My buddy has a big block and his tranmission guy says lower stall for drag racing.

#41

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

Horsepower is the measurement of torque over time. To many people base their crap off of hp numbers. You look at the entire torque curve and hp curve to determine the stall speed.

What I haven't seen are the rest of the numbers. So it makes what ever for HP and torque at what ever. None of that **** tells the story. That freakin thing could have a torque curve that falls flat on its face at 4500 for all you have told us. I don't know how ANYONE is having a legitimate argument on this topic at this point. You know nothing of the rest of the story. How in the funkiddydooda do you come up with a suggestion based on a couple tid bits of info for THE BEST RESULTS?

Show a dyno chart for the best stall pick.

What I haven't seen are the rest of the numbers. So it makes what ever for HP and torque at what ever. None of that **** tells the story. That freakin thing could have a torque curve that falls flat on its face at 4500 for all you have told us. I don't know how ANYONE is having a legitimate argument on this topic at this point. You know nothing of the rest of the story. How in the funkiddydooda do you come up with a suggestion based on a couple tid bits of info for THE BEST RESULTS?

Show a dyno chart for the best stall pick.

#42

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

why does my buddy run a 7200 converter in a bbc with a 6000ish torque peak? Well he runs a glide with a steep gear, and the shift extension was killing him with a 6200 converter. But OMG he's wasting all that peak torque!!!! No he's making a lot more average hp now, and even though he has to spin it another 300 rpm past peak where power was falling off, he still trapped 1 mph more with the converter change, and his 60 improved .08 in worse weather. Trans, tire, gear, weight, powerband, shift rpm all play different roles in converter selection, which is a lot more complicated that most on this site realize. That's why i paid the big bucks for a custom converter and let the pro's do it for me, gotta pay to play.

#43

Launching!

Join Date: Jun 2008

Location: Glen Rock, PA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

Its not just about a peak number, you gotta look at the entire tq curve. Just because it shows a max at 4400rpm doesnt mean its not making alot already at a lower rpm. You could see 500tq @ 4400rpm and be at 450tq from 2500rpm and up. In that case, you would want the stall being around 2500rpm cause your already seeing majority of the tq.

#44

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

Its not just about a peak number, you gotta look at the entire tq curve. Just because it shows a max at 4400rpm doesnt mean its not making alot already at a lower rpm. You could see 500tq @ 4400rpm and be at 450tq from 2500rpm and up. In that case, you would want the stall being around 2500rpm cause your already seeing majority of the tq.

#45

Launching!

Join Date: Jun 2008

Location: Glen Rock, PA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

So you want to stall the car at 4400rpm at "peak tq" and leave that large area of already made tq behind? If you stall the car too high you will destroy the tq curve by leaving so much of it behind. We all need to see a dyno graph of the engine to make a real assumption on what stall is needed. Were all kinda pissing in a lake here without seeing the real information.

#47

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

So you want to stall the car at 4400rpm at "peak tq" and leave that large area of already made tq behind? If you stall the car too high you will destroy the tq curve by leaving so much of it behind. We all need to see a dyno graph of the engine to make a real assumption on what stall is needed. Were all kinda pissing in a lake here without seeing the real information.

#48

Launching!

