2 bolt main block vs 4 bolt main block

#1

Teching In

Thread Starter

Join Date: Jan 2007

Location: Misawa Air Base Japan

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

I found out the sbc 350 I just got from my friend is a 2 bolt main block, how much of a restriction or limiting factor will this be? Either NA or blower I would like to make around 400whp/400wtq.

#3

Teching In

Thread Starter

Join Date: Jan 2007

Location: Misawa Air Base Japan

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

Thanks a lot man, I would like to get a hold of a 4 bolt main. But for now I can only get a hold of a 2 bolt, when another camaro comes along or a 4 bolt block is on the auction. Ill pick it up and swap my parts over to it, and buy a new crank. Thats if I am looking for more hp. Any more information is great though.

Edit:

I searched on google and this time this thread popped up.

https://ls1tech.com/forums/archive/i.../t-244664.html

Splayed cap conversion? Will research more on it, but could use some input. But it seems that I will be able to make the power that I desire with a 2 bolt.

Always thankful for the information.

Edit:

I searched on google and this time this thread popped up.

https://ls1tech.com/forums/archive/i.../t-244664.html

Splayed cap conversion? Will research more on it, but could use some input. But it seems that I will be able to make the power that I desire with a 2 bolt.

Always thankful for the information.

Last edited by sil; 01-09-2007 at 03:37 AM.

#5

On The Tree

iTrader: (5)

Join Date: Dec 2006

Location: Newport, NC (the Stix)

Posts: 193

Likes: 0

Received 0 Likes

on

0 Posts

you can splay a 2 bolt into a 4 bolt. some say its even stronger in the end due to the extra material in a 2 bolt to increase rigidity, not sure about that though... what year block you lookin for? i have a '71 4-bolt out of a vette, standard 4" bore with caps i would be willing to part with but i doubt you want to pay shipping pm me if your interested its an "010" (casting number ends in 010) which is the strongest old school block chevy made due to its high nickel content, very desireable look into it

#6

6 & 8 Second Club

Join Date: Aug 2006

Location: Illinois, RT 66 dragway area

Posts: 2,284

Likes: 0

Received 0 Likes

on

0 Posts

Actually the 2 bolt blocks are much more popular, for that exact reason.

I wouldn't worry about getting the new caps for only 400 HP.

If you ever plan to go higher in the future, get the new caps now and be done with it.

Good luck.

I wouldn't worry about getting the new caps for only 400 HP.

If you ever plan to go higher in the future, get the new caps now and be done with it.

Good luck.

#7

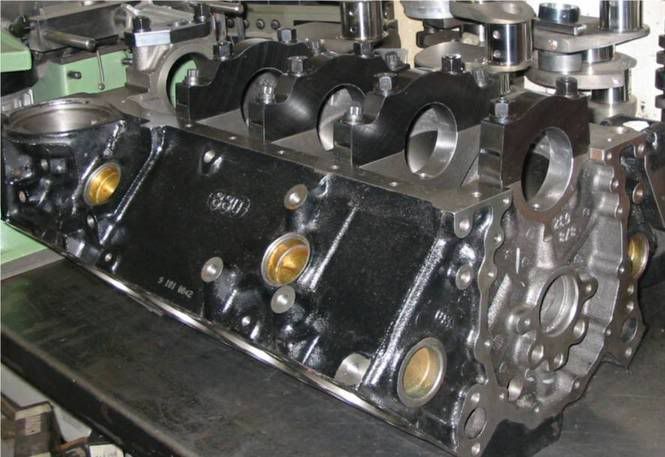

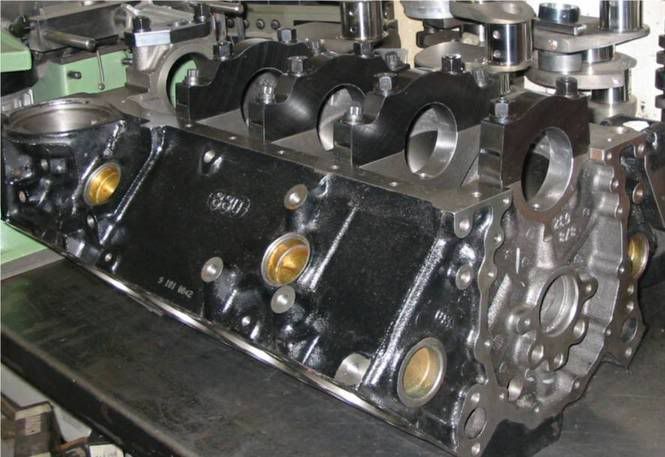

We splay both the 2 and 4 bolt main blocks as we deal with a couple hundred blocks a year and we have seen what happens when a 2 bolt block has been used where a good 4 bolt block should have been used and we have seen a 4 bolt block used where it should have had splayed caps.

