Pease help with crank case problem VIDEO

#1

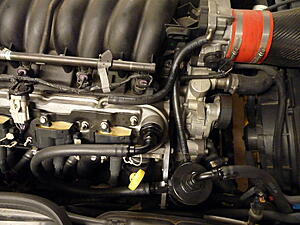

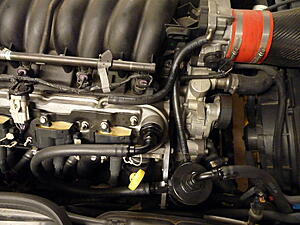

Recent engine rebuild. Keeps blowing oil from the rear main seal. Left gauge is connected to the valley port. Right gauge is T-ed into the line between the valve cover and and throttle body. As you can see it builds pressure at high RPM at part throttle and sometimes at full throttle. Need to understand what is happening and why. Crank case is vented with pictured Mighty Mouse system. Thanks for helping.

#2

Maybe this will help, because I really can't see everything that's going on: http://ls1howto.com/index.php?article=18

#3

Maybe this will help, because I really can't see everything that's going on: http://ls1howto.com/index.php?article=18

#6

I want to know why my crankcase is pressurizing and how to fix it. The video shows under what conditions it builds pressure, how fast it builds it, and how fast it drops. It should be very useful for understanding what is going on.

Trending Topics

#8

This used to be a good place, now days its more of what cam and heads do i use,

and a know it all Vendor who ****** up most threads trying to push Cheap

Chinese crap on everybody. And that probably lost the interest of a lot of people, and they don't post in here anymore.

#10

You might try Yellow Bullet . com

This used to be a good place, now days its more of what cam and heads do i use,

and a know it all Vendor who ****** up most threads trying to push Cheap

Chinese crap on everybody. And that probably lost the interest of a lot of people, and they don't post in here anymore.

This used to be a good place, now days its more of what cam and heads do i use,

and a know it all Vendor who ****** up most threads trying to push Cheap

Chinese crap on everybody. And that probably lost the interest of a lot of people, and they don't post in here anymore.

#13

TECH Senior Member

iTrader: (25)

You might try Yellow Bullet . com

This used to be a good place, now days its more of what cam and heads do i use,

and a know it all Vendor who ****** up most threads trying to push Cheap

Chinese crap on everybody. And that probably lost the interest of a lot of people, and they don't post in here anymore.

This used to be a good place, now days its more of what cam and heads do i use,

and a know it all Vendor who ****** up most threads trying to push Cheap

Chinese crap on everybody. And that probably lost the interest of a lot of people, and they don't post in here anymore.

#14

11 Second Club

Watching your vid & looking at your pic I'll make a guess. First off I find it odd it creates the pressures intermittently. Also your leak down test being good. From the picture the routing of the system looks useless. A vented catch can from the intake manifold to the pass. side valve cover. The clean air line 6 inches away. So any vacuum that is pulled just sucks from the clean air line. Anyway the thought I have is the valve in the catch can may be malfunctioning? Keeping it from venting. Maybe try another setup/routing see if things change. Just a thought. Good luck.

#16

11 Second Club

This does interest me a bit. I know every motor is different. So just for reference. I've been driving around for over a year w/ vacuum pump & vacuum gauge connected to drivers valve cover. No matter the rpm I always see crankcase pressure, vacuum drop, relevant to throttle position. WOT making the biggest drop. Saying there is always an amount of blow by during throttle.

The times when you are getting crank case pressure looks more normal to me. As to when you make WOT pulls & the gauge is solid as a rock at zero. Like said it interests me.

The little I know about ring flutter is that a big part of it can be just from driving styles. I think most likely high rpm/low throttle. Along with other things.

Ring flutter may be. When you get this taken care of please update with what you find.

The times when you are getting crank case pressure looks more normal to me. As to when you make WOT pulls & the gauge is solid as a rock at zero. Like said it interests me.

The little I know about ring flutter is that a big part of it can be just from driving styles. I think most likely high rpm/low throttle. Along with other things.

Ring flutter may be. When you get this taken care of please update with what you find.

