View Poll Results: Get rid of CNC track lines on the intake runners?

Yes

21

23.08%

No

70

76.92%

Voters: 91. You may not vote on this poll

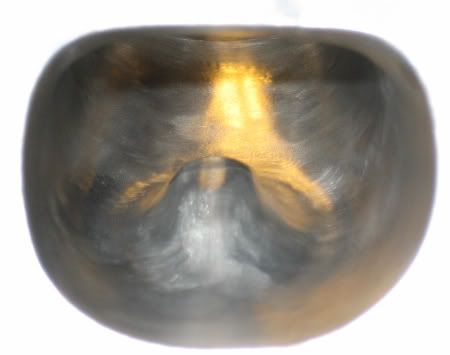

CNC track lines on intake runner

#21

TECH Junkie

iTrader: (3)

Join Date: Nov 2001

Location: TEXASS

Posts: 3,202

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Xtnct00WS6

If the design of the intake port wasn't changed, which it wasn't, it's safe to assume that I increased flow. I'll post pics as soon as I can get access to a digital camera.

There are inherent flaws from CNC machines that hand porting can take away. There seemed to be a ridge from where the CNC machine couldn't go any further from one direction that I was able to take down and make it smooth. I've seen this in many different pics from different companies. It's hard to see, but you can feel it when you run your finger over it. That itself convinved me why I should touch up the intake. I have plenty of time until I'm going to be installing these, so I decided to go the extra mile.

I'm not staying with the 224 cam for forever, so maybe one day my efforts will pay off

No disrespect here, I appreciate all the posts. Many of you have much much more experience than I do.

There are inherent flaws from CNC machines that hand porting can take away. There seemed to be a ridge from where the CNC machine couldn't go any further from one direction that I was able to take down and make it smooth. I've seen this in many different pics from different companies. It's hard to see, but you can feel it when you run your finger over it. That itself convinved me why I should touch up the intake. I have plenty of time until I'm going to be installing these, so I decided to go the extra mile.

I'm not staying with the 224 cam for forever, so maybe one day my efforts will pay off

No disrespect here, I appreciate all the posts. Many of you have much much more experience than I do.

#23

Originally Posted by LETHL_SS

Not sure if this helps but here are some pics of mine...

#24

TECH Enthusiast

iTrader: (21)

Join Date: Oct 2005

Location: New Bern, NC

Posts: 726

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Xtnct00WS6

Any pics of the intake runner? Those were handfinished I take it?

#26

TECH Enthusiast

iTrader: (21)

Join Date: Oct 2005

Location: New Bern, NC

Posts: 726

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Ryan02SS

Lethl, Those are Rapid heads right? I saw a set of Mikey's heads and they do look very good and always seem to perform. Just look at the ET's they have produced.

Yes, these are Mikey's creation!

#28

Originally Posted by CTSmechanic

So if you do this are you just going to let all the grindings and grit hang out in the head or are you gunna dissassemble the heads?

#32

Originally Posted by 777

You doing this to try and get every little bit out could be reverse and you taking a little bit out. I wouldn't mess with what's proven. JMO They didn't just throw these up and port them. There was research done.

#33

TECH Resident

iTrader: (2)

So why did you run a poll if you went ahead and did it anyways? More airflow dosent always mean more power..Our heads for our race motors are upwards of 15 grand and they dont seem to worry about the cutting tool marks to much... But there your heads and they do look clean..

#34

Originally Posted by CTSmechanic

So why did you run a poll if you went ahead and did it anyways? More airflow dosent always mean more power..Our heads for our race motors are upwards of 15 grand and they dont seem to worry about the cutting tool marks to much... But there your heads and they do look clean..

Was it worth my time? Yes, because I enjoy that sorta stuff and they're better than they were before. Would it be worth someone elses time? Probably not.

I've been told that handfinishing will result anywhere from 1 to 2 percent gain in airflow. Doesn't sound like much but with my heads that'll range from 3-6 cfm. I'll take that! I also had a lot of time from when I'd be able to put the heads on. The blending of the valve guide could have used some work too. That was reason enough for me.