Join Date: Jun 2008

Location: Glen Rock, PA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

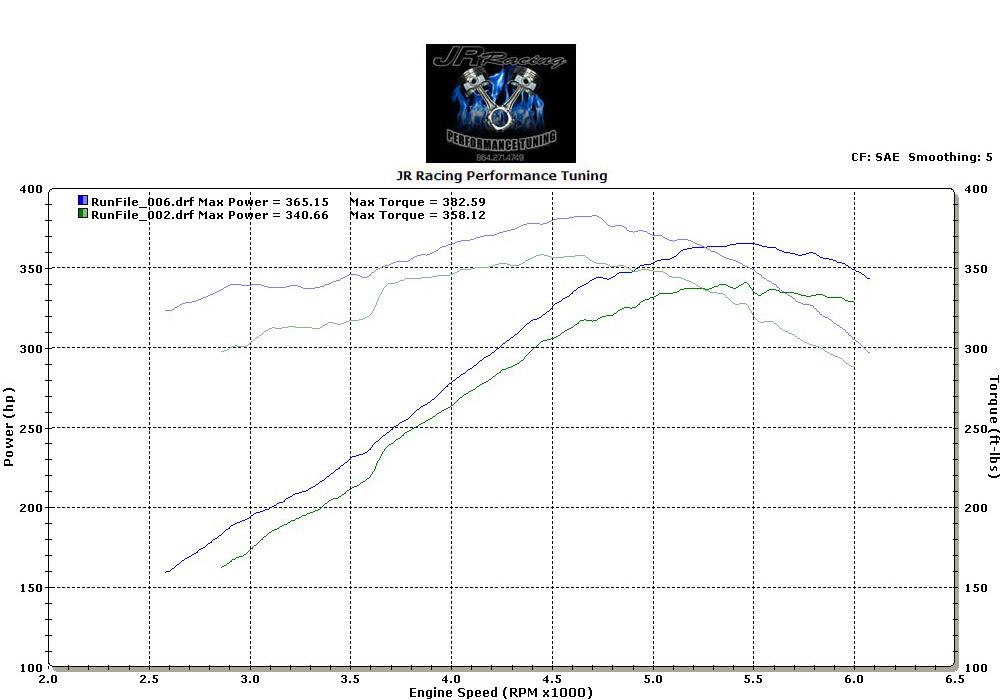

Heres a graph i found online. Not sure what engine it is but whatever, lets look at it. Where would you place the stall? At 4700rpm where the tq peaks, or more around 3600rpm where the tq begins to make its rise, then plateau, then fall? Maybe im wrong but i wouldnt stall it at peak tq because just after the tq is falling pretty hard. You stall it at 3600rpm and your already seeing alot tq and has a good bit left to keep accelerating. Should launch hard and keep pulling for a while, compared to a hard launch then falling flat on its face from the loss of tq. 4000rpm would probably be even better.

#49

Launching!

Join Date: Jun 2008

Location: Glen Rock, PA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

First off I told him 4000. But if he was going for street/strip a 3500 stall should be fine on the street as long as he has a good tranny cooler. By the way horsepower is better than torque like explained above with my 6 speed I would bog at my peak torque but at my peak horsepower bog was completely gone. I will get his dyno sheet I think his peak torque was at 4400 and peak power was 5800. So torque did not drop off to fast since his horsepower kep climbing.

#50

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

A stick car launch is totally different. The only way to compare a peak tq launch is by using a 2 step, going full throttle at your peak tq rpm and let out the clutch. I had a turbo car with anti lag and had to do it that way to get it up on boost for a hard launch. Same principles apply to a NA manual car. You only see peak numbers at WOT.

Last edited by djm_e22; 05-16-2010 at 09:29 PM.

#53

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

I think someone already said it but, without more info about gearing and traction, who could make a real recommendation? I do know that a 58 Chevy truck isn't light by any means. Someone else hear may have a more similar combo to your friends, but this is my convertor experience with my 433/TH400/4.88:1 Twelve bolt combo in a 61 Bel Air.

Engine is 13.5:1 cr, aluminum rods, CC solid roller

278*/282* @ .050" lift - .714"/.680" - 110* LSA - 106* ICL

675 HP @ 7,400 RPM - 550 ft/lb @ 5,600 RPM - flywheel numbers

The car is lightened some and I run on MT 28"x10.5's

When I originally put the motor in, it had stock suspension...which is a three link. The lowers are much like fox mustang lowers where the coil sits on the LCA, then it has one upper offset on the RH and a panhard bar to center. Comp Cams suggested a minimum 5,000 RPM convertor. They said anything else and the car would be a dog and I'd be lucky to get it moving at all.

