NEED HELP from a reputable GM authority, technical data on LS7 block

#1

I had a LS7 block sent in for machine work, and I got boned big time. I requested that a pair of sleeves be added to the rearmost cylinders (as they were slightly damaged, and I wanted .005 over. The shop owner decided, without asking me; that to save some money, he's going to install ONE sleeve, and bore the block to 4.165 to remove the scratches from the other one that was lightly damaged. Therefore, I have one aftermarket sleeve, bored to 4.165, and SEVEN oem sleeves bored WAY past the bore limits of the LS7. I need proof/evidence/testimony that the LS7's design limits its overbore to .020. I've seen it before, but I can't find it.

Also, he billed me $300 to mill my deck surface, and as I walk in the shop and inquire about the deck's flatness, I was told that they were "slightly off (warped), but we got them flat" As I get the block to my friend's house, we notice that there is still head gasket material on the deck surface. Do the sleeves only require machining? I was pretty sure that they were supposed to be machined flush with a bi-metal cutter. Any help will be appreciated, I have a junk block that costs $3000+ new, I've got $1700 in machining it, and installing the sleeves. I was charged for 2 sleeves and their installation, miraculously only got one, and one is magically gone. Maybe he thought I wouldn't notice. Thanks for any input.

Also, he billed me $300 to mill my deck surface, and as I walk in the shop and inquire about the deck's flatness, I was told that they were "slightly off (warped), but we got them flat" As I get the block to my friend's house, we notice that there is still head gasket material on the deck surface. Do the sleeves only require machining? I was pretty sure that they were supposed to be machined flush with a bi-metal cutter. Any help will be appreciated, I have a junk block that costs $3000+ new, I've got $1700 in machining it, and installing the sleeves. I was charged for 2 sleeves and their installation, miraculously only got one, and one is magically gone. Maybe he thought I wouldn't notice. Thanks for any input.

Last edited by 67RSCamaroVette; 05-25-2011 at 12:53 AM.

#2

TECH Resident

I had a LS7 block sent in for machine work, and I got boned big time. I requested that a pair of sleeves be added to the rearmost cylinders (as they were slightly damaged, and I wanted .005 over. The shop owner decided, without asking me; that to save some money, he's going to install ONE sleeve, and bore the block to 4.165 to remove the scratches from the other one that was lightly damaged. Therefore, I have one aftermarket sleeve, bored to 4.165, and SEVEN oem sleeves bored WAY past the bore limits of the LS7. I need proof/evidence/testimony that the LS7's design limits its overbore to .020. I've seen it before, but I can't find it.

Also, he billed me $300 to mill my deck surface, and as I walk in the shop and inquire about the deck's flatness, I was told that they were "slightly off (warped), but we got them flat" As I get the block to my friend's house, we notice that there is still head gasket material on the deck surface. Do the sleeves only require machining? I was pretty sure that they were supposed to be machined flush with a bi-metal cutter. Any help will be appreciated, I have a junk block that costs $3000+ new, I've got $1700 in machining it, and installing the sleeves. I was charged for 2 sleeves and their installation, miraculously only got one, and one is magically gone. Maybe he thought I wouldn't notice. Thanks for any input.

Also, he billed me $300 to mill my deck surface, and as I walk in the shop and inquire about the deck's flatness, I was told that they were "slightly off (warped), but we got them flat" As I get the block to my friend's house, we notice that there is still head gasket material on the deck surface. Do the sleeves only require machining? I was pretty sure that they were supposed to be machined flush with a bi-metal cutter. Any help will be appreciated, I have a junk block that costs $3000+ new, I've got $1700 in machining it, and installing the sleeves. I was charged for 2 sleeves and their installation, miraculously only got one, and one is magically gone. Maybe he thought I wouldn't notice. Thanks for any input.

4.125 to 4.165 is 0.040 which is 0.020 per side which is one quarter of the sleeve thickness. How much power you intending to make?

GM from memory limits the cast in sleeves to 0.010 or 0.020 over (recommendation) but that is so that they dont get too thin when the sleeves sit off centre, which they do a lot. Sorry cant remember where I saw that, but google may help.

Last edited by rsz288; 05-25-2011 at 07:13 AM. Reason: Editing

#3

Yah you got boned good. Sorry to hear it. Check a dealer and see whether there are any LS7 spare pistons available and what oversizes they are. 0.020 over is only 0.010 per side. From memory the sleeves are 2mm thick and 0.010 per side equates to 12% of the thickness. $300 is a chunk for a deck even with a diamond cutter. Normally LS7 blocks are pretty straight across the top.

