355 (LE2 head/LE1.5 cam) valve float solution found. Dyno graph inside

#1

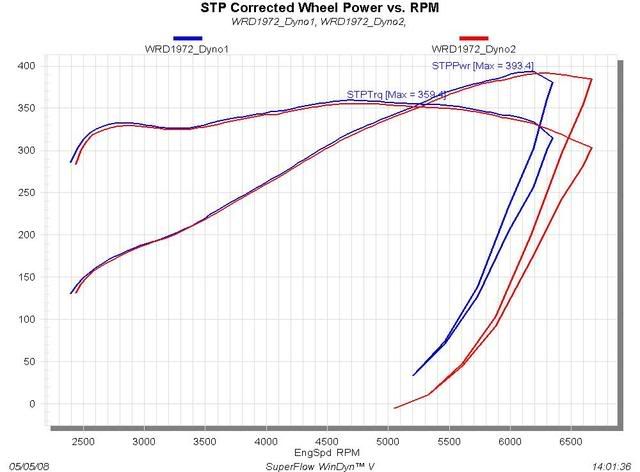

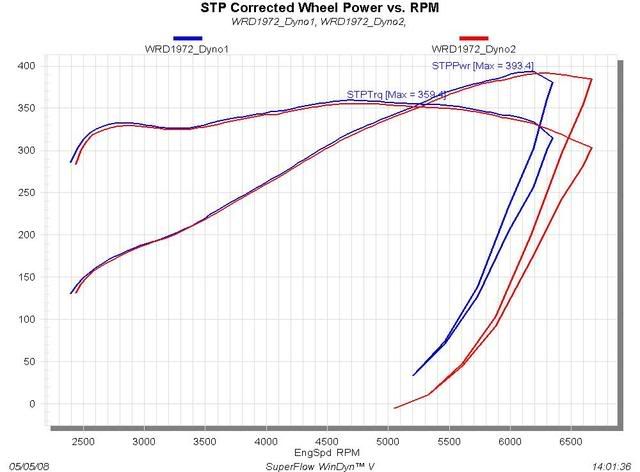

Well as everyone knows I have been chasing down a nasty valve float problem with my new motor for the past couple of months. The problem was that the motor would pull hard to ~6K RPM then just fall flat on its face and start making unusual noises. I can now happily report that the problem is fixed.

I went to the local dyno and made a baseline pull and clearly saw the float just like before. I then replaced the inadequate PAC 1218's (130#/320#) with some new Manley 221428 beehives installed at (160#/360#). Three hours later we made two more dyno pulls and ALL of the radical power fall off was completely gone. Also the motor was much more quiet as a result of the valvetrain being more tightened up and the valves not bouncing. The motor now pulls hard to 6600 RPM just like it should. Shift point will be 6400 RPM.

On the road it just keeps reving higher and higher unlike before. There is no doubt that according to the attached plot, this problem is fixed as a result of installing valve springs that are able to properly control the valves. The funny thing now is, the inadequate PAC 1218's made 2 RWHP / 4 RWTQ more compared to the better Manley springs. I assume that is as a result of the higher spring pressures which can be attributed most likely to parasitic loss. Obviously I am not concerned with this. One other interesting positive is that nearly all of my random knock retard is gone too.

Engine specs:

355 ci. through M6

Mahle forged pistons w/ 6" rods

Stock crankshaft

ASP UD pulley

Le2 heads

LE 1.5 camshaft

Manley 221428 beehive springs

1.6 Comp pro-mags

LE ported intake

30# SVO injectors

52mm throttle body

AS&M cold air induction

RK sport headers (1.75" primaries and 2.5" collectors)

Borla cat-back

No catalytic converter

E-cutout (open)

Midwest Fabricated 9" rear w/ 3.89 gears

Strange Chromeoly drive shaft

Spec 3+ clutch

Tuned by Bluecat

Final Dyno numbers are:

391 RWHP corrected

355 RWTQ corrected

Here is the dyno plot showing before (blue) and after (red):

Thanks again to all who chimed in on my older thread and helped me along the way.

And special thanks to Lloyd Elliot for his excellent customer dedication. Lloyd took a genuine interest in the problem and offered advice and support till a solution was found.

I am hoping to get this thing to the strip very soon. I am hoping for low 12 second ET's on stickies.

I went to the local dyno and made a baseline pull and clearly saw the float just like before. I then replaced the inadequate PAC 1218's (130#/320#) with some new Manley 221428 beehives installed at (160#/360#). Three hours later we made two more dyno pulls and ALL of the radical power fall off was completely gone. Also the motor was much more quiet as a result of the valvetrain being more tightened up and the valves not bouncing. The motor now pulls hard to 6600 RPM just like it should. Shift point will be 6400 RPM.

On the road it just keeps reving higher and higher unlike before. There is no doubt that according to the attached plot, this problem is fixed as a result of installing valve springs that are able to properly control the valves. The funny thing now is, the inadequate PAC 1218's made 2 RWHP / 4 RWTQ more compared to the better Manley springs. I assume that is as a result of the higher spring pressures which can be attributed most likely to parasitic loss. Obviously I am not concerned with this. One other interesting positive is that nearly all of my random knock retard is gone too.

Engine specs:

355 ci. through M6

Mahle forged pistons w/ 6" rods

Stock crankshaft

ASP UD pulley

Le2 heads

LE 1.5 camshaft

Manley 221428 beehive springs

1.6 Comp pro-mags

LE ported intake

30# SVO injectors

52mm throttle body

AS&M cold air induction

RK sport headers (1.75" primaries and 2.5" collectors)

Borla cat-back

No catalytic converter

E-cutout (open)

Midwest Fabricated 9" rear w/ 3.89 gears

Strange Chromeoly drive shaft

Spec 3+ clutch

Tuned by Bluecat

Final Dyno numbers are:

391 RWHP corrected

355 RWTQ corrected

Here is the dyno plot showing before (blue) and after (red):

Thanks again to all who chimed in on my older thread and helped me along the way.

