Half of rockers getting oil, half dry

#21

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

The following users liked this post:

grinder11 (08-01-2020)

#23

Iíve taken off the heads and inspected everything. Oil flows through the galleys when cranking the starter, but very slowly since the RPMs are so low. Lifters slide in their bores without much resistance. Didnít see any bad scuffing on the lifters or their bores. No lifters were clogged, I could push air through them just by blowing. All lifters micíd to the same diameter, havenít checked the bore diameters with a gauge yet. So no standout issues I could find. I think the lifter feed holes are being sealed by the lifter bore and have no access for the oil from the galleys, this explains why I couldnít push oil or air through them from the top.

Iím going to cut grooves into the lifter body below the feed and run oil restricting pushrods to control flow at the top end. Hopefully that fixes it.

Im getting good pressure to the oil pressure sensor at the back of the valley cover, so I donít think an internal leak is the issue. Iím going to clean and lube everything before reinstall. Whatís wrong with Vaseline to prime the pump? (Edit: FYI these are solid lifters so no pump up)

Iím going to cut grooves into the lifter body below the feed and run oil restricting pushrods to control flow at the top end. Hopefully that fixes it.

Im getting good pressure to the oil pressure sensor at the back of the valley cover, so I donít think an internal leak is the issue. Iím going to clean and lube everything before reinstall. Whatís wrong with Vaseline to prime the pump? (Edit: FYI these are solid lifters so no pump up)

Last edited by Famine67; 08-11-2020 at 01:24 AM.

#24

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

Try style lifters or link bar? If link bar, the bar is located toward the valley, not the cylinders, yes?

#25

TECH Addict

Iíve taken off the heads and inspected everything. Oil flows through the galleys when cranking the starter, but very slowly since the RPMs are so low. Lifters slide in their bores without much resistance. Didnít see any bad scuffing on the lifters or their bores. No lifters were clogged, I could push air through them just by blowing. All lifters micíd to the same diameter, havenít checked the bore diameters with a gauge yet. So no standout issues I could find. I think the lifter feed holes are being sealed by the lifter bore and have no access for the oil from the galleys, this explains why I couldnít push oil or air through them from the top.

Iím going to cut grooves into the lifter body below the feed and run oil restricting pushrods to control flow at the top end. Hopefully that fixes it.

Im getting good pressure to the oil pressure sensor at the back of the valley cover, so I donít think an internal leak is the issue. Iím going to clean and lube everything before reinstall. Whatís wrong with Vaseline to prime the pump? (Edit: FYI these are solid lifters so no pump up)

Iím going to cut grooves into the lifter body below the feed and run oil restricting pushrods to control flow at the top end. Hopefully that fixes it.

Im getting good pressure to the oil pressure sensor at the back of the valley cover, so I donít think an internal leak is the issue. Iím going to clean and lube everything before reinstall. Whatís wrong with Vaseline to prime the pump? (Edit: FYI these are solid lifters so no pump up)

If you aren't planning on starting it, you probably don't have to use another head gasket just to get the head in place to use the valvetrain.

The following users liked this post:

00pooterSS (08-14-2020)

#26

Has the OP ever check to see if the cam brgs were installed correctly/ oil hole wise ? What ever was found out? I find it hard to believe this hasn't happened to users before.

#27

General Update: I've cut big grooves below the oil inlet ports on each of the lifters, much deeper than the tiny grooves I've seen some people add to their lifters. I'm using Smith Bros .040" restricting pushrods to control oil flow to the top end. An engine builder I know doesn't like the combination of high volume oil pump with restricting pushrods but when I was running the car without the valve covers on there seemed to be plenty of flow covering the good rockers with restrictive pushrods.

The heads are back on with the modified lifters inside. Before all of this I was unable to get compressed air to flow through the "bad" pushrods, as if the lifter was making a seal against its bore. Now all pushrods flow compressed air and I can hear the air going into the galleys. This is encouraging so I'm going to finish putting the car back together and hope I get good oiling up top. Thanks very much for the support!

