New LT-1 Cylinder Head Arrives at Texas Speed!

#1

Our first 2014 6.2L LT-1 cylinder head arrived today for port development! As you can see in the pictures, it is a radical new design over any of the LS-based cylinder heads. We flowed the cylinder head on our SuperFlow 600 flow bench, and it moved 319 cfm in stock form. Port development will start ASAP, so those of you looking to purchase or those that have purchased a new 2014 Corvette will have some go-fast goodies ready soon after their car is delivered!  We will keep everyone updated as we get closer to production with them!

We will keep everyone updated as we get closer to production with them!

Here's a video of the cylinder head flowing 318 cfm on our flow bench, as well as multiple pictures. Enjoy!

http://www.youtube.com/watch?v=Vzewa...ature=youtu.be

A special thanks to Nicky at Scoggin Dickey Parts Center for helping us obtain the first LT-1 cylinder head!

We will keep everyone updated as we get closer to production with them!

We will keep everyone updated as we get closer to production with them!Here's a video of the cylinder head flowing 318 cfm on our flow bench, as well as multiple pictures. Enjoy!

http://www.youtube.com/watch?v=Vzewa...ature=youtu.be

A special thanks to Nicky at Scoggin Dickey Parts Center for helping us obtain the first LT-1 cylinder head!

Last edited by Trevor @ Texas Speed & Perf.; 07-11-2013 at 11:08 PM.

#2

I said it in other threads... you have to consider swirl and tumble motion on a DI head, not just flow.

https://ls1tech.com/forums/advanced-...on-system.html

https://ls1tech.com/forums/advanced-...on-system.html

#4

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

I said it in other threads... you have to consider swirl and tumble motion on a DI head, not just flow.

https://ls1tech.com/forums/advanced-...on-system.html

https://ls1tech.com/forums/advanced-...on-system.html

TSP, do you happen to have any other measurements yet besides flow?

#5

That's another way of describing it, yes.

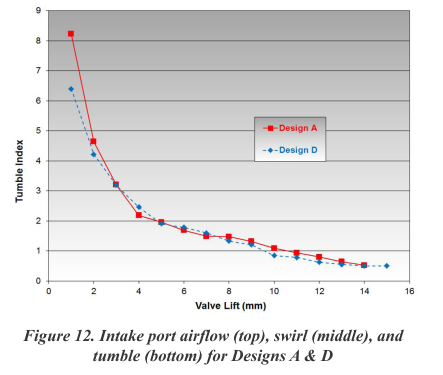

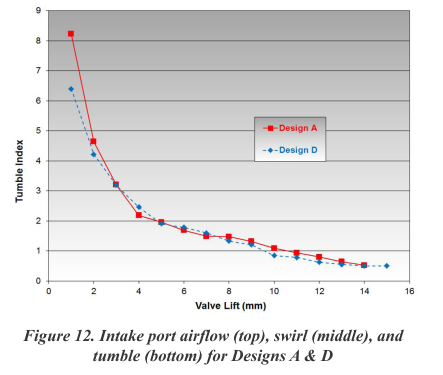

If you dig into what GM has published, you'll find out that the first thing they tried was installing direct injection onto an LS7 style head, which they called "Design A." The problem with that is it knocked and underperformed. Then they tried a couple other architectures and finally arrived at the one used in the Gen V, called "Design D."

I don't know exactly what's going to happen when vendors start offering the typical high flow heads that everyone is used to. What I can tell you is that combustion quality will degrade. Combustion phasing (50% mass burn position and location of peak pressure), knock sensitivity, and combustion stability (Coefficient of variation of indicated mean effective pressure) will get worse. I absolutely guarantee that, even though you need lab-grade equipment to quantify it.

The question is whether good fuel + the higher flowing aftermarket heads and other parts (reduced exhaust backpressure) will ultimately result in higher power anyway despite the degraded combustion. If everything works out you could still pick up worthwhile power. But if the LT1 doesn't respond well to typical aftermarket heads I won't be surprised.

If you dig into what GM has published, you'll find out that the first thing they tried was installing direct injection onto an LS7 style head, which they called "Design A." The problem with that is it knocked and underperformed. Then they tried a couple other architectures and finally arrived at the one used in the Gen V, called "Design D."