I had a TIGHT 10" convertor that was built for a big displacement nitrous motor that I installed. I knew it would stall much less than they recommended (ended up being barely over 2,000 on the foot brake) BUT I also knew that the car was at it's limits as far as traction based on my old 468"/2800 stall combo. (a much milder engine to say the least)

I went against what the "experts" recommended because I knew the car would do nothing but blow the tires off if I used the stall they suggested.

With the TIGHT convertor I ran 7.30's @ 96 MPH with only a 1.74 sixty foot hooking good, but lazy for a good 20' out.

The MPH shows enough power to run high 6's at least if I got the sixty foot down in the 1.5X range. If I had installed the 5,000 stall, IF I had even been able to run the same 1.7X sixty foot, the car would have been slip sliding all over the track.

Since then I have re-worked the rear suspension with Meto Billet LCA's, UMI double adj UCA's (two of them now), adj PHR, chunked the original coils, and fabbed up my own design upper shock crossmember that bolts in and allows me to run Chassis Engineering adj aluminum coil-overs. The UCA's also have adj mounts I fabbed that allow changing the instant center. Along with this, I went to an 8" - 5,500 rpm stall. Even with all these changes, the car still runs about the same 60' yet it's spinning a good 30' off the line and breaking lose on the 1-2 shift. Hoping fine tuning pinion angle and instant center will solve some of this.

So many variables in choosing a convertor that someone really needs to know the car (or truck) to pick the right one.

Engine is 13.5:1 cr, aluminum rods, CC solid roller

278*/282* @ .050" lift - .714"/.680" - 110* LSA - 106* ICL

675 HP @ 7,400 RPM - 550 ft/lb @ 5,600 RPM - flywheel numbers

The car is lightened some and I run on MT 28"x10.5's

When I originally put the motor in, it had stock suspension...which is a three link. The lowers are much like fox mustang lowers where the coil sits on the LCA, then it has one upper offset on the RH and a panhard bar to center. Comp Cams suggested a minimum 5,000 RPM convertor. They said anything else and the car would be a dog and I'd be lucky to get it moving at all.

I had a TIGHT 10" convertor that was built for a big displacement nitrous motor that I installed. I knew it would stall much less than they recommended (ended up being barely over 2,000 on the foot brake) BUT I also knew that the car was at it's limits as far as traction based on my old 468"/2800 stall combo. (a much milder engine to say the least)

I went against what the "experts" recommended because I knew the car would do nothing but blow the tires off if I used the stall they suggested.

With the TIGHT convertor I ran 7.30's @ 96 MPH with only a 1.74 sixty foot hooking good, but lazy for a good 20' out.

The MPH shows enough power to run high 6's at least if I got the sixty foot down in the 1.5X range. If I had installed the 5,000 stall, IF I had even been able to run the same 1.7X sixty foot, the car would have been slip sliding all over the track.

Since then I have re-worked the rear suspension with Meto Billet LCA's, UMI double adj UCA's (two of them now), adj PHR, chunked the original coils, and fabbed up my own design upper shock crossmember that bolts in and allows me to run Chassis Engineering adj aluminum coil-overs. The UCA's also have adj mounts I fabbed that allow changing the instant center. Along with this, I went to an 8" - 5,500 rpm stall. Even with all these changes, the car still runs about the same 60' yet it's spinning a good 30' off the line and breaking lose on the 1-2 shift. Hoping fine tuning pinion angle and instant center will solve some of this.

So many variables in choosing a convertor that someone really needs to know the car (or truck) to pick the right one.

#54

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

I think someone already said it but, without more info about gearing and traction, who could make a real recommendation? I do know that a 58 Chevy truck isn't light by any means. Someone else hear may have a more similar combo to your friends, but this is my convertor experience with my 433/TH400/4.88:1 Twelve bolt combo in a 61 Bel Air.

Engine is 13.5:1 cr, aluminum rods, CC solid roller

278*/282* @ .050" lift - .714"/.680" - 110* LSA - 106* ICL

675 HP @ 7,400 RPM - 550 ft/lb @ 5,600 RPM - flywheel numbers

The car is lightened some and I run on MT 28"x10.5's

When I originally put the motor in, it had stock suspension...which is a three link. The lowers are much like fox mustang lowers where the coil sits on the LCA, then it has one upper offset on the RH and a panhard bar to center. Comp Cams suggested a minimum 5,000 RPM convertor. They said anything else and the car would be a dog and I'd be lucky to get it moving at all.

