T56 Beef up?

#1

Teching In

Thread Starter

iTrader: (1)

Join Date: Jan 2008

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Ive read many things and seen many ways to beef up a t56.

But im wondering what are the known problem spots with the t56 so i can gather everything up in one thread.

as far as im concerned, I have a t56 from a '94 camaro SS with unknown miles.

So im looking to prolong the life of this tranny and still be able to give it hell without blowing it up like my last 3 T-5's I ate in a 2 month span.

I have heard about 3-4 billet shift key, 3-4 steel shift fork, bronze fork pads, and the "drill" mod will help out. is 3-4 the usual problem? or is there anything else i can do on a budget?

Please correct anything that is wrong or set the facts straight for me. I just dont want to overspend on a simple beef up.

But im wondering what are the known problem spots with the t56 so i can gather everything up in one thread.

as far as im concerned, I have a t56 from a '94 camaro SS with unknown miles.

So im looking to prolong the life of this tranny and still be able to give it hell without blowing it up like my last 3 T-5's I ate in a 2 month span.

I have heard about 3-4 billet shift key, 3-4 steel shift fork, bronze fork pads, and the "drill" mod will help out. is 3-4 the usual problem? or is there anything else i can do on a budget?

Please correct anything that is wrong or set the facts straight for me. I just dont want to overspend on a simple beef up.

#2

Launching!

iTrader: (2)

Join Date: May 2008

Location: Acworth

Posts: 257

Likes: 0

Received 0 Likes

on

0 Posts

if it grinds at all going into any geer espesially if you speed shifting get new syncro's asap and don't speed shift cause you will brake a geer!

skip shift sucks on it so get an iliminator its only about $30

and use automatic transmission fluid when you change fluids even though its a manual

other then that the transmission is a beast

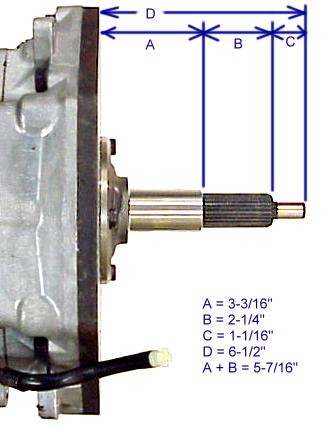

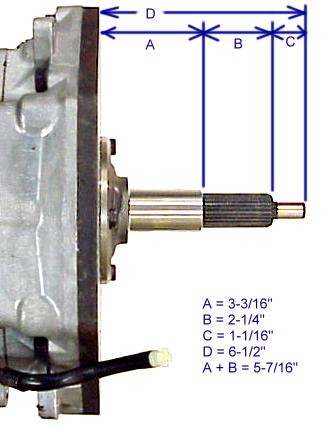

also if you install it on an LS motor it wont fit cause the (**** i forgot its name but here is a picture of it its on the bottom right on its side there are two more set up right.... on the tranny it come out the front of the tranny and goes in the motor you can see it on the second pic of the transmission) well any way its about an inch too short and it will brake your slave cylinder and you'll just have to take it all apart again and a slave cylindar is about $70 also the slaves are different between 93-97 and 98-02 the 93-97 were had a manual slave cylindarand the 98-02 had a hydrolic slave cylindar i'll include a pic of that too

its on its side on bottom right and there are two that are right side up

here is the difference in the part

hydrolic slave cylindar

skip shift sucks on it so get an iliminator its only about $30

and use automatic transmission fluid when you change fluids even though its a manual

other then that the transmission is a beast

also if you install it on an LS motor it wont fit cause the (**** i forgot its name but here is a picture of it its on the bottom right on its side there are two more set up right.... on the tranny it come out the front of the tranny and goes in the motor you can see it on the second pic of the transmission) well any way its about an inch too short and it will brake your slave cylinder and you'll just have to take it all apart again and a slave cylindar is about $70 also the slaves are different between 93-97 and 98-02 the 93-97 were had a manual slave cylindarand the 98-02 had a hydrolic slave cylindar i'll include a pic of that too

its on its side on bottom right and there are two that are right side up

here is the difference in the part

hydrolic slave cylindar

Last edited by Fotis; 05-19-2008 at 01:21 AM.

#3

Teching In

Thread Starter

iTrader: (1)

Join Date: Jan 2008

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Forgot to give a little background info.

This is going into a 1989 Iroc with a 2 piece RMS.

thats why i went with the LT style.

Engine is putting ~380 fwhp and with the TPI setup...too much torque for a T5

I have gone 12.87 @ 106 with the t5 before it blew again... (1.7 60')

I have been told that skip shift will be disabled as long as i plug nothing into it.

and reverse lockout just needs a 12v + Ground to function so im going to wire it to my break lights.

not to flame to your good response, but this is knowledge I have seen in other threads, Im trying to consolidate all the t56 flaws in this thread for future swaps and matinence rebuilds

This is going into a 1989 Iroc with a 2 piece RMS.

thats why i went with the LT style.

