New Mamo Motorsports Mantic twin clutch with pics

#21

It's a reminder and an appreciation of all the time I spent in a product no one ever gets to see after its installed!! Looks great on the shop wall and is a conversation piece for sure

Guys if you have any questions or an interest in purchasing one just reach out to me via email or phone (both of those options preferred over PM's).

I offer this clutch in various configurations based on the application (and who is driving the car) and how mild or aggressive the combo is.

Different friction materials (cerametalic and a premium copper infused organic) and even different thickness marcel as well as a heavier flywheel if that's better suited to your combination.

Cheers,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

The following 2 users liked this post by Tony @ Mamo Motorsports:

NSFW (01-29-2022), wannafbody (01-26-2022)

#22

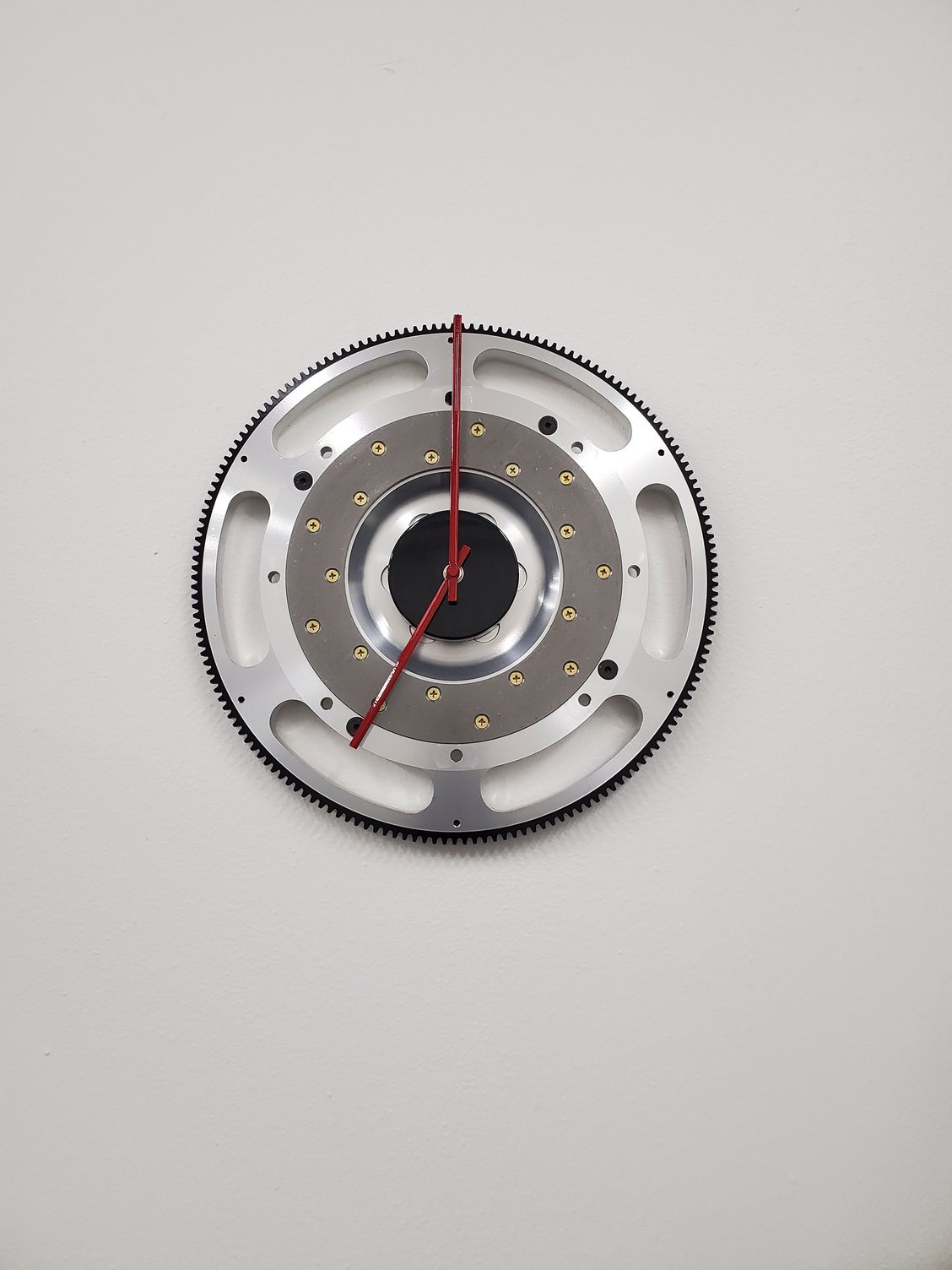

I felt the same way so I took one of the prototype flywheels that was made during this lengthy process with Mantic (I worked on this design with them for over 6 months) and turned it into a nice looking wall clock for my shop!.....LOL

It's a reminder and an appreciation of all the time I spent in a product no one ever gets to see after its installed!! Looks great on the shop wall and is a conversation piece for sure

Guys if you have any questions or an interest in purchasing one just reach out to me via email or phone (both of those options preferred over PM's).

