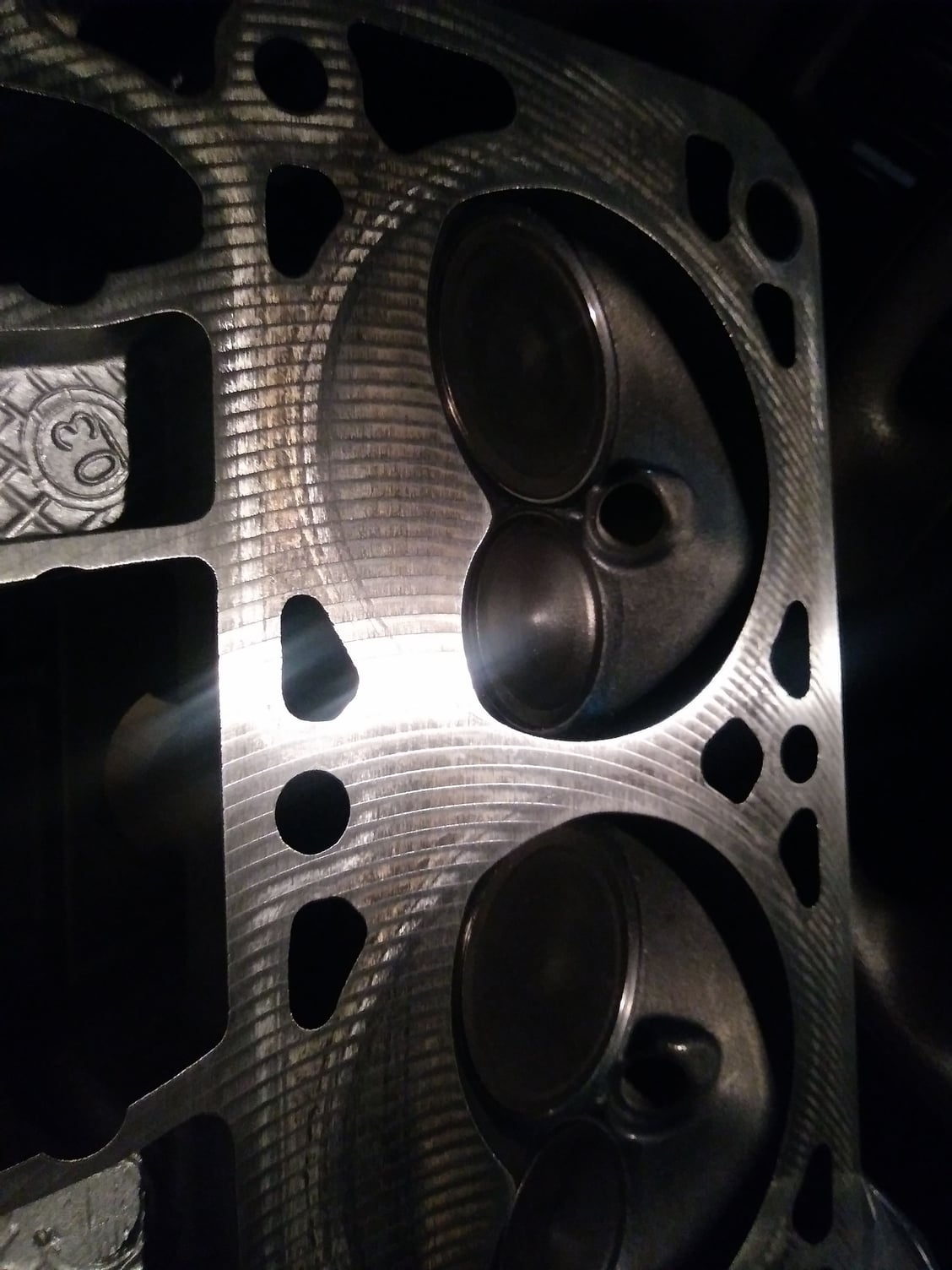

Just got my heads back from the machine shop

#1

Staging Lane

Thread Starter

Sent them in to get a valve job an the springs installed since i didnt have a tool.. As soon as i posted a pic on social media my buddy informed me that it was a shitty resurface job an that my heads will cause a head gasket leak alot faster.. Any insight?

#5

Staging Lane

Thread Starter

" HE TOLD ME (Try sliding your finger nail down the resurface area if it feels like ridges and bumps, it mean you will burn your gaskets very fast. The Black lines you see are stripes that were skipped from the cutting blade. I'm just looking out bro but hopefully everything comes out good)

#6

TECH Fanatic

I can't say I've seen a resurface ever look like that. That looks like the machine may need to get looked at... Every head I've had done is always clean and flat with nothing that pronounced. I guess if you can't feel it under a fingernail then maybe it's just superficial? Still doesn't look right though.

#7

TECH Senior Member

I've seen plenty of milled heads by good shops, and NONE of them looked like these. Something's wrong here....

Trending Topics

#8

11 Second Club

iTrader: (3)

I've never seen that either but like ChopperDoc said. If you run your finger nail across the surface of the head and you can feel the change in the surface that's not good!

