Project "fix that damn 5th/6th gear high speed vibration".

#41

If you can drive those same speed in only 5th or even 4th and it is totally vibe free, I think its safe to say you dont have a driveline or rear diff issue.

It might be possible that just the 6th driven gear is loose on the main shaft similar to how my 5/6 driven gear was. Call Jason at TDP and troubleshoot with him and get his thoughts.

#46

Thanks for the thread. I now have something to look for when I finally go through it.

#47

I dont believe for a second that a slightly mis-shimmed main shaft can cause the 5/6 80MPH vibe. If that were reall true, why would it not vibrate in other gears at 80MPH??? If it were majorly mis-shimmed, I would guess it would make a tone of noise. I also dont believe I wasted my time and money as 85Mike stated because I have clearly shown in this thread, beyond the shadow of a doubt, that the 5/6 gear and mainshaft were damaged and the press fit of the 5/6 gear onto the main shaft, according to Tremac spec was non existant.

I believe you have the 5/6 gear issue like I did.

BTW, still 100% vibe free in 5th and 6th gears.

I believe you have the 5/6 gear issue like I did.

BTW, still 100% vibe free in 5th and 6th gears.

#48

I dont believe for a second that a slightly mis-shimmed main shaft can cause the 5/6 80MPH vibe. If that were reall true, why would it not vibrate in other gears at 80MPH??? If it were majorly mis-shimmed, I would guess it would make a tone of noise. I also dont believe I wasted my time and money as 85Mike stated because I have clearly shown in this thread, beyond the shadow of a doubt, that the 5/6 gear and mainshaft were damaged and the press fit of the 5/6 gear onto the main shaft, according to Tremac spec was non existant.

I believe you have the 5/6 gear issue like I did.

BTW, still 100% vibe free in 5th and 6th gears.

I believe you have the 5/6 gear issue like I did.

BTW, still 100% vibe free in 5th and 6th gears.

I just know that mine exhibits the same issues and want to be able to determine what is the cause when I tear it down (probably not till next winter) as long as it doesn't break this coming summer. I hate that I have to keep mine in 5th and under 85 to ride smooth. The whole point was to be able to cruise nicely with the double OD coming from a 4 speed swap over.

Again, thank you for this thread. Honestly until I read it this AM I forgot about this issue since the car has been parked. But, each summer when it is out I go nuts trying to logically determine what it is. Only thing I have no touched is the trans.

#49

Nah you did not say anything wrong. 85Mike is an asset to the board and is very helpful to all. But when he stated "That was your problem all along... You just wasted time and money throwing parts at a mis-shimmed unit.." .003" too sloppy FTR, I was rubbed. Even after I posted from the beginning, the videos, pics showing that the 5/6 gear was worn and fluttering around on the worn main shaft, his statement came off to me as arrogant considering the facts I have posted.

Last edited by wrd1972; 04-05-2011 at 08:13 PM.

#50

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

I'm going to have to agree with Mike on this subject. How is the vibration coming from an internal part of the transmission when the vibration is felt in the seat but not in the shifter itself which is directly mounted to the transmission with no form of cushion or dampner mechanism?

The 5-6 cluster rides upon the output shaft between the rear output shaft bearing and the tail housing bushing. Both of those are points of support and span a distance of about 10" roughly. The 5-6 cluster rides directly against the 5th and 6th gears which are supported by the cluster gear extension shaft that too has two points of support in a span of about 6". On top of that, you have the reverse gear which rides against the reverse idler gear which is rigid mounted into the reverse extension housing and offers another point of support.

All in all you have area less than a foot long with no less than 5 points of support and a vibration only felt in the seat but not in the shifter located directly above the area in question??? I find that hard to believe personally.

The 5-6 cluster rides upon the output shaft between the rear output shaft bearing and the tail housing bushing. Both of those are points of support and span a distance of about 10" roughly. The 5-6 cluster rides directly against the 5th and 6th gears which are supported by the cluster gear extension shaft that too has two points of support in a span of about 6". On top of that, you have the reverse gear which rides against the reverse idler gear which is rigid mounted into the reverse extension housing and offers another point of support.

All in all you have area less than a foot long with no less than 5 points of support and a vibration only felt in the seat but not in the shifter located directly above the area in question??? I find that hard to believe personally.

#51

I'm going to have to agree with Mike on this subject. How is the vibration coming from an internal part of the transmission when the vibration is felt in the seat but not in the shifter itself which is directly mounted to the transmission with no form of cushion or dampner mechanism?

The 5-6 cluster rides upon the output shaft between the rear output shaft bearing and the tail housing bushing. Both of those are points of support and span a distance of about 10" roughly. The 5-6 cluster rides directly against the 5th and 6th gears which are supported by the cluster gear extension shaft that too has two points of support in a span of about 6". On top of that, you have the reverse gear which rides against the reverse idler gear which is rigid mounted into the reverse extension housing and offers another point of support.

All in all you have area less than a foot long with no less than 5 points of support and a vibration only felt in the seat but not in the shifter located directly above the area in question??? I find that hard to believe personally.

