Ring gear runout

#1

TECH Apprentice

Thread Starter

I'm rebuilding the 10 bolt and I'm getting runout but I'm talking runout on the diameter of the gear...the back face is within spec but when I rotate I get tight spots. 001 backlash, up to .014 at 180 degrees. I measured the runout along the diameter and am getting .014 runout. So say at 3 oclock the ring gear is tight, 9 o'clock is loose, but 6 and 12 are both perfect at .0075 backlash, I let QP know and they called me back and recommended I deburr the ring gear and mount it 90 degrees from where it's at now. What do you guys think is the problem? Also I was able to correct the runout within .002 with the ring gear bolts snugged then when I torque it down the runout comes back. My theory is the bolt pattern is slightly off or maybe one hole is not straight?

#2

TECH Veteran

iTrader: (4)

Ring gear is a slip fit/slightly snug slip fit onto the carrier, was it ?

I've had your problem a couple times.

One time is was cured be taking a flat stone(the type used for knife sharpening) and cleaning any burrs/high spots on the carrier flange surface that the ring gear mates to and 'stoning' the ring gear surface that mounts to that flange.

Another time I measured the run-out of the carrier (without the ring gear) (with the carrier bearing shims and caps torqued) , carrier wasn't running true and had to be scrapped. If the carrier won't run true, ring gear on it won't run true. The carriers' ends that the bearings are pressed onto (I'll call them tube ends) can become stressed beyond useable and create a 'wobble'.

Why was it necessary to rebuild,what happened to it ?

I've had your problem a couple times.

One time is was cured be taking a flat stone(the type used for knife sharpening) and cleaning any burrs/high spots on the carrier flange surface that the ring gear mates to and 'stoning' the ring gear surface that mounts to that flange.

Another time I measured the run-out of the carrier (without the ring gear) (with the carrier bearing shims and caps torqued) , carrier wasn't running true and had to be scrapped. If the carrier won't run true, ring gear on it won't run true. The carriers' ends that the bearings are pressed onto (I'll call them tube ends) can become stressed beyond useable and create a 'wobble'.

Why was it necessary to rebuild,what happened to it ?

#3

TECH Apprentice

Thread Starter

Ring gear is a slip fit/slightly snug slip fit onto the carrier, was it ?

I've had your problem a couple times.

One time is was cured be taking a flat stone(the type used for knife sharpening) and cleaning any burrs/high spots on the carrier flange surface that the ring gear mates to and 'stoning' the ring gear surface that mounts to that flange.

Another time I measured the run-out of the carrier (without the ring gear) (with the carrier bearing shims and caps torqued) , carrier wasn't running true and had to be scrapped. If the carrier won't run true, ring gear on it won't run true. The carriers' ends that the bearings are pressed onto (I'll call them tube ends) can become stressed beyond useable and create a 'wobble'.

Why was it necessary to rebuild,what happened to it ?

I've had your problem a couple times.

One time is was cured be taking a flat stone(the type used for knife sharpening) and cleaning any burrs/high spots on the carrier flange surface that the ring gear mates to and 'stoning' the ring gear surface that mounts to that flange.

Another time I measured the run-out of the carrier (without the ring gear) (with the carrier bearing shims and caps torqued) , carrier wasn't running true and had to be scrapped. If the carrier won't run true, ring gear on it won't run true. The carriers' ends that the bearings are pressed onto (I'll call them tube ends) can become stressed beyond useable and create a 'wobble'.

Why was it necessary to rebuild,what happened to it ?

#4

TECH Veteran

iTrader: (4)

You provided more info as far as what you're using.

A spacer, did you stone the spacer ? And then 'mic' it in many places ? I find many spacers are not flat and parallel. There are quite a few threads advising against using a spacer.

2 series carrier with 4.10s'. Is the car an automatic,because of the 2 series carrier ? Or was it a 3 series carrier car that the original was replaced with a 2 series ?

A spacer, did you stone the spacer ? And then 'mic' it in many places ? I find many spacers are not flat and parallel. There are quite a few threads advising against using a spacer.

2 series carrier with 4.10s'. Is the car an automatic,because of the 2 series carrier ? Or was it a 3 series carrier car that the original was replaced with a 2 series ?

