Project "fix that damn 5th/6th gear high speed vibration".

#1

Quick recap.

I have a annoying vibration that starts at 80MPH (4.11 gears) in 5th and 6th gears only, 4th, 3rd gear at 80MPH is smooth as silk. It is entirely speed related and not RPM, and I have troubleshooted every damn thing imaginable over and over and have determined that the source of the vibe is in the T56 transmission. I have tried multiple drive shafts, rebalanced multiple driveshafts, checked pinion angles and mounts till me eyes crossed and my brain hurt.

After talking to Jason at Texas Drivetrain Performance, he is convinced that the problem is the 5th/6th driven gear which is supposed to be pressed tightly on the main shaft. He claims that the 5th/6th driven gear loses its tight pressed fit and it starts to flutter at high speed. After searching the net, I found others that had the same problem and have also blamed this gear or the main shaft.

So I have pulled the transmission and started the disassembly to check this gear and guess what? The 5th/6th driven gear was easily removed from the main shaft by hand with absolutely no effort. Normally, it should take a sophisticated puller to pull this gear off the main shaft. I also saw that the small end which is 6th gear, had the most slop on the main shaft. This is consistent with the fact that 6th gears vibrates more than 5th.

I have already purchased a repaired main shaft from Jason at TDP and have quickly verified that the 5th/6th driven gear will fit tightly on the repaired shaft. There appears to be some damage to the gear splines and the inside diameter so it might have to be replaced too. I am feeling very confident that this is the root cause for my high speed related vibrations. Clearly I have found a smoking gun with this loose gear.

Click the video below to see the loose gear:

I will keep this thread updated with my findings. I know there are several that are fighting the same problem so hopefully they will see this.

I have a annoying vibration that starts at 80MPH (4.11 gears) in 5th and 6th gears only, 4th, 3rd gear at 80MPH is smooth as silk. It is entirely speed related and not RPM, and I have troubleshooted every damn thing imaginable over and over and have determined that the source of the vibe is in the T56 transmission. I have tried multiple drive shafts, rebalanced multiple driveshafts, checked pinion angles and mounts till me eyes crossed and my brain hurt.

After talking to Jason at Texas Drivetrain Performance, he is convinced that the problem is the 5th/6th driven gear which is supposed to be pressed tightly on the main shaft. He claims that the 5th/6th driven gear loses its tight pressed fit and it starts to flutter at high speed. After searching the net, I found others that had the same problem and have also blamed this gear or the main shaft.

So I have pulled the transmission and started the disassembly to check this gear and guess what? The 5th/6th driven gear was easily removed from the main shaft by hand with absolutely no effort. Normally, it should take a sophisticated puller to pull this gear off the main shaft. I also saw that the small end which is 6th gear, had the most slop on the main shaft. This is consistent with the fact that 6th gears vibrates more than 5th.

I have already purchased a repaired main shaft from Jason at TDP and have quickly verified that the 5th/6th driven gear will fit tightly on the repaired shaft. There appears to be some damage to the gear splines and the inside diameter so it might have to be replaced too. I am feeling very confident that this is the root cause for my high speed related vibrations. Clearly I have found a smoking gun with this loose gear.

Click the video below to see the loose gear:

I will keep this thread updated with my findings. I know there are several that are fighting the same problem so hopefully they will see this.

Last edited by wrd1972; 08-26-2013 at 09:42 AM.

#2

Banned

iTrader: (11)

Join Date: Mar 2004

Location: Rowing 6 speeds Maryland

Posts: 376

Likes: 0

Received 0 Likes

on

0 Posts

Awesome! I don't know if it was you who posted the vibration issue but I remember it was only in 6th and NOT in 5th. If it was in both gears, there is no other possible problem other than the 5-6 cluster (or driven) gear. I bet the vibration will disappear when you have the trans back in the car.

#3

Update:

I have the entire mainshaft completely out of the transmission. I still need to completely disassemble it and swap all those parts to the repaired shaft. The job thus far still has not overwelming to take apart but I am taking plenty of photos. The shifting shaft and internal mechanisms were a little tricky but I got through it.