I had a TIGHT 10" convertor that was built for a big displacement nitrous motor that I installed. I knew it would stall much less than they recommended (ended up being barely over 2,000 on the foot brake) BUT I also knew that the car was at it's limits as far as traction based on my old 468"/2800 stall combo. (a much milder engine to say the least)

I went against what the "experts" recommended because I knew the car would do nothing but blow the tires off if I used the stall they suggested.

With the TIGHT convertor I ran 7.30's @ 96 MPH with only a 1.74 sixty foot hooking good, but lazy for a good 20' out.

The MPH shows enough power to run high 6's at least if I got the sixty foot down in the 1.5X range. If I had installed the 5,000 stall, IF I had even been able to run the same 1.7X sixty foot, the car would have been slip sliding all over the track.

Since then I have re-worked the rear suspension with Meto Billet LCA's, UMI double adj UCA's (two of them now), adj PHR, chunked the original coils, and fabbed up my own design upper shock crossmember that bolts in and allows me to run Chassis Engineering adj aluminum coil-overs. The UCA's also have adj mounts I fabbed that allow changing the instant center. Along with this, I went to an 8" - 5,500 rpm stall. Even with all these changes, the car still runs about the same 60' yet it's spinning a good 30' off the line and breaking lose on the 1-2 shift. Hoping fine tuning pinion angle and instant center will solve some of this.

So many variables in choosing a convertor that someone really needs to know the car (or truck) to pick the right one.

Engine is 13.5:1 cr, aluminum rods, CC solid roller

278*/282* @ .050" lift - .714"/.680" - 110* LSA - 106* ICL

675 HP @ 7,400 RPM - 550 ft/lb @ 5,600 RPM - flywheel numbers

The car is lightened some and I run on MT 28"x10.5's

When I originally put the motor in, it had stock suspension...which is a three link. The lowers are much like fox mustang lowers where the coil sits on the LCA, then it has one upper offset on the RH and a panhard bar to center. Comp Cams suggested a minimum 5,000 RPM convertor. They said anything else and the car would be a dog and I'd be lucky to get it moving at all.

I had a TIGHT 10" convertor that was built for a big displacement nitrous motor that I installed. I knew it would stall much less than they recommended (ended up being barely over 2,000 on the foot brake) BUT I also knew that the car was at it's limits as far as traction based on my old 468"/2800 stall combo. (a much milder engine to say the least)

I went against what the "experts" recommended because I knew the car would do nothing but blow the tires off if I used the stall they suggested.

With the TIGHT convertor I ran 7.30's @ 96 MPH with only a 1.74 sixty foot hooking good, but lazy for a good 20' out.

The MPH shows enough power to run high 6's at least if I got the sixty foot down in the 1.5X range. If I had installed the 5,000 stall, IF I had even been able to run the same 1.7X sixty foot, the car would have been slip sliding all over the track.

Since then I have re-worked the rear suspension with Meto Billet LCA's, UMI double adj UCA's (two of them now), adj PHR, chunked the original coils, and fabbed up my own design upper shock crossmember that bolts in and allows me to run Chassis Engineering adj aluminum coil-overs. The UCA's also have adj mounts I fabbed that allow changing the instant center. Along with this, I went to an 8" - 5,500 rpm stall. Even with all these changes, the car still runs about the same 60' yet it's spinning a good 30' off the line and breaking lose on the 1-2 shift. Hoping fine tuning pinion angle and instant center will solve some of this.

So many variables in choosing a convertor that someone really needs to know the car (or truck) to pick the right one.