I still don't know what may have caused this. I've heard Morel manufactures their lifters on the big side, so it's possible the lifters bores were just too tight.

Morel 5452 tie bar solid lifters. They were all correctly oriented. The "X" on the bar was facing the wrong way on a couple but it didn't seem to be an issue. I've put the lifters back in correctly with all X's facing forward.

I swapped around the lifters on one side and left them the same on the other. Heads are back on with fresh LS9 gaskets.

I didn't check this but the shortblock builder is pretty reputable so hopefully this isn't the issue. I must've called a dozen LS specialists and everybody was just as confused as I was and seemed curious to find out the solution. It's my understanding that the cam bearings shouldn't affect the lifter oiling, and if they did I would expect to see matching oiling issues on each side of the engine.

The heads are back on with the modified lifters inside. Before all of this I was unable to get compressed air to flow through the "bad" pushrods, as if the lifter was making a seal against its bore. Now all pushrods flow compressed air and I can hear the air going into the galleys. This is encouraging so I'm going to finish putting the car back together and hope I get good oiling up top. Thanks very much for the support!

I still don't know what may have caused this. I've heard Morel manufactures their lifters on the big side, so it's possible the lifters bores were just too tight.

I didn't check this but the shortblock builder is pretty reputable so hopefully this isn't the issue. I must've called a dozen LS specialists and everybody was just as confused as I was and seemed curious to find out the solution. It's my understanding that the cam bearings shouldn't affect the lifter oiling, and if they did I would expect to see matching oiling issues on each side of the engine.

#28

Another update:

Got the car running today with all the new stuff. The oiling appears to be fixed! All rockers were getting a stream of oil during cranking. Getting ~35psi idling oil pressure. I'm going to take the car out for some shake downs in the next few days and then onto a dyno tune. Thanks everyone here for the good suggestions!

Not sure what exactly caused the issue, but my guess would be the lifters were too tight in their bores and were effectively making a seal around the oil port. I would guess the way the bores are drilled into the block may be the reason why there was a strange "pattern" with the dry rockers.

Got the car running today with all the new stuff. The oiling appears to be fixed! All rockers were getting a stream of oil during cranking. Getting ~35psi idling oil pressure. I'm going to take the car out for some shake downs in the next few days and then onto a dyno tune. Thanks everyone here for the good suggestions!

Not sure what exactly caused the issue, but my guess would be the lifters were too tight in their bores and were effectively making a seal around the oil port. I would guess the way the bores are drilled into the block may be the reason why there was a strange "pattern" with the dry rockers.

The following 2 users liked this post by Famine67:

00pooterSS (09-10-2020), G Atsma (09-10-2020)

#29

TECH Fanatic

iTrader: (5)