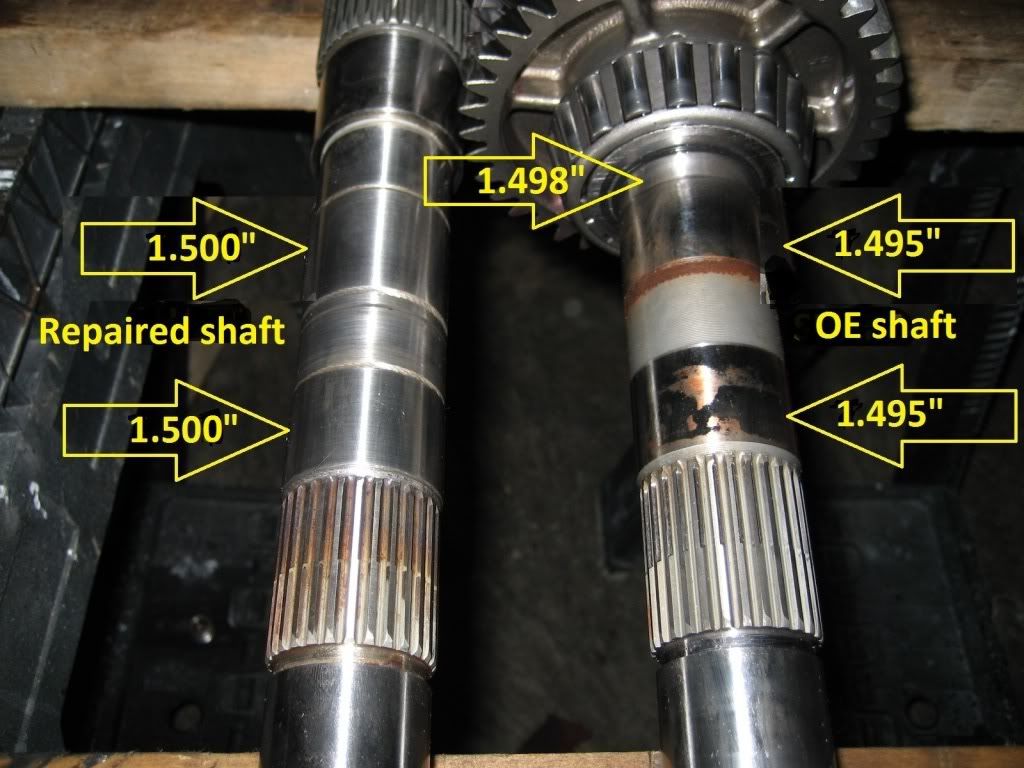

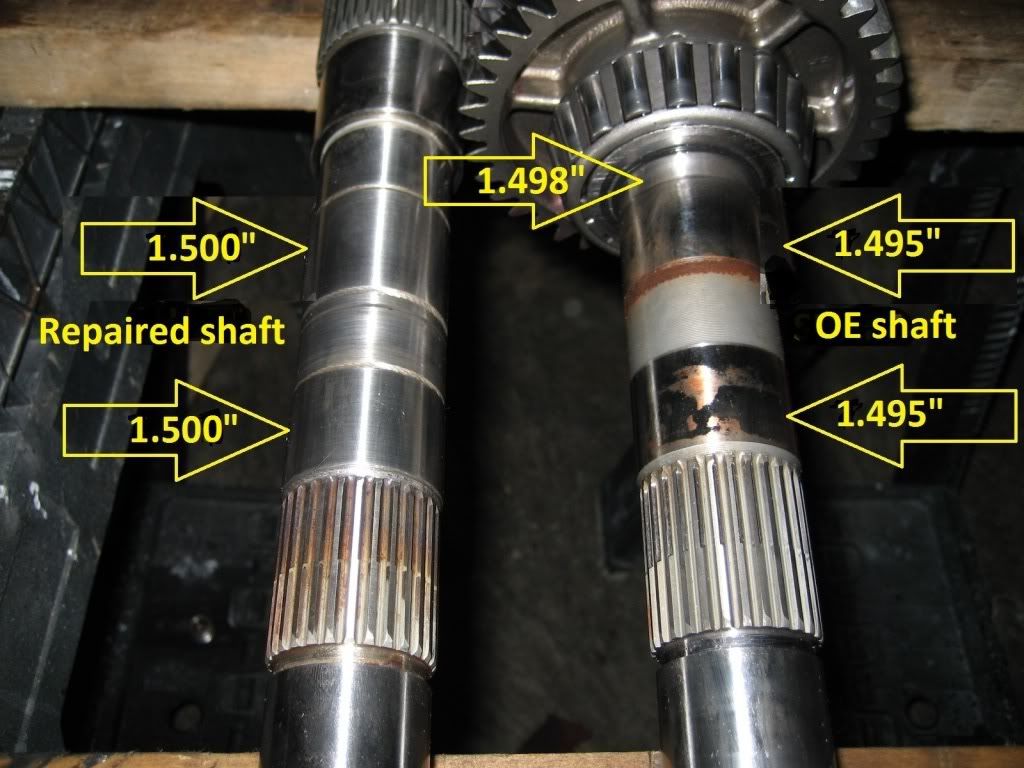

There are two worn journals that are concealed by the 5/6 driven gear. I believe these were intended to provide some interference fit when new but now they both measure ~1.495".

There is evidence that these two journals used to be 1.498" when new because there is a 1/4" area on the front most journal that has not been worn away by the gear. It is just totally obvious that metal has worn off these two journals of the shaft (area concealed by the gear) because there is now a leather like surface which is the scarring of the metal. Anyway, the size of the repaired journal on the repaired main shaft measures 1.500" which will hopefully result in the 5/6 driven being captured much tighter.

Its also obvious that the splines are worn from the gear fluttering around.

Time to start taking the main shaft apart.

I have the entire mainshaft completely out of the transmission. I still need to completely disassemble it and swap all those parts to the repaired shaft. The job thus far still has not overwelming to take apart but I am taking plenty of photos. The shifting shaft and internal mechanisms were a little tricky but I got through it.

There are two worn journals that are concealed by the 5/6 driven gear. I believe these were intended to provide some interference fit when new but now they both measure ~1.495".

There is evidence that these two journals used to be 1.498" when new because there is a 1/4" area on the front most journal that has not been worn away by the gear. It is just totally obvious that metal has worn off these two journals of the shaft (area concealed