Holley Sniper intake review

#1

OK guys, I was reluctant to be one of the first to buy it mainly because I couldn't find any hands on reviews. The intake is made in China which I really don't like. So I called Holley up and asked a few questions. One of them was about quality control. The Holley rep told me each intake is individually tested for proper craftsmanship and integrity. Each intake is pressure tested to 30psi. I asked if it was done in batches or individualy. He assured me it was individually. So what do I do? I check to see if it will fit under the cowl of my car. Cannot find any information on a 4th Gen fbody with this intake installed. So I think as but it for a few days and not willing to throw down thousands of dollars on a Beck or Wilson intake and not willing to sacrifice my wipers I call my guy Eli over at Tick Performance and place my order. Four days later I receive the intake. It's boxed very well. After unboxing and setting it on the kitchen table I'm thinking this thing is beautiful. Here's a couple pictures

I then started to attach the fuel rails and first thing I noticed was gritty cap in the threads. Be sure to run the bolts through the threads first before attaching the rails just to make sure you don't cross thread the bolts. Now for more candy.

O-ring machining looks beautiful.

Fuel rails look great. Come with crossover line and the two 90 degree fittings to connect it to the supplied -8an O-ring fittings. Intake came with a total of 4 O-ring fittings and one O-ring cap.

Supplied intake gaskets installed

Intake gasket comes pre-installed

Intake runners look real nice

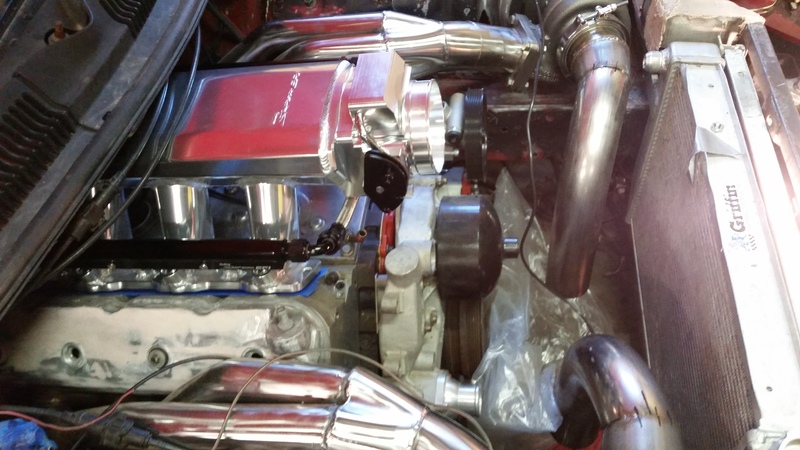

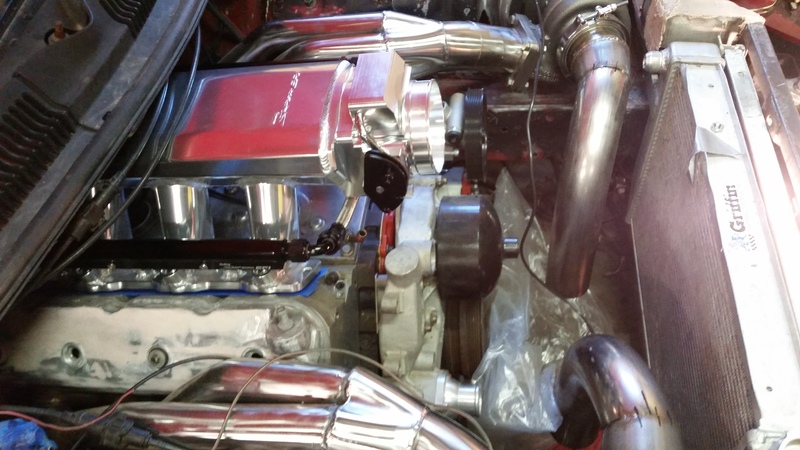

Now for the meat and potatoes, will it fit? Initially, no it would not. Did I make it fit?

Yup... sure did. I took a small hammer a massaged the cowl a little bit. Not much but there is about 1/8" clearance between the cowl and the intake.