Over powering a 2 bolt block the caps will tend to walk and and even then when the engines are taken apart the bearings never look as compared to a a block with better caps.

After 33 years of building performance engines we have seen a lot and if we build a 400 plus engine we will use a 2482 cap block or go to 4 bolt billet replacement caps and over 500 horse we step up to the splayed caps. As this seems to work for our shop.

Here is a pic of a block we machined for another shop with billet caps and a strap on the rear main cap.

Over powering a 2 bolt block the caps will tend to walk and and even then when the engines are taken apart the bearings never look as compared to a a block with better caps.

After 33 years of building performance engines we have seen a lot and if we build a 400 plus engine we will use a 2482 cap block or go to 4 bolt billet replacement caps and over 500 horse we step up to the splayed caps. As this seems to work for our shop.

Here is a pic of a block we machined for another shop with billet caps and a strap on the rear main cap.

Trending Topics

#8

Here is a good link to go over if you have the time.

http://www.chevelles.com/forums/showthread.php?t=38173

http://www.chevelles.com/forums/showthread.php?t=38173

#9

Teching In

Thread Starter

Join Date: Jan 2007

Location: Misawa Air Base Japan

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by CNC BLOCKS N/E

Here is a good link to go over if you have the time.

http://www.chevelles.com/forums/showthread.php?t=38173

http://www.chevelles.com/forums/showthread.php?t=38173

As for sending the block to you for machining, since I am in japan I would like to use a machine shop down in tokyo. Faster and cost less due to the boat trip to the states and back is taking out of the equation. I doubt the engine will need to make near or over 500whp (I hope were talking about wheel horsepower, if were talking about crank horsepower... I will search out another block. Dont want to spend twice the money fixing an obvious mistake.

Originally Posted by Black02Bird

i have a '71 4-bolt out of a vette, standard 4" bore with caps i would be willing to part with but i doubt you want to pay shipping pm me if your interested

#11

Originally Posted by SHAKER

2 Bolt Will Hold Up To 400 Fine. Be Sure The Caps Are Registering Well And That You Have The Line Bore Checked.

#12

No you see what happens when they dont do their home work and get a set up that isnt balanced, they put in less that desirable parts or dont have the block gone over through a reputable shop. These blocks have been around for 50 years in some cases and run fine to this day even after the proper upgrades to them to reach 400. 283's have been built to run 10,000 rpm and the last time I checked they were all 2 bolt blocks. Has been done, is being done and will always be done if done correctly. i am not saying you wont see the problems you are seeing but after failure analisis the reasons are usually not the block itself. If you do want a better block than yes go 4 bolt but that wont cure a problem that is built into the engine. Pinning the caps. balancing the rotating assembly, line honing, proper thrust bearing clearance , cleanliness of assembly, new or used cranks, failure to magnaflux to find defects, not even mentioning a poorly cast block from the factory. The list goes on to find the weak link causing problems. The 2 bolt block will be fine to 400 IF BUILT PROPERLY!!!

