So i Finally bought an 8.8!

#21

#22

TECH Senior Member

iTrader: (8)

I stand corrected, thanks for the info.

How do you know what it's made out of.

I was repeating what I thought was good info but had never tested it for myself.

FWIW people are using normal MIG on them and it's working fine, but its always best to have the proper alloy and to follow the best procedure for what you're welding.

How do you know what it's made out of.

I was repeating what I thought was good info but had never tested it for myself.

FWIW people are using normal MIG on them and it's working fine, but its always best to have the proper alloy and to follow the best procedure for what you're welding.

#23

I stand corrected, thanks for the info.

How do you know what it's made out of.

I was repeating what I thought was good info but had never tested it for myself.

FWIW people are using normal MIG on them and it's working fine, but its always best to have the proper alloy and to follow the best procedure for what you're welding.

How do you know what it's made out of.

I was repeating what I thought was good info but had never tested it for myself.

FWIW people are using normal MIG on them and it's working fine, but its always best to have the proper alloy and to follow the best procedure for what you're welding.

#27

well... i said id be slow to update this and i have been. But hopefully within the next 2 weeks or so there will be more progress.. i just picked up a used 10 bolt housing from 69TA and i have to say. thanks aain kevin for the housing! I cant wait to get working on this! im going to be cutting the axle tubes off of the 8.8 this week. and i might be wanting to make completely new tubes for the whole rear. i have to see how i like the thickness of the 10 bolt tubes. time will tell tho. anyway heres a pic showing the 8.8 i got and the 10 bolt housing waiting to get cut up. stay tuned for more progress

#28

12 Second Club

iTrader: (15)

Join Date: Mar 2007

Location: Cheyenne, Wy

Posts: 1,928

Likes: 0

Received 0 Likes

on

0 Posts

Is there any way to find out what 8.8 rear ends will work for our cars? I know there are ALOT out there to choose from and I am curious what models and years I should be looking for at junk yards/etc. I am interested in possibly trying this!

#31

TECH Enthusiast

iTrader: (7)

Join Date: Jun 2007

Location: St Joseph, MO

Posts: 739

Likes: 0

Received 0 Likes

on

0 Posts

Looking forward to seeing your progress.

Here is a good read on looking for what vehicles came with what...

http://www.therangerstation.com/tech_library/Axles.html

Here is a good read on looking for what vehicles came with what...

http://www.therangerstation.com/tech_library/Axles.html

#32

Ok, So being busy has its ups and downs. Ups being i get paid for working and doing side jobs. Downs are me being left with no time for anything else. and with getting that big snow storm last week its kept me home. Needless to say more about that i found alittle bit of time today. In doing so i decided to cut the tubes on the 8.8 to start to measure up for the coupler. Even tho part of me is wondering if i should completely replace the tubes all together with a single piece of steel. Ill have my decision sometime this week hopefully. I just want it to be as strong as possible. Im currently saving up for my internals so within the month i should be getting things in to put it together. again, sorry for the slow updates.

some pics

I was actually very surprised by the wall thickness of the 8.8 housing! i havent miked it out yet but its nice and heavy as you can see. The tubes on the 10 bolt feel like there made out of paper in comparison!

some pics

I was actually very surprised by the wall thickness of the 8.8 housing! i havent miked it out yet but its nice and heavy as you can see. The tubes on the 10 bolt feel like there made out of paper in comparison!

#34

Im sorry for the Extremely long delay but my lifes been really busy lately. As a result of that i havent had much time to do anything for myself lately. Luckily however i found time early this week to continue with my little project.