by the gear) because there is now a leather like surface which is the scarring of the metal. Anyway, the size of the repaired journal on the repaired main shaft measures 1.500" which will hopefully result in the 5/6 driven being captured much tighter.

Its also obvious that the splines are worn from the gear fluttering around.

Time to start taking the main shaft apart.

Last edited by wrd1972; 12-31-2010 at 08:12 AM.

#4

TECH Addict

iTrader: (9)

Where you're pointing to doesn't even come in to play. The 5/6 cluster sits against the large tapered bearing right above the driven 1st gear. If you're going to get any rock, it would be down by the bearing, not in the middle.

In the OEM setup, the splines themselves support the cluster. When they wear, the cluster press will suffer. The correct way of doing this is replacing the mainshaft. Adding material on the shaft in the machined region is just masking the problem. (Like knurling a valve for a loose guide)

In the OEM setup, the splines themselves support the cluster. When they wear, the cluster press will suffer. The correct way of doing this is replacing the mainshaft. Adding material on the shaft in the machined region is just masking the problem. (Like knurling a valve for a loose guide)

Last edited by 85MikeTPI; 12-05-2010 at 05:39 PM.

#6

FormerVendor

iTrader: (23)

Join Date: Aug 2003

Location: Fort Worth, TX

Posts: 800

Likes: 0

Received 0 Likes

on

0 Posts

Where you're pointing to doesn't even come in to play. The 5/6 cluster sits against the large tapered bearing right above the driven 1st gear. If you're going to get any rock, it would be down by the bearing, not in the middle.