#15

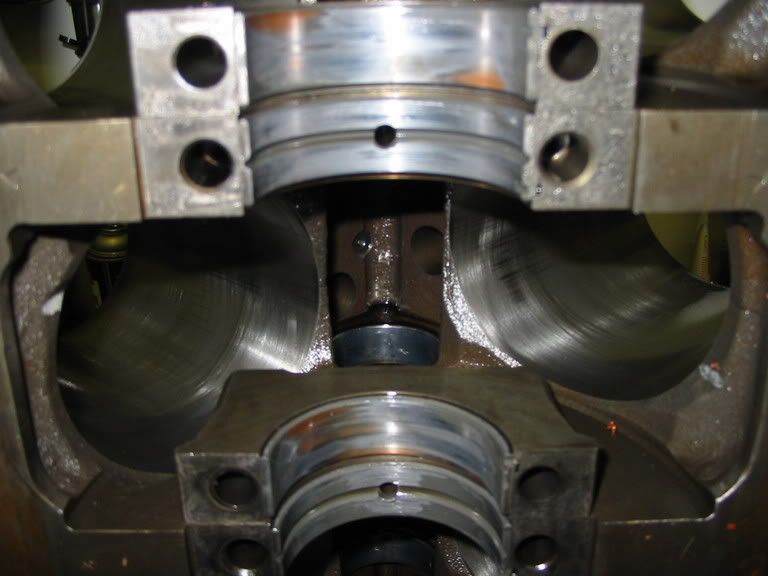

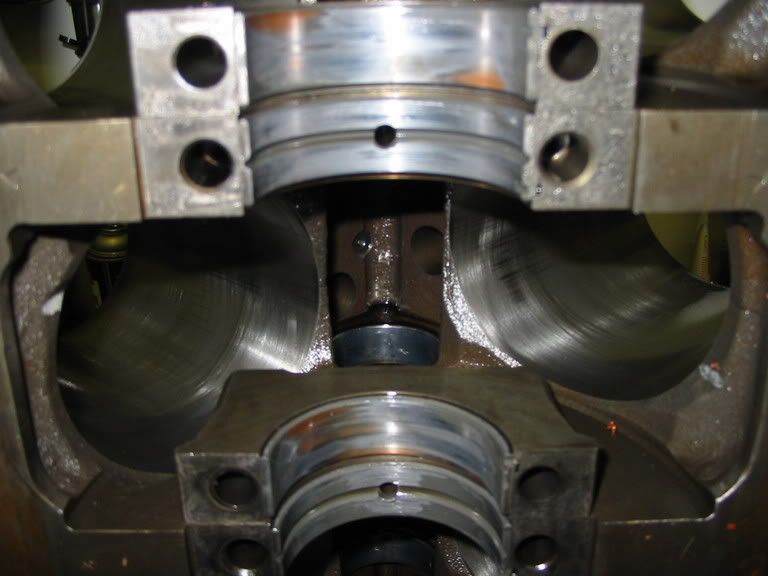

Here is a pic of an block that was sent to us to put splayed caps on as this was a 420 horse circle track engine tha was taken apart do to oil pressure was droping as you tell by the bearings and the caps there was a lot of cap walk. The engine was assembled with the same parts as the cast crank was turned the only differance and so far the engine has been taken apart twice for rebuilds and the word is every thing looks fine.

They ran this 2 bolt because his friend said he read it in a magazine that a 2 bolt was good for 500 horse, BUT FOR HOW LONG as this one had about 12 races on it and they did use studs.

We see 2 or 3 of these blocks a year that have to have caps put on them do to cap walk on the 2 bolt blocks.

If the 010 2 bolt caps were wide the 400 2 bolt caps that be a much better deal.

They ran this 2 bolt because his friend said he read it in a magazine that a 2 bolt was good for 500 horse, BUT FOR HOW LONG as this one had about 12 races on it and they did use studs.

We see 2 or 3 of these blocks a year that have to have caps put on them do to cap walk on the 2 bolt blocks.

If the 010 2 bolt caps were wide the 400 2 bolt caps that be a much better deal.

#16

Thats absurd to suggest a 2 bolt block is incapable of handling 420 hp. I have saw well over 500hp with 2 bolt main engines. For a more popular name that has built them well over 500 hp with 2 bolts just check some of Joe Shermans past work.

BTW it looks like that block had some issues other than just needing the caps done. Really doesn't look like it had a favorable mating surface to start with does it?

Cap walk does not leave pit marks like that.

BTW it looks like that block had some issues other than just needing the caps done. Really doesn't look like it had a favorable mating surface to start with does it?

Cap walk does not leave pit marks like that.

Last edited by The stunningman; 02-01-2007 at 10:14 AM.

#17

Originally Posted by The stunningman

Thats absurd to suggest a 2 bolt block is incapable of handling 420 hp. I have saw well over 500hp with 2 bolt main engines. For a more popular name that has built them well over 500 hp with 2 bolts just check some of Joe Shermans past work.

BTW it looks like that block had some issues other than just needing the caps done. Really doesn't look like it had a favorable mating surface to start with does it?

Cap walk does not leave pit marks like that.

BTW it looks like that block had some issues other than just needing the caps done. Really doesn't look like it had a favorable mating surface to start with does it?

Cap walk does not leave pit marks like that.

