383 LT1 road race engine water pump gear failure... why?

#21

TECH Veteran

iTrader: (1)

I bought a Cloyes replacement chain/gear set about 7-8 years ago, and had issues with the camshaft/water pump gear. Good thing I had access to machining equipment at the time, and I had to make a couple of "adjustments" to the gear, despite several calls to Cloyes, and their insistence that the gear was "within spec". Nonetheless, there was still a lot more slack in this LT1 replacement set, than the "true roller" set that I installed in a regular SBC a few years earlier....

#22

Thanks for all of the replies guys!

There is no windage tray in the pan. Due to clearance with the Porsche bits the pan is about 1/4" off the crank counter weights for the front 2/3rds. The dry sump system was actually in the chassis when it was still a 4 banger and in the first build was adapted to the V8. Admittedly there were mistakes made due to my own ignorance of the Chevy engine both then and now. It's a statement to the general reliability of the LT1 that most of the 13 cars I did simply got low mileage junkyard engines installed with nothing more than some cleanup; I never had any reason to learn what was going on inside ;-).

I'm interested in all of the negative comments on the Edelbrock parts. I've always heard of them being a somewhat trusted name in the domestic car parts market and I've seen both my own actual dyno results plus magazine tests where they gained significant power over stock. The fact that with these same parts installed this car made more power than it does now tells me that they are not the cause of the drop in power. I'm sure that some custom ported heads by a good head shop would be better, but they'd also cost a ton more. In the future I could have these heads (and head runners) ported just the same so I don't see it as money down the drain. The air gap manifold *seems* like a good idea for road racing where heat soak over a 40 minute race is a legitimate concern and I've got lots of air flowing through the engine bay.

The engine definitely needs a good going through, but I don't see much need to toss it all out and start over. I do know that the machine work and, at least, the bottom end assembly was done by a very reputable SBC guy locally (http://www.dvengines.com/), but NOBODY around here knows **** about LT's. I'll accept that the water pump drive gear had some hard miles on it and could have been previously damaged. I'm going to replace everything under the timing cover. I'm also going to replace all of the bottom end bearings with Calico bearings. I don't really see any legitimate reason to pull the heads off; that doesn't open up any areas to clean that can't be cleaned with the heads on and it just seems a waste of money (head gaskets). I will go ahead and pull the intake to clean the valley.

I keep forgetting to check for the plugs with holes in them while at the shop (I haven't had time to touch the engine), but I'll definitely check that out.

There is no windage tray in the pan. Due to clearance with the Porsche bits the pan is about 1/4" off the crank counter weights for the front 2/3rds. The dry sump system was actually in the chassis when it was still a 4 banger and in the first build was adapted to the V8. Admittedly there were mistakes made due to my own ignorance of the Chevy engine both then and now. It's a statement to the general reliability of the LT1 that most of the 13 cars I did simply got low mileage junkyard engines installed with nothing more than some cleanup; I never had any reason to learn what was going on inside ;-).

I'm interested in all of the negative comments on the Edelbrock parts. I've always heard of them being a somewhat trusted name in the domestic car parts market and I've seen both my own actual dyno results plus magazine tests where they gained significant power over stock. The fact that with these same parts installed this car made more power than it does now tells me that they are not the cause of the drop in power. I'm sure that some custom ported heads by a good head shop would be better, but they'd also cost a ton more. In the future I could have these heads (and head runners) ported just the same so I don't see it as money down the drain. The air gap manifold *seems* like a good idea for road racing where heat soak over a 40 minute race is a legitimate concern and I've got lots of air flowing through the engine bay.

The engine definitely needs a good going through, but I don't see much need to toss it all out and start over. I do know that the machine work and, at least, the bottom end assembly was done by a very reputable SBC guy locally (http://www.dvengines.com/), but NOBODY around here knows **** about LT's. I'll accept that the water pump drive gear had some hard miles on it and could have been previously damaged. I'm going to replace everything under the timing cover. I'm also going to replace all of the bottom end bearings with Calico bearings. I don't really see any legitimate reason to pull the heads off; that doesn't open up any areas to clean that can't be cleaned with the heads on and it just seems a waste of money (head gaskets). I will go ahead and pull the intake to clean the valley.

