My Custom Air Suspension Install - 99 Trans Am

#141

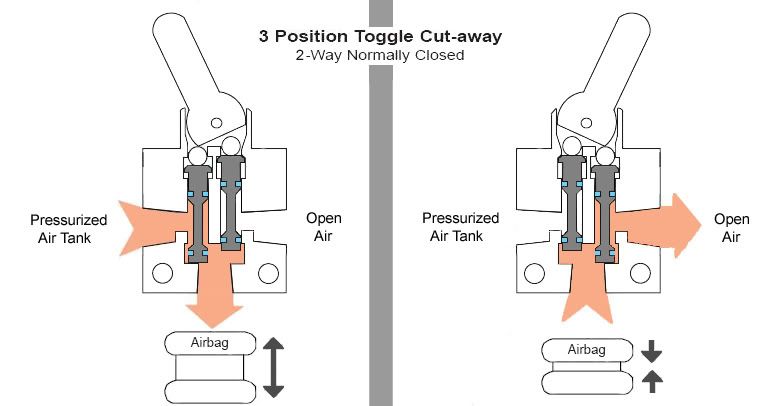

I got my toggle valve in. It's a big sucker and looks very proffessionally made. It flows a lot of air, too. The only thing not perfect about it is the notchy feel when moving the toggle. I think think it's due to the ball bearing setup on the top. I'm tempted to take it apart, but I better not. Let me run some tests on it's flow and pressure limits and I'll get back to you.

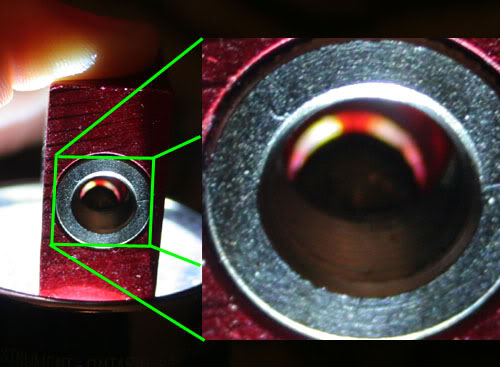

Large air gap for good flow.

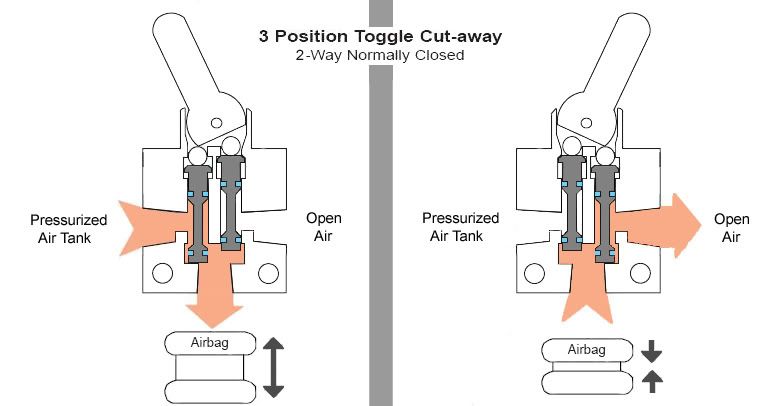

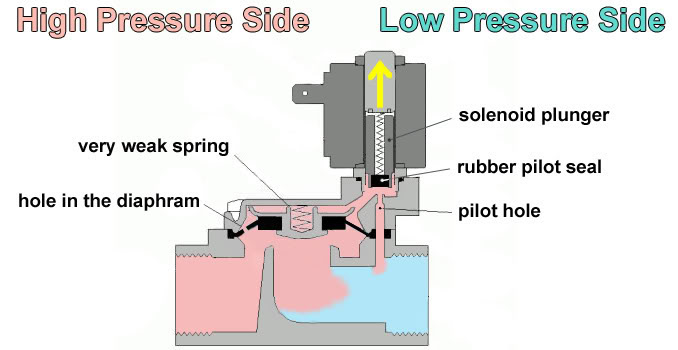

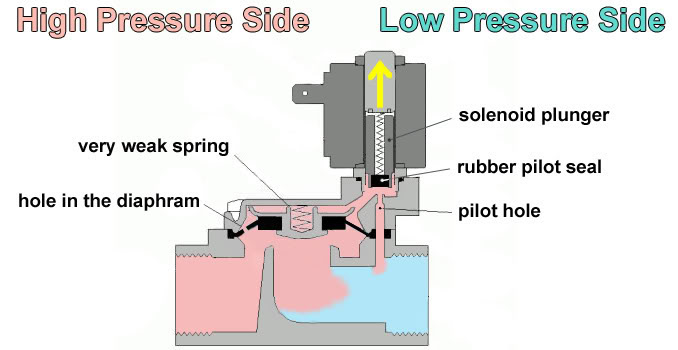

Here is a reminder of the internal workings.

Large air gap for good flow.

Here is a reminder of the internal workings.

Last edited by JasonWW; 07-21-2009 at 03:33 AM.

#142

Hey guys, I'm trying to make a simplifed mounting kit for those who want to use the Aero Sport bags on the front and the Firestone sleeve bags on the rear.

I already have a pattern for the rear brackets (looks like the ART piece) that I'm making for Drew. Once I get his laser cut plates and bend them to just the right shape, I can make a jig to easily make more.

Right now I'm trying to streamline the fab process on the front. I'd like to make a somewhat universal kit due to all the different shocks out there. I could make the pipe for the lower mount extra long so the customer can cut it to the right length for their particular brand of shock. The one problem I have is making the part that fits over the snap ring.

On my car, I cut and welded the pipe to a smaller diameter and then had a notch machined into the end. If I did that much work for everyone the price would be pretty high, plus I may not have the time to do that much labor.