4.125 to 4.165 is 0.040 which is 0.020 per side which is one quarter of the sleeve thickness. How much power you intending to make?

GM from memory limits the cast in sleeves to 0.010 or 0.020 over (recommendation) but that is so that they dont get too thin when the sleeves sit off centre, which they do a lot. Sorry cant remember where I saw that, but google may help.

4.125 to 4.165 is 0.040 which is 0.020 per side which is one quarter of the sleeve thickness. How much power you intending to make?

GM from memory limits the cast in sleeves to 0.010 or 0.020 over (recommendation) but that is so that they dont get too thin when the sleeves sit off centre, which they do a lot. Sorry cant remember where I saw that, but google may help.

) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

#4

TECH Resident

That is a good idea, I will look up part#'s for piston size, to indicate that there isn't a piston .040 over. I don't think there are factory oversize pistons at 4.165 without going custom. Still looking for technical spreadsheet. I had the block machined while I was in Afghanistan, and I went to pick it up when I got back, and nearly had a heart attack when I saw the bill. I just wanted my block back, and the mains and bores looked good at first glance. I was even more pissed when I noticed that the ARP main studs (billed me for $280  ) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

#5

Moderator

iTrader: (20)

That is a good idea, I will look up part#'s for piston size, to indicate that there isn't a piston .040 over. I don't think there are factory oversize pistons at 4.165 without going custom. Still looking for technical spreadsheet. I had the block machined while I was in Afghanistan, and I went to pick it up when I got back, and nearly had a heart attack when I saw the bill. I just wanted my block back, and the mains and bores looked good at first glance. I was even more pissed when I noticed that the ARP main studs (billed me for $280  ) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

) that were installed, were missing the ARP side bolts.

#6

It looks that way. There are bolts installed (that I did not provide) but they are stock M8x1.25 or whatever, instead of the nice ARP hardware. I KNOW what hardware the kit comes with, and to charge me $85 over retail and leave them out, pisses me off.