#18

Watching your vid & looking at your pic I'll make a guess. First off I find it odd it creates the pressures intermittently. Also your leak down test being good. From the picture the routing of the system looks useless. A vented catch can from the intake manifold to the pass. side valve cover. The clean air line 6 inches away. So any vacuum that is pulled just sucks from the clean air line. Anyway the thought I have is the valve in the catch can may be malfunctioning? Keeping it from venting. Maybe try another setup/routing see if things change. Just a thought. Good luck.

If this were just a street car, yes, I could easily just drive in a manner to not induce this condition. In fact, I would probably never know the condition exists. But the primary use of this car is a track car and high rpm and varying throttle is not something you can reasonably avoid.

#19

Banned

iTrader: (1)

My name is Jordan and I am a PCV freak. I spend more time on my PCV system design than anything else, because to me it is more important and essential to long-lived street cars than anything else. And before you ask, yes filtration (air filter, oil filters) are part of the pcv system.

If you wanted to make absolutely sure the system was plumbing correctly, you could do a boost leak test to simulate compression-blowby into the crankcase (by slightly pressurizing the crankcase) and I Would do this simultaneously with the top-end pressure test (for a complete survey/picture of the pcv system). In other words, when the rings pass 'pressurized exhaust gas' into the crankcase, this generates the +0.01PSI you see on the gauge (since you are not FI). Where that pressure goes, how the engine handles it, is up to you. For example right now you say it is passing out the rear main. Well, that is because you are containing it, or rather, trying to contain it, within the crankcase. Whatever route you have that is setup to relief the pressure- isn't working- or the pressure would stay near 0.01psi and no higher. Unless it was an obscene amount of air molecules.

more details;

Pressurize the plumbing with compression air so that you have simulated boost in the intake manifold. I have a valve on my boost leak tester device that allows me to set a constant pressure-flow, usually I start around 5psi. This would be fine for your test.

Now that the intake manifold has 5psi in it, you should have 0psi in the crankcase still. If you see anything in there you have a bad checkvalve or incorrect route somewhere already, assuming you blocked off that one line that leads from the throttle body to the crankcase (you can see it in the picture) which was the original blow-by relief from the factory. This is the first essential step to testing a pcv system because it ensures pcv valve function correctly and eliminates any possible vacuum leaks/hoses tied to the intake air system.

Once you verify that pressure in the intake != pressure in the crankcase in the above steps, I would then turn the engine over manually with a socket, go through all 8 cylinders (360* times 2) to ensure that as each intake valve opens, that 5psi is presented to the cylinder, which is sealed up nicely, so you still see 0psi in the crankcase. If the pressure rises while you spin the motor slowly it means you have a missing part of a piston ring or piston.

Now, you are ready for the final test. Remember that hose from the throttle body that leads to the valve cover? Allow approx 1-2psi into the crankcase through that hose into the crankcase. No more than 2psi max. Does the crankcase hold the pressure? If it does, you may find the rear main start to leak when this pressure is applied. If it does NOT hold pressure you have another hole somewhere that crankcase pressure is leaving from- if you find that, it is likely a high chance to be your problem. My theory is that your rear crankcase evacuation port (LS6 cover) Is somehow interfering with the front cover evacuation, perhaps plumbed wrong through the checkvalves. I hope you know the LS6 cover is not a PCV valve, it does not have a check valve. It needs a check valve on it, just like the valve cover does on the intake manifold suction side. So if running the PCV valve in the valve cover, you would also need a PCV valve between the LS6 cover and the evacuation route

On the other hand, if you note the pressure isn't leaking anywhere else, then the evacuation route is simply too small. There is no limitation to the size of the evac. i.e. I guarantee you that even if the engine had terrible blow-by conditions, you could make a hole big enough to relief the pressure (and probably a lot of oil) but I digress

If you would like me to more thoroughly detail how I would run the hoses please feel free to ask, and there are good pics online elsewhere on the forum already

If you wanted to make absolutely sure the system was plumbing correctly, you could do a boost leak test to simulate compression-blowby into the crankcase (by slightly pressurizing the crankcase) and I Would do this simultaneously with the top-end pressure test (for a complete survey/picture of the pcv system). In other words, when the rings pass 'pressurized exhaust gas' into the crankcase, this generates the +0.01PSI you see on the gauge (since you are not FI). Where that pressure goes, how the engine handles it, is up to you. For example right now you say it is passing out the rear main. Well, that is because you are containing it, or rather, trying to contain it, within the crankcase. Whatever route you have that is setup to relief the pressure- isn't working- or the pressure would stay near 0.01psi and no higher. Unless it was an obscene amount of air molecules.

more details;

Pressurize the plumbing with compression air so that you have simulated boost in the intake manifold. I have a valve on my boost leak tester device that allows me to set a constant pressure-flow, usually I start around 5psi. This would be fine for your test.