In the OEM setup, the splines themselves support the cluster. When they wear, the cluster press will suffer. The correct way of doing this is replacing the mainshaft. Adding material on the shaft in the machined region is just masking the problem. (Like knurling a valve for a loose guide)

In the OEM setup, the splines themselves support the cluster. When they wear, the cluster press will suffer. The correct way of doing this is replacing the mainshaft. Adding material on the shaft in the machined region is just masking the problem. (Like knurling a valve for a loose guide)

Its just a crappy design to begin with. It would have been a lot better if all T56s were like the 03-04 Cobra T56s with 100% splined and pressed fit.

Trending Topics

#8

So the only OE spec interference fit was at the "teeth" of the 5/6 gear and nowhere else? That does seem horribly inadequate looking at the length of the gear. Wonder why they did not create more interference fit using more of the available journal? Just seems stupid to me.

Sorry for the confusion. I thought the burned area in the pic was "intended" to be interference fit. Seemed logical to me anyway.

It now appears that the repaired shaft will indeed, use more of the available journal for the interference fit rather than solely relying on the teeth which are only on the big end of the gear.

Sorry for the confusion. I thought the burned area in the pic was "intended" to be interference fit. Seemed logical to me anyway.

It now appears that the repaired shaft will indeed, use more of the available journal for the interference fit rather than solely relying on the teeth which are only on the big end of the gear.

#9

TECH Addict

iTrader: (9)

So the only OE spec interference fit was at the "teeth" of the 5/6 gear and nowhere else? That does seem horribly inadequate looking at the length of the gear. Wonder why they did not create more interference fit using more of the available journal? Just seems stupid to me.

Sorry for the confusion. I thought the burned area in the pic was "intended" to be interference fit. Seemed logical to me anyway.

It now appears that the repaired shaft will indeed, use more of the available journal for the interference fit rather than solely relying on the teeth which are only on the big end of the gear.

Sorry for the confusion. I thought the burned area in the pic was "intended" to be interference fit. Seemed logical to me anyway.

It now appears that the repaired shaft will indeed, use more of the available journal for the interference fit rather than solely relying on the teeth which are only on the big end of the gear.

#10

There's some slight inference at the other end (near the large bearing), but the splines are the large part of it. If you think about it, cluster doesn't move on the shaft, so how would the middle area of the mainshaft wear.. The splines take all the rotational torque from the driven gears and wear on the spline faces.

I wonder how that heat discoloration occurred in the photo? Is it from the gear fluttering causing the vibe at 80MPH?

#13

TECH Resident

iTrader: (127)

I have plenty of mainshafts sitting around that have perfect splines and they are worn down where the 5-6 cluster rides.

One side of the mainshaft is worn down significantly and the other is perfect. Which leads me to believe that they do wobble inside even if they have perfect spline teeth. I will take pics when I get off of work. If the mainshaft has a tight fit the splines have no room to walk.

One side of the mainshaft is worn down significantly and the other is perfect. Which leads me to believe that they do wobble inside even if they have perfect spline teeth. I will take pics when I get off of work. If the mainshaft has a tight fit the splines have no room to walk.

#14

TECH Resident

iTrader: (5)

I am sure you have probably already checked it but what about your tail shaft bushing? I have a post (that I never got a reply too) about my vibration problem. Mine became amplified after I installed 4.10 gears in my car, drive shaft spinning around 12% faster at every speed compared to stock 3.42. Around 70mph i could feel a vibe that came on during a load, at first it seemed like it was only in 6th but it was there in 5th just harder to notice due to the exhaust and higher engine RPM. I knew the seal was leaking but hadn’t checked for play on the bushing. I put the car on a lift and ran it up to speed while having a friend check under the car. He said the rear-end was smooth and that the vibe was coming from the back of the trans. There was play in the yoke going into the back of the trans.