I don't know exactly what's going to happen when vendors start offering the typical high flow heads that everyone is used to. What I can tell you is that combustion quality will degrade. Combustion phasing (50% mass burn position and location of peak pressure), knock sensitivity, and combustion stability (Coefficient of variation of indicated mean effective pressure) will get worse. I absolutely guarantee that, even though you need lab-grade equipment to quantify it.

The question is whether good fuel + the higher flowing aftermarket heads and other parts (reduced exhaust backpressure) will ultimately result in higher power anyway despite the degraded combustion. If everything works out you could still pick up worthwhile power. But if the LT1 doesn't respond well to typical aftermarket heads I won't be surprised.

#6

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

That's another way of describing it, yes.

If you dig into what GM has published, you'll find out that the first thing they tried was installing direct injection onto an LS7 style head, which they called "Design A." The problem with that is it knocked and underperformed. Then they tried a couple other architectures and finally arrived at the one used in the Gen V, called "Design D."

<snip>

I don't know exactly what's going to happen when vendors start offering the typical high flow heads that everyone is used to. What I can tell you is that combustion quality will degrade. Combustion phasing (50% mass burn position and location of peak pressure), knock sensitivity, and combustion stability (Coefficient of variation of indicated mean effective pressure) will get worse. I absolutely guarantee that, even though you need lab-grade equipment to quantify it.

The question is whether good fuel + the higher flowing aftermarket heads and other parts (reduced exhaust backpressure) will ultimately result in higher power anyway despite the degraded combustion. If everything works out you could still pick up worthwhile power. But if the LT1 doesn't respond well to typical aftermarket heads I won't be surprised.

If you dig into what GM has published, you'll find out that the first thing they tried was installing direct injection onto an LS7 style head, which they called "Design A." The problem with that is it knocked and underperformed. Then they tried a couple other architectures and finally arrived at the one used in the Gen V, called "Design D."

<snip>

I don't know exactly what's going to happen when vendors start offering the typical high flow heads that everyone is used to. What I can tell you is that combustion quality will degrade. Combustion phasing (50% mass burn position and location of peak pressure), knock sensitivity, and combustion stability (Coefficient of variation of indicated mean effective pressure) will get worse. I absolutely guarantee that, even though you need lab-grade equipment to quantify it.

The question is whether good fuel + the higher flowing aftermarket heads and other parts (reduced exhaust backpressure) will ultimately result in higher power anyway despite the degraded combustion. If everything works out you could still pick up worthwhile power. But if the LT1 doesn't respond well to typical aftermarket heads I won't be surprised.

Trending Topics

#8

Yes, there are a LOT of different aspects that must be considered. Direct injection changes the game quite a bit, and we started with the flow numbers because that is what everyone is most interested in. We tell customers everyday that cylinder heads aren't just about the flow numbers. If you don't think so, try a set of ported LS3 heads and a set of PRC 247cc cathedral-port heads.  More is not always better. Flow numbers are one aspect of many that go into making cylinder heads perform well. We will be doing a LOT of testing, and we will also have an LT1 on our engine dyno for tons of testing. All of our findings on our engine dyno will be translated into RWHP numbers in our C7 Corvette. We will discover what does and does not work, so our customers don't have to worry about if it will make power. It will be like the other vehicle platforms: we help you pick the correct parts to match your intended use and application.

More is not always better. Flow numbers are one aspect of many that go into making cylinder heads perform well. We will be doing a LOT of testing, and we will also have an LT1 on our engine dyno for tons of testing. All of our findings on our engine dyno will be translated into RWHP numbers in our C7 Corvette. We will discover what does and does not work, so our customers don't have to worry about if it will make power. It will be like the other vehicle platforms: we help you pick the correct parts to match your intended use and application.

Good to hear from you Brooke! Yes, we will have various cam packages, as well as heads/cam packages, available for them. I cannot give you a date as of yet as to when they will be available since we are still so early in the R&D phase. We are working hard to get testing done early so we can get the parts in customers' hands as quickly as possible. Just like with past platforms, lots of guys will be ready to mod the car with the temporary tags still on it! Is a C7 in your near future?