Now that the intake manifold has 5psi in it, you should have 0psi in the crankcase still. If you see anything in there you have a bad checkvalve or incorrect route somewhere already, assuming you blocked off that one line that leads from the throttle body to the crankcase (you can see it in the picture) which was the original blow-by relief from the factory. This is the first essential step to testing a pcv system because it ensures pcv valve function correctly and eliminates any possible vacuum leaks/hoses tied to the intake air system.

Once you verify that pressure in the intake != pressure in the crankcase in the above steps, I would then turn the engine over manually with a socket, go through all 8 cylinders (360* times 2) to ensure that as each intake valve opens, that 5psi is presented to the cylinder, which is sealed up nicely, so you still see 0psi in the crankcase. If the pressure rises while you spin the motor slowly it means you have a missing part of a piston ring or piston.

Now, you are ready for the final test. Remember that hose from the throttle body that leads to the valve cover? Allow approx 1-2psi into the crankcase through that hose into the crankcase. No more than 2psi max. Does the crankcase hold the pressure? If it does, you may find the rear main start to leak when this pressure is applied. If it does NOT hold pressure you have another hole somewhere that crankcase pressure is leaving from- if you find that, it is likely a high chance to be your problem. My theory is that your rear crankcase evacuation port (LS6 cover) Is somehow interfering with the front cover evacuation, perhaps plumbed wrong through the checkvalves. I hope you know the LS6 cover is not a PCV valve, it does not have a check valve. It needs a check valve on it, just like the valve cover does on the intake manifold suction side. So if running the PCV valve in the valve cover, you would also need a PCV valve between the LS6 cover and the evacuation route

On the other hand, if you note the pressure isn't leaking anywhere else, then the evacuation route is simply too small. There is no limitation to the size of the evac. i.e. I guarantee you that even if the engine had terrible blow-by conditions, you could make a hole big enough to relief the pressure (and probably a lot of oil) but I digress

If you would like me to more thoroughly detail how I would run the hoses please feel free to ask, and there are good pics online elsewhere on the forum already

#20

My name is Jordan and I am a PCV freak. I spend more time on my PCV system design than anything else, because to me it is more important and essential to long-lived street cars than anything else. And before you ask, yes filtration (air filter, oil filters) are part of the pcv system.

If you wanted to make absolutely sure the system was plumbing correctly, you could do a boost leak test to simulate compression-blowby into the crankcase (by slightly pressurizing the crankcase) and I Would do this simultaneously with the top-end pressure test (for a complete survey/picture of the pcv system). In other words, when the rings pass 'pressurized exhaust gas' into the crankcase, this generates the +0.01PSI you see on the gauge (since you are not FI). Where that pressure goes, how the engine handles it, is up to you. For example right now you say it is passing out the rear main. Well, that is because you are containing it, or rather, trying to contain it, within the crankcase. Whatever route you have that is setup to relief the pressure- isn't working- or the pressure would stay near 0.01psi and no higher. Unless it was an obscene amount of air molecules.

more details;

Pressurize the plumbing with compression air so that you have simulated boost in the intake manifold. I have a valve on my boost leak tester device that allows me to set a constant pressure-flow, usually I start around 5psi. This would be fine for your test.

Now that the intake manifold has 5psi in it, you should have 0psi in the crankcase still. If you see anything in there you have a bad checkvalve or incorrect route somewhere already, assuming you blocked off that one line that leads from the throttle body to the crankcase (you can see it in the picture) which was the original blow-by relief from the factory. This is the first essential step to testing a pcv system because it ensures pcv valve function correctly and eliminates any possible vacuum leaks/hoses tied to the intake air system.

Once you verify that pressure in the intake != pressure in the crankcase in the above steps, I would then turn the engine over manually with a socket, go through all 8 cylinders (360* times 2) to ensure that as each intake valve opens, that 5psi is presented to the cylinder, which is sealed up nicely, so you still see 0psi in the crankcase. If the pressure rises while you spin the motor slowly it means you have a missing part of a piston ring or piston.