Engine is putting ~380 fwhp and with the TPI setup...too much torque for a T5

I have gone 12.87 @ 106 with the t5 before it blew again... (1.7 60')

I have been told that skip shift will be disabled as long as i plug nothing into it.

and reverse lockout just needs a 12v + Ground to function so im going to wire it to my break lights.

not to flame to your good response, but this is knowledge I have seen in other threads, Im trying to consolidate all the t56 flaws in this thread for future swaps and matinence rebuilds

#4

Launching!

iTrader: (2)

Join Date: May 2008

Location: Acworth

Posts: 257

Likes: 0

Received 0 Likes

on

0 Posts

Forgot to give a little background info.

This is going into a 1989 Iroc with a 2 piece RMS.

thats why i went with the LT style.

Engine is putting ~380 fwhp and with the TPI setup...too much torque for a T5

I have gone 12.87 @ 106 with the t5 before it blew again... (1.7 60')

I have been told that skip shift will be disabled as long as i plug nothing into it.

and reverse lockout just needs a 12v + Ground to function so im going to wire it to my break lights.

not to flame to your good response, but this is knowledge I have seen in other threads, Im trying to consolidate all the t56 flaws in this thread for future swaps and matinence rebuilds

This is going into a 1989 Iroc with a 2 piece RMS.

thats why i went with the LT style.

Engine is putting ~380 fwhp and with the TPI setup...too much torque for a T5

I have gone 12.87 @ 106 with the t5 before it blew again... (1.7 60')

I have been told that skip shift will be disabled as long as i plug nothing into it.

and reverse lockout just needs a 12v + Ground to function so im going to wire it to my break lights.

not to flame to your good response, but this is knowledge I have seen in other threads, Im trying to consolidate all the t56 flaws in this thread for future swaps and matinence rebuilds

#5

10 Second Club

iTrader: (28)

I have heard about 3-4 billet shift key, 3-4 steel shift fork, bronze fork pads, and the "drill" mod will help out. is 3-4 the usual problem? or is there anything else i can do on a budget?

Please correct anything that is wrong or set the facts straight for me. I just dont want to overspend on a simple beef up.

Please correct anything that is wrong or set the facts straight for me. I just dont want to overspend on a simple beef up.

#6

TECH Fanatic

iTrader: (6)

Join Date: Oct 2002

Location: Charlotte metro area

Posts: 1,967

Likes: 0

Received 4 Likes

on

4 Posts

If its strength you want, start with an '03/'04 Viper gearset. The 9310 single piece cluster ,2nd and input make it the strongest. Also the 30T output shaft is much beefier.Vipers have carbon blockers and an iron 3/4 shift fork std.

#7

When I pulled my T-56 apart I did the usual 3-4 cast iron, brass pads, billit keys, etc... What I did notice was from lugging the car in 5th and 6th gear it wore out the shaft, the 1 piece 5-6 gearset was shot also. (Could of been form powershifting 4-5  ) You will see where the shaft and gearset is splined it will have thinned out the splines to where they would just strip in no time. I also went with the carbon blocker rings, you will be set after that. You will not believe the difference of how smooth it will shift compared to other T-56's that are still stock. Also I have an extra set of shims to get the endplay set correctly, PM if your interested in them. They will cost you roughly $25 to purchase them new, I have them sitting in the drawer since I ended up with two packs of them.

) You will see where the shaft and gearset is splined it will have thinned out the splines to where they would just strip in no time. I also went with the carbon blocker rings, you will be set after that. You will not believe the difference of how smooth it will shift compared to other T-56's that are still stock. Also I have an extra set of shims to get the endplay set correctly, PM if your interested in them. They will cost you roughly $25 to purchase them new, I have them sitting in the drawer since I ended up with two packs of them.

) You will see where the shaft and gearset is splined it will have thinned out the splines to where they would just strip in no time. I also went with the carbon blocker rings, you will be set after that. You will not believe the difference of how smooth it will shift compared to other T-56's that are still stock. Also I have an extra set of shims to get the endplay set correctly, PM if your interested in them. They will cost you roughly $25 to purchase them new, I have them sitting in the drawer since I ended up with two packs of them.

) You will see where the shaft and gearset is splined it will have thinned out the splines to where they would just strip in no time. I also went with the carbon blocker rings, you will be set after that. You will not believe the difference of how smooth it will shift compared to other T-56's that are still stock. Also I have an extra set of shims to get the endplay set correctly, PM if your interested in them. They will cost you roughly $25 to purchase them new, I have them sitting in the drawer since I ended up with two packs of them. Trending Topics

#8

Teching In

Thread Starter

iTrader: (1)

Join Date: Jan 2008

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

lol after i read totally off topic posts, i came across yours! so will the carbon syncro's along with the previously listed really handle that torque? I'd expect less but I hear these 6 speeds are a glutton for punishment.

My biggest problem with the t5 wasnt the shifting mechanism's... it was simply my torque shreading the teeth off of the gears every time I hit 3rd... ( I granny shift a lot)

#9

10 Second Club

iTrader: (28)

Thank you!!!

lol after i read totally off topic posts, i came across yours! so will the carbon syncro's along with the previously listed really handle that torque? I'd expect less but I hear these 6 speeds are a glutton for punishment.