I offer this clutch in various configurations based on the application (and who is driving the car) and how mild or aggressive the combo is.

Different friction materials (cerametalic and a premium copper infused organic) and even different thickness marcel as well as a heavier flywheel if that's better suited to your combination.

Cheers,

Tony

It's a reminder and an appreciation of all the time I spent in a product no one ever gets to see after its installed!! Looks great on the shop wall and is a conversation piece for sure

Guys if you have any questions or an interest in purchasing one just reach out to me via email or phone (both of those options preferred over PM's).

I offer this clutch in various configurations based on the application (and who is driving the car) and how mild or aggressive the combo is.

Different friction materials (cerametalic and a premium copper infused organic) and even different thickness marcel as well as a heavier flywheel if that's better suited to your combination.

Cheers,

Tony

#23

I always felt they had a very high percentage of happy customers and alot of shops seem to swear by their products. To be honest I have seen very little in the way of negative feedback but I didnt scour the Net to find some because the reality is when you ship as many products as they have your bound to have some issues and failures and the feedback I have continually seen over the years has almost always been positive.

Im sorry you had a problem (twice).....wouldn't have blamed you for moving on after the 2nd one failed. Seems that set up wasn't happy in your car but there may have been conditions that helped create that (seems it would take a serious shock load to hurt a solid hub design).

Was this recently or a long time ago? Maybe they have improved the design since then. I did send a copy of your response to Geoff to get his input.....he is a straight shooter and it will be interesting to hear what he has to say

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#24

Geoff was certainly my main contact here in the States but alot of other folks were involved as well. I have followed these guys for the better part of 15 years (met Geoff numerous times during that period).

I always felt they had a very high percentage of happy customers and alot of shops seem to swear by their products. To be honest I have seen very little in the way of negative feedback but I didnt scour the Net to find some because the reality is when you ship as many products as they have your bound to have some issues and failures and the feedback I have continually seen over the years has almost always been positive.

Im sorry you had a problem (twice).....wouldn't have blamed you for moving on after the 2nd one failed. Seems that set up wasn't happy in your car but there may have been conditions that helped create that (seems it would take a serious shock load to hurt a solid hub design).

Was this recently or a long time ago? Maybe they have improved the design since then. I did send a copy of your response to Geoff to get his input.....he is a straight shooter and it will be interesting to hear what he has to say

-Tony

I always felt they had a very high percentage of happy customers and alot of shops seem to swear by their products. To be honest I have seen very little in the way of negative feedback but I didnt scour the Net to find some because the reality is when you ship as many products as they have your bound to have some issues and failures and the feedback I have continually seen over the years has almost always been positive.

Im sorry you had a problem (twice).....wouldn't have blamed you for moving on after the 2nd one failed. Seems that set up wasn't happy in your car but there may have been conditions that helped create that (seems it would take a serious shock load to hurt a solid hub design).

Was this recently or a long time ago? Maybe they have improved the design since then. I did send a copy of your response to Geoff to get his input.....he is a straight shooter and it will be interesting to hear what he has to say

-Tony

#25

Mr scott, what was the driving factor for this clutch over the rps bc2? I’m usually a little behind times now a days but last I thought was the rps was pretty much the go to or holy grail as mr Tony calls it.

none the less, that thing is beautiful. Agree with others, sucks it won’t be seen

none the less, that thing is beautiful. Agree with others, sucks it won’t be seen

#26

Mr scott, what was the driving factor for this clutch over the rps bc2? I’m usually a little behind times now a days but last I thought was the rps was pretty much the go to or holy grail as mr Tony calls it.

none the less, that thing is beautiful. Agree with others, sucks it won’t be seen

none the less, that thing is beautiful. Agree with others, sucks it won’t be seen

I think it's best if I field this one

Bottom line is RPS decided they didnt want to build any more "custom" parts which my lightweight steel flywheel with the extra CNC windows cut into it was one of those.

It requires more set-up and machining time and their core business was busy enough they didnt mind losing the revenue of my stuff and some of the other custom lower volume parts they had made in the past.

That fact coupled with some aggressive recent price increases from them (my cost had gone up over $400 per unit) and a more expensive clutch bearing they were now recommending adding another $100 per unit had basically pushed the retail cost of these clutches into the low/mid 3K range.

It made for a much more difficult sale and it left me no choice but to work with another company on designing a different lightweight clutch option that would work just as well and potentially be more cost effective.

To be honest, I was already pursuing alternative solutions due to the large price increases and then their decision to not make my custom flywheels any longer pretty much sealed that course of action for me. Mantic was my first choice having closely followed them since 2005 or so, always visiting with them at the Tradeshows etc.

This new clutch meets all of the most important criteria I had set forth when I started looking.....significantly lower pricing to the end user, lightweight with a low MOI (moment of inertia), and something that would still drive well and be easy to live with.

This unit is close to $700 less than the most recent RPS pricing, and it has even less MOI considering the total weight is close to a pound less and the Mantic flywheel is made of aluminum with much larger CNC perimeter "lightening windows"

That means a much higher percentage of the clutches mass is closer to the crankshaft's centerline in the Mantic unit requiring less horsepower to accelerate it, putting the extra power that saves into your rear wheels and driveline.

