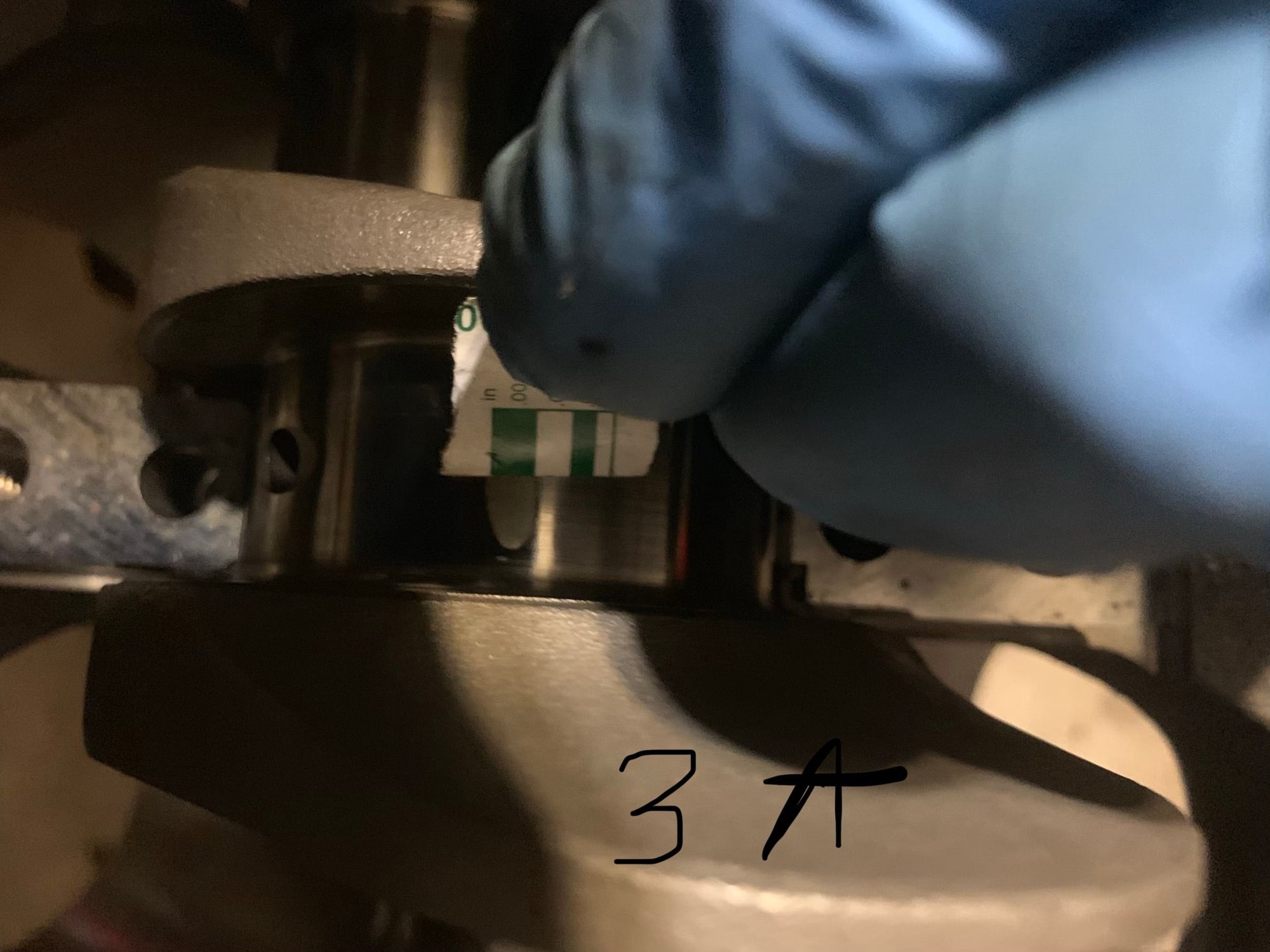

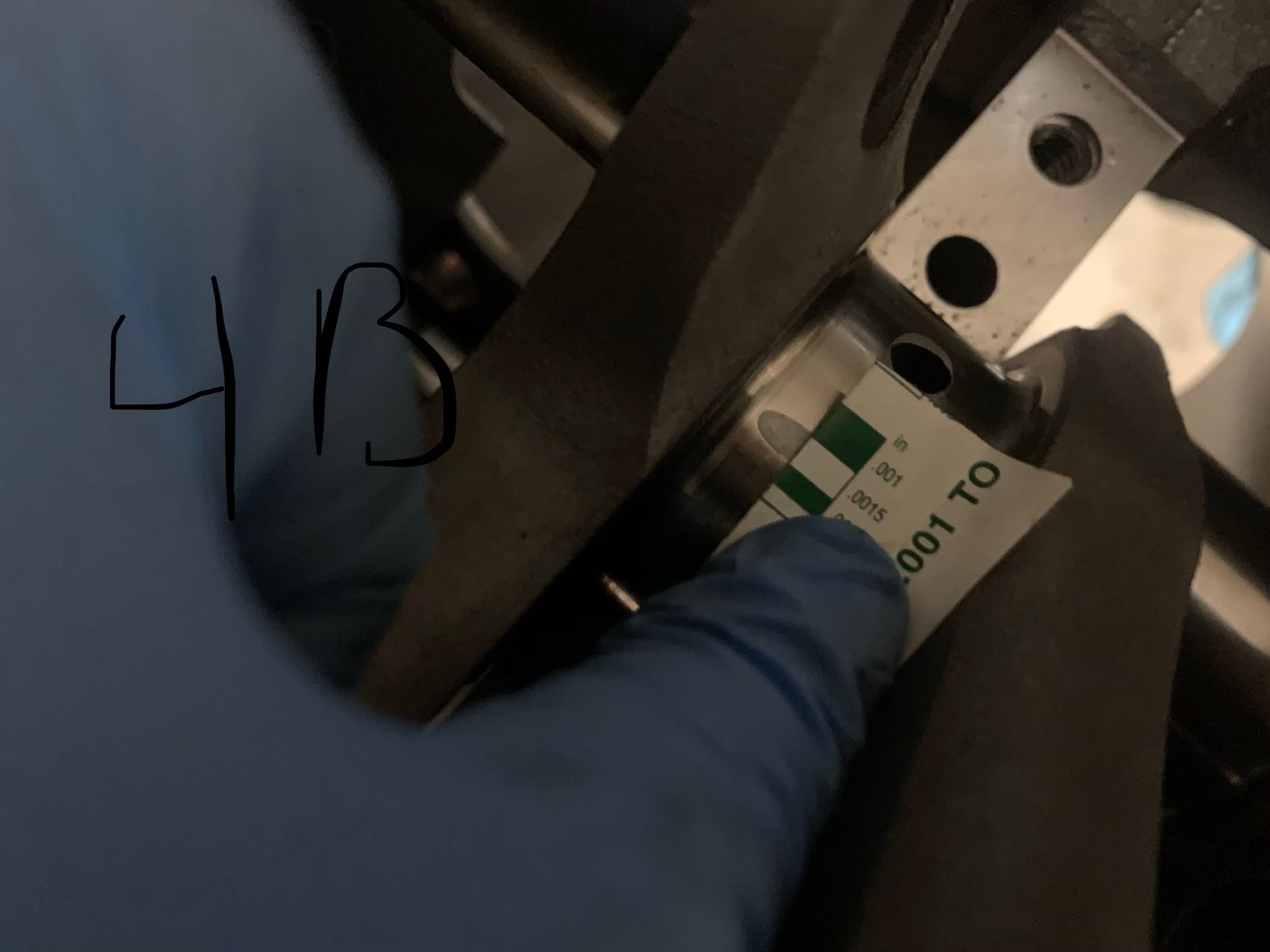

