Ahh Missing bolts! Rocker Question!

#64

12 Second Club

iTrader: (15)

Join Date: Mar 2007

Location: Cheyenne, Wy

Posts: 1,928

Likes: 0

Received 0 Likes

on

0 Posts

Preload is the pressure on your lifter. it is a hydraulic lifter so there is a cushion inside it. Preload is where there is enough pressure to not have the lifter's cushion all the way to the top of the lifter, but it is not bottomed out. If there is not enough preload you could have valve float...if there is too much preload, you will bottom out the lifter and tear it up. You have to find that happy medium

#66

Launching!

Thread Starter

Join Date: Jan 2010

Location: Maryland

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

okay starting over again, I turn the crank until the INTAKE begins to CLOSE, i take the Exhaust rocker and and tighten the lock until while shaking the back of the rocker on the push rod until rocker is seated on the pushrod and no longer makes that "clicking noise" i then turn it 1/2 a turn and set it with the allen key, i can spin the push rod although it takes a little bit of effort, getting close?

#69

Launching!

Thread Starter

Join Date: Jan 2010

Location: Maryland

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

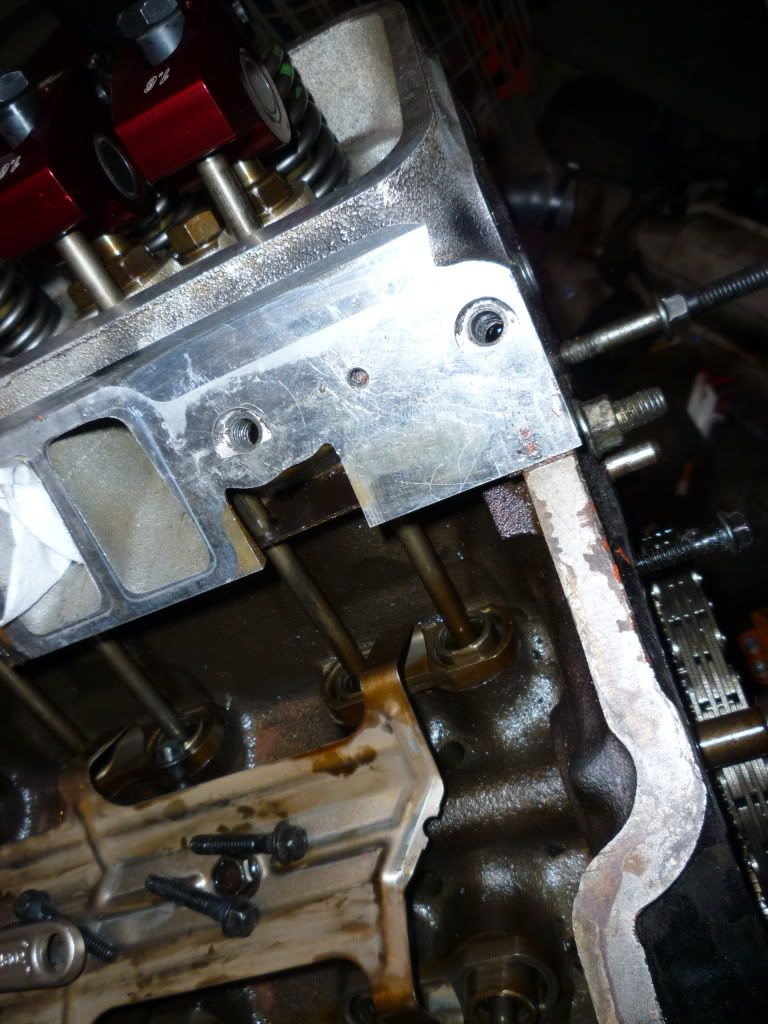

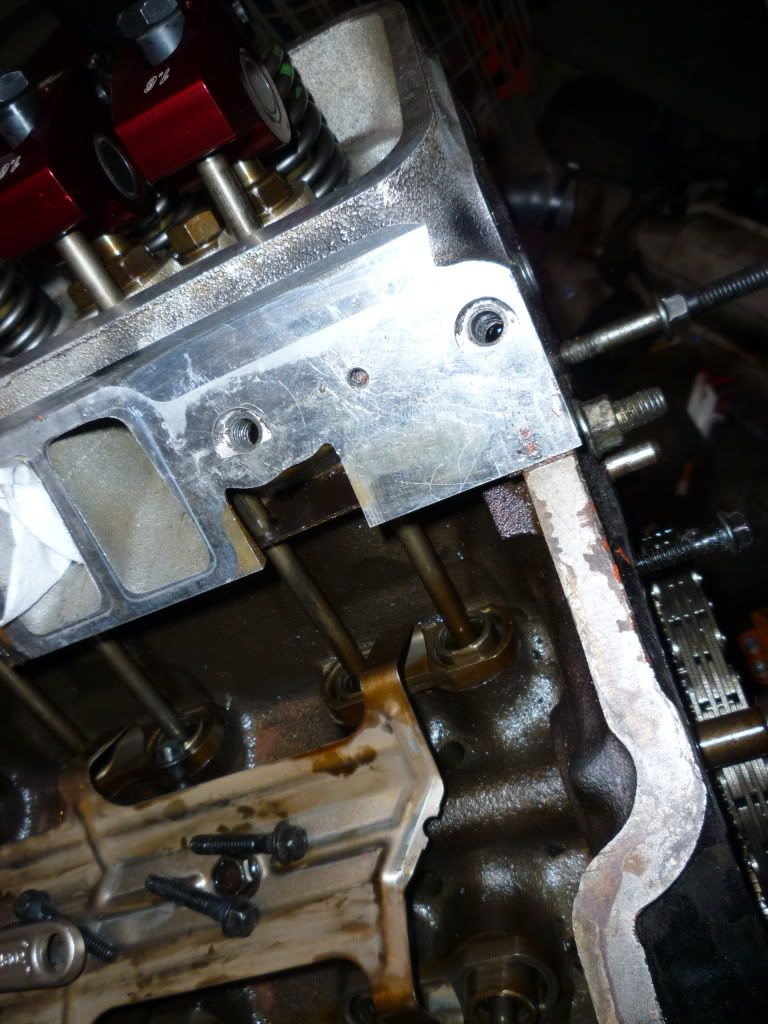

Followed the Comp Cams Guide, Here is my step by step.... Step one: rotate engine until the Exhaust pushrod begins to raise/open, Stop rotation.

Pic->

then apply a some assembly lube to top of INTAKE push rod and place rocker back on... Pic->

Hand tighten the poly lock while rotating the pushrod until you feel the slightest bit of slack (we are now at zero lash)

Then turn the poly lock 1/2 a turn... pics->

Then set lock with allen key... Pic->

