ARP2000 to block clearance? (402 LS2)

#1

Launching!

Thread Starter

iTrader: (1)

Join Date: Dec 2014

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

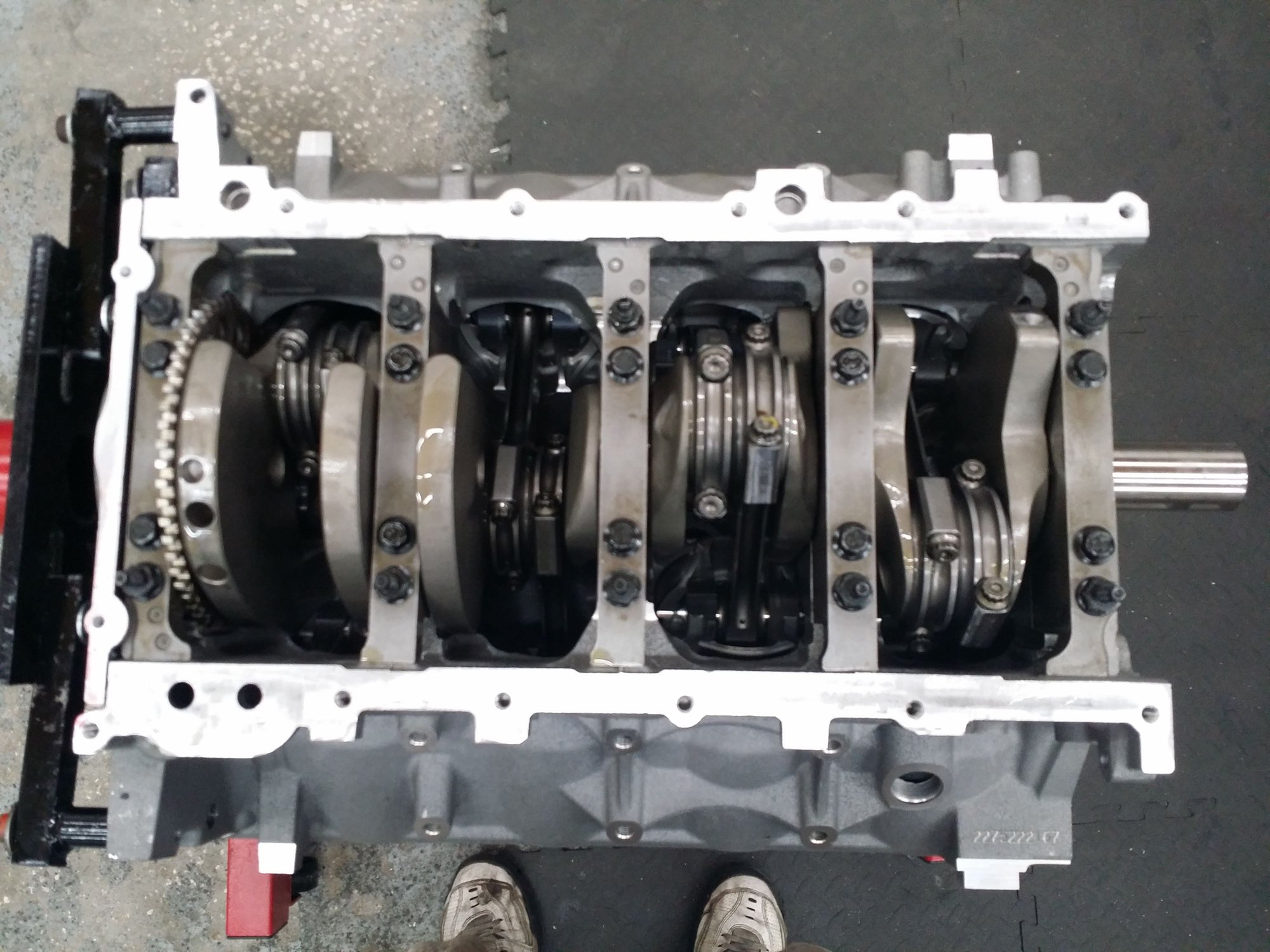

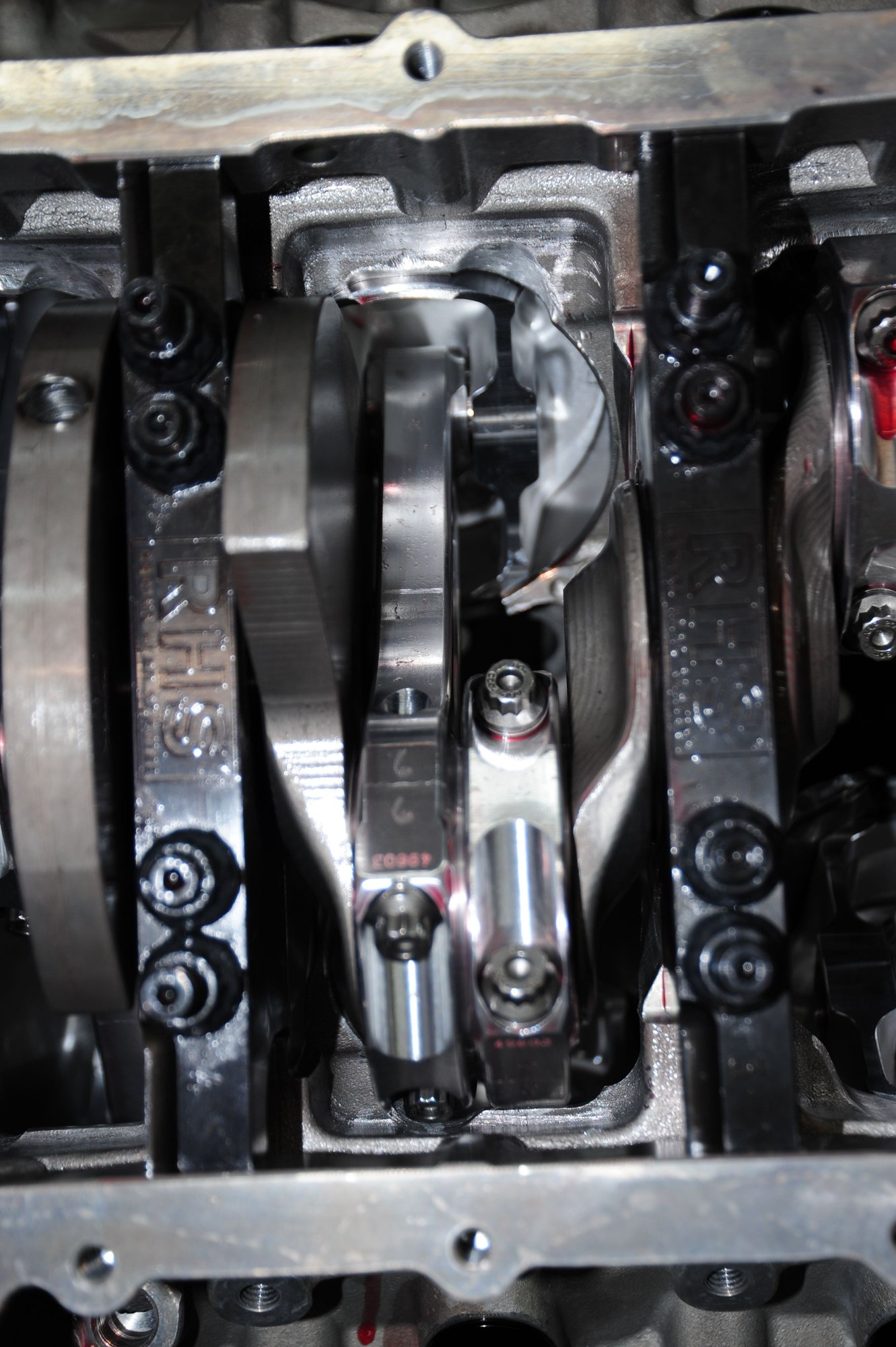

LS2 Stroker Clearance https://imgur.com/gallery/ro4Xb

There's the best picture I could get of the clearance. We got the rings gapped and got the first rod and pistons in, haven't torqued the rod bolts down yet, just by hand with a socket. It's really really close in my opinion, but then again this is the first stroker I've ever put together. Setup is a 4" Lunati crank, 6.125" Lunati H-beam rods with ARP2000 bolts, and a Weisco +5cc dome aluminium piston. Main caps are torqued and degreed in the picture so the crank is in place properly. Block already bored and decked by the machine shop.

