Late Model Racecraft LT1 Cylinder Head CNC Program Underway!

#21

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

There isnt really a vane or wing anything in the factory port to remove. Now people used to think (Some still do) swirl and tumble were important on regular port injection engines too. But as time went on people started grinding them (Wings/Vanes) out. Take the ls7 heads for example. They came with a wing, people ground them out, lost airflow but made more power. Now how important is swirl and tumble? I know DI is different from PI but the question still remains.

concerning the rest: the SAE paper points out how badly the 'DI LS7' ran compared to the final design we have now. part of it being the lack of mixing airflow (swirl) at the point of injection in the cylinder. it also seemed to point out that DI engines are very sensitive to port design and can become sensitive to timing changes if the air/fuel doesnt mix well enough. more sensitive than what the community is used to.

the advantage that PFI has on DI is that the air and fuel has more time to mix inside the port (fuel spraying the back of a closed valve at lower RPM) and because of that, swirl isnt all that important.

#22

I think the main factors will be whether changing other aspects of the system, such as the amount of exhaust backpressure, valve timing events, etc can overcome possible degradation of combustion performance. Only time will tell though; modding for power has a different set of conditions and constraints than developing heads for mass production. I'm excited to see what our vendors learn.

I can also say that on PFI, high swirl and tumble flow are mostly for cold start emissions. That's why you'll see swirl or tumble control valves on overhead cam PFI engines that only operate when the engine is cold. The emissions aspect applies to DI as well. The fundamental difference as we've pointed out is that you've only got about 1/3 the time in actual seconds (~5 milliseconds on DI vs ~15 on PFI) and in crank angle degrees (~150 degrees on DI vs ~600, maybe even full 720 at max duty cycle) for the mixture to form.

I can also say that on PFI, high swirl and tumble flow are mostly for cold start emissions. That's why you'll see swirl or tumble control valves on overhead cam PFI engines that only operate when the engine is cold. The emissions aspect applies to DI as well. The fundamental difference as we've pointed out is that you've only got about 1/3 the time in actual seconds (~5 milliseconds on DI vs ~15 on PFI) and in crank angle degrees (~150 degrees on DI vs ~600, maybe even full 720 at max duty cycle) for the mixture to form.

#23

#26

TECH Fanatic

Not bad, now for the dyno results.. and tuning info.

With DI perhaps AFR can be closer to stoich? Maybe even some lean burn at part throttle.

Surely compression can also rise. 11.5 seems very low when ferrari run 12.5:1 in the 458.

Looks to be plenty of additional variables to play with.

Thanks for sharing your development info guys.

With DI perhaps AFR can be closer to stoich? Maybe even some lean burn at part throttle.

Surely compression can also rise. 11.5 seems very low when ferrari run 12.5:1 in the 458.

Looks to be plenty of additional variables to play with.

Thanks for sharing your development info guys.

#27

Closed ex-Sponsor Account

Thread Starter

Join Date: Jan 2012

Posts: 122

Likes: 0

Received 0 Likes

on

0 Posts

Not bad, now for the dyno results.. and tuning info.

With DI perhaps AFR can be closer to stoich? Maybe even some lean burn at part throttle.

Surely compression can also rise. 11.5 seems very low when ferrari run 12.5:1 in the 458.

Looks to be plenty of additional variables to play with.

Thanks for sharing your development info guys.

With DI perhaps AFR can be closer to stoich? Maybe even some lean burn at part throttle.

Surely compression can also rise. 11.5 seems very low when ferrari run 12.5:1 in the 458.

Looks to be plenty of additional variables to play with.

Thanks for sharing your development info guys.

#30

Closed ex-Sponsor Account

Thread Starter

Join Date: Jan 2012

Posts: 122

Likes: 0

Received 0 Likes

on

0 Posts

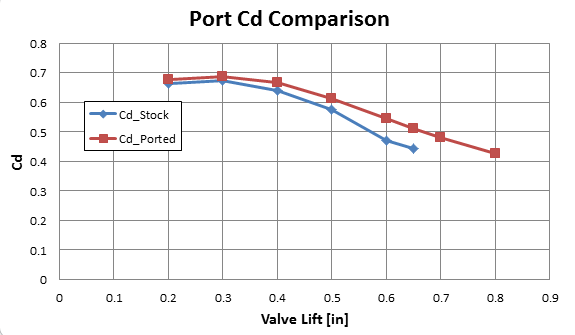

Here is a video of our Proprietary CNC porting program being run on a fresh set of 2014 Gen V LT1 cylinder head. Our porting program picks up the airflow of this cylinder head by 45cfm over stock at .650 lift on the intake and 42cfm at .650 lift over the factory exhaust port at 28" of water when flowed on a 4.060" bore.