Besides, they look better

#35

On The Tree

Join Date: Sep 2005

Location: Suburbs of Detroit

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

You should always leave the lines, rougher ports atomize fuel better, smoother ports will allow fuel to puddle and seperate from the air. We finish our heads in the runners to a very rough finish. The exhaust and chamber wont hurt to finish with about a 80 grit hard roll. We have done alot of testing with this exact question in mind, and when you wet flow the heads, the rougher port works much better, moves more fuel, doesnt have puddling, or seperation, when we dyno the motor it makes more power, and the car goes faster..

Just some free tech information!!!

John

Dart

Just some free tech information!!!

John

Dart

#36

Originally Posted by Dart331Stroker

You should always leave the lines, rougher ports atomize fuel better, smoother ports will allow fuel to puddle and seperate from the air. We finish our heads in the runners to a very rough finish. The exhaust and chamber wont hurt to finish with about a 80 grit hard roll. We have done alot of testing with this exact question in mind, and when you wet flow the heads, the rougher port works much better, moves more fuel, doesnt have puddling, or seperation, when we dyno the motor it makes more power, and the car goes faster..

Just some free tech information!!!

John

Dart

Just some free tech information!!!

John

Dart

Last edited by Xtnct00WS6; 04-17-2006 at 07:08 PM.

#37

TECH Senior Member

iTrader: (4)

Originally Posted by Xtnct00WS6

Wow! What kind of test scenario was it? Was that with an LSX type engine? I was under the impression that with fuel injected engines that fuel atomization wasn't an issue.

#38

Originally Posted by GuitsBoy

To the best of my knowledge, you are correct. The fuel is squirted right onto the back of the hot intake valve which boils off the fuel into vapor. If you had a carbed setup, then yes, the roughness would help mix the fuel.

In a real life scenario there would be no use to the ridges from the cnc machine because the fuel had little to no contact to the part of the head that originally had cnc marks. It's not like the fuel is flowing all through the head like it would be in wet flow test. The area near the base of the valve seat hardly had any cnc marks to begin with and that is about the only spot where fuel will have contact to the intake port.

I'd love to see some back to back comparisons on this.

Last edited by Xtnct00WS6; 04-17-2006 at 09:29 PM.

#39

On The Tree

Join Date: Sep 2005

Location: Suburbs of Detroit

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

Fuel doesnt flow through the head? How do you figure, does it dissapear after it comes out of the injector or carb?

FUEL INJECTION: What is the first word there, FUEL, yes its injected further downstream from from the throttle body, but it isnt like a down nozzle on a sprint car. So fuel is still entering the port, how do you think we test on a wet bench? Just like an injected car, the fuel is added to the air stream just prior to it entering the intake port, so yes it makes a difference.

We have tested this, and we have worked with fuel injection, we know it still makes difference. But if you dont want to believe thats cool, do it your way. Just giving away more free information, that people once again want to dispute.

John

Dart

FUEL INJECTION: What is the first word there, FUEL, yes its injected further downstream from from the throttle body, but it isnt like a down nozzle on a sprint car. So fuel is still entering the port, how do you think we test on a wet bench? Just like an injected car, the fuel is added to the air stream just prior to it entering the intake port, so yes it makes a difference.

We have tested this, and we have worked with fuel injection, we know it still makes difference. But if you dont want to believe thats cool, do it your way. Just giving away more free information, that people once again want to dispute.

John

Dart

#40

Wouldn't you agree though that the majority of the fuel doesn't touch the port wall? Our injectors are pointed directly at the top of the intake valve. I agree that a rough surface could be benificial to the parts where the fuel hits the port, but that part (below the valve seat) is pretty smooth in the first place. I did a little bit of research and come to find out that a fuel injector is "designed" to atomize the fuel. http://auto.howstuffworks.com/fuel-injection3.htm "The injectors are mounted in the intake manifold so that they spray fuel directly at the intake valves." As long as the fuel injector is doing it's job, then the majority of the intake port could have the cnc marks taken out with no adverse effects...right?

By the way I appreciate all the advice and the "free information"

Could you elaborate on the test scenario though John? I'm just curious.

By the way I appreciate all the advice and the "free information"

Could you elaborate on the test scenario though John? I'm just curious.