T56 Swap Hole for Clutch, Other Question

#1

This is my first swap, and I am essentially functionally retarded when it comes to visualizing how parts go together.

I am at the stage where I need to drill holes for the u-bolt and also drill the larger 1 1/2 or so hole for the master in the firewall.

First, how freaking precise must the clutch bracket be lined up in the embossed template in the rubber mat on the firewall? Is this good enough?

Also, when I drill the hole for the master, does it matter if the hole saw bit is angled up or down? I held the bit in place inside the perimeter of the bracket to see exactly where to drill. Holding it here, it was angled upwards a bit, like this:

That ok?

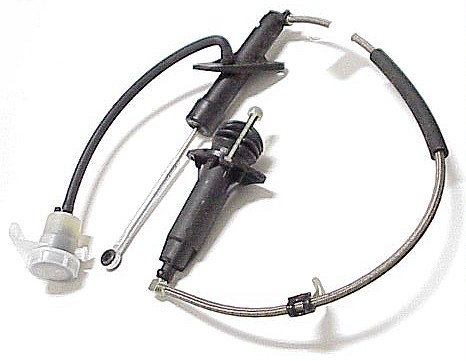

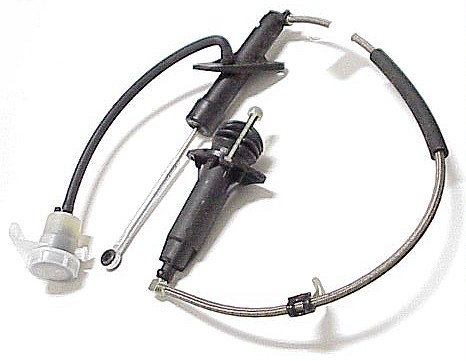

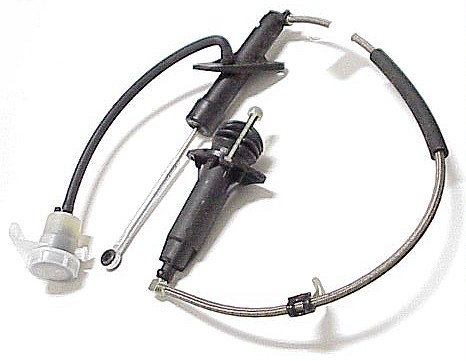

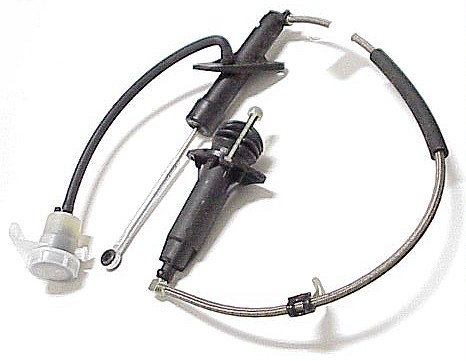

Finally, someone pointed out that my slave is missing a little white plastic mushroom shaped cap on the tip, that acts as some kind of a spacer. Does this matter?

In the pic below, you can see a new slave with the plastic tip held on by some white straps that break upon first use. I do not have this cap:

Thanks for any help.

I am at the stage where I need to drill holes for the u-bolt and also drill the larger 1 1/2 or so hole for the master in the firewall.

First, how freaking precise must the clutch bracket be lined up in the embossed template in the rubber mat on the firewall? Is this good enough?

Also, when I drill the hole for the master, does it matter if the hole saw bit is angled up or down? I held the bit in place inside the perimeter of the bracket to see exactly where to drill. Holding it here, it was angled upwards a bit, like this:

That ok?

Finally, someone pointed out that my slave is missing a little white plastic mushroom shaped cap on the tip, that acts as some kind of a spacer. Does this matter?

In the pic below, you can see a new slave with the plastic tip held on by some white straps that break upon first use. I do not have this cap:

Thanks for any help.

Last edited by Bull; 08-25-2009 at 02:55 PM.

#4

I have been using the step by step guide by Alex Afrashteh, that is linked from this very forum: http://www.afrashteh.com/tranny_pics/T56.htm

Those instructions say to leave the plastic in place, so that is how I bolted up the pedals this morning.

I am not intentionally holding the hole saw bit at an angle. But, I don't believe the firewall is flat in that spot. I figured that if I put it to the firewall right above the bracket, the hole would be in the correct spot, and the bit naturally assume an angle upwards. Is this going to be an issue?

the merv, I'm going to read through your thread tonight...I need all the help I can get.