#55

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

I appreciate your opinion, but I am tired of y'all talking about traction. The transmission guy said "a higher stall will help your take off but you will lose at the end of the track cause of the lost in horsepower. So he expected him to get traction. Plus with nitrous yes you would want a lower stall. In other words if you wanted to have your stall set at 4000 rpm with nitrous you need a converter that stalls at many 2700 NA. So that does not mean you don't have a stall converter of 4000, it just simply means you have a stall converter of 4000 with nitrous.

Anyone who thinks traction isn't a MAJOR concern when choosing a convertor on a 600 lb/ft TQ big block drag application obviously has ZERO experience with it. The transmission guy "expecting" him to get traction is about like Comp Cams expecting my stock suspension 10.5" 61 to get traction with the 5,000 stall they recommended - - ideally it would be nice, but it wasn't going to happen.

YES a loose and inefficient convertor will slip enough to cost you a few MPH (more in the 1/4 than the 1/8th)

But to think a 2500 stall will be better given the dyno numbers and rpm's you stated for his combo (assuming that your trans guy is correct and he has traction) is hilarious. Give us an update if/when he puts a convertor in that actually stalls near 2500 and tell us how he does. Will it be quicker than a low torque small block? Maybe so...but it will still be nowhere near it's potential. If he is planning to run in one of those "real street tire" classes where they don't allow even drag radials like is gaining popularity then a convertor that lets him leave well below where his engine starts working so he doesn't fry the tires would be good, but that is about the only time.

#56

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

I said it was a nitrous convertor. I never said I used nitrous. I run NA. I also stated the convertor only stalled to about 2000 rpm on the footbrake.

Anyone who thinks traction isn't a MAJOR concern when choosing a convertor on a 600 lb/ft TQ big block drag application obviously has ZERO experience with it. The transmission guy "expecting" him to get traction is about like Comp Cams expecting my stock suspension 10.5" 61 to get traction with the 5,000 stall they recommended - - ideally it would be nice, but it wasn't going to happen.

YES a loose and inefficient convertor will slip enough to cost you a few MPH (more in the 1/4 than the 1/8th)

But to think a 2500 stall will be better given the dyno numbers and rpm's you stated for his combo (assuming that your trans guy is correct and he has traction) is hilarious. Give us an update if/when he puts a convertor in that actually stalls near 2500 and tell us how he does. Will it be quicker than a low torque small block? Maybe so...but it will still be nowhere near it's potential. If he is planning to run in one of those "real street tire" classes where they don't allow even drag radials like is gaining popularity then a convertor that lets him leave well below where his engine starts working so he doesn't fry the tires would be good, but that is about the only time.

Anyone who thinks traction isn't a MAJOR concern when choosing a convertor on a 600 lb/ft TQ big block drag application obviously has ZERO experience with it. The transmission guy "expecting" him to get traction is about like Comp Cams expecting my stock suspension 10.5" 61 to get traction with the 5,000 stall they recommended - - ideally it would be nice, but it wasn't going to happen.

YES a loose and inefficient convertor will slip enough to cost you a few MPH (more in the 1/4 than the 1/8th)

But to think a 2500 stall will be better given the dyno numbers and rpm's you stated for his combo (assuming that your trans guy is correct and he has traction) is hilarious. Give us an update if/when he puts a convertor in that actually stalls near 2500 and tell us how he does. Will it be quicker than a low torque small block? Maybe so...but it will still be nowhere near it's potential. If he is planning to run in one of those "real street tire" classes where they don't allow even drag radials like is gaining popularity then a convertor that lets him leave well below where his engine starts working so he doesn't fry the tires would be good, but that is about the only time.

#57

TECH Enthusiast

Thread Starter

iTrader: (2)

Join Date: May 2005

Posts: 516

Likes: 0

Received 0 Likes

on

0 Posts

Maybe his transmission guy's only experience with 10" or smaller convertors are the cheap, sorry ones that slip so bad that they soak up a ton of power. Just because two convertor are both stall at 4000 rpm doesn't mean one won't be extremely more efficient.....with an E.T. and MPH much better than the other....as well as slipping much less at part throttle.

Last edited by djm_e22; 05-17-2010 at 09:02 AM.