And special thanks to Lloyd Elliot for his excellent customer dedication. Lloyd took a genuine interest in the problem and offered advice and support till a solution was found.

I am hoping to get this thing to the strip very soon. I am hoping for low 12 second ET's on stickies.

Last edited by wrd1972; 05-05-2008 at 03:39 PM.

#6

I had some very minor cam surge under 1.8K RPM but after the dyno tune it fixed that. Does not drive like a cammed car hardly at all.

Trending Topics

#10

TECH Resident

iTrader: (9)

Join Date: Jun 2005

Location: Wichita/Derby, KS

Posts: 858

Likes: 0

Received 0 Likes

on

0 Posts

#11

The PAC's were installed at 1.765". I checked them on the pressure tester and the range was 115#-125# each at 1.765 after 2K miles. Even if the Manleys soften up a bit they stll have a much greater chance of controlling the valves. Now that I know what to look for I can monitor things like with my Datamaster which clearly showed the float in the AFGS. I will check the springs on four cylinders every six months to play it safe and if I have to replace springs every 2-3 years then thats fine too. I knew that going into the deal with the high lift of the cam.

Another benefit is that the Manleys are nitrited simialrly to the PAC 1518's. This gives them a big leg up on the un-nitrited PAC 1218's.

Another benefit is that the Manleys are nitrited simialrly to the PAC 1518's. This gives them a big leg up on the un-nitrited PAC 1218's.

#16

12 Second Club

iTrader: (7)

Join Date: Oct 2005

Location: NYC

Posts: 1,666

Likes: 0

Received 0 Likes

on

0 Posts

in terms of different types of lobe design what makes some more agressive than others? and when people say they are more agressive what are we reffering to the way the valves are opened and closed? just trying to boost my cam knowledge.

#18

Those springs, like the 918's and clones, want a installed height of 1.8", not 1.7xx"

Glad to hear they solved your problem of float but with the lower installed height...the open and seat pressure is higher than spec. This may shorten their life and bring you closer to coil bind pending the lift of your cam.

I experienced the same high RPM float with another cam and spring and it was the dedicated help of Ed Wright who pointed me to the bee hives. Even though my old springs did meet and exceed the open/seat pressure of my cam specs the "bee hives" dealt with the lobes I have.

Good to hear the motor pulls to the higher RPM's, I know your problem was frustrating....been there.

Glad to hear they solved your problem of float but with the lower installed height...the open and seat pressure is higher than spec. This may shorten their life and bring you closer to coil bind pending the lift of your cam.

I experienced the same high RPM float with another cam and spring and it was the dedicated help of Ed Wright who pointed me to the bee hives. Even though my old springs did meet and exceed the open/seat pressure of my cam specs the "bee hives" dealt with the lobes I have.

Good to hear the motor pulls to the higher RPM's, I know your problem was frustrating....been there.

#19

11 Second Club

iTrader: (1)

Those springs, like the 918's and clones, want a installed height of 1.8", not 1.7xx"

Glad to hear they solved your problem of float but with the lower installed height...the open and seat pressure is higher than spec. This may shorten their life and bring you closer to coil bind pending the lift of your cam.

I experienced the same high RPM float with another cam and spring and it was the dedicated help of Ed Wright who pointed me to the bee hives. Even though my old springs did meet and exceed the open/seat pressure of my cam specs the "bee hives" dealt with the lobes I have.

Good to hear the motor pulls to the higher RPM's, I know your problem was frustrating....been there.

Glad to hear they solved your problem of float but with the lower installed height...the open and seat pressure is higher than spec. This may shorten their life and bring you closer to coil bind pending the lift of your cam.

I experienced the same high RPM float with another cam and spring and it was the dedicated help of Ed Wright who pointed me to the bee hives. Even though my old springs did meet and exceed the open/seat pressure of my cam specs the "bee hives" dealt with the lobes I have.

Good to hear the motor pulls to the higher RPM's, I know your problem was frustrating....been there.

http://www.impalassforum.com/vBullet...light=beehives

#20

yep Dwayne that was my thread. Many people contributed great advice.

My original ? was to Ed Wright because I thought it was a tuning issue. After I sent him some date logs he requested. He nailed it on the bee hives and I then posted on the forum ?'s.

Hindsight is 20/20 and I should have simply followed the spring specs that were on the cam card. At the time of my XFI install that cam was new on the market and even though "other" springs did meet open/seat pressure their design simply could not deal with the XFI lobes. I assume custom LE & AI cams have similar fast ramp lobes requireing the "bee hive" design.

Back to the ?'s of this threads author I strongly encourage that "installed height", valve train geometry (PR length), and valve lash be right on spec for proper valve train performance and durability.

My original ? was to Ed Wright because I thought it was a tuning issue. After I sent him some date logs he requested. He nailed it on the bee hives and I then posted on the forum ?'s.

Hindsight is 20/20 and I should have simply followed the spring specs that were on the cam card. At the time of my XFI install that cam was new on the market and even though "other" springs did meet open/seat pressure their design simply could not deal with the XFI lobes. I assume custom LE & AI cams have similar fast ramp lobes requireing the "bee hive" design.

Back to the ?'s of this threads author I strongly encourage that "installed height", valve train geometry (PR length), and valve lash be right on spec for proper valve train performance and durability.