Thanks for the help so far, guys...I am sure I will have more questions.

Those instructions say to leave the plastic in place, so that is how I bolted up the pedals this morning.

I am not intentionally holding the hole saw bit at an angle. But, I don't believe the firewall is flat in that spot. I figured that if I put it to the firewall right above the bracket, the hole would be in the correct spot, and the bit naturally assume an angle upwards. Is this going to be an issue?

the merv, I'm going to read through your thread tonight...I need all the help I can get.

Thanks for the help so far, guys...I am sure I will have more questions.

#5

I just took a quick look at that write-up, the merv. Will read in full later.

The wiring nearly gave me an aneurysm. I definitely don't want to tear into my harness like that. The instructions I have just mention splicing some pigtails for the trans and whatnot. I'm actually going to buy a T56 harness from tpi-parts on eBay. I hope there is no need to rip the harness apart...I'll never get it back together properly.

The wiring nearly gave me an aneurysm. I definitely don't want to tear into my harness like that. The instructions I have just mention splicing some pigtails for the trans and whatnot. I'm actually going to buy a T56 harness from tpi-parts on eBay. I hope there is no need to rip the harness apart...I'll never get it back together properly.

#9

That's hugely appreciated. Seriously.

For now, what I am gathering here is that I don't have to worry much about drilling the hole for the master, right? I just can't visualize it. I know the master enters the firewall at an extreme angle, pointing up towards the clutch pedal pin. A 1 1/2 or so hole allows it to be positioned how it needs to go?

For now, what I am gathering here is that I don't have to worry much about drilling the hole for the master, right? I just can't visualize it. I know the master enters the firewall at an extreme angle, pointing up towards the clutch pedal pin. A 1 1/2 or so hole allows it to be positioned how it needs to go?

#10

11 Second Club

iTrader: (88)

Yea, kinda. An ovaled hole works great, you will see in my pics. Hold it in your hand to where the part of the Master that has the Bolt Holes is straight up and down.. that is how it will sit, flush against the Fire Wall with the Master itself at like a 55* angle..something like that, I saw it one time.

#14

Finally, someone pointed out that my slave is missing a little white plastic mushroom shaped cap on the tip, that acts as some kind of a spacer. Does this matter?

In the pic below, you can see a new slave with the plastic tip held on by some white straps that break upon first use. I do not have this cap:

Thanks for any help.

In the pic below, you can see a new slave with the plastic tip held on by some white straps that break upon first use. I do not have this cap:

Thanks for any help.

#16

Ok, I had some time today to make a little bit of progress. Tough to do when there is a newborn in the house!

Anyway, I cut/drilled the holes for the clutch master cylinder and mounted it in the car with the pedals. The clutch rod lines up with the stud on the clutch pedal, and the brake and accelerator cables line up with their respective pedals, too. This makes me feel that my hole is in the right spot and my pedals are bolted up correctly.

However, I have some issues/questions:

The mounting plate for the clutch master does NOT sit flush on the firewall. This is because it is hung up on the back side of the stud that used to be used to mount the automatic pedals. In the pics of swaps I have seen, no one removes that stud and no one has mentioned it causing the master to not sit flush, but that is what I am experiencing. Because everything lines up and I feel like my hole is in the right spot, it has me confused. Anyone run into this, or have any thoughts?