Thoughts? It's only pretty close on this side, but it's still making me worry a little...

#2

TECH Senior Member

That's a little TOO close for my comfort, but that's just me.....

#4

TECH Senior Member

I think you could grind clearance notches in the cylinder bottoms without ill effect, but check with some of the real experts on here to be sure.

#5

TECH Fanatic

iTrader: (1)

Mark it and clearance with a hand carbide. Nothing bad will come from grinding in clearance here, but a lot of bad will come from the bolts hitting the block from flex and thermal expansion. I generally go a little over board here and give about .100" - .125" radial clearance. It will move a little less forward and aft. Just make sure that there are no burrs on the inside of the cylinder to scrape on the piston as it moves.

Last edited by Crf450r420; 10-29-2017 at 10:33 PM.

#7

Launching!

Thread Starter

iTrader: (1)

Join Date: Dec 2014

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

Thanks everyone for the pictures and advice! The machine shop didn't listen to me because I had seen guys need to clearance LS2 blocks for a 400+ stroker. Gonna have a nice little chat with the owner tomorrow to see what he can do for me since he had my block for almost a week longer than he was supposed to. Either that or a local friend of mine said he'd come and help me in trade for moonshine lol

Trending Topics

#9

TECH Senior Member

The moonshine deal sounds good if you don't want to learn for yourself.... kind of a painless deal, lol

#10

Launching!

Thread Starter

iTrader: (1)

Join Date: Dec 2014

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

He's going to be there for guidance, he's built a ton of LS motors for the speed shop he works at. Since this is my first time and my GTO is my baby, I'd rather have two sets of eyes. My other question is that I have brand new Chevy Performance main cap bolts, and since I'm assuming the crank and everything need to come out to safely grind, can I reuse those bolts?

#11

ModSquad

iTrader: (6)

He's going to be there for guidance, he's built a ton of LS motors for the speed shop he works at. Since this is my first time and my GTO is my baby, I'd rather have two sets of eyes. My other question is that I have brand new Chevy Performance main cap bolts, and since I'm assuming the crank and everything need to come out to safely grind, can I reuse those bolts?

Take caution...there are water jackets in there somewhere...

#13

TECH Fanatic

iTrader: (1)

Torque to yield bolts have a few torques in them or you would have to change the bolts from just a line hone. My rule is I never use them again if the motor was ran and this would be your 3rd torque if you did a line hone, so in my mind the last. The stock line hone is only off by a couple 10ths from the factory.

Tape up the oil passages in the mains and most of the metal will fall out through the cylinder. Then blow off the rest in the webs. Remove the tape and do a clean with brake cleaner and air. Your buddy will have his own process, so if you trust him, trust him.

Tape up the oil passages in the mains and most of the metal will fall out through the cylinder. Then blow off the rest in the webs. Remove the tape and do a clean with brake cleaner and air. Your buddy will have his own process, so if you trust him, trust him.

#14

11 Second Club

iTrader: (2)

Another "less messy" fix would be to remove that rod bolt and grind the head of it for clearance It will only lighten it a few grams ands shouldn't ruin the balance job

I've actually shortened the twelve point head to half its height and as long as you can torque it up with a quality brand socket it will be fine

No main bolts issues. No shavings. Nothing to clean but the rod bolt/s

I've actually shortened the twelve point head to half its height and as long as you can torque it up with a quality brand socket it will be fine

No main bolts issues. No shavings. Nothing to clean but the rod bolt/s

#15

Just remove the needed material and you'll be fine. If you're this worried about it, I'm sure you'll be extremely careful when doing this job.

All of the answers are in this thread. Tape up the oil galleys and take great care blowing out all leftover debri inside and outside of the block especially in the oil galleys.

(I would have cleaned the oil galleys anyways because you can't trust anyone and this just came from the machine shop)

Or run it and let it clearance itself out

All of the answers are in this thread. Tape up the oil galleys and take great care blowing out all leftover debri inside and outside of the block especially in the oil galleys.

(I would have cleaned the oil galleys anyways because you can't trust anyone and this just came from the machine shop)

Or run it and let it clearance itself out

#16

TECH Senior Member