Now, you are ready for the final test. Remember that hose from the throttle body that leads to the valve cover? Allow approx 1-2psi into the crankcase through that hose into the crankcase. No more than 2psi max. Does the crankcase hold the pressure? If it does, you may find the rear main start to leak when this pressure is applied. If it does NOT hold pressure you have another hole somewhere that crankcase pressure is leaving from- if you find that, it is likely a high chance to be your problem. My theory is that your rear crankcase evacuation port (LS6 cover) Is somehow interfering with the front cover evacuation, perhaps plumbed wrong through the checkvalves. I hope you know the LS6 cover is not a PCV valve, it does not have a check valve. It needs a check valve on it, just like the valve cover does on the intake manifold suction side. So if running the PCV valve in the valve cover, you would also need a PCV valve between the LS6 cover and the evacuation route

On the other hand, if you note the pressure isn't leaking anywhere else, then the evacuation route is simply too small. There is no limitation to the size of the evac. i.e. I guarantee you that even if the engine had terrible blow-by conditions, you could make a hole big enough to relief the pressure (and probably a lot of oil) but I digress

If you would like me to more thoroughly detail how I would run the hoses please feel free to ask, and there are good pics online elsewhere on the forum already

If you wanted to make absolutely sure the system was plumbing correctly, you could do a boost leak test to simulate compression-blowby into the crankcase (by slightly pressurizing the crankcase) and I Would do this simultaneously with the top-end pressure test (for a complete survey/picture of the pcv system). In other words, when the rings pass 'pressurized exhaust gas' into the crankcase, this generates the +0.01PSI you see on the gauge (since you are not FI). Where that pressure goes, how the engine handles it, is up to you. For example right now you say it is passing out the rear main. Well, that is because you are containing it, or rather, trying to contain it, within the crankcase. Whatever route you have that is setup to relief the pressure- isn't working- or the pressure would stay near 0.01psi and no higher. Unless it was an obscene amount of air molecules.

more details;

Pressurize the plumbing with compression air so that you have simulated boost in the intake manifold. I have a valve on my boost leak tester device that allows me to set a constant pressure-flow, usually I start around 5psi. This would be fine for your test.

Now that the intake manifold has 5psi in it, you should have 0psi in the crankcase still. If you see anything in there you have a bad checkvalve or incorrect route somewhere already, assuming you blocked off that one line that leads from the throttle body to the crankcase (you can see it in the picture) which was the original blow-by relief from the factory. This is the first essential step to testing a pcv system because it ensures pcv valve function correctly and eliminates any possible vacuum leaks/hoses tied to the intake air system.

Once you verify that pressure in the intake != pressure in the crankcase in the above steps, I would then turn the engine over manually with a socket, go through all 8 cylinders (360* times 2) to ensure that as each intake valve opens, that 5psi is presented to the cylinder, which is sealed up nicely, so you still see 0psi in the crankcase. If the pressure rises while you spin the motor slowly it means you have a missing part of a piston ring or piston.

Now, you are ready for the final test. Remember that hose from the throttle body that leads to the valve cover? Allow approx 1-2psi into the crankcase through that hose into the crankcase. No more than 2psi max. Does the crankcase hold the pressure? If it does, you may find the rear main start to leak when this pressure is applied. If it does NOT hold pressure you have another hole somewhere that crankcase pressure is leaving from- if you find that, it is likely a high chance to be your problem. My theory is that your rear crankcase evacuation port (LS6 cover) Is somehow interfering with the front cover evacuation, perhaps plumbed wrong through the checkvalves. I hope you know the LS6 cover is not a PCV valve, it does not have a check valve. It needs a check valve on it, just like the valve cover does on the intake manifold suction side. So if running the PCV valve in the valve cover, you would also need a PCV valve between the LS6 cover and the evacuation route

On the other hand, if you note the pressure isn't leaking anywhere else, then the evacuation route is simply too small. There is no limitation to the size of the evac. i.e. I guarantee you that even if the engine had terrible blow-by conditions, you could make a hole big enough to relief the pressure (and probably a lot of oil) but I digress

If you would like me to more thoroughly detail how I would run the hoses please feel free to ask, and there are good pics online elsewhere on the forum already