Gen IV DOD towers blockoff

#1

I looked around and couldn't find much on blocking off the DOD towers on a Gen IV motor. Mine in particular is an LY6. One option was to use pipe plugs but I didn't like the idea of adding the extra stress to the casting. I decided to plug the tower holes with cup plugs but of course no one makes them in the hole size of the DOD feed towers. The closest size was 3/8" from Dorman auto but this required drilling and the motor is assembled. I will try to outline what I did here.

Last edited by Chefordiac; 01-29-2013 at 08:31 PM.

#3

I then covered the engine internals with furnace tape because a.) it sticks well and b.) it conforms well also. Then I cut the tape around the tower holes and stuffed a wad of paper towel into each hole. After this I rolled the motor over on it's back as it is on an engine stand. I WOULD NOT recommend doing this if the engine cannot be flipped upside down to keep chips from falling into the engine oil holes.

#4

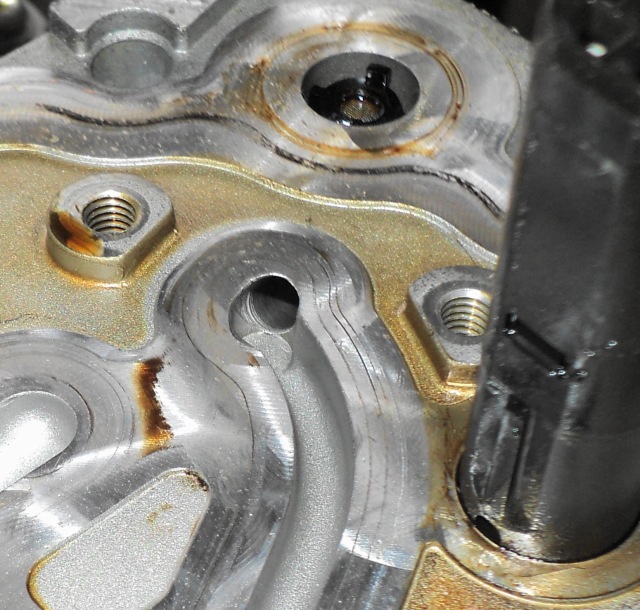

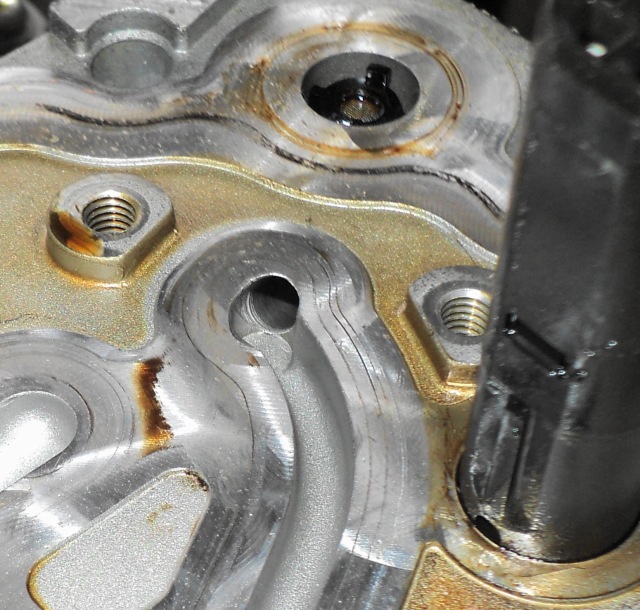

With the engine upside down I drilled out the holes to the depth set by the shaft collar. I then vacuumed out the remaining chips and cleaned the holes with a gun cleaning brush. After that I removed the paper towel plugs and vacuumed the holes again to be sure. It's tough to see here but the hole is enlarged to 3/8" dia. down about 3/8" in the hole.

#7

I probably would have been fine doing that as well. My only concern was that that the tower castings have no side support and I thought that the pipe plugs might crack them from the pressure exerted. Probably just paranoia.

Trending Topics

#9

TECH Regular

iTrader: (5)

Join Date: Jan 2008

Location: Sparta, Mo. in southwest Missouri

Posts: 452

Likes: 0

Received 2 Likes

on

2 Posts

I'm inclined to agree with you, Russ, although I see nothing wrong with the way *Chefordiac * did the job. We did this on a Gen lV aluminum block 5.3 about a year ago. I checked the factory holes with a drill bit for size and they were the size recomended for a 3/8x16 tap, so we bought 3/8 allen head plugs at Lowes and tapped the block so the slightly tapered plugs would screw down flush. We also used *Chefordiac's* method of turning the block upside down on an engine stand and using a strong shop vac both during and after the process.