So after being happy it fit and looking at my intake on the floor I noticed there was no revision for my MAP sensor. After talking to my fabricator he said I could use an old style map sensor and use one of the 4 vacuum ports on the bottom to connect it. After all was said and done I went to close the hood and it would not latch because the throttle body was too tall. Have not taken it any further but where it's hitting I think can be clearanced. It's hitting on part of the hood that has a reinforcement. Trim a small piece out and re-fiberglass it. Anyway that's about it for now and thanks to Eli over at Tick Performance for working with me.

I then started to attach the fuel rails and first thing I noticed was gritty cap in the threads. Be sure to run the bolts through the threads first before attaching the rails just to make sure you don't cross thread the bolts. Now for more candy.

O-ring machining looks beautiful.

Fuel rails look great. Come with crossover line and the two 90 degree fittings to connect it to the supplied -8an O-ring fittings. Intake came with a total of 4 O-ring fittings and one O-ring cap.

Supplied intake gaskets installed

Intake gasket comes pre-installed

Intake runners look real nice

Now for the meat and potatoes, will it fit? Initially, no it would not. Did I make it fit?

Yup... sure did. I took a small hammer a massaged the cowl a little bit. Not much but there is about 1/8" clearance between the cowl and the intake.

So after being happy it fit and looking at my intake on the floor I noticed there was no revision for my MAP sensor. After talking to my fabricator he said I could use an old style map sensor and use one of the 4 vacuum ports on the bottom to connect it. After all was said and done I went to close the hood and it would not latch because the throttle body was too tall. Have not taken it any further but where it's hitting I think can be clearanced. It's hitting on part of the hood that has a reinforcement. Trim a small piece out and re-fiberglass it. Anyway that's about it for now and thanks to Eli over at Tick Performance for working with me.

#4

9 Second Club

IMO you would be well advised to make stronger rail brackets.

Supporting the rails from one side only, with a thin bit if metal is asking for things to bend and **** fuel all over your hot engine bay.

Or adapt the brackets so they pull directly downwards from both sides of the rail.

At the end of the day it may be Chinese...as if everyone didnt know. They do still look nice.

Supporting the rails from one side only, with a thin bit if metal is asking for things to bend and **** fuel all over your hot engine bay.

Or adapt the brackets so they pull directly downwards from both sides of the rail.

At the end of the day it may be Chinese...as if everyone didnt know. They do still look nice.

#5

10 Second Club

iTrader: (10)

You are correct but if you look at these rails that are not the standard Holley efi rails. Like in the post above, they are a revised version of the original China rails that used npt. Either way, this intake certainly appears to be improved over the original China versions.

Trending Topics

#9

#14

TECH Veteran

iTrader: (7)

Good write up-is the intake for a 92mm TB-I remember playing around with TB's there were 2 diff 4 bolt patterns, I think the 90 had a diff one than a 92

Sometimes you can raise the trans mount a tiny bit to dip the front of the engine for clearance, and not throw off the driveline angle

Sometimes you can raise the trans mount a tiny bit to dip the front of the engine for clearance, and not throw off the driveline angle

#16

8 Second Club

iTrader: (13)

That seems odd since the similar styled ebay intake gained 52hp on an NA engine compared to a stock intake.

#17

TECH Apprentice

iTrader: (2)

Join Date: Nov 2011

Location: Newport News, VA

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

To me, it looks like the stacks on the inside of the plenum would hurt more than help. Air coming through the TB is going to pile the side of the stack and create a ton of turbulence inside the plenum. Also, the turbulence is going to kill any velocity you have going into the intake. The plenum around the stack kind of negates the benefits of a velocity stack.

I think it would make more power if you cut the stacks off on the inside of the plenum.

I think it would make more power if you cut the stacks off on the inside of the plenum.

#19

TECH Fanatic

iTrader: (1)

#20

8 Second Club

iTrader: (13)

To me, it looks like the stacks on the inside of the plenum would hurt more than help. Air coming through the TB is going to pile the side of the stack and create a ton of turbulence inside the plenum. Also, the turbulence is going to kill any velocity you have going into the intake. The plenum around the stack kind of negates the benefits of a velocity stack.

I think it would make more power if you cut the stacks off on the inside of the plenum.

I think it would make more power if you cut the stacks off on the inside of the plenum.