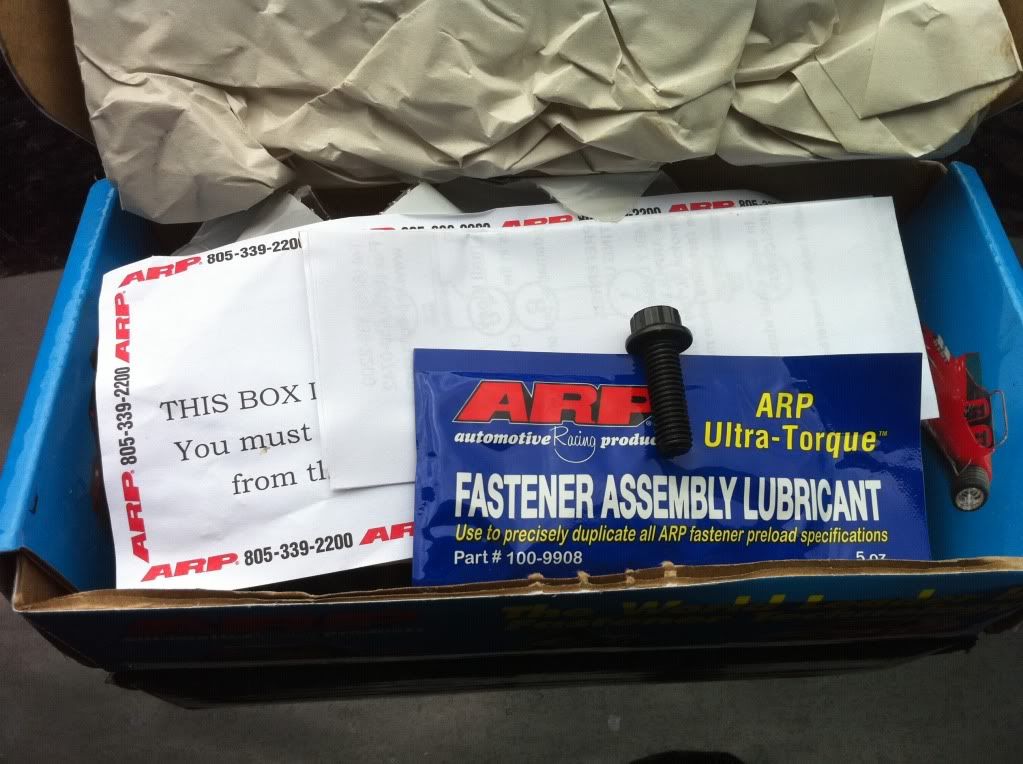

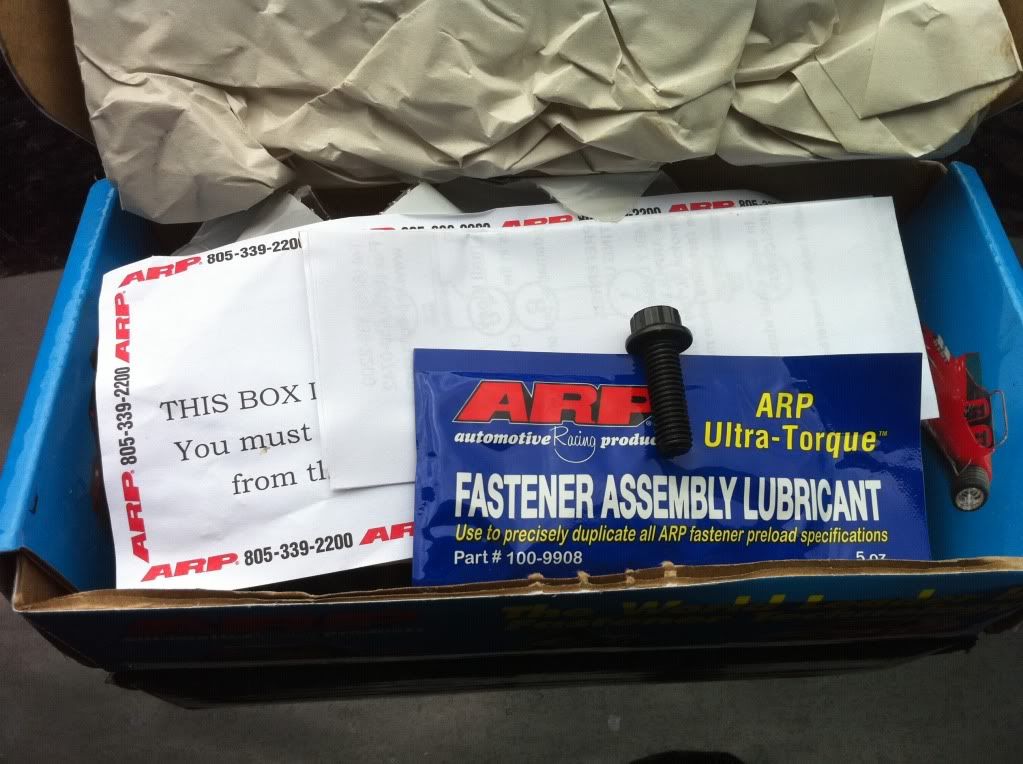

This is MY box of ARP hardware, as you can see it comes with side bolts.

This is MY box of ARP hardware, as you can see it comes with side bolts.

#7

I would honestly just approach him and give him the option of making it right. If he ends up being the two faced bitch he seems to be, get a quote from a better source to fix it all and take him to small claims court.

Trending Topics

#10

I think so. He's proven himself as a chicken-****, by taking my money for services not rendered. Anyone who does that, in my book, isn't worth negotiating with. There is NO WAY i'd take money from someone, either through their ignorance or otherwise, that I didn't deserve, ESPECIALLY for work that I know was shoddy. If it was me, I would make it right, but I don't think that will happen here. I'll sic a snake lawyer to counter his snake tactics, and may the best snake win.

#11

I'd say he owes you a block. Yes, GM sells .020 over pistons for LS7 rebuilds, but I would never use them in something over 505hp. The LS7 liner is about .077 thick at 4.125. That means at 4.165 your liner is .055 thick. That is way too thin for even stock power let alone if you modify.

#13

I'd say he owes you a block. Yes, GM sells .020 over pistons for LS7 rebuilds, but I would never use them in something over 505hp. The LS7 liner is about .077 thick at 4.125. That means at 4.165 your liner is .055 thick. That is way too thin for even stock power let alone if you modify.