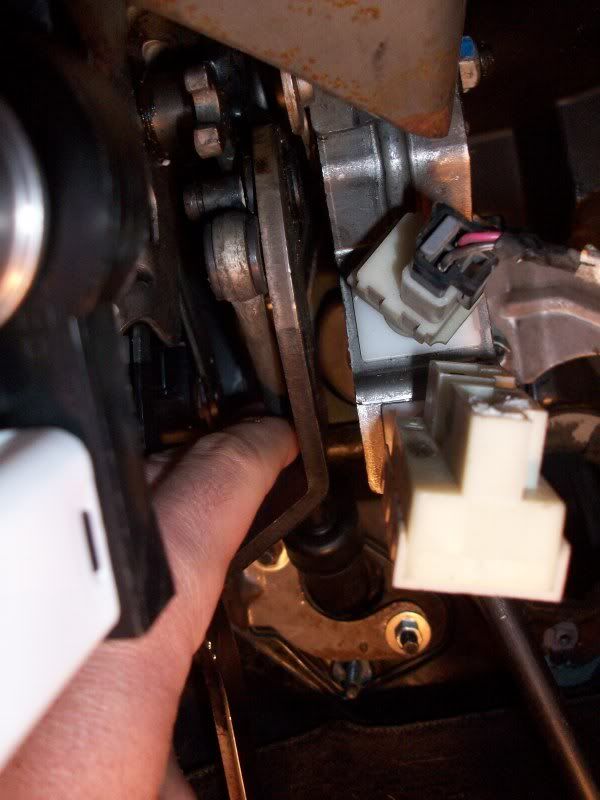

In the pic below, you can see how my clutch linkage lines up with the pedal. The stud in question is visible at the bottom of the pic, below the bracket on the 6 speed pedals.

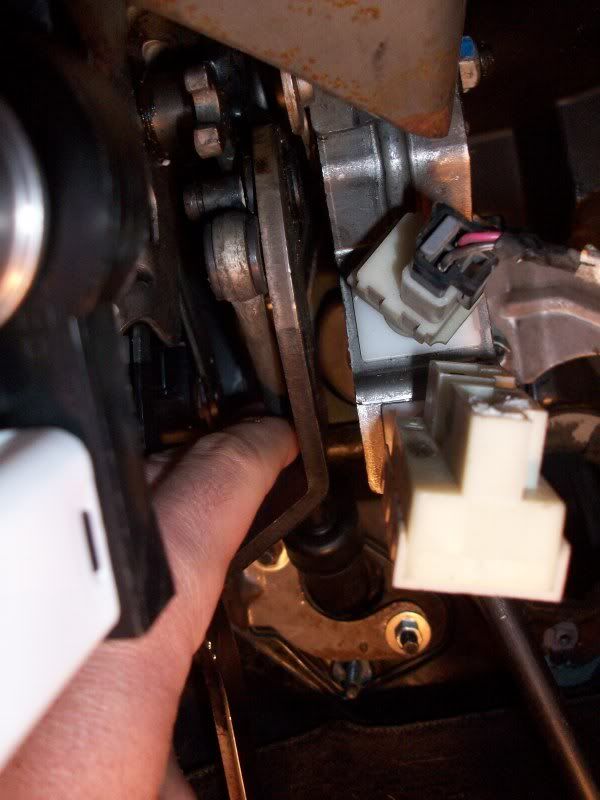

Here is a view from under the car, of the master cylinder's bracket hitting the back of that stud:

Also, are you supposed to connect the clutch rod to the pedal before mounting the pedals, or after? I have the pedals mounted, and although the rod lines up, I do not have enough side-to-side play to get it onto the stud.

Lastly, the rubber boot on the cabin-side of the master cylinder has a tear in it. Is this just a dust boot? If so, I am going to put RTV sealant on the tear, but I'm not sure if it needs to be pressure tight or anything.

Thanks guys.

Anyway, I cut/drilled the holes for the clutch master cylinder and mounted it in the car with the pedals. The clutch rod lines up with the stud on the clutch pedal, and the brake and accelerator cables line up with their respective pedals, too. This makes me feel that my hole is in the right spot and my pedals are bolted up correctly.

However, I have some issues/questions:

The mounting plate for the clutch master does NOT sit flush on the firewall. This is because it is hung up on the back side of the stud that used to be used to mount the automatic pedals. In the pics of swaps I have seen, no one removes that stud and no one has mentioned it causing the master to not sit flush, but that is what I am experiencing. Because everything lines up and I feel like my hole is in the right spot, it has me confused. Anyone run into this, or have any thoughts?

In the pic below, you can see how my clutch linkage lines up with the pedal. The stud in question is visible at the bottom of the pic, below the bracket on the 6 speed pedals.

Here is a view from under the car, of the master cylinder's bracket hitting the back of that stud:

Also, are you supposed to connect the clutch rod to the pedal before mounting the pedals, or after? I have the pedals mounted, and although the rod lines up, I do not have enough side-to-side play to get it onto the stud.

Lastly, the rubber boot on the cabin-side of the master cylinder has a tear in it. Is this just a dust boot? If so, I am going to put RTV sealant on the tear, but I'm not sure if it needs to be pressure tight or anything.

Thanks guys.

#17

How do you go about removing the button (engine bay) side of the stud without hacking up the firewall?

I am referring to post #16, the middle picture.

I am referring to post #16, the middle picture.

Last edited by Norbit2; 05-30-2017 at 06:43 PM.

Wasted my money.

Wasted my money.