L92 DynoJet Numbers Plus Plan B, C, D, E and F...

#683

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

Here are some pics of the sleeve machining and installation process.

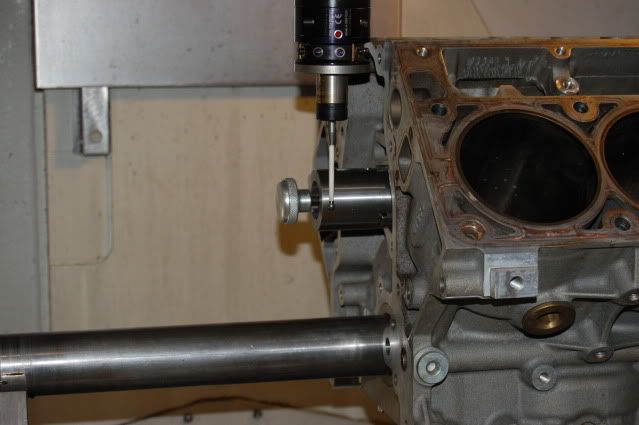

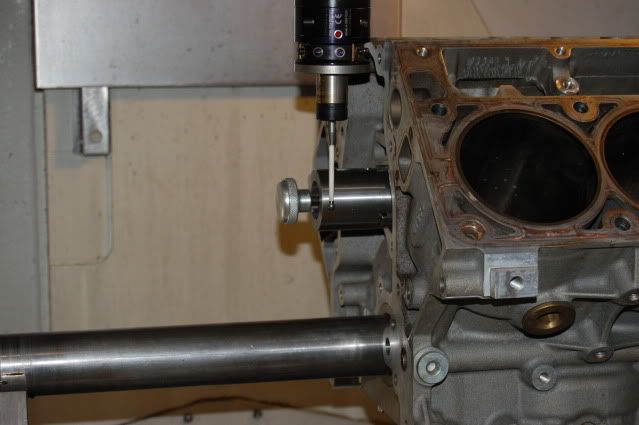

first thing is the block setup in the cnc-here the probe is finding the crankshaft center line

now we find the camshaft centerline-this way we ensure the bores and decks are exactly 45 deg from the camshaft to crankshaft centerline

now we probe the bore locations to determine the location of the bores

now we probe the decks in 6 locations on each bank-this tells us the height and straightness of the decks

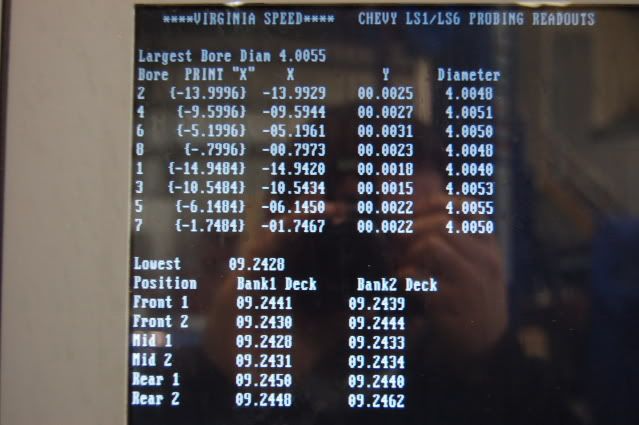

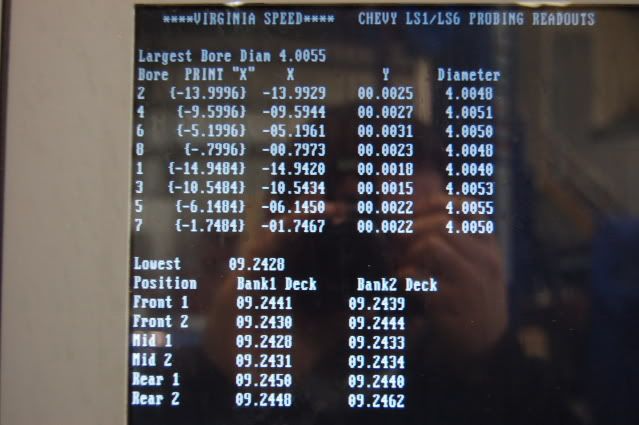

here is a report of the locations of the bores and the deck heights-the x locations in parenthesis are the blueprint locations the one beside them are actual.All y locations should be zero