#5

TECH Apprentice

Thread Starter

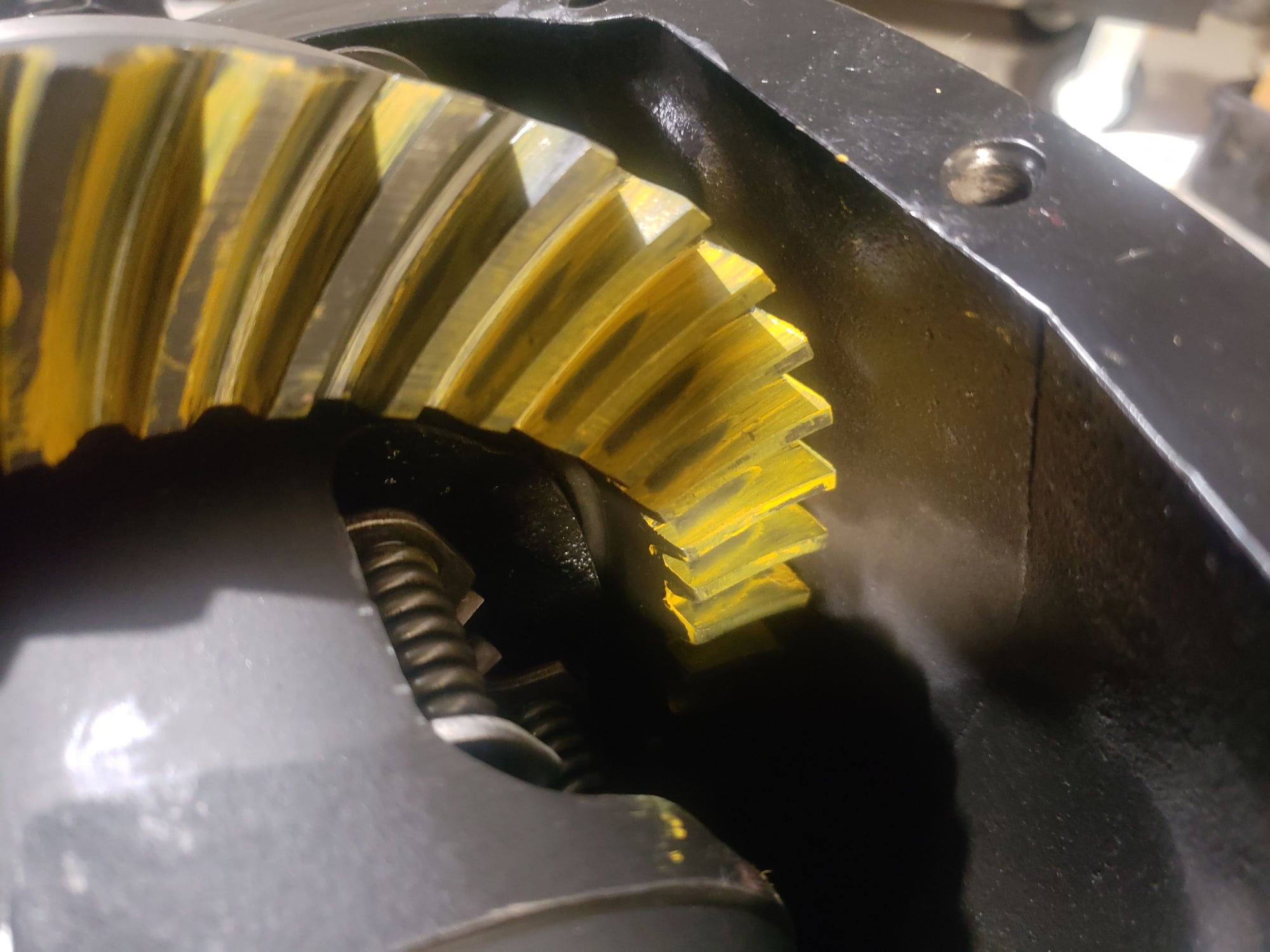

Drive side

Drive side

Coast, couldnt get much better pic, the marking is swiped pretty much in the center of the tooth

Update* I took the carrier apart and re stoned all surfaces. Including the spacer. Then reassembled and its within .001 runout! Now I have it together and I have a variance between .0045-.010 backlash. It's weird, I am checking at 3, 6, 9, and 12 o clock and every revolution my values change. I assume because the ring gear is mating with different teeth on each revolution. But I looked up specs and the tightest tolerance I found was .004 and the loosest was .012...so I am assuming it will have to do, considering if I make it looser it'll b too loose on one side and vise versa. I ran a pattern and I think it's good. I will attach some a plus photos for you guys to look at as I'm not 100% sure it's good.