#10

TECH Fanatic

I would take those to a different machine shop if the one you got them back from won't stand by their work, which is clearly shotty. Have them decked down a bit more. I can't tell by the pics if those are 4" bores, but if they are order some LS9 gaskets and call it a day. The compressed thickness on those is .058", so they can offset the mistake and additional milling.

#11

Staging Lane

Thread Starter

I would take those to a different machine shop if the one you got them back from won't stand by their work, which is clearly shotty. Have them decked down a bit more. I can't tell by the pics if those are 4" bores, but if they are order some LS9 gaskets and call it a day. The compressed thickness on those is .058", so they can offset the mistake and additional milling.

#12

TECH Fanatic

That really just depends on your ptv clearance. You can install them like that with the old gaskets and check ptv before deciding how much you can safely shave off. Lots of guys mill their heads a lot more than that AND run thinner gaskets to boost compression... including myself, though I went with LS9 gaskets for my LS3. I also have valve reliefs though, so ptv isn't a big deal for me.

#13

TECH Fanatic

And you won't be able to run the LS9's because of your bore. Just get a good check on ptv, which is pretty easy with some clay on the piston. Make sure you put some oil in the chamber and on the piston though so the clay doesn't stick to anything. It makes a real mess if it sticks.

#14

TECH Junkie

I would have them cleaned up somewhere else as opposed to running a thicker gasket. Don't go to a thicker gasket.

What cam are you running?

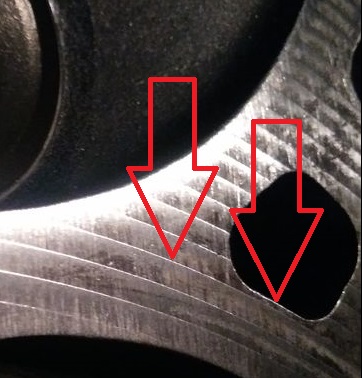

Here is a picture of what's on my car milled .030"

And you won't be able to run the LS9's because of your bore. Just get a good check on ptv, which is pretty easy with some clay on the piston. Make sure you put some oil in the chamber and on the piston though so the clay doesn't stick to anything. It makes a real mess if it sticks.

https://ls1tech.com/forums/generatio...ve-method.html

#15

That's horrific. That's not going to seal. There are hard corners on each one of those swipes - clearly one of the inserts on his cutter isn't seated properly. As an actual machinist for over 21 years, I have the authority to identify **** like that - and that's exactly what that is - ****. Do not accept those.

#16

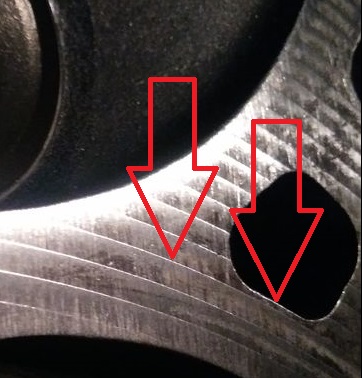

Notice how you see the exact same reflection in both of these places even though one is a hole and the other is supposedly a smooth surface? That's because there's a hard edge in both of these spots. This is a tell-tale sign that there's a mis-match in one of the inserts.

This is what a typical cutter looks like on an engine mill. It's a large diameter tool - upwards of 12" - and it has a ton of inserts. All of these inserts need to be set within a "tenth" or so to make sure the finish comes out smooth. And when I say tenth, that means ten-thousandth of an inch - four places over. One of the inserts on that cutter was clearly kicked out of place and was leaving that heavy swipe. That may only be a few tenths deep, but that's more than enough to leak everything, especially compression. A surface that's wavy by a few tenths will seal, but sharp corners like that most certainly will not.

This is what a typical cutter looks like on an engine mill. It's a large diameter tool - upwards of 12" - and it has a ton of inserts. All of these inserts need to be set within a "tenth" or so to make sure the finish comes out smooth. And when I say tenth, that means ten-thousandth of an inch - four places over. One of the inserts on that cutter was clearly kicked out of place and was leaving that heavy swipe. That may only be a few tenths deep, but that's more than enough to leak everything, especially compression. A surface that's wavy by a few tenths will seal, but sharp corners like that most certainly will not.

#17

Moderator

iTrader: (20)

Sent them in to get a valve job an the springs installed since i didnt have a tool.. As soon as i posted a pic on social media my buddy informed me that it was a shitty resurface job an that my heads will cause a head gasket leak alot faster.. Any insight?

#18

That is poor machining. I have seen this before when working as a Mori Seiki Tech. As 8.Lug pointed out, tooling was set up improperly and not touched off and rechecked before and after tooling change. Probably have some run out issues on mill head also. Should have been obvious to the operator. definitely some heat buildup there also, feed rate set too high. I would check cc of head and see where you're at. Hope this helps.

#20

Moderator

iTrader: (20)

It's the factory machining from GM. I used to go over the decks with a fine stone about 10-12" long when cleaning used heads and it would bring out those machining marks just like on the OP's heads. You can't feel them, but they look like they're a couple thousandths deep. I assume the machine shop used a similar method.