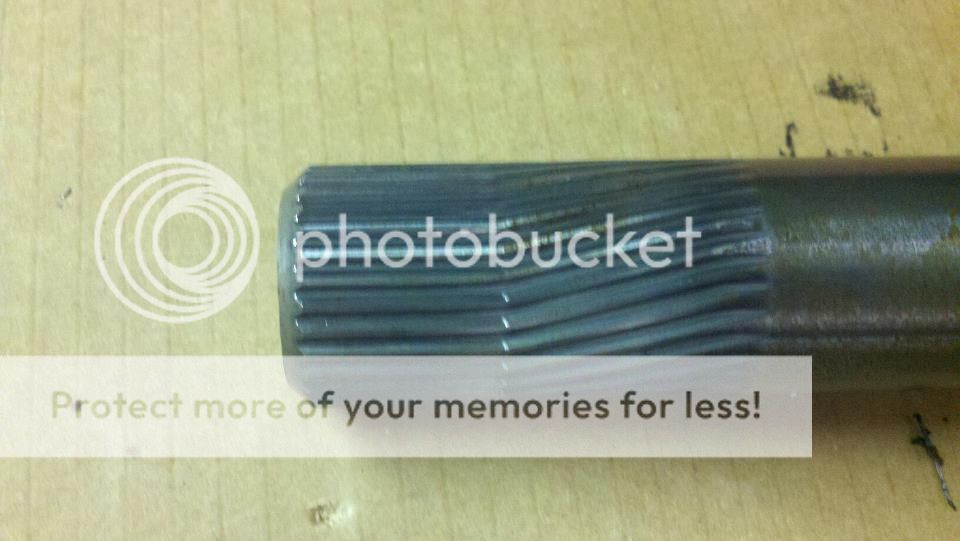

Twisted Axle Splines

#22

It appears that they only place there is any twisting is where the splines are fluted! That area is obviously weaker and if the splines had been more fully engaged into the Spool Splines MAY NOT have failed. It seems to me that even though they say a minimum of 1" engagement is all that is required, having splines that long just leads to more potential for failure!

Joe

Joe

#24

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

It appears that they only place there is any twisting is where the splines are fluted! That area is obviously weaker and if the splines had been more fully engaged into the Spool Splines MAY NOT have failed. It seems to me that even though they say a minimum of 1" engagement is all that is required, having splines that long just leads to more potential for failure!

Joe

Joe

Also....what people said about going to a larger spline is correct. 33 or 35 splines are larger in diameter and therefore stronger overall.

It's nice to hear you are still taking the car out and having fun with it even though it is for sale. (Can't believe it hasn't sold!!!)

#29

TECH Senior Member

iTrader: (8)

It appears that they only place there is any twisting is where the splines are fluted! That area is obviously weaker and if the splines had been more fully engaged into the Spool Splines MAY NOT have failed. It seems to me that even though they say a minimum of 1" engagement is all that is required, having splines that long just leads to more potential for failure!

Joe

Joe

I agree with this. Deeper engagement may have kept it from twisting since it only twisted in the unsupported area that is cut for splines.

Also....what people said about going to a larger spline is correct. 33 or 35 splines are larger in diameter and therefore stronger overall.

It's nice to hear you are still taking the car out and having fun with it even though it is for sale. (Can't believe it hasn't sold!!!)

Also....what people said about going to a larger spline is correct. 33 or 35 splines are larger in diameter and therefore stronger overall.

It's nice to hear you are still taking the car out and having fun with it even though it is for sale. (Can't believe it hasn't sold!!!)

They are not twisting in the carrier, or snapping / stripping splines etc. It could have 2 feet of engagement and still twist at the splined area that is NOT engaged....

What WOULD help is for it to be solid where the splines are not engaged.

Or just have better materials all together.

#31

TECH Fanatic

iTrader: (1)

Deeper spline engagement wouldn't do ****. Just think about it, the area at the transition of the splines being engaged are where they are twisting.

They are not twisting in the carrier, or snapping / stripping splines etc. It could have 2 feet of engagement and still twist at the splined area that is NOT engaged....

What WOULD help is for it to be solid where the splines are not engaged.

Or just have better materials all together.

They are not twisting in the carrier, or snapping / stripping splines etc. It could have 2 feet of engagement and still twist at the splined area that is NOT engaged....

What WOULD help is for it to be solid where the splines are not engaged.

Or just have better materials all together.

Sheesh.....come on guys!

#32

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

In my post, I was saying deeper engagement may have kept it from twisting because I was meaning that there would not have been the unsupported section of splines sticking out there. If that whole area was inside the spool I don't think it would have twisted. Perhaps I should have said "if the axle splines were not so long and if the axle had been a little bit longer with deeper spline engagement."

Either way, I'd make the move up to 33 or 35 spline axles now. More splines equal larger diameter and more strentgh. My 33 spline axles dwarf my stock 30 spline 12 bolt axles.

Either way, I'd make the move up to 33 or 35 spline axles now. More splines equal larger diameter and more strentgh. My 33 spline axles dwarf my stock 30 spline 12 bolt axles.

#33

TECH Fanatic

iTrader: (1)

Less exposed splines would only make for a less dramatic picture.

The degree of total twist is all that would change; the critical material damage and the failure point is going to be right at the spool engagement point regardless.

Yes, the fix is simply moving up in axle size.

The degree of total twist is all that would change; the critical material damage and the failure point is going to be right at the spool engagement point regardless.

Yes, the fix is simply moving up in axle size.

#34

Teching In

Join Date: Oct 2009

Location: Dayton, Ohio

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

I would go ahead and run that axle because it likely has already twisted as much as it's going to, is not bent and is comfortable now. I also do speak from experience, having sheared off several.

#35

TECH Fanatic

iTrader: (26)

Join Date: Mar 2010

Location: Milledgeville, GA

Posts: 1,909

Likes: 0

Received 0 Likes

on

0 Posts

I thought about that too, but wasn't going to say it outloud. LOL All of that twisting may have happened the first time you took it to the track. I'd be tempted to mark it and then make some more runs....pull it and check the mark to see if it twisted more. That would be the experimental way to go.

Buy the 33 or 35 spline axles and spool and sell your one good axle and spool to offset the cost some.

Buy the 33 or 35 spline axles and spool and sell your one good axle and spool to offset the cost some.

#36

TECH Fanatic

iTrader: (1)

I understand Mike's point. When the material moves, it work-hardens, so this axle has just as good a chance of survival as a new one of the same size/spline count.