If 2 bolt blocks were good for 500 horse and be DEPENDABLE why did GM even make a 4 bolt main block and then make a 4 bolt main block using 2482 caps that is rated at 450 horse.HMMMMMMMMMMM

The performance shops and engine builders we deal with that build 500 horse engines DON'T use stock 2 bolt main blocks . Now maybe your local jobber shop would try to attemt this but there not going to build a 500 horse engine either.

Just comparing apples to apples here do own a shop and spec out engines for a living?? As we deal with a couple hundred blocks a year and we have been in this bussiness for 33 years now and I have seen what works and what does not.

And if GM said there 2 bolt block were good for 500 horse that would save me a lot of machining blocks for splayed caps.

The 327 was a 2 bolt main block that made up to 375 horse but only had a 3.250 stroke and buy adding 3.480 or 3.750 stroke it will side load the caps more then the 3.250 stroke.

Take one of our 500 horse circle track engnes build one with a 2 bolt mains and one with billet main caps and take them apart at the end of the season and tell me which one will have the better looking bearings and the better looking registers its really a no brainer.

#18

Most machine shops want to sell machining its called making money. The fact you say 2 bolt mains won't hold a 400 hp engine says a lot. For all that fretting the bearing edges look pretty good wouldn't you say?

Last edited by The stunningman; 02-01-2007 at 11:58 AM.

#19

Originally Posted by The stunningman

Most machine shops want to sell machining its called making money. The fact you say 2 bolt mains won't hold a 400 hp engine says a lot. For all that fretting the bearing edges look pretty good wouldn't you say?

The bearings are down to copper I really don't think that looks pretty good with only 12 races on them and after putting on the PROPER caps the last 2 sets of bearings looked fine according to the owner.

We are not most machine shops as we are a performance machne shop, BIG BIG differance here as all we do is performance engines and machine work.

And if a customer came in the shop and ordered a 500 horse engine and I told him we were going to use a 2 bolt main block because the magazine artcle I read said it would be fine. I am sure they would go some where else to have the proper work done.

Find a GM engineer that would put in writing that a 2 bolt block is good for 500 horse or even 400 horse and be DEPENDABLE. But I assume you have done more testing on this subject and have more knowledge then the engineers at GM. LOL

#20

#1.... I have built personally many 350 and 400 SBC's that push well over 450 hp with 2 bolt mains. And have several race cars that run at the track at VMP. No magazine article needed Sherman reference was someone that actually tells it like it is yes he will recomend a 4 bolt but if you got it and want to use it he will tell you where the line is. 400 hp isn't the line buddy.

#2.... You haven't truthfully answered his question

Can it be done and reliably... Yes is the TRUE answer . It has been done Many a time.

He's not asking can he run 8,000 rpm for 500 miles he's asking if he can make 400 hp for his driver theres a big difference there.

You find 1 "supposed example" as a total truth ...But wow your business is selling machine work.... even block machine work. Coincidence I think not. PLEASE tell this to all these guys at the local track running sub 11's 1/4 mile times with their 2 bolt main engines. Especially the 86 up late model guys which have a harder time finding 4 bolts. Better yet question them having a true 400 hp engine because it doesn't have a 4 bolt mains. Just go over there and tell them they need to pull it apart and have you convert it to 4 bolt mains while handing them your price sheet.

Feel free to start questioning my references. I need to prove nothing. I 'm not trying to sell anything. I can give many examples of over 400 even 500 hp 2 bolt main engines. The latter requiring some prep.

#2.... You haven't truthfully answered his question

Can it be done and reliably... Yes is the TRUE answer . It has been done Many a time.

He's not asking can he run 8,000 rpm for 500 miles he's asking if he can make 400 hp for his driver theres a big difference there.

You find 1 "supposed example" as a total truth ...But wow your business is selling machine work.... even block machine work. Coincidence I think not. PLEASE tell this to all these guys at the local track running sub 11's 1/4 mile times with their 2 bolt main engines. Especially the 86 up late model guys which have a harder time finding 4 bolts. Better yet question them having a true 400 hp engine because it doesn't have a 4 bolt mains. Just go over there and tell them they need to pull it apart and have you convert it to 4 bolt mains while handing them your price sheet.

Feel free to start questioning my references. I need to prove nothing. I 'm not trying to sell anything. I can give many examples of over 400 even 500 hp 2 bolt main engines. The latter requiring some prep.

Last edited by The stunningman; 02-01-2007 at 04:07 PM.