My biggest problem with the t5 wasnt the shifting mechanism's... it was simply my torque shreading the teeth off of the gears every time I hit 3rd... ( I granny shift a lot)

lol after i read totally off topic posts, i came across yours! so will the carbon syncro's along with the previously listed really handle that torque? I'd expect less but I hear these 6 speeds are a glutton for punishment.

My biggest problem with the t5 wasnt the shifting mechanism's... it was simply my torque shreading the teeth off of the gears every time I hit 3rd... ( I granny shift a lot)

The problem with those T5's is that the case distorts with that kind of torque and it eats itself to pieces. There's a reason GM wouldn't even put them behind a TPI 350.

#10

I have a 97 trans and like others went with steel 3-4 fork since my aluminum one was very sloppy on the shift rail, (common problem) 3-4 solid syncro keys (mine were broken in the trans I bought.....VERY common problem), and also got the carbon fiber syncros.

I went to put my trans together this last weekend and move onto modifying it for a cable drive speedo, and pulled the 3-4 syncro hub and found this. Had melted plastic coming out from behind the 3-4 hub and plastic melted onto my 3rd gear. I'd not torn down every component so I could keep them in order as much as possible and build sub assemblies one at a time, but never expected this and never saw any mention of this spacer until I did search and found a quick mention of it.

What the picture is of is my 3rd gear bearing spacer. From 93-97 they used this plastic spacer, and 98 and up use a steel spacer from the info I found. I ordered one from my dealer for $8.33. He couldn't tell me if this was a steel one, but he did look it up for a 99 trans. GM part number is 12369466. When it comes in I'll post and let you know if the replacement is steel or plastic. If it's not steel I'll keep searching until I find a steel one, or make one up myself if necessary. I'll not put a plastic one back in under any circumstances. The trans only had 60,000 miles on it and this happened. I'm not going to take a chance on ruining a good transmission using another plastic spacer.

I'd go ahead and order one along with the rebuild kit if I were you. Not having this part cost me a week's delay unfortunately. Hopefully others will read this not be delayed like I was.

I went to put my trans together this last weekend and move onto modifying it for a cable drive speedo, and pulled the 3-4 syncro hub and found this. Had melted plastic coming out from behind the 3-4 hub and plastic melted onto my 3rd gear. I'd not torn down every component so I could keep them in order as much as possible and build sub assemblies one at a time, but never expected this and never saw any mention of this spacer until I did search and found a quick mention of it.

What the picture is of is my 3rd gear bearing spacer. From 93-97 they used this plastic spacer, and 98 and up use a steel spacer from the info I found. I ordered one from my dealer for $8.33. He couldn't tell me if this was a steel one, but he did look it up for a 99 trans. GM part number is 12369466. When it comes in I'll post and let you know if the replacement is steel or plastic. If it's not steel I'll keep searching until I find a steel one, or make one up myself if necessary. I'll not put a plastic one back in under any circumstances. The trans only had 60,000 miles on it and this happened. I'm not going to take a chance on ruining a good transmission using another plastic spacer.

I'd go ahead and order one along with the rebuild kit if I were you. Not having this part cost me a week's delay unfortunately. Hopefully others will read this not be delayed like I was.

#11

LS1TECH Sponsor

iTrader: (5)

The reason that plastic spacer is melted is because when the keys broke they wedged the blocker ring causing it to get hot. Theres really nothing wrong with the plastic spacer, for that matter the cage on the bearing is plastic also. There is a steel one available, but they deffinately didn't come factory in all 98-up LS1 t56's. If you cant find one give us a call and I'll get one sent out to you.

#12

TECH Fanatic

iTrader: (6)

Join Date: Oct 2002

Location: Charlotte metro area

Posts: 1,967

Likes: 0

Received 4 Likes

on

4 Posts

Actually , the plastic spacer is the newer part that replaces the steel one. You will look a long time to find a steel spacer and it won't be a new one. It is not often these end up this way. This can happen if the 3rd gear synchro sees excessive heat . That type of heat would be caused by driving the box a long time after it needed a rebuild. It can also be caused by operation with extremely contaminated oil( chunks of debris in it and some lodged in the gear bore)

You should be alright with the new plastic spacer assembled correctly and freshen the box. The spacer is under the cone portion of the 3rd speed driven gear. This places the bearing under the gear mesh portion of the gear ( that needs the bearing support).

You should be alright with the new plastic spacer assembled correctly and freshen the box. The spacer is under the cone portion of the 3rd speed driven gear. This places the bearing under the gear mesh portion of the gear ( that needs the bearing support).

#13

What everyone has said to upgrade is what I ended up with which was the 2A package but the 1A is the same minus the 5/6 slider. I guess the lt1 t56 transmissions have smaller notches on the 2nd gear than the newer ls1 t56. I have a 99 t56 which from what Amber said had a 2nd gear the same as the lt1. In the end I've spent close to $3k on everything from the clutch to the driveshaft. My transmission was from a wrecked camaro ss and well you can put 2 and 2 together bad driver = bad tranny = large bill .

.

.

.