powered stock applications for obvious reasons but we do our best to achieve higher levels of performance using parts that will go the distance. In some cases overbuilding the part is the simple answer but this part (the rocker arm) is a very delicate balance to get the results we want and that's what you guys need to understand

I hope some of you reading this found what I wrote here helpful and hopefully provided you a different perspective on this situation. Also, if any of you need some assistance with a Yella Terra product (whether you purchased them from me or not) don't hesitate to reach out. Alex, your rocker arm will be in the mail on Monday as soon as I return from my trip.

Regards,

Tony

Just to be clear, I did not intend to bash any brands, products or dealers with this thread...just wanted to get some insight on whether or not other users of this product have experienced the same issue and/or common causes of failure and what was done to correct the issue.

Thanks for addressing the issue as quickly as possible, looking forward to getting her back on her feet

#26

Curious, how close are you to coil bind? Might also want to measure that one pushrod with a caliper while the motor is apart as pushrods have a tolerance on length as well. It could just be a random failure, which is unfortunate, but might as well investigate a bit while the motor is down just to make sure the rocker wasn't telling you something.

#27

When the OP said he used 6 different push-rod lengths I thought that was the problem. They are saying it's an isolated incident, but it will probably happen again. Six different push-rods is too many different sizes and there is a problem somewhere else.

#28

Tolerances stack up, and this isn't a ls7 lifter which has a huge window for preload.

#29

No one runs 16 identical pushrods with short travel lifters. I run 6-7 different lengths myself.

#30

Hey guys,

Just an update...

Tony sent me 2 new rocker arms, no charge...car is back up n running good, about 500 miles trouble free.

Thanks again Tony Mamo, awesome service!

Cheers,

Alex

Just an update...

Tony sent me 2 new rocker arms, no charge...car is back up n running good, about 500 miles trouble free.

Thanks again Tony Mamo, awesome service!

Cheers,

Alex

#31