#6

TECH Apprentice

Thread Starter

You provided more info as far as what you're using.

A spacer, did you stone the spacer ? And then 'mic' it in many places ? I find many spacers are not flat and parallel. There are quite a few threads advising against using a spacer.

2 series carrier with 4.10s'. Is the car an automatic,because of the 2 series carrier ? Or was it a 3 series carrier car that the original was replaced with a 2 series ?

A spacer, did you stone the spacer ? And then 'mic' it in many places ? I find many spacers are not flat and parallel. There are quite a few threads advising against using a spacer.

2 series carrier with 4.10s'. Is the car an automatic,because of the 2 series carrier ? Or was it a 3 series carrier car that the original was replaced with a 2 series ?

Trending Topics

#8

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

The worst variance i have ever seen in backlash was like .006-.010-.006 in a circle. It was a 12 bolt and i let it go out the door like that. It never came back (was a buddys car). Most vary about .001.

#9

TECH Apprentice

Thread Starter

Well I'm not sure why mine varies so much, I must have pinion runout? Ring gear axial runout and radial runout are good. Unless my Richmond excel gear set sucks...it was cheaper than most

#10

TECH Junkie

iTrader: (9)

Something is not right there bud. Thats WAYYYY too much runout imo. I like to see 0.0002 or less. Even 0.0004" will usually make an oscillating noise at cruise speed which can be super annoying. You sure theres no hard loktite gooped up in the holes on the ring gear? No burrs anywhere? I dont use a stone for facing I have a HUGE 2.5" w x 14" long single cut file that I use for facing. Easy to find the high spots with such a file and in your case probably well worth it. Black Diamond, file btw, dont be cheap with files buy a good one, take care of it, lasts a loooooooong time.

#11

TECH Apprentice

Thread Starter

Something is not right there bud. Thats WAYYYY too much runout imo. I like to see 0.0002 or less. Even 0.0004" will usually make an oscillating noise at cruise speed which can be super annoying. You sure theres no hard loktite gooped up in the holes on the ring gear? No burrs anywhere? I dont use a stone for facing I have a HUGE 2.5" w x 14" long single cut file that I use for facing. Easy to find the high spots with such a file and in your case probably well worth it. Black Diamond, file btw, dont be cheap with files buy a good one, take care of it, lasts a loooooooong time.

#14

TECH Junkie

iTrader: (9)

I'd work the pinion depth on that and see if it fares better. Am I reading correctly that your backlash is varied from 0.0045 - 0.0010?? Thats not right, somethings up. Patterns can be witchy processes to play with so I typically start with the stock shim, add 5 thou and test, subtract 5 from stock and test and compare patterns and work from there. This vid might prove helpful for you

#15

TECH Apprentice

Thread Starter

I'd work the pinion depth on that and see if it fares better. Am I reading correctly that your backlash is varied from 0.0045 - 0.0010?? Thats not right, somethings up. Patterns can be witchy processes to play with so I typically start with the stock shim, add 5 thou and test, subtract 5 from stock and test and compare patterns and work from there. This vid might prove helpful for you

https://www.youtube.com/watch?v=nVb5WRUfM7Y

https://www.youtube.com/watch?v=nVb5WRUfM7Y

#16

TECH Junkie

iTrader: (9)

You want the contact as centered on the tooth as possible. Not rolling off the top or buried into the root. Looks like your into deep captain, take 5 or ten thou off the pinion shim and see how it goes. If you dont have a set up bearing I highly recommend one. Easy to make with a flap abrasive wheel 60 grit or so run through a new bearing until it JUST slides over the pinion, dont take off too much it must stay concentric

#17

TECH Apprentice

Thread Starter

I did make a setup bearing and took several pinion depth readings, got it right in the money with what was scribed on the pinion and then when I pressed the new one on it sat about .005 lower.

#18

TECH Junkie

iTrader: (9)

As I said, witchy. These things can be a bear to dial in especially the torque arm diffs because the pumpkin is getting torqued all over the place, age, bumps hits all play a part. Best is to be sure the contact is nicely centered on the tooth which yours is not yet there. i'd start by adjusting pinion shim, set backlash the same as now, compare patterns. This way you can see where your winning and losing and add/subtract accordingly.

#19

TECH Apprentice

Thread Starter

Yeah these are pretty annoying. Although in that video u posted the guy said u want the pattern to sit in towards to root so as torque is applied it spreads along the tooth