Importance of bay-to-bay breathing windows

#1

I am wondering how important the bay-to-bay windows are in the LS block. I am in the middle of a 1200+hp build and want to make sure I start with the right platform. My original plan was to use an RHS block but it seems that they are on backorder for almost ever and have a huge waiting list. My second option would be to use a 5.3L gen IV block core and have it sent to either RED or ERL for sleeve work. My understanding with the 5.3L block is that is lacks the bay-to-bay breathing windows found in other LS blocks but is a little stronger because of it. A spoke with an engine builder awhile back that said they would never consider a block without the windows to be used in a shallow oil pan application like in a Corvette such as mine. My question is how much do those windows play a role in things if I run a full EVAC system and constantly be pulling vacuum on the case? I have heard that in a regular wetsump system with no EVAC that the loss of windows results in a 50hp loss.

#3

I am not saying that the oiling system will cause a hp loss like that. I reputable engine builder shop has done some back to back testing and come up with a loss from a block without the bay-to-bay windows. I will not be using a 5.3L motor for that kind of power. It will be a sleeved 427 possibly utilizing a 5.3L block core.

#4

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

Bay to Bay breathing is very important!

Wait for the RHS block. Talk to the folks at Flatlander Racing and see if they have any RHS blocks in stock.

The oiling system on LS engines is TERRIBLE! Most individuals and engine shops I have read about on this Forum do not realize and/or deal with this issue.

Oil Return: The block and cylinder head drain back design on the LS engine thows oil onto the connecting rod journals as they are spinning at 6,000 + rpms and the oil gets turned into foam, then the foam gets thrown back up into the cylinder heads, and the valley. This overloads the ability of the oil to return to the pan and keeps too much of it suspended into the heads or blown out of the valley cover tube and into the intake manifold.

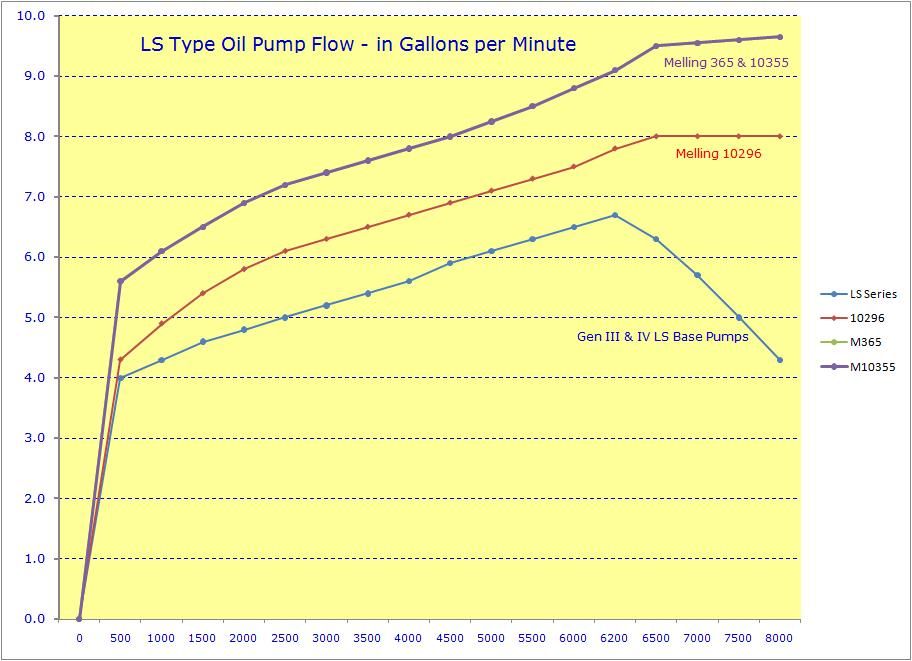

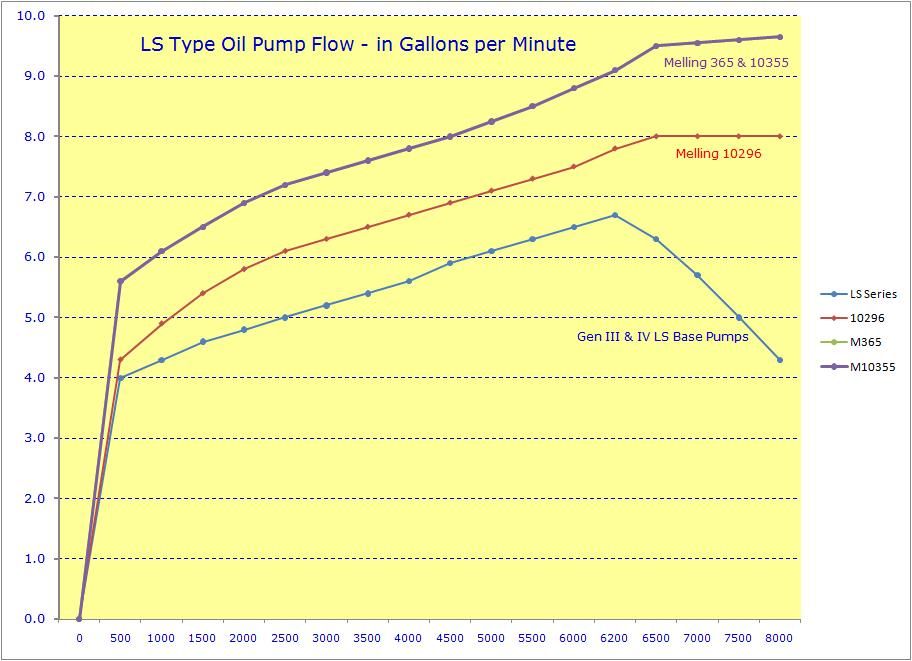

Main and Rod Oiling: The LS engine does not have main bearing and rod bearing priority oiling. The RHS block was designed for main and rod priority oiling. The standard GM Gen III and Gen IV oil pumps start to cavitate above 6,200 rpms. Melling makes three pumps that are significantly better than the GM pumps:

There isn't room in this post, but an article on correcting the design deficiencies of the LS engine's oiling system should be posted on this Forum.