I bought the Timken 5200 seal kit from Azone and removed the tail shaft this weekend. I pressed it into the housing and the bushing bulged out into the machined oil grove in the housing, there are a few posts going around about this happening. So I ran out and bought 2 more bushings. This time I took everything off the housing and stuck it in the oven and heated it to 500 degrees. I also put the bushings in the freezer. If you look inside the tail shaft housing the machined surface for the bushing is almost 3 inches. The bushings measure 1 7/16" so 2 of them together measure about 2 7/8". So, i decided to put 2 bushings in my housing to have more supported area for the yoke to ride on. That’s exactly what I did. The bushings went in fairly easy with the housing that hot and the bushing cold, I pressed one in from the top and one in from the bottom until the just touched. It was a little tricky but it worked. Now my drive shaft is good and tight, I drove the car yesterday and could tell a difference as soon as I took off. Vibes that I thought were normal in the shifter are gone in all gears and the high speed 5th/6th vibes are gone. Everything is smooth as silk.

The only thing I didn’t like inside the tranny was the amount of metal on the 2 magnets. How much did you find in yours? I thought about going ahead and pulling it out and tearing it down, but it seems to shift fine.

I bought the Timken 5200 seal kit from Azone and removed the tail shaft this weekend. I pressed it into the housing and the bushing bulged out into the machined oil grove in the housing, there are a few posts going around about this happening. So I ran out and bought 2 more bushings. This time I took everything off the housing and stuck it in the oven and heated it to 500 degrees. I also put the bushings in the freezer. If you look inside the tail shaft housing the machined surface for the bushing is almost 3 inches. The bushings measure 1 7/16" so 2 of them together measure about 2 7/8". So, i decided to put 2 bushings in my housing to have more supported area for the yoke to ride on. That’s exactly what I did. The bushings went in fairly easy with the housing that hot and the bushing cold, I pressed one in from the top and one in from the bottom until the just touched. It was a little tricky but it worked. Now my drive shaft is good and tight, I drove the car yesterday and could tell a difference as soon as I took off. Vibes that I thought were normal in the shifter are gone in all gears and the high speed 5th/6th vibes are gone. Everything is smooth as silk.

The only thing I didn’t like inside the tranny was the amount of metal on the 2 magnets. How much did you find in yours? I thought about going ahead and pulling it out and tearing it down, but it seems to shift fine.

#15

I installed one Rockland no walk tailshaft bushing and I am on my second OEM tailshaft bushing now. No improvement at all.

I have also seen other fbody with no vibes and the slip yoke was sloppy as Hell. Also I had a lifted Jeep Wrangler with a sip yoke angle of 14 degrees and it was mega sloppy too and it had no vibes. Based on that I am not convinced the slip yoke has to be extremely snug in the tailshaft bushing.

I had no metal fuzz on the magnets at all. There was a little gold flake in the fluid from breaking in the recent newer tailshaft bushing as the result of a very tight fit. I really wish the problem was a tailshaft bushing.

I have also seen other fbody with no vibes and the slip yoke was sloppy as Hell. Also I had a lifted Jeep Wrangler with a sip yoke angle of 14 degrees and it was mega sloppy too and it had no vibes. Based on that I am not convinced the slip yoke has to be extremely snug in the tailshaft bushing.

I had no metal fuzz on the magnets at all. There was a little gold flake in the fluid from breaking in the recent newer tailshaft bushing as the result of a very tight fit. I really wish the problem was a tailshaft bushing.

#16

TECH Resident

iTrader: (5)

I installed one Rockland no walk tailshaft bushing and I am on my second OEM tailshaft bushing now. No improvement at all.

I have also seen other fbody with no vibes and the slip yoke was sloppy as Hell. Also I had a lifted Jeep Wrangler with a sip yoke angle of 14 degrees and it was mega sloppy too and it had no vibes. Based on that I am not convinced the slip yoke has to be extremely snug in the tailshaft bushing.

I had no metal fuzz on the magnets at all. There was a little gold flake in the fluid from breaking in the recent newer tailshaft bushing as the result of a very tight fit. I really wish the problem was a tailshaft bushing.

I have also seen other fbody with no vibes and the slip yoke was sloppy as Hell. Also I had a lifted Jeep Wrangler with a sip yoke angle of 14 degrees and it was mega sloppy too and it had no vibes. Based on that I am not convinced the slip yoke has to be extremely snug in the tailshaft bushing.

I had no metal fuzz on the magnets at all. There was a little gold flake in the fluid from breaking in the recent newer tailshaft bushing as the result of a very tight fit. I really wish the problem was a tailshaft bushing.