Hoping Scott can get a quick clip of how quickly the engine rev's in a mostly stock C5.....keeping in mind a modded engine with higher compression, better induction and a good heads/cam pkg would rap up alot faster.

The installation of this clutch is easily worth a 15 RWHP gain besides being an awesome clutch that's easy to drive and a sexy piece of machine work to appreciate while your installing it (what can I tell you....I go for that kind of thing.....LOL)

Its a performance upgrade as well as a clutch that drives and works great and you really have to consider both of these things when your deciding about the value this clutch offers for the money spent.

-Tony

PS.....Im still a W/D for the RPS line and can still sell any "standard" clutch they offer on their website, but my unique lightweight option clutch is no longer available. The same twin clutch without the custom flywheel I used to sell weighs about 38 lbs

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 01-29-2022 at 04:36 AM.

#27

I've talked to people who've said that steel prices have tripled in the last 1.5 years. That's affecting the cost of lots of manufactured goods. Hopefully, these prices decrease over the next couple years.

#28

PS.....Im still a W/D for the RPS line and can still sell any "standard" clutch they offer on their website, but my unique lightweight option clutch is no longer available. The same twin clutch without the custom flywheel I used to sell weighs about 38 lbs

#29

Thread Starter

Joined: Jan 2012

Posts: 6,718

Likes: 3,798

From: Dawsonville Ga.

For those whom already purchased a RPS Twin carbon with lightened flywheel from you that need much more clamping force to handle higher hp/tq projects, can those current rps clutches be upgraded to a triple and quad disk rps setup? Already have the lightened flywheel just need a different pressure plate and accompanying accessories.

#31

My Mantic 9000+ Twin Ceremetallic that we ordered direct from Mantic in July 2020 started slipping a week or two ago. No leaks to be found. Debating on trying them again with a twin organic (since I despised the takeoff chatter). I generally don't give a vendor a second chance if there was a premature parts failure that isn't due to human error. I basically want the OEM behavior of a LS7 clutch (that lasted me over 10 years and began slipping only after I installed the 416) with some weight/MOI savings that doesn't effect drivability or reliability. What master cylinder are you using with the MMS Mantic, and which bore diameter?

#32

Thread Starter

Joined: Jan 2012

Posts: 6,718

Likes: 3,798

From: Dawsonville Ga.

My Mantic 9000+ Twin Ceremetallic that we ordered direct from Mantic in July 2020 started slipping a week or two ago. No leaks to be found. Debating on trying them again with a twin organic (since I despised the takeoff chatter). I generally don't give a vendor a second chance if there was a premature parts failure that isn't due to human error. I basically want the OEM behavior of a LS7 clutch (that lasted me over 10 years and began slipping only after I installed the 416) with some weight/MOI savings that doesn't effect drivability or reliability. What master cylinder are you using with the MMS Mantic, and which bore diameter?

The following users liked this post:

JimMueller (04-19-2022)

#33

Im using a new OEM slave with OEM original master. This is in a 25k mile ‘03 C5Z. I have zero takeoff chatter. Not even a hint of it. Are you using sprung or non-sprung discs? How many miles do you have on the Mantic? Have you noticed pedal creep that could possibly be related to the slippage?

Last edited by JimMueller; 04-19-2022 at 12:16 PM.

#34

Thread Starter

Joined: Jan 2012

Posts: 6,718

Likes: 3,798

From: Dawsonville Ga.

I can't find the photos I took of the clutch before it was installed but I inferred from Geoff that all of their disc hubs were sprung on this model? I'm not sure on the mileage, but it's been about 13K since summer of 2019 (engine rebuild) without any unusually long trips... maybe 10K on the clutch? The pedal engagement point does seem to have moved up. Once in awhile it's notchy getting it into gear from neutral.

The following users liked this post:

JimMueller (04-19-2022)

#35

I just took the shop at their word that the new Tick adj master I had them install was properly adjusted. I provided the Tick shims but I was told they were not needed thus not installed. Do you think adjusting the master will help now or clutch now too far gone? Which way would I need to adjust the master... shorten the rod?

#36

Thread Starter

Joined: Jan 2012

Posts: 6,718

Likes: 3,798

From: Dawsonville Ga.

I just took the shop at their word that the new Tick adj master I had them install was properly adjusted. I provided the Tick shims but I was told they were not needed thus not installed. Do you think adjusting the master will help now or clutch now too far gone? Which way would I need to adjust the master... shorten the rod?

The following users liked this post:

JimMueller (04-19-2022)

#37

Last edited by QwkTrip; 04-20-2022 at 03:46 AM.

#39

I think Chevelle's advice about the adjustable master is spot on. If you didn't slip the clutch badly and properly re-adjust it that should do the trick

If you need any help with a new clutch or any other advice feel free to reach out (Email or phone call preferred)

But I would agree that at this point a new thread dedicated to your situation would be helpful to get other peoples input that may have experienced a similar situation

Cheers,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

The following 2 users liked this post by Tony @ Mamo Motorsports:

JimMueller (04-21-2022), Project GatTagO (06-25-2023)