The 5-6 cluster rides upon the output shaft between the rear output shaft bearing and the tail housing bushing. Both of those are points of support and span a distance of about 10" roughly. The 5-6 cluster rides directly against the 5th and 6th gears which are supported by the cluster gear extension shaft that too has two points of support in a span of about 6". On top of that, you have the reverse gear which rides against the reverse idler gear which is rigid mounted into the reverse extension housing and offers another point of support.

All in all you have area less than a foot long with no less than 5 points of support and a vibration only felt in the seat but not in the shifter located directly above the area in question??? I find that hard to believe personally.

IMO, the 80MPH, 5th and 6th gears only vibes were transmitted from the tranny, through the tranny mount, throught the tranny cross member and into the floorboard. The vibes were most noticable in the seat and to a lesser degree in the shifter. When I said they were not in the shifter, that was not accurate. It was just most noticable in the seat in a similar manner a DS imbalance would be felt.

#52

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

I dont understand your statement. 85Mike blamed the preload on the mainshaft within the tranny as the source of the vibes. Are you suggesting the cause of the vibe is outside of the tranny.

IMO, the 80MPH vibes were transmitted from the tranny, through the tranny mount, throught the tranny cross member and into the floorboard. The vibes were most noticable in the seat and to a lesser degree in the shifter.

IMO, the 80MPH vibes were transmitted from the tranny, through the tranny mount, throught the tranny cross member and into the floorboard. The vibes were most noticable in the seat and to a lesser degree in the shifter.

I simply do not see how a vibration is going to be so intense that you can feel it through a rubber transmission mount, through the crossmember, into the chassis and into the seat of the car but not in the shifter which is located less than 6" away from the 5-6 cluster gear and has no form of harmonic dampning.

#53

I am agreement with Mike about the wear on the mainshaft not being the root of the cause.

I simply do not see how a vibration is going to be so intense that you can feel it through a rubber transmission mount, through the crossmember, into the chassis and into the seat of the car but not in the shifter which is located less than 6" away from the 5-6 cluster gear and has no form of harmonic dampning.

I simply do not see how a vibration is going to be so intense that you can feel it through a rubber transmission mount, through the crossmember, into the chassis and into the seat of the car but not in the shifter which is located less than 6" away from the 5-6 cluster gear and has no form of harmonic dampning.

Edit.

Also after thinking about it a bit more, I cant say what the actual main shaft clearance was on the original worn main shaft, it was not checked. I determined the main shaft clearance was not right when the TDP repaired main shaft was installed using the existing shim pack. There may have been a slight variance between the two shafts so that could have accounted for the difference in clearance measurements.

Not trying to be confrontational here. Just simply pointing out the obvious damaged things that were found that once addressed, completely remedied the problem.

Last edited by wrd1972; 04-05-2011 at 03:15 PM.

#54

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

Just think about how tight the 5-6 cluster gear and the 5th and 6th gears mesh together. The lower gears ride on the cluster gear extension shaft so they aren't going anywhere. The mainshaft when shimmed correctly has the output shaft bearing and the tailhousing bushing as points of support so its not going anywhere. That only leaves the 5-6 cluster gear movement. You said that amounted to about .010" which is the slack from both sides of the shaft. That means the total maximum amount on either side is .005".

#55

Just think about how tight the 5-6 cluster gear and the 5th and 6th gears mesh together. The lower gears ride on the cluster gear extension shaft so they aren't going anywhere. The mainshaft when shimmed correctly has the output shaft bearing and the tailhousing bushing as points of support so its not going anywhere. That only leaves the 5-6 cluster gear movement. You said that amounted to about .010" which is the slack from both sides of the shaft. That means the total maximum amount on either side is .005".

So what do you think the problem was with my T56 based on what has been said?

#56

Banned

iTrader: (60)

Join Date: Mar 2005

Location: Adkins - Tx

Posts: 2,693

Likes: 0

Received 0 Likes

on

0 Posts

My response is the .005" on each side must have been doing some freaky, funky, wiggly wierd kind of **** in 5th and 6th once 80MPH was reached. I cant explain it beyond that other than to say it did not come from Tremac like that.

So what do you think the problem was with my T56 based on what has been said?

So what do you think the problem was with my T56 based on what has been said?

I know some will disagree with my opinions and tolerances when building transmissions but I put preload on every tapered bearing inside the T56(how much is an ancient chinese secret). .000 is too loose for me because once the unit sees torque applied to it, its going to loosen up. I learned this on T5's way before T56's really started showing up for repairs. Excessive slack in the mainshaft assembly and cluster gear allowed the gears to pull away from each other thus reducing the surface area they ride against each other and allowed the teeth to bust off. Keeping the unit tight helps out big time with keeping it from blowing up.