I keep forgetting to check for the plugs with holes in them while at the shop (I haven't had time to touch the engine), but I'll definitely check that out.

#23

Interestingly I see that the GM performance timing set comes with a water pump drive gear:

http://www.summitracing.com/parts/na...make/chevrolet

http://www.summitracing.com/parts/na...make/chevrolet

#24

TECH Veteran

iTrader: (23)

GO here and register

www.frrax.com.

Most of these guys run LT1's in the American Iron and Camaro/Mustang Challenge series.

They probably know more about LT1 durability in the road race environment than anyone else.

www.frrax.com.

Most of these guys run LT1's in the American Iron and Camaro/Mustang Challenge series.

They probably know more about LT1 durability in the road race environment than anyone else.

#26

JC

The comments on the Edelbrock parts has more to do with the fact that for the same $ there are better 'performing" choices. Nothing wrong with the parts themselves. you mention the motor makes more useable power anyway so since you have them may as well keep them.

Companies like Avanced Induction and Lloyd Elliott Portworks have been the go to for head/cam packages for the LT1 (and other) SBC platforms. Given the road race enviroment the car is used for exclusively maybe the "air gap" edelbrock intake is a benefit over a LT1 intake ported to match LT1 AL heads regarding heat soak.

the 383, if anything, should yeild more TQ than the 350 motor. The ?'s fastfatboy asks will assist in people commenting.

Given the crap that went through the motor when the gears sheared...I would really take a look at all bearings, including cam bearings. I think at this point head gaskets $ should not prevent pulling the heads to have the block really checked out

The comments on the Edelbrock parts has more to do with the fact that for the same $ there are better 'performing" choices. Nothing wrong with the parts themselves. you mention the motor makes more useable power anyway so since you have them may as well keep them.

Companies like Avanced Induction and Lloyd Elliott Portworks have been the go to for head/cam packages for the LT1 (and other) SBC platforms. Given the road race enviroment the car is used for exclusively maybe the "air gap" edelbrock intake is a benefit over a LT1 intake ported to match LT1 AL heads regarding heat soak.

the 383, if anything, should yeild more TQ than the 350 motor. The ?'s fastfatboy asks will assist in people commenting.

Given the crap that went through the motor when the gears sheared...I would really take a look at all bearings, including cam bearings. I think at this point head gaskets $ should not prevent pulling the heads to have the block really checked out

#27

11 Second Club

iTrader: (1)

Far as the Edelbrock stuff they claim 396flywheel HP from their full kit and I think 406fwhp from their LT4 kit.

These days most folks expect numbers like those at the wheel from ported GM heads and even an unported GM intake.

Even the magazine testing who have to play nice for advertizing dollars have the Edelbrock intake looking like it HURTS power compared to stock.

Edelbrock made good parts when it was easy to improve on factory stuff. GM stepped up their game with the LT1 and given the cowl/hood limitations of the f-body nobody has come up with a simple boltin intake improvement. These days sad as it is to say Edelbrock is relying on their name not products that actually improve performance. Best you could really say is it is well made STOCK REPLACEMENT parts but not the performance parts people expect.

Far as what you said about low mileage junkyard engines, MOST builds are better off there, GM has better resources far as getting the machining right than small shops have and a LOT of aftermarket stuff is a step backwards, the stock cast crank I would put up against the popular chinese forged stuff any day. Most of the pistons guys want to put in these are heavier than stock and many of them have more parasitic ring packages. Don't get me wrong the stock stuff is not perfect, but at the same time most performance "built" engines do not endup better. The stock stuff absolutely can be improved on but it takes an above average machineshop and better parts than most are willing to buy.

These days most folks expect numbers like those at the wheel from ported GM heads and even an unported GM intake.