#17

Teching In

Join Date: Jan 2008

Location: Yardville, NJ

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

i am having a simliar problem are the same speeds in my regal with 3.73s and a t56 swap. i read a post last year this time that basically said the same thing about the 5/6 gear needing to be press fit otherwise a vibration may occur under load. has anyone heard of anyone using a retaining compound instead of welding and machining another shaft? does anyone know the shear strength(i guess that would be the term) of a .005" interference on a 1.5 inch diameter steel shaft? i was thinking about trying one of these products http://www.ibgengineering.net/RetainingCompounds.pdf since they restore an interference between .005" and .02" depending on the compound and what shear strength you are looking for. i don't want to overdo it to the point that i have to incinerate the 5/6 gear to get it off if i need to take the trans apart again but i thought this might be a good idea to try since it will allow a press fit fix without having to completely disassemble an otherwise sound trans.

Mike

Mike

#18

TECH Apprentice

iTrader: (5)

damn i wonder if this is my problem... i have a vibration at about 85+... i know in 5th, maybe 6th.. ill have to try another gear. my tires are balanced perfect and the wheels arent bent., I have a moser 12 bolt, 33 spline axles, eaton 4.11 posi, and a dennys driveshaft.. i thought maybe the driveshaft, but ill have to look into this..

#19

TECH Fanatic

iTrader: (6)

Join Date: Oct 2002

Location: Charlotte metro area

Posts: 1,967

Likes: 0

Received 4 Likes

on

4 Posts

The fit of the 5th/6th spool gear to the mainshaft is BOTH a press at the journal on the mainshaft AND a spline interference. The spline is a side-fit NOT an OD fit. This combitation allows a concentric fit to control vibration concerns , as stated in the OP. The "fix" of plating or depositing bonus material to the journal... and then reusing an old( worn) 5th/6th driven gear ( YES THE SPOOL GEAR IS THE DRIVEN GEAR-NOT as was mis stated earlier) is simply a hack repair. Any "good "results are truely accidental and certainly short-lived. The ONLY effective repair for this wear is the mainshaft AND spool gear replacement. This wear is exactly why the later T56 & newer TR6060 designs went with the full-spline mainshaft & separate 5th & 6th driven gears. The provide the control AND address higher torque.

#20

Update.

After closer examination of the wear on the original shaft, There is damage to both the journals areas that are covered by the 5/6 driven gear. Somehow all that fluttering and vibrating just ate away these two areas of the shaft. Again I see evidence that the two journals in question, at one time, measured 1.498" because there is a 1/4" area of the front journal that does not make contact with the 5/6 driven gear. I can also easily feel the transition from worn to unworn with the touch of a finger.

Also after closer inspection, there appears to be enough wear on the inside of the original 5/6 driven gear that I am not getting any intererance fit on the repaired shaft. The inside of the gear also has the leather like texture indicating wear and is measuring anywhere from 1.503" - 1.506" or so with the greatest wear at the 6th gear end. That means that I still have a clearance fit which is no good.

It appears that the ID of a new 5/6 driven gear is 1.498" on the 5th gear end and 1.499" on the 6th gear end.

After closer examination of the wear on the original shaft, There is damage to both the journals areas that are covered by the 5/6 driven gear. Somehow all that fluttering and vibrating just ate away these two areas of the shaft. Again I see evidence that the two journals in question, at one time, measured 1.498" because there is a 1/4" area of the front journal that does not make contact with the 5/6 driven gear. I can also easily feel the transition from worn to unworn with the touch of a finger.

Also after closer inspection, there appears to be enough wear on the inside of the original 5/6 driven gear that I am not getting any intererance fit on the repaired shaft. The inside of the gear also has the leather like texture indicating wear and is measuring anywhere from 1.503" - 1.506" or so with the greatest wear at the 6th gear end. That means that I still have a clearance fit which is no good.

It appears that the ID of a new 5/6 driven gear is 1.498" on the 5th gear end and 1.499" on the 6th gear end.

Last edited by wrd1972; 12-22-2010 at 05:09 PM.