No mees, no fuss bleeder line, no wrench needed

#1

Well I had to change out my slave today. Did not want to fight with a wrench on the bleeder fitting or a mess of spilled fluid in the bell housing.

Here is what I came up with, line works as a wrench and a bleeder extension.

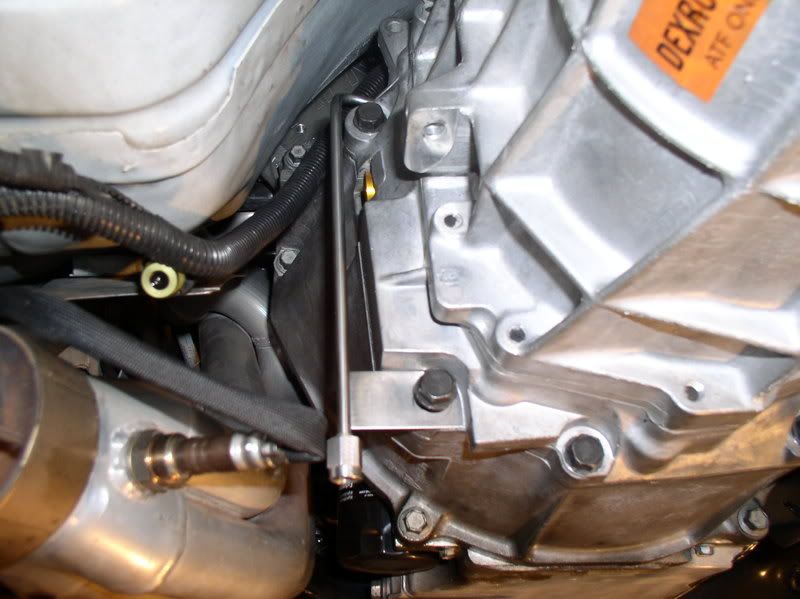

Front shot.........

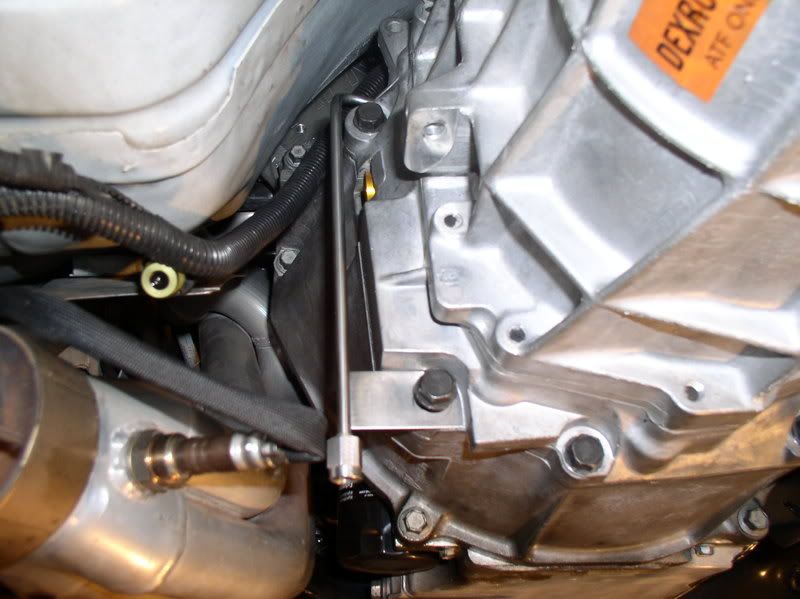

Side shot............

Bleeder in the closed and stowed position. Held in place by a mount bolt.

Here is the bleeder in the open position, with a flex line installed no mess no fuss.

Here is what I came up with, line works as a wrench and a bleeder extension.

Front shot.........

Side shot............

Bleeder in the closed and stowed position. Held in place by a mount bolt.

Here is the bleeder in the open position, with a flex line installed no mess no fuss.

#4

TECH Apprentice

iTrader: (5)

Join Date: Feb 2008

Location: Michigan

Posts: 397

Likes: 0

Received 0 Likes

on

0 Posts

Looks good, only issue that I see is that you will have to put a lot of fluid thru it to ensure that there is zero air in the system. You won't be able to see the spurts of air like normal.

Trending Topics

#8

That's why a Mity-Vac is awesome. Fill it with fluid, set the pressure and let it loose.

#9

Thanks

Tired of having a mess inside the bellhousing, have had the idea for a while know but never put it into action.

Was able to carry out a normal bleeding process, looking for bubbles was not a issue. Might add when much quicker which made the wife a bit a little more at ease. Due the fact I was using her leg.

Thanks.......right now the only way to produce something like this. It would be slave specific. Due to the fact that each bleeder port stops at a different position. Trust me I tried this on the junk slave 1st on the bench. Then swapping the bleeder port to the new slave, clocking was off.

Thank you......Yes it is a clean T56 want to keep it that way.

Tired of having a mess inside the bellhousing, have had the idea for a while know but never put it into action.

Thank you......Yes it is a clean T56 want to keep it that way.

#15

TECH Addict

iTrader: (49)

Not sure how the OP did his, but brazing or welding will work and your Lincoln mig will do it. I welded a steel AN fitting on the end of a stock bleeder. Not sure the type of steel the bleeder is and it's not real happy about being welded on, but nothing that a grinder can't smooth down and it's not going anywhere.

Last edited by HavATampa; 05-31-2011 at 10:15 PM.