Main bearing clearance issues

#3

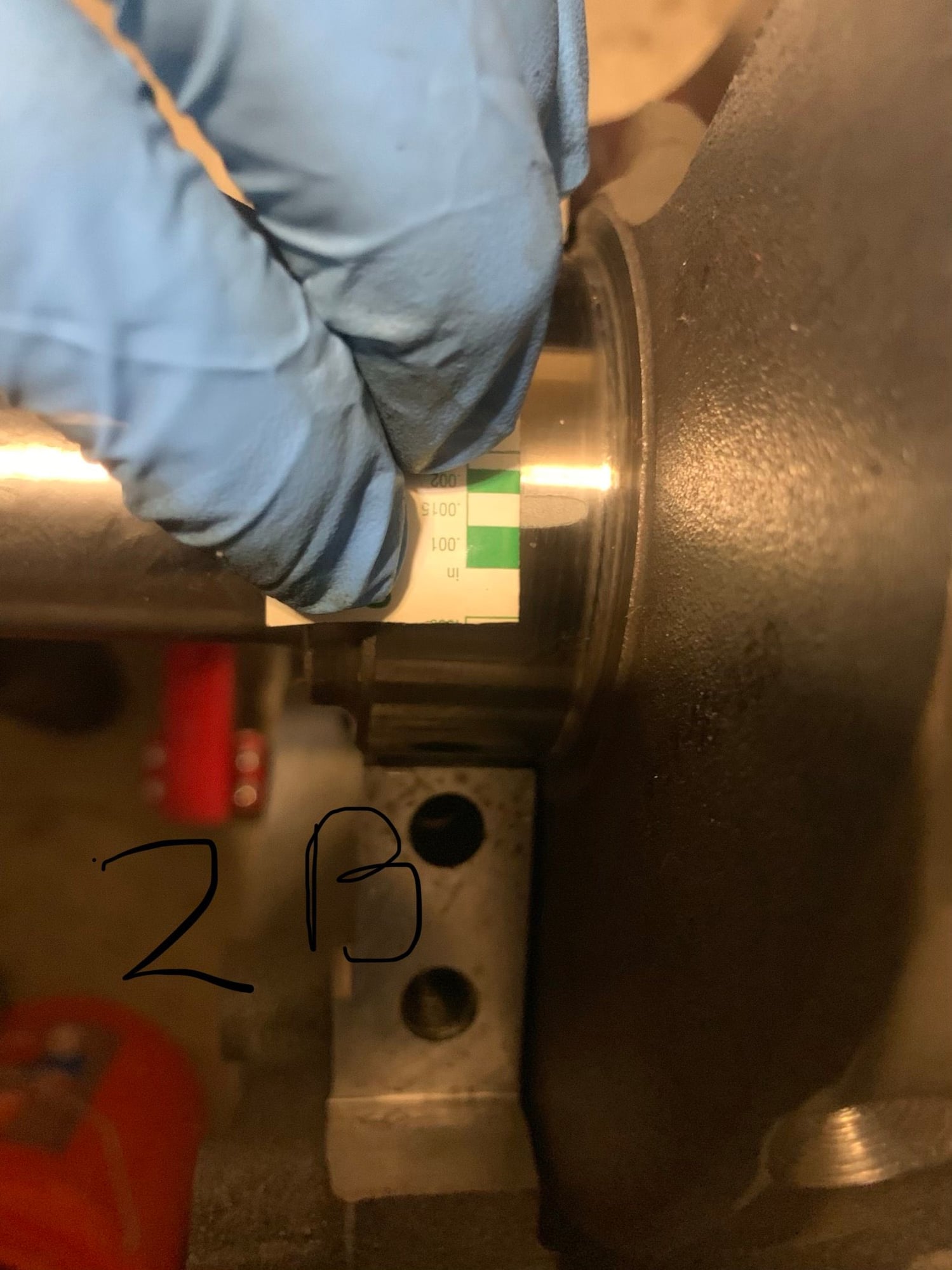