Is a C7 in your near future?

Let me know if you have any other questions.

Trevor

Texas Speed & Performance

More is not always better. Flow numbers are one aspect of many that go into making cylinder heads perform well. We will be doing a LOT of testing, and we will also have an LT1 on our engine dyno for tons of testing. All of our findings on our engine dyno will be translated into RWHP numbers in our C7 Corvette. We will discover what does and does not work, so our customers don't have to worry about if it will make power. It will be like the other vehicle platforms: we help you pick the correct parts to match your intended use and application.

More is not always better. Flow numbers are one aspect of many that go into making cylinder heads perform well. We will be doing a LOT of testing, and we will also have an LT1 on our engine dyno for tons of testing. All of our findings on our engine dyno will be translated into RWHP numbers in our C7 Corvette. We will discover what does and does not work, so our customers don't have to worry about if it will make power. It will be like the other vehicle platforms: we help you pick the correct parts to match your intended use and application.Good to hear from you Brooke! Yes, we will have various cam packages, as well as heads/cam packages, available for them. I cannot give you a date as of yet as to when they will be available since we are still so early in the R&D phase. We are working hard to get testing done early so we can get the parts in customers' hands as quickly as possible. Just like with past platforms, lots of guys will be ready to mod the car with the temporary tags still on it!

Is a C7 in your near future?

Is a C7 in your near future?Let me know if you have any other questions.

Trevor

Texas Speed & Performance

#9

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

well thats certainly interesting.. as swirl increases, flow decreases or flattens out. if one wanders into the other 'cylinder head dev' thread that has before and after flow numbers: the head gains 20-30 cfm at .600 and increases out to .850 lift. im not a betting man but i would bet they knocked out most of what creates that swirl.

the question to TSP, other head dev programs, and you is... how do you increase flow and keep the 'swirl index' at its original start point?

the question to TSP, other head dev programs, and you is... how do you increase flow and keep the 'swirl index' at its original start point?

#10

12 Second Club

iTrader: (10)

Join Date: Jan 2009

Location: 5.0

Posts: 1,302

Likes: 0

Received 0 Likes

on

0 Posts

well thats certainly interesting.. as swirl increases, flow decreases or flattens out. if one wanders into the other 'cylinder head dev' thread that has before and after flow numbers: the head gains 20-30 cfm at .600 and increases out to .850 lift. im not a betting man but i would bet they knocked out most of what creates that swirl.

the question to TSP, other head dev programs, and you is... how do you increase flow and keep the 'swirl index' at its original start point?

the question to TSP, other head dev programs, and you is... how do you increase flow and keep the 'swirl index' at its original start point?

#11

Clearly when modifying for more power you're not concerned about cat lightoff and such, so there's still freedom to play around.

Last edited by arghx7; 07-15-2013 at 05:41 PM.

#12

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

Every design involves a tradeoff and optimization process. Typically to create charge motion without installing a swirl or tumble control valve (common on overhead cam engines) you have to put a ridge somewhere on the intake port, or have the air come in at an angle in some way. You might hear the term "port masking" or shrouding. Maybe back in the days of the original Gen 1 smallblock you could both add charge motion and flow, but the easy gains aren't there anymore. You can increase swirl, tumble, or flow at a certain valve lift and lose it at some other point.

Clearly when modifying for more power you're not concerned about cat lightoff and such, so there's still freedom to play around.

Clearly when modifying for more power you're not concerned about cat lightoff and such, so there's still freedom to play around.

#14

There are some very specific questions here that you're going to be very hard pressed to get very specific answers on from any of the companies currently working on development ports. What I can tell you is all of the theories and data will translate into real-world data on our flow bench, our engine dyno, and our chassis dyno. Everyone is absolutely correct that flow is not everything. We can show you multiple examples of dynoing a higher flowing head and losing power. With that said, the end result of the power that it makes will tell the story.

Let me know if anyone has any other questions.

Trevor

Texas Speed & Performance

#18

That's such a broad question. The design of the piston bowl affects gasflows and mixture formation which then affects knock, combustion efficiency, and therefore power. The compression ratio affects thermal efficiency, knock, etc. The design of the rings affects friction, which affects power.