Even the magazine testing who have to play nice for advertizing dollars have the Edelbrock intake looking like it HURTS power compared to stock.

Edelbrock made good parts when it was easy to improve on factory stuff. GM stepped up their game with the LT1 and given the cowl/hood limitations of the f-body nobody has come up with a simple boltin intake improvement. These days sad as it is to say Edelbrock is relying on their name not products that actually improve performance. Best you could really say is it is well made STOCK REPLACEMENT parts but not the performance parts people expect.

Far as what you said about low mileage junkyard engines, MOST builds are better off there, GM has better resources far as getting the machining right than small shops have and a LOT of aftermarket stuff is a step backwards, the stock cast crank I would put up against the popular chinese forged stuff any day. Most of the pistons guys want to put in these are heavier than stock and many of them have more parasitic ring packages. Don't get me wrong the stock stuff is not perfect, but at the same time most performance "built" engines do not endup better. The stock stuff absolutely can be improved on but it takes an above average machineshop and better parts than most are willing to buy.

#28

Icon forged pistons, 4.9cc reliefs

Not certain on block decking

Cam specs: 280/288 duration, .576/.57 lift http://www.compcams.com/Company/CC/c...csid=1111&sb=0

Head gasket is .040 compressed

Rocker arms are 1.6 ratio Proform aluminum full rollers

Pushrods are Comp Cams 7/16" chromoly 7.200" length

Last edited by jcforbes; 06-23-2013 at 04:28 PM.

#29

TECH Veteran

iTrader: (23)

Really need to know if the piston is in the hole or not, this makes a huge difference.

If the block was not "zero decked" the piston is in the hole from GM about .027-.030

Which would put you in the mid 11's on compression.

The combo should make more power than that. I would do a good pushrod measurement.

Is the knock sensor hooked up?

You have a data log?

If the block was not "zero decked" the piston is in the hole from GM about .027-.030

Which would put you in the mid 11's on compression.

The combo should make more power than that. I would do a good pushrod measurement.

Is the knock sensor hooked up?

You have a data log?

#30

11 Second Club

iTrader: (1)

As I said the Edeblrock kit is rated at under 400fwhp and that is with 1 3/4" headers, no accessories etc. IMO that cam gave him some extra HP over what the Edelbrock cam would have. Say the engine made 420flywheel adding 24hp from his better then Edelbrock cam choice, then knock off 15% for accessories and manual tranny losses which is probably conservative and you have 357rwhp which is close to what he has. The heads and intake are just that bad. Edelbock themselves proves it with their 396fwhp rating. If the bore work is a step backwards from stock or the breaking poor that would easily cost him a few more HP.

You break it down like that and his result seems about what you would expect.

You break it down like that and his result seems about what you would expect.

#31

Really need to know if the piston is in the hole or not, this makes a huge difference.

If the block was not "zero decked" the piston is in the hole from GM about .027-.030

Which would put you in the mid 11's on compression.

The combo should make more power than that. I would do a good pushrod measurement.

Is the knock sensor hooked up?

You have a data log?

If the block was not "zero decked" the piston is in the hole from GM about .027-.030

Which would put you in the mid 11's on compression.

The combo should make more power than that. I would do a good pushrod measurement.

Is the knock sensor hooked up?

You have a data log?

Knock sensor is hooked up and working.

I don't have a recent log handy. I'll get one off my tuning laptop.

#33

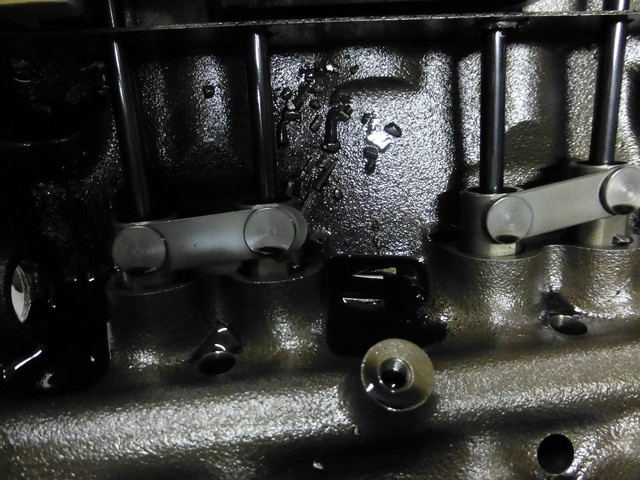

So today on my lunch break I pulled the intake, a head, and the cam. Cam bearings look good.