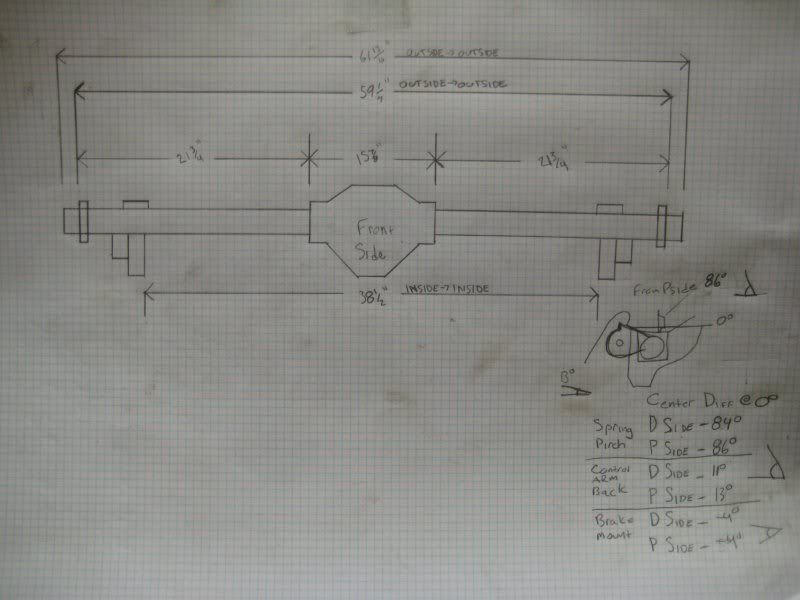

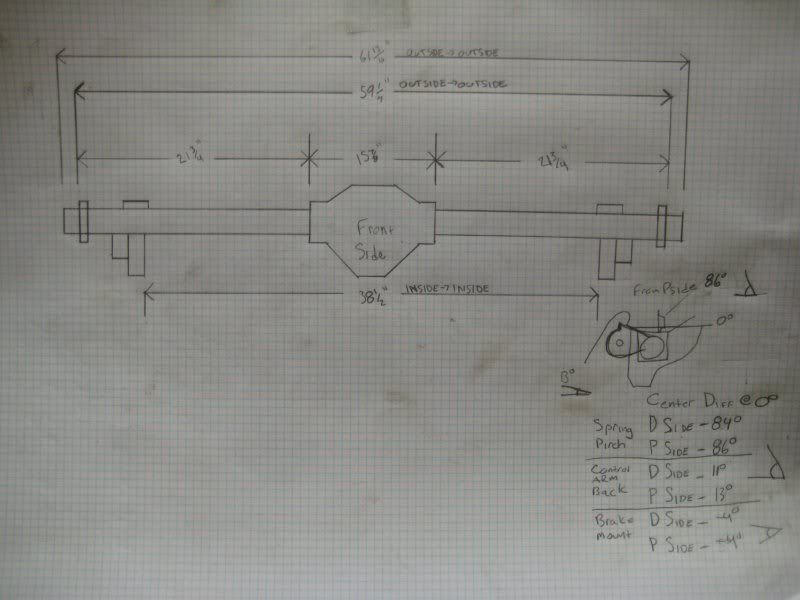

After cutting both the tubes off the 8.8 housing and off the 10 bolt housing. i found that if i just cut the outside of the 10 bolt tube down just alittle. It should be able to slide into the inside of the 8.8 tubes... That meant blueprinting my 10 bolt housing and cutting her up! and thats exactly what i did.

By the weekend i want to have the 10 bolt tubes cut down and ready to get welding inside the 8.8 tubes.. fingers crossed for no problems!

After cutting both the tubes off the 8.8 housing and off the 10 bolt housing. i found that if i just cut the outside of the 10 bolt tube down just alittle. It should be able to slide into the inside of the 8.8 tubes... That meant blueprinting my 10 bolt housing and cutting her up! and thats exactly what i did.

By the weekend i want to have the 10 bolt tubes cut down and ready to get welding inside the 8.8 tubes.. fingers crossed for no problems!

#38

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

Do the tubes need to be from a 93 and newer Fbody or will they work fine all the way back to 82? I have better access to 3rd gen rears for chopping up. If I use an older one that came with drums, will my 4th gen discs bolt up? This set-up is the best thing I have heard about for Fbodies ever. I've always said that the one thing GM goofed on was weak rears. They could have at least made something optional or easier to swap. Why in the world wasn't the 8.5" at least optional? Seems like it would have not only helped they buyer, but possible saved them some warranty money?? It couldn't have cost them that much more to go 8.5 instead of 7.5. Bet they own stock in Moser/Strange/Currie.

#39

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

Also...If I want to keep functional ABS (3 channel) what do I look for and what do I need to do to get this to work?? I saw pics of a ranger rear with a reluctor on the differential....and also read about Mustang rears with ABS reluctors on the axles. I'd assume the ranger set-up would work for 3 channel and the Mustang for 4 channel?? Know how assuming goes.

that saves 700.00 right up front and when the LSD unit goes out like most all fords do after racing them i will install a NEW locker...my swap is roughly 800.00 w/MOSER axles and rear girdle

that saves 700.00 right up front and when the LSD unit goes out like most all fords do after racing them i will install a NEW locker...my swap is roughly 800.00 w/MOSER axles and rear girdle