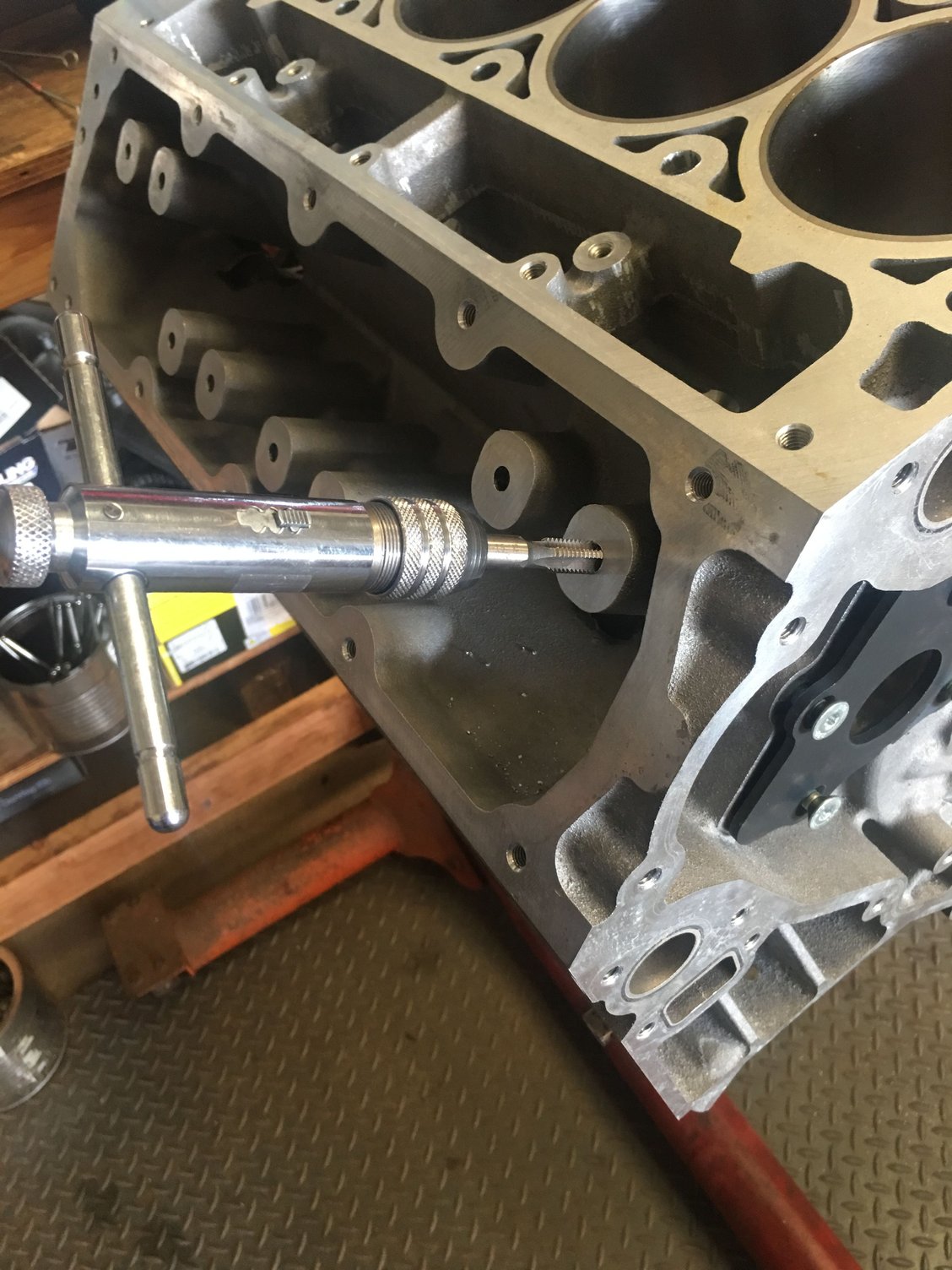

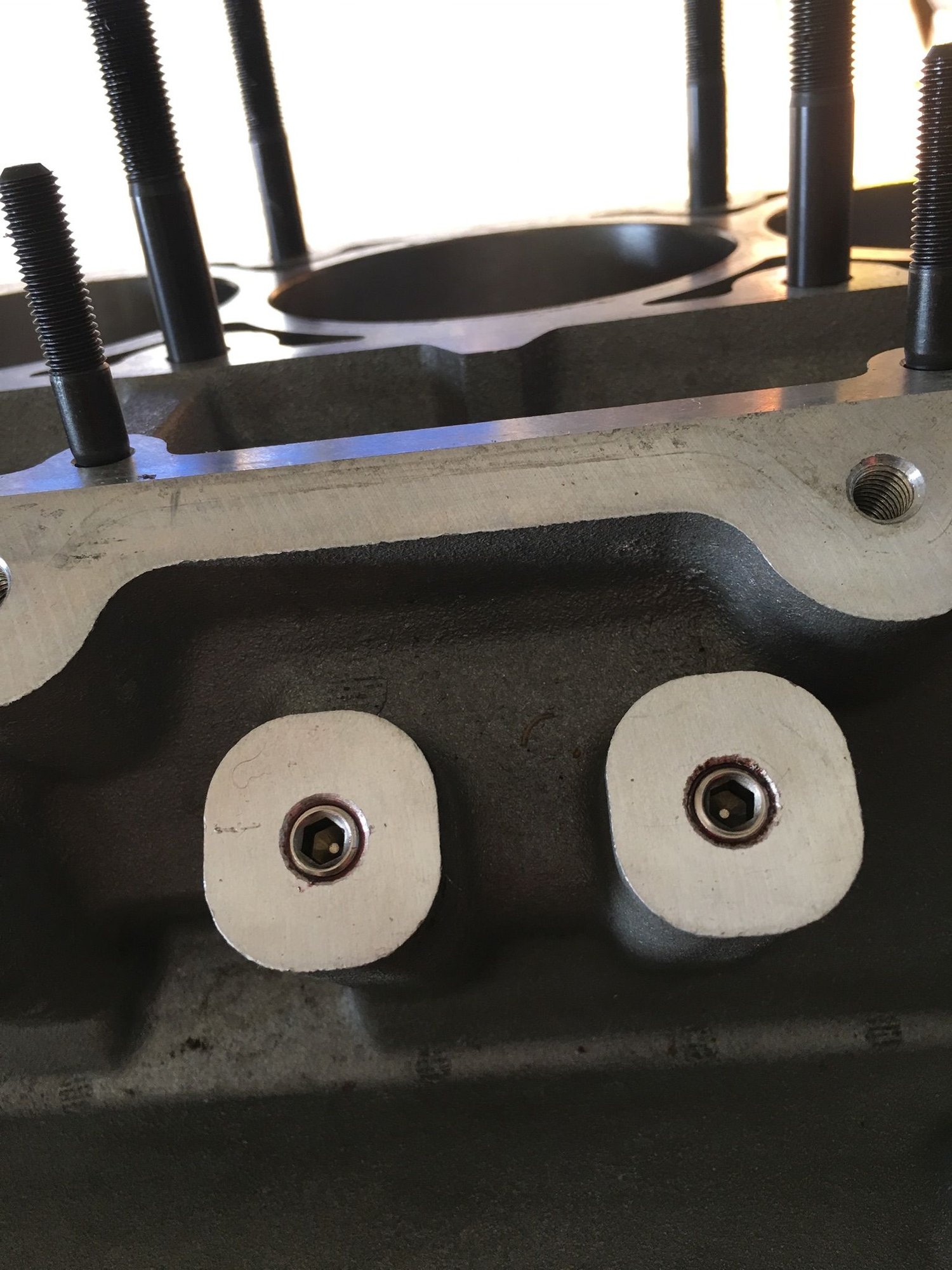

In the future, when your motor is all apart, do this. 3/8-16 tap, no need to enlarge hole they’re just the right size, add set screws, I like stainless type so I ordered a large quantity from online hardware. Plug them towers and never worry about oil loss there.

The following users liked this post:

G Atsma (09-10-2020)

#30

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

Another update:

Got the car running today with all the new stuff. The oiling appears to be fixed! All rockers were getting a stream of oil during cranking. Getting ~35psi idling oil pressure. I'm going to take the car out for some shake downs in the next few days and then onto a dyno tune. Thanks everyone here for the good suggestions!

Not sure what exactly caused the issue, but my guess would be the lifters were too tight in their bores and were effectively making a seal around the oil port. I would guess the way the bores are drilled into the block may be the reason why there was a strange "pattern" with the dry rockers.

Got the car running today with all the new stuff. The oiling appears to be fixed! All rockers were getting a stream of oil during cranking. Getting ~35psi idling oil pressure. I'm going to take the car out for some shake downs in the next few days and then onto a dyno tune. Thanks everyone here for the good suggestions!

Not sure what exactly caused the issue, but my guess would be the lifters were too tight in their bores and were effectively making a seal around the oil port. I would guess the way the bores are drilled into the block may be the reason why there was a strange "pattern" with the dry rockers.