Oil galley plugs are solid:

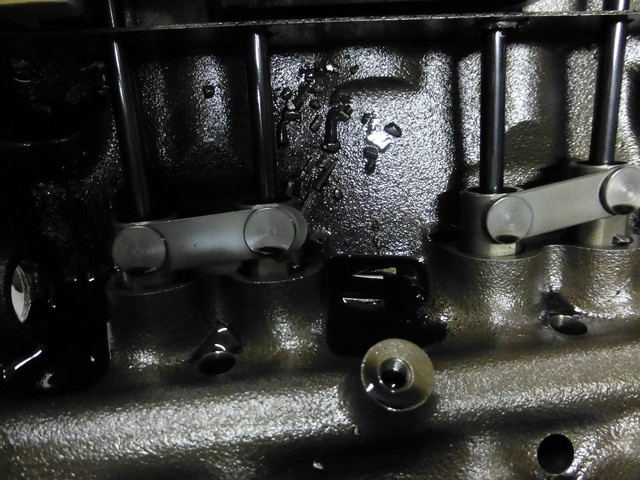

Found a TON more gear teeth in the valley, odd place for them to land:

I also found that the pushrods on the receipt I have are NOT the pushrods in the engine. The ones in the engine are 7.500". I'll be sure to check the length when I get a timing chain on it.

Deck to piston height is .020". That puts the compression ratio in the 11.8:1 area which should be plenty low for pump gas, yay.

Oil galley plugs are solid:

Found a TON more gear teeth in the valley, odd place for them to land:

I also found that the pushrods on the receipt I have are NOT the pushrods in the engine. The ones in the engine are 7.500". I'll be sure to check the length when I get a timing chain on it.

Deck to piston height is .020". That puts the compression ratio in the 11.8:1 area which should be plenty low for pump gas, yay.

#36

So today on my lunch break I pulled the intake, a head, and the cam. Cam bearings look good.

Oil galley plugs are solid:

I also found that the pushrods on the receipt I have are NOT the pushrods in the engine. The ones in the engine are 7.500". I'll be sure to check the length when I get a timing chain on it.

.

Oil galley plugs are solid:

I also found that the pushrods on the receipt I have are NOT the pushrods in the engine. The ones in the engine are 7.500". I'll be sure to check the length when I get a timing chain on it.

.

7.500 PR is LONG. I would really check that. If witness mark on top of valve is closer to exhaust manifold side....they are to long.

#37

TECH Fanatic

Join Date: Jan 2004

Location: Kingfisher Oklahoma

Posts: 1,157

Likes: 0

Received 0 Likes

on

0 Posts

What is funny is they scored the surface to keep the plugs in better and it appears they did little to help that at all. You can drill a small hole in those plugs in the future to take care of this. I have found that most machinists do not know the LT1s had that.

#38

Neither have holes, what you see in the picture is just a spec of dirt or something. I read up last night about the holes and I'm going to go ahead and drill a .025" hole in each of the two plugs.

And yeah, they sure wanted to peen the **** out of the edges of the galley holes for some reason.

#39

12 Second Club

iTrader: (7)

JC while you certainly are knowlegable, the LT1 has some idiosycrasies such as the .030 holes in the galley plugs to oil the wp drive gears that are missing from your plugs. A good refernce book to get yourself up to speed is 'How to rebuild small block Chevy LT1/LT4 Engines' published by HP Books. p/n Hp1393. It's well worth a look.