Wait for the RHS block. Talk to the folks at Flatlander Racing and see if they have any RHS blocks in stock.

The oiling system on LS engines is TERRIBLE! Most individuals and engine shops I have read about on this Forum do not realize and/or deal with this issue.

Oil Return: The block and cylinder head drain back design on the LS engine thows oil onto the connecting rod journals as they are spinning at 6,000 + rpms and the oil gets turned into foam, then the foam gets thrown back up into the cylinder heads, and the valley. This overloads the ability of the oil to return to the pan and keeps too much of it suspended into the heads or blown out of the valley cover tube and into the intake manifold.

Main and Rod Oiling: The LS engine does not have main bearing and rod bearing priority oiling. The RHS block was designed for main and rod priority oiling. The standard GM Gen III and Gen IV oil pumps start to cavitate above 6,200 rpms. Melling makes three pumps that are significantly better than the GM pumps:

There isn't room in this post, but an article on correcting the design deficiencies of the LS engine's oiling system should be posted on this Forum.

Last edited by Pumba; 03-21-2012 at 01:03 PM.

#6

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

#7

TECH Fanatic

iTrader: (8)

Join Date: Nov 2009

Location: phx the cactus patch

Posts: 1,095

Likes: 0

Received 13 Likes

on

13 Posts

Wow I would imagine that would explain alot for a whole bunch of guys on here ,,,,,,,,,like why their engine died ,,,,,,,,,,,,,,and how to prevent it from happening again .

Trending Topics

#9

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

#10

I'm gonna take a stab in the dark here and just throw out a guess.... ooooh, I don't know... maybe.....Melling?

#13

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

#14

LS1Tech Sponsor

iTrader: (12)

Towards the pump - In one sentence it says the oil can't return at high rpm then it is recommended to run a pump that feeds alot more oil? Wouldn't it all stay in the head and just dry out the pan?

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

#15

On The Tree

Join Date: Dec 2004

Location: Northville, Michigan

Posts: 124

Likes: 0

Received 0 Likes

on

0 Posts

Towards the pump - In one sentence it says the oil can't return at high rpm then it is recommended to run a pump that feeds alot more oil? Wouldn't it all stay in the head and just dry out the pan?

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

What does "Towards the pump" mean?

NO, it does not say that the oil can't return at high rpm. The graph shows that the standard GM pumps cavitate the oil above 6,200 rpms, causing the output of the pump to fall.

The LS2 block is not a solution without significant modifications to its oil drain back characteristics and the drain back characteristics of the cylinder heads.

"Most individuals and engine shops I have read about on this Forum do not realize and/or deal with this issue." - Self analyze.

Last edited by Pumba; 02-14-2012 at 07:17 AM.

#16

Can't speak for a block without 'em, but I did get to watch a few dyno pulls a few years back with an LX454. Made great power, builder was hyped in anticipation of how much it would pick up with an evac system.

Zilch, zip, nada. Tried in in a few different configurations with the same results every time.

The bays allow that heavy air/oil hurricane mix to exit sideways (it's actually pulled and pushed through at the same time) rather than having to be pushed all the way around.

Zilch, zip, nada. Tried in in a few different configurations with the same results every time.

The bays allow that heavy air/oil hurricane mix to exit sideways (it's actually pulled and pushed through at the same time) rather than having to be pushed all the way around.

#17

TECH Veteran

iTrader: (11)

Towards the pump - In one sentence it says the oil can't return at high rpm then it is recommended to run a pump that feeds alot more oil? Wouldn't it all stay in the head and just dry out the pan?

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

For the OP- I would wait for the block or the other option is to do a resleeved LS2 block. I just did one for my personal 1200-1400rwhp car.

What does "Towards the pump" mean?

NO, it does not say that the oil can't return at high rpm. The graph shows that the standard GM pumps cavitate the oil above 6,200 rpms, causing the output of the pump to fall.

The LS2 block is not a solution without significant modifications to its oil drain back characteristics and the drain back characteristics of the cylinder heads.

"Most individuals and engine shops I have read about on this Forum do not realize and/or deal with this issue." - Self analyze.

NO, it does not say that the oil can't return at high rpm. The graph shows that the standard GM pumps cavitate the oil above 6,200 rpms, causing the output of the pump to fall.

The LS2 block is not a solution without significant modifications to its oil drain back characteristics and the drain back characteristics of the cylinder heads.

"Most individuals and engine shops I have read about on this Forum do not realize and/or deal with this issue." - Self analyze.

Did you ask Kurt what he does to modify the oiling characteristics of all those stock block motors he builds? I know the people he give the motors back to don't turn them to 6200 and stop.

#18

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

Increased output does not help most engines, and can hurt some. Loose aluminum engines will use 6-7gpm, the iron stuff normally will stay below 3gpm except for some drag stuff that is purposely loose. The excess oil will increase oil pressure at low speed, that could be good in a high load towing engine but increased volume without increased need is counter productive. It creates heat and turbulence with hp. If you couple high volume pump with stock pan capacity you will pump the pan dry and cause engine bearing failure.

Kurt

Kurt