#57

11 Second Club

iTrader: (37)

I know some will disagree with my opinions and tolerances when building transmissions but I put preload on every tapered bearing inside the T56(how much is an ancient chinese secret). .000 is too loose for me because once the unit sees torque applied to it, its going to loosen up. I learned this on T5's way before T56's really started showing up for repairs. Excessive slack in the mainshaft assembly and cluster gear allowed the gears to pull away from each other thus reducing the surface area they ride against each other and allowed the teeth to bust off. Keeping the unit tight helps out big time with keeping it from blowing up.

Mike

#59

TECH Fanatic

iTrader: (6)

Join Date: Oct 2002

Location: Charlotte metro area

Posts: 1,959

Likes: 0

Received 3 Likes

on

3 Posts

Wow there sure seems to be a lot of posturing in this thread.

The Tremec spec is .0003 -.0035 loose for the input( mainshaft) NOT the several other specs thrown about. On earlier T56s the spec was -.003 to +.003. I suspect the spec was changed because it takes more effort to build with preload. Also, its easy to get way too much preload and not know it.

The original concern of a vibe in od gears is the EXACT outcome I would expect to see with a poor 5th/6th spool fit. The design calls for a press-fit . That press-fit is on the journal AND on the spline. Both together. A poor fit with either will result in vibration. The fact that the shafts are supported by x bearings is NOT a factor. With this gear(s) loose, the mesh of the gears is not correct and vibration is the result. These are helical gears and they will move (thrust) all over the place if not retained in place.

I don't intend to get into a sissing match here , but just set out useful and correct info. I have seen this concern many times before and I do know what causes it. If you don't agree, Ill give you a full refund.

The Tremec spec is .0003 -.0035 loose for the input( mainshaft) NOT the several other specs thrown about. On earlier T56s the spec was -.003 to +.003. I suspect the spec was changed because it takes more effort to build with preload. Also, its easy to get way too much preload and not know it.

The original concern of a vibe in od gears is the EXACT outcome I would expect to see with a poor 5th/6th spool fit. The design calls for a press-fit . That press-fit is on the journal AND on the spline. Both together. A poor fit with either will result in vibration. The fact that the shafts are supported by x bearings is NOT a factor. With this gear(s) loose, the mesh of the gears is not correct and vibration is the result. These are helical gears and they will move (thrust) all over the place if not retained in place.

I don't intend to get into a sissing match here , but just set out useful and correct info. I have seen this concern many times before and I do know what causes it. If you don't agree, Ill give you a full refund.

#60

Wow there sure seems to be a lot of posturing in this thread.

The Tremec spec is .0003 -.0035 loose for the input( mainshaft) NOT the several other specs thrown about. On earlier T56s the spec was -.003 to +.003. I suspect the spec was changed because it takes more effort to build with preload. Also, its easy to get way too much preload and not know it.

The original concern of a vibe in od gears is the EXACT outcome I would expect to see with a poor 5th/6th spool fit. The design calls for a press-fit . That press-fit is on the journal AND on the spline. Both together. A poor fit with either will result in vibration. The fact that the shafts are supported by x bearings is NOT a factor. With this gear(s) loose, the mesh of the gears is not correct and vibration is the result. These are helical gears and they will move (thrust) all over the place if not retained in place.

I don't intend to get into a sissing match here , but just set out useful and correct info. I have seen this concern many times before and I do know what causes it. If you don't agree, Ill give you a full refund.

The Tremec spec is .0003 -.0035 loose for the input( mainshaft) NOT the several other specs thrown about. On earlier T56s the spec was -.003 to +.003. I suspect the spec was changed because it takes more effort to build with preload. Also, its easy to get way too much preload and not know it.

The original concern of a vibe in od gears is the EXACT outcome I would expect to see with a poor 5th/6th spool fit. The design calls for a press-fit . That press-fit is on the journal AND on the spline. Both together. A poor fit with either will result in vibration. The fact that the shafts are supported by x bearings is NOT a factor. With this gear(s) loose, the mesh of the gears is not correct and vibration is the result. These are helical gears and they will move (thrust) all over the place if not retained in place.

I don't intend to get into a sissing match here , but just set out useful and correct info. I have seen this concern many times before and I do know what causes it. If you don't agree, Ill give you a full refund.

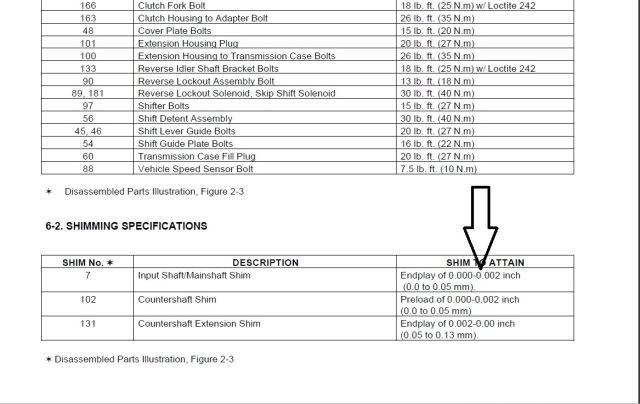

I referred to the Tremac service manual for the 0 -.002" spec I mentioned:

However I agree with everything else you stated.