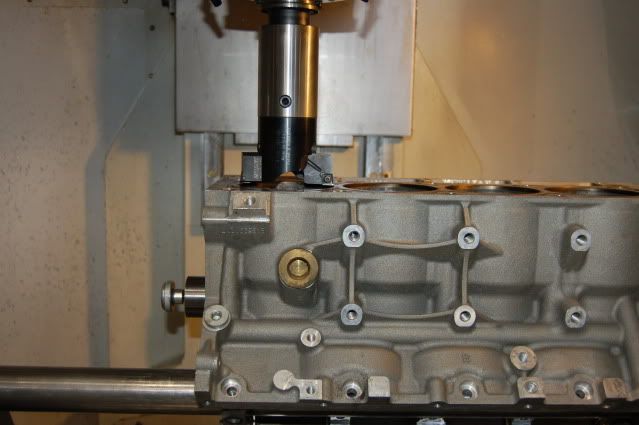

here we are rough boring-this will get us to within .020 of the actual size

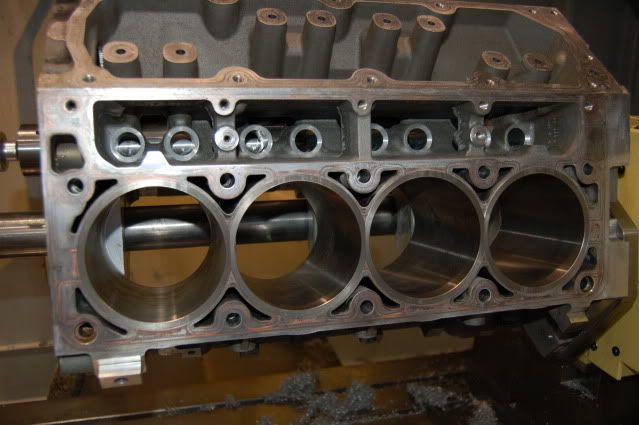

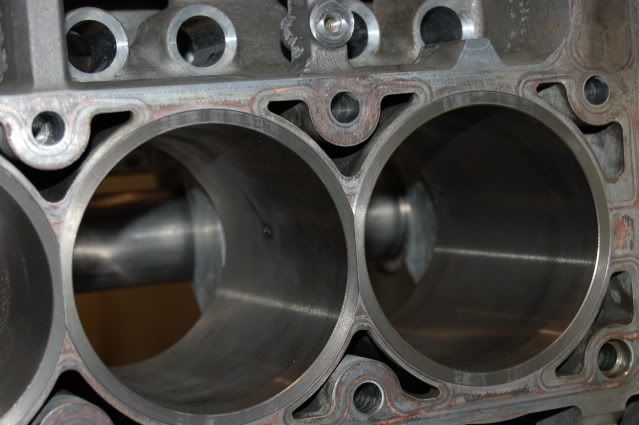

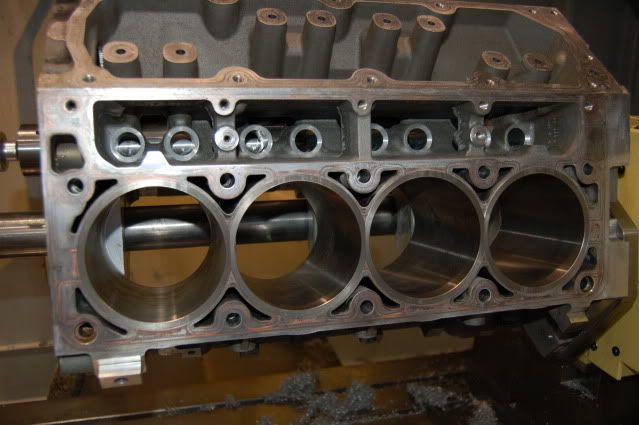

block after rough boring

couple shavings underneath

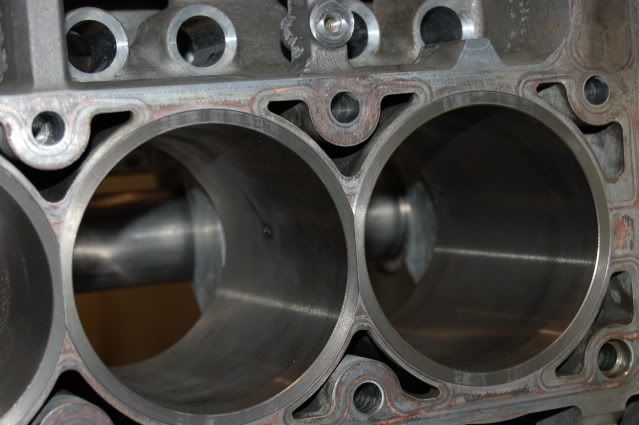

finish boring-we need to be within .0002 when finish boring-that's 2 ten thousanth's of an inch.Accuracy is really the key here-if not bored perfectly-you can crack the block when installing the sleeve or you can have a loose sleeve.There are not too many machines out there that can hold this accuracy-we are very fortunate to have one.