#11

Staging Lane

Join Date: Dec 2006

Location: Calgary, Alberta

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

I bought a new valley cover and it comes with seals to block off those towers. Or at least I thought that is what they were for. Is plugging these with pipe plugs just extra safety?

#12

TECH Regular

iTrader: (5)

Join Date: Jan 2008

Location: Sparta, Mo. in southwest Missouri

Posts: 452

Likes: 0

Received 2 Likes

on

2 Posts

The valley cover with the o-rings works just fine. I have an LS2 with that setup and have had no problems. The reason we plugged the towers on the 5.3 was that we had the cover plate but no o-rings. They were on national back order at the time and were not available anywhere. We re-used the original cover gasket by cutting out the middle part that fits over the towers because we couldn't buy the flat cover gasket either. I see no reason you couldn't use the DOD cover also if trying to save money. OK....after thinking about this, I may have mis-spoken and I came back to EDIT.!!! I don't have one to look at but I'm afraid the passage to the oil pressure sender would be left open causing ZERO! oil pressure. So.... anybody trying to use the original DOD cover needs to check this. Sorry, my bad.

Last edited by rojs234; 02-03-2013 at 05:45 PM. Reason: spoke before thinking, sorry

#13

Staging Lane

Join Date: Dec 2006

Location: Calgary, Alberta

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

The valley cover with the o-rings works just fine. I have an LS2 with that setup and have had no problems. The reason we plugged the towers on the 5.3 was that we had the cover plate but no o-rings. They were on national back order at the time and were not available anywhere. You could also probably use the ugly DOD cover in some cases (like under the factory intake) and save the cost of the flat cover and o-rings. We re-used the original cover gasket by cutting out the middle part that fits over the towers because we couldn't buy the flat cover gasket either. I see no reason you couldn't use the DOD cover also if trying to save money.

#15

Launching!

iTrader: (1)

Join Date: Nov 2012

Location: Central Indiana

Posts: 201

Likes: 0

Received 0 Likes

on

0 Posts

The valley cover with the o-rings works just fine. I have an LS2 with that setup and have had no problems. The reason we plugged the towers on the 5.3 was that we had the cover plate but no o-rings. They were on national back order at the time and were not available anywhere. We re-used the original cover gasket by cutting out the middle part that fits over the towers because we couldn't buy the flat cover gasket either. I see no reason you couldn't use the DOD cover also if trying to save money. OK....after thinking about this, I may have mis-spoken and I came back to EDIT.!!! I don't have one to look at but I'm afraid the passage to the oil pressure sender would be left open causing ZERO! oil pressure. So.... anybody trying to use the original DOD cover needs to check this. Sorry, my bad.

BTW I tapped and plugged my towers, they are super stout and I dont see any danger of stressing them.

#16

Launching!

iTrader: (1)

Join Date: Sep 2006

Location: soFlo

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

The DOD cover can be used, simply remove all hardware underneath and then tap and plug the angle channel that supplies oil to the dod system. Good job pointing that out rojs234, in many of the threads I have seen about this, most do not mention the rear oil feed.

BTW I tapped and plugged my towers, they are super stout and I dont see any danger of stressing them.

BTW I tapped and plugged my towers, they are super stout and I dont see any danger of stressing them.

how do u get the solenoids off the cover? and where exactly do u tap the cover . can u post a pic?

#17

Launching!

iTrader: (1)

Join Date: Nov 2012

Location: Central Indiana

Posts: 201

Likes: 0

Received 0 Likes

on

0 Posts

Sure can. The first shows the "angle" passage that supplies oil from the rear oil sender to the solenoids to opperate them. This is the one that needs tapped and plugged, many over look this. This can be tapped a standard thread (only go half way), and then use a set screw (or bolt) bottomed out with a little loctite to hold in place good.

The soleniods are just held in with plastic snaps and then rotate them to remove. The rest of the hardware is attached using tork headed screws. Here are a couple showing the hardware and stripped cover. This cover when stripped is a little lighter then the ls2/3 cover.

The soleniods are just held in with plastic snaps and then rotate them to remove. The rest of the hardware is attached using tork headed screws. Here are a couple showing the hardware and stripped cover. This cover when stripped is a little lighter then the ls2/3 cover.

#18

Launching!

iTrader: (20)

Join Date: Feb 2011

Location: Commerce, Ga

Posts: 274

Likes: 0

Received 0 Likes

on

0 Posts

I found a valley cover Gm sells that blocks it off and comes as a kit with the valley cover, gasket, o rings and bolts for 35 bucks, ALOT cheaper that the ls2/3 valley cover. heres the pn#12598832

http://www.performancetrucks.net/for...delete-495725/

http://www.performancetrucks.net/for...delete-495725/