Pic->

then apply a some assembly lube to top of INTAKE push rod and place rocker back on... Pic->

Hand tighten the poly lock while rotating the pushrod until you feel the slightest bit of slack (we are now at zero lash)

Then turn the poly lock 1/2 a turn... pics->

Then set lock with allen key... Pic->

#73

TECH Addict

iTrader: (15)

Join Date: Sep 2005

Location: San Antonio, TX

Posts: 2,062

Likes: 0

Received 0 Likes

on

0 Posts

Yeah it's a lot better when you have the right tools so you don't start messing up parts because you're lazy. But it sounds like you're doing it right now i would just keep my fingers crossed that you actually did everything else right

#75

Village Troll

iTrader: (2)

It's just that, for me, adjusting valves is one of those things where I like to feel what is going on. Can't do that so much with a clunky crescent wrench. Besides that using something like that can easily scuff up the tops of the rockers if you aren't careful. It's just one more thing to watch out for.

#76

Launching!

Thread Starter

Join Date: Jan 2010

Location: Maryland

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

and it did just that lol whoops (scuff up the top) so through the confusion when doing exhaust side, can i do the same, rotate motor until intake side begins to lift/raise, then set lash on the exhaust side, or must i open the intake side fully and then once it starts to close set the lash for the exhaust side....

#80

Launching!

Thread Starter

Join Date: Jan 2010

Location: Maryland

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

I am listening to you ramair you've been helping me the whole time?!?! i did the comp cams guide and on the second to last rocker i found a lifter that was rock solid!