#4

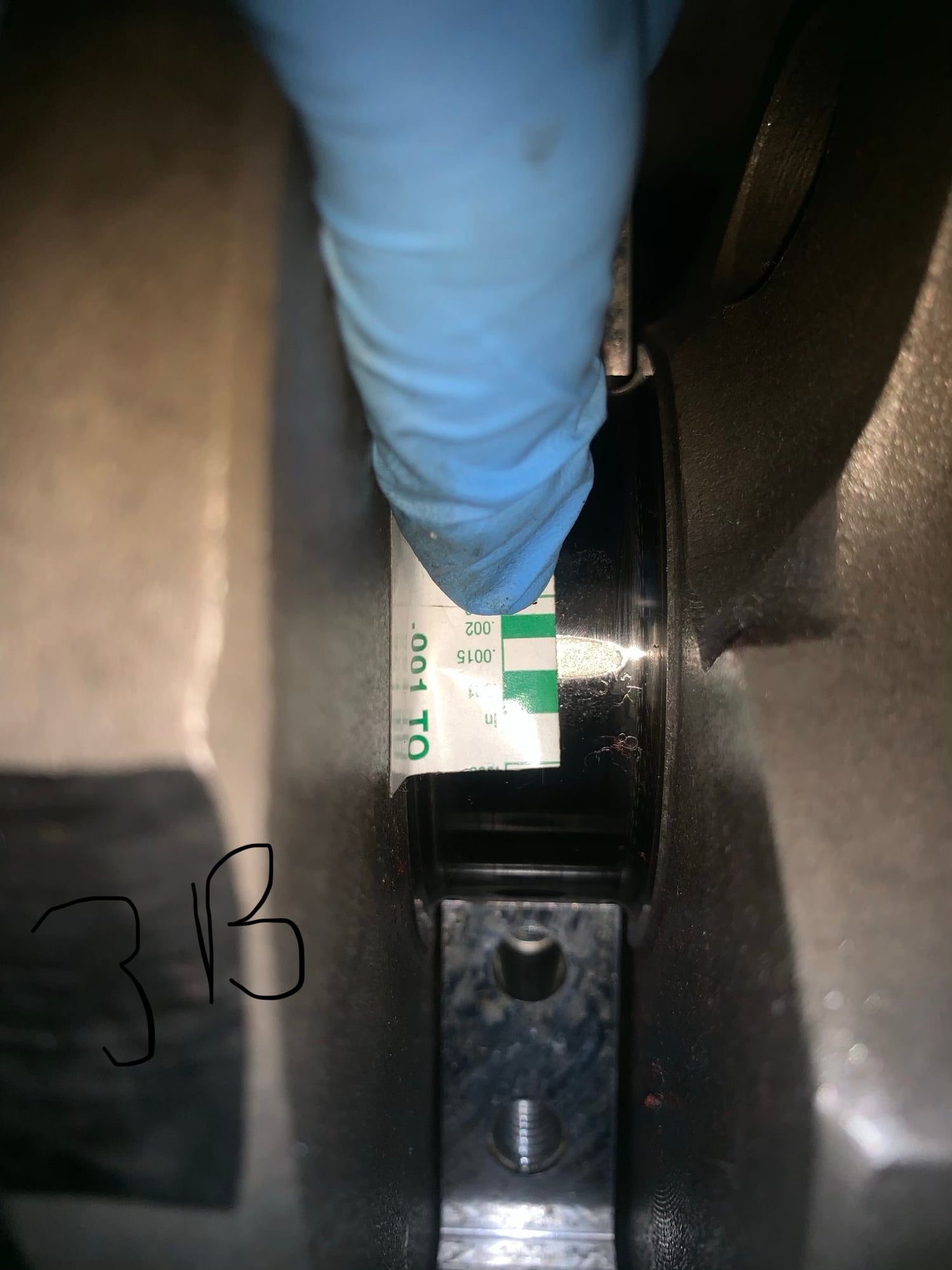

Excellant idea. If you donít have the means to accurately measure it yourself, please have it done by a pro.

