wtf!!! How do you break an oil pump?

#21

TECH Addict

iTrader: (4)

8 quart pans (it's actually a little more than that...8.5 I think, I forget, always have to look it up when I change my oil) are stock in 2010+ Camaro SS's, checked the level myself before the cars went out on the track...keep cornering at close to if not over 1G in a road race prepped car, while you've got the tach hanging on at 5500+ RPM...the cars with stock pumps never had problems, the cars with aftermarket pumps all lost oil pressure and then bearings. Higher fluid volume is not always better...sometimes it's more harm than good. In a street car that see's the occasional drag race, there's not enough time for it to be a problem...cars that are on a road course for a lot of time though, will find problems.

#22

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

The OD of the large round driven side of the pump has a chamfer on one side, it must be installed with the chamfer towards the back of the car. If installed backwards the pump gears can bind. I align the pump housing by eye with all the parts out. I also do some mild grinding in the pump housing. I have never broke a GM pump, but air in the inlet can cause the outer gear to split in endurance use.

Kurt

Kurt

Here is what I do:

First, disassemble the pump. Pull the cover off, take out the rotors, take out the plug, spring, and plunger for the bypass. Clean everything.

Next, line up the bare pump housing on the pump drive on the crank with three .002" feeler gauges or three strips of paper if you're in a pinch. Center the housing so that each of the three strips will pull right out from between the pump drive on the crank and the pump housing, but tighten the bolts before removing the strips.

Then lube the rotors with assembly lube and reinstall in the housing. Reinstall the pump cover bolts with medium strength loctite and torque to spec. Lube the bypass plunger and install, then the spring, and finally the threaded plug and torque the plug to spec.. In the cast aluminum housing, over torquing the plug could cause the plunger to bind.

I do this on every install hundreds of times now and no problems whatsoever. Usually, if you don't center the pump housing, you will see a nice scar around the circumference of the pump drive.

First, disassemble the pump. Pull the cover off, take out the rotors, take out the plug, spring, and plunger for the bypass. Clean everything.

Next, line up the bare pump housing on the pump drive on the crank with three .002" feeler gauges or three strips of paper if you're in a pinch. Center the housing so that each of the three strips will pull right out from between the pump drive on the crank and the pump housing, but tighten the bolts before removing the strips.

Then lube the rotors with assembly lube and reinstall in the housing. Reinstall the pump cover bolts with medium strength loctite and torque to spec. Lube the bypass plunger and install, then the spring, and finally the threaded plug and torque the plug to spec.. In the cast aluminum housing, over torquing the plug could cause the plunger to bind.

I do this on every install hundreds of times now and no problems whatsoever. Usually, if you don't center the pump housing, you will see a nice scar around the circumference of the pump drive.

#23

LS1Tech Sponsor

iTrader: (12)

I've never, ever broke a gm pump. All just bolted on, no issues in over 10 years and hundreds of builds. Not saying they can't break.

L99 pumps, have pulled 3 of them with stuck pressure valves.

Mellings? I hear they can be good but never used them. We use ported stock on all builds.

L99 pumps, have pulled 3 of them with stuck pressure valves.

Mellings? I hear they can be good but never used them. We use ported stock on all builds.

#24

TECH Addict

iTrader: (32)

Ok please inform me on this subject. I got a used melling high pressure that has barely any miles on it. Looks brand new. I installed it directly put together and tightened it down. Does it really need to be checked for alignment? I installed it with a double roller chain and ground front cover. It all seemed to fit fine so far.

Just don't want no problems in long run.

Just don't want no problems in long run.

#25

Moderator

iTrader: (20)

The OD of the large round driven side of the pump has a chamfer on one side, it must be installed with the chamfer towards the back of the car. If installed backwards the pump gears can bind. I align the pump housing by eye with all the parts out. I also do some mild grinding in the pump housing. I have never broke a GM pump, but air in the inlet can cause the outer gear to split in endurance use.

Kurt

Kurt

#26

Well I guess I am just the lucky one. I have built a few ls3's and never had any issue before. I have been installying the pump finger tight and turning the crank over to center the pump. This is totally an endurance situation but it is a crate class and has to remain with the stock unmodified GM pump. Guess I will be using feeler guages from now one to make sure.

#28

12 Second Club

iTrader: (20)

Well I guess I am just the lucky one. I have built a few ls3's and never had any issue before. I have been installying the pump finger tight and turning the crank over to center the pump. This is totally an endurance situation but it is a crate class and has to remain with the stock unmodified GM pump. Guess I will be using feeler guages from now one to make sure.

#33

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

The factory pump is moving about 6 gallons a minute at 240F/ 6000rpm. That means it will empty that 8 quarts in 20 seconds not accounting for drain back. A high volume pump will empty it faster depending on volume ability, that can cause problems in these engines. If you start pumping oil/air the outer pump gear may crack from the harmonics induced by the air pockets. In my opinion certain engines could use the high volume pump, but most engines it will not help and might hurt them.

Kurt

Kurt

#35

12 Second Club

iTrader: (20)

Had mine since 2008 and used it in the Ls1 and now the build in my sig, NEVER a problem (knocking on wood) lol

Some flow rates I found.

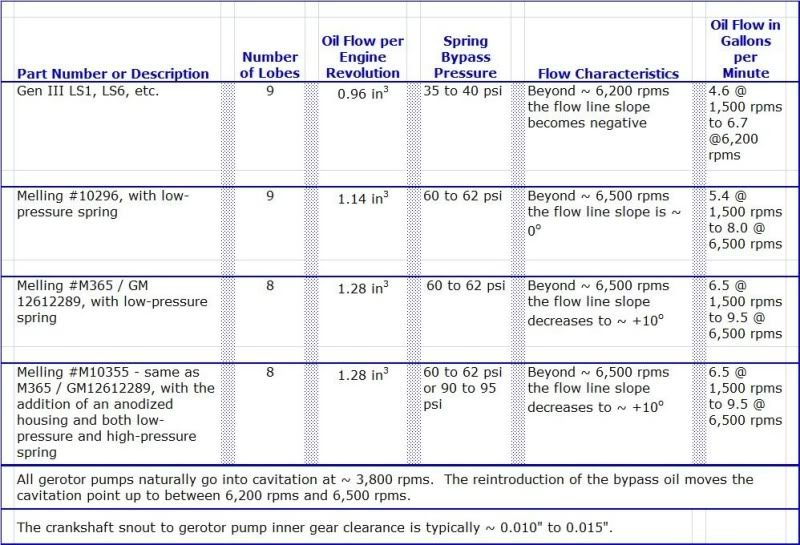

Fwi a melling 10296 will only flow ~18% percent more than a stocker