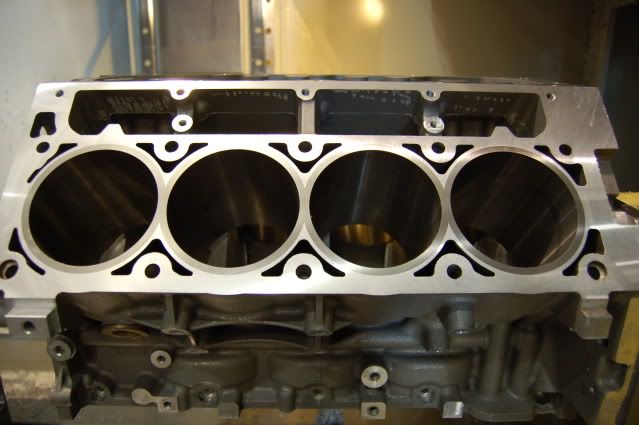

bores ready for sleeves

sleeves installed

ready for final machining

first thing is the block setup in the cnc-here the probe is finding the crankshaft center line

now we find the camshaft centerline-this way we ensure the bores and decks are exactly 45 deg from the camshaft to crankshaft centerline

now we probe the bore locations to determine the location of the bores

now we probe the decks in 6 locations on each bank-this tells us the height and straightness of the decks

here is a report of the locations of the bores and the deck heights-the x locations in parenthesis are the blueprint locations the one beside them are actual.All y locations should be zero

here we are rough boring-this will get us to within .020 of the actual size

block after rough boring

couple shavings underneath

finish boring-we need to be within .0002 when finish boring-that's 2 ten thousanth's of an inch.Accuracy is really the key here-if not bored perfectly-you can crack the block when installing the sleeve or you can have a loose sleeve.There are not too many machines out there that can hold this accuracy-we are very fortunate to have one.

bores ready for sleeves

sleeves installed

ready for final machining

Last edited by Shawn @ VA Speed; 01-14-2010 at 08:36 PM.

#691

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

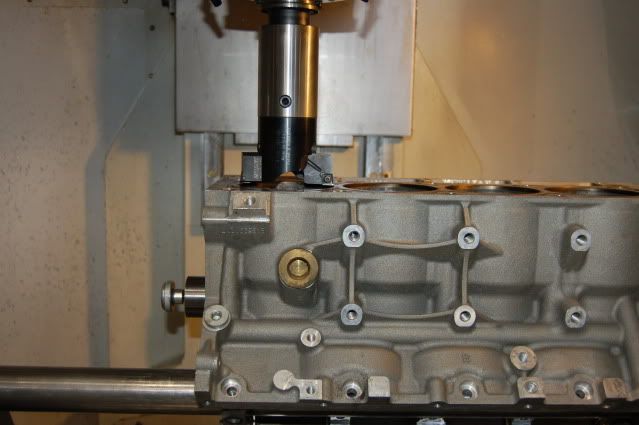

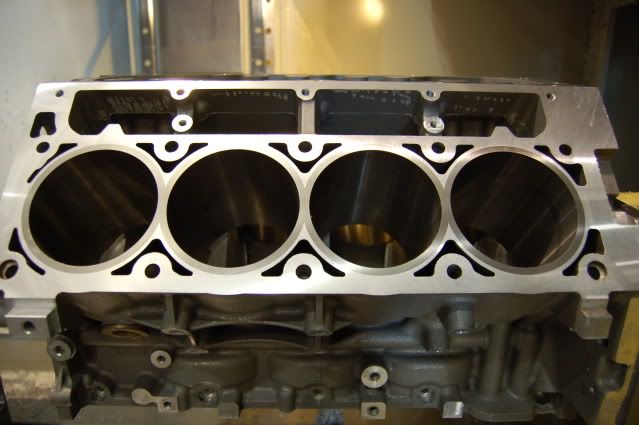

here is the block decked to the proper height-give or take .0001

hopefully next week i can get the block honed and rotating asy balanced-i got a lot of other blocks to hone as well

hopefully next week i can get the block honed and rotating asy balanced-i got a lot of other blocks to hone as well

#699

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

these can be taken to a 4.155 bore-so if you start at 4.125,you can rebuild several times-this block could last for several seasons even in a race application that gets honed .005 over every season.