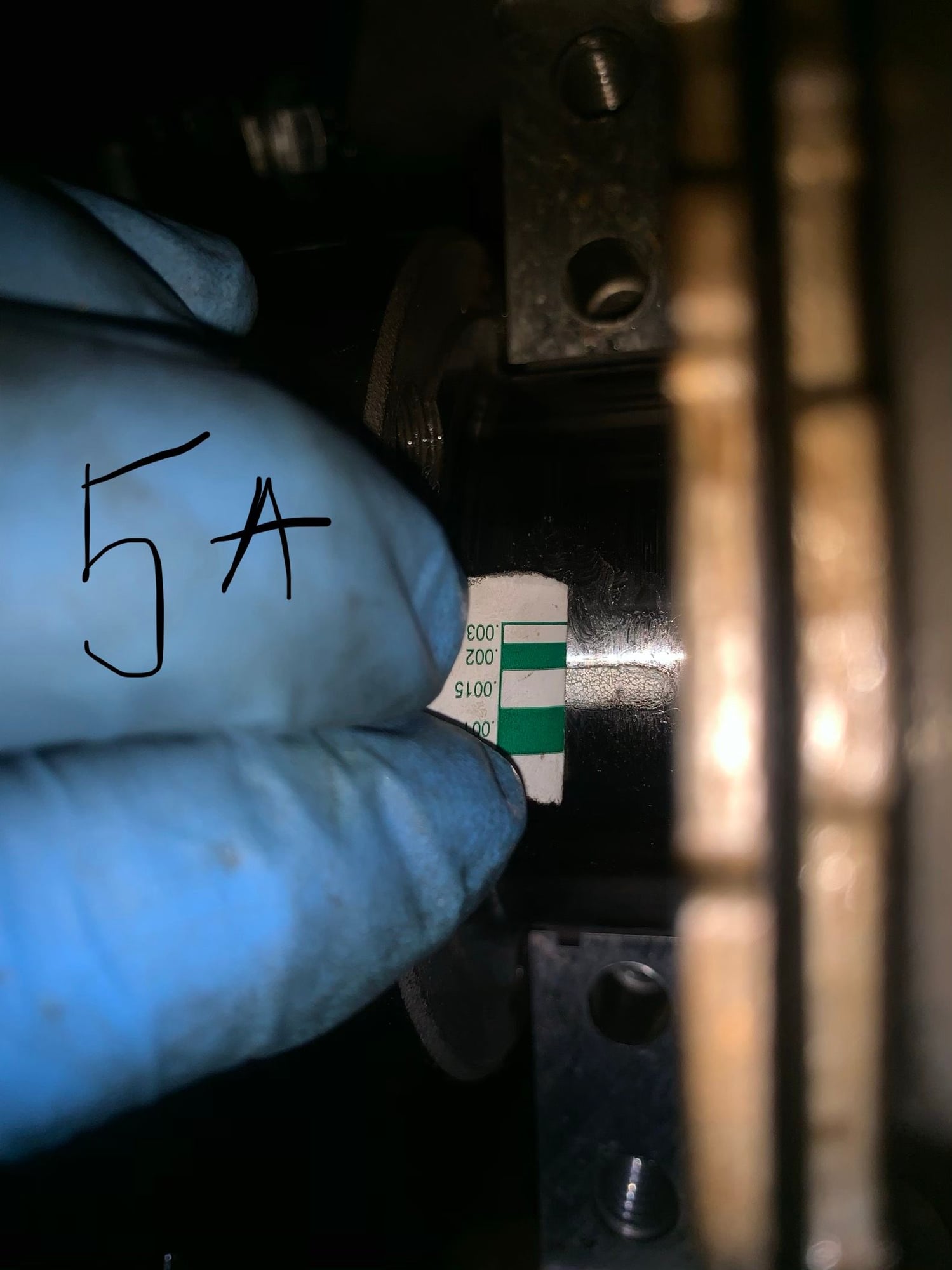

#5

I'm going to wait until it cools down and see if the temperature has something to do with it as it is supposed to be done at room temp.

Trending Topics

#9

You stated this is a new block. What Block are you using?

It appears there is some rust or debris on the registers of the caps and the block. If the caps and block look that way where the bearing sits, that will affect the clearances.

It appears there is some rust or debris on the registers of the caps and the block. If the caps and block look that way where the bearing sits, that will affect the clearances.

#10

#13

You could put 1and #5 bearing in the block if u have a dial indicator and check run out on your crank.and just because it new means nothing.im dealing new RHS block that supposed been honed to 4.165 guess what.wiseco was right on the money 4.161

#14

New should, but does not mean, correct.

Have all the bearing ring caps on the correct way? I just learned there is a little more to this than I thought.

Also, some people use a seating torque for the main caps at first, break them loose, then torque to value.

Have all the bearing ring caps on the correct way? I just learned there is a little more to this than I thought.

Also, some people use a seating torque for the main caps at first, break them loose, then torque to value.

#16

Ok changed several things and re did it twice. Got a new degree torque tool and on the first one I used the same plasti gauge brand on the second one I used a different brand. The 2nd one I rotated the crank 180 degrees ish.