I could save a lot of money by having the user cut the pipe to the right length and then take it and their old spring perch to the local muffler shop and have them weld the 2 together. It would need to be welded all the way around where the arrow is pointing.

Give me your opinion, is that expecting too much labor for the end user to do?

Another thought would be to add a donut plate and have the pipe welded to it. That way you don't alter the stock perch should you want to use it for something else.

I'll keep working on it.

I already have a pattern for the rear brackets (looks like the ART piece) that I'm making for Drew. Once I get his laser cut plates and bend them to just the right shape, I can make a jig to easily make more.

Right now I'm trying to streamline the fab process on the front. I'd like to make a somewhat universal kit due to all the different shocks out there. I could make the pipe for the lower mount extra long so the customer can cut it to the right length for their particular brand of shock. The one problem I have is making the part that fits over the snap ring.

On my car, I cut and welded the pipe to a smaller diameter and then had a notch machined into the end. If I did that much work for everyone the price would be pretty high, plus I may not have the time to do that much labor.

I could save a lot of money by having the user cut the pipe to the right length and then take it and their old spring perch to the local muffler shop and have them weld the 2 together. It would need to be welded all the way around where the arrow is pointing.

Give me your opinion, is that expecting too much labor for the end user to do?

Another thought would be to add a donut plate and have the pipe welded to it. That way you don't alter the stock perch should you want to use it for something else.

I'll keep working on it.

Last edited by JasonWW; 07-07-2009 at 10:15 AM.

#143

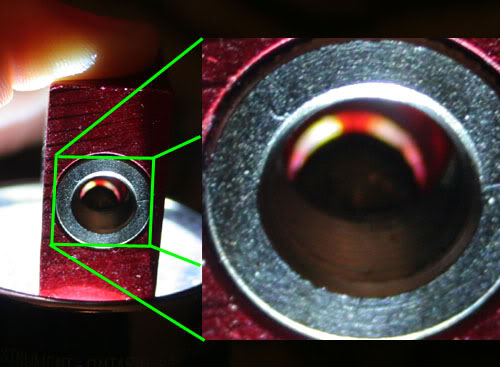

Well, I finished testing out this red toggle valve.

The good news is that it does hold a hefty 160psi on all 3 ports with the adjacent port at 0psi. It also flows a ton of air.

The bad news is that it's not reliable. While testing it out, one of the lower o-rings got pushed to the side and the valve would not close all the way. I'm assuming this was caused by high velocity air while the valve was partially open.

Since the whole point of using a manual valve in the first place is to improve reliability, I'm going to have to give this valve a failing grade. I guess I could test out a common paddle valve, but it's really bulky looking. What I want is 4 toggle switches mounted behind the shifter. I'm not even sure 4 paddle valves side by side will fit. It's either that or go electric. My research has at least shown me what diaphram and o-ring material to avoid when using an engine driven compressor.

Does anyone here want to know how a direct acting valve or pilot operating valve works? They're pretty cool.

The good news is that it does hold a hefty 160psi on all 3 ports with the adjacent port at 0psi. It also flows a ton of air.

The bad news is that it's not reliable. While testing it out, one of the lower o-rings got pushed to the side and the valve would not close all the way. I'm assuming this was caused by high velocity air while the valve was partially open.

Since the whole point of using a manual valve in the first place is to improve reliability, I'm going to have to give this valve a failing grade. I guess I could test out a common paddle valve, but it's really bulky looking. What I want is 4 toggle switches mounted behind the shifter. I'm not even sure 4 paddle valves side by side will fit. It's either that or go electric. My research has at least shown me what diaphram and o-ring material to avoid when using an engine driven compressor.

Does anyone here want to know how a direct acting valve or pilot operating valve works? They're pretty cool.

Last edited by JasonWW; 07-09-2009 at 07:34 PM.

#145

I had hopes that those valves would work because I liked the look of them. I'll pry use my electric valves so I can use any style switch.

I really don't understand when people don't like this idea just because it has "bags". Isn't every person that has a sports car interested in suspension and making it better in one way or another? I know if they read your threads they would realize that that it isn't just to be lower it's to have the best performance and to make things like steep drives and speed bumps easier for the daily driver.

I really don't understand when people don't like this idea just because it has "bags". Isn't every person that has a sports car interested in suspension and making it better in one way or another? I know if they read your threads they would realize that that it isn't just to be lower it's to have the best performance and to make things like steep drives and speed bumps easier for the daily driver.

#146

Do you mean the toggle valve or the adjustable ride height? You don't like the way air springs ride? Even I haven't had a good test drive yet as I'm working on the rest of the car. You mention taste, so do you mean the overall look of the car? It's pretty stock looking except for the bigger rims. You've got me a little confused. What exactly are you talking about?

It is sharp looking. The stem is machined stainless steel. It would look real good installed in the gray center console.

Can anyone make a few suggestions on high quality soleniod valves? So far I've heard these where good:

Danz

Blitzluft

SMC

Parker

Can anyone make a few suggestions on high quality soleniod valves? So far I've heard these where good:

Danz

Blitzluft

SMC

Parker

Last edited by JasonWW; 07-09-2009 at 09:29 PM.

#147

I could ship you one or two for testing purposes if it'd help you.

I could ship you one or two for testing purposes if it'd help you.

#148

I can't think of any real reason to test an electric valve. They've proven themselves to be fairly reliable. In fact, I think most of the problems they have is either due to debris getting in them, moisture freezing inside them or oil degrading the rubber seals. A good filter from the tank to the valves should keep the debris out. Any compressor using oil will allow oil mist to circulate through the setup, so you just have to make sure all the rubber parts are going to be compatible with it. Water can be tricky, but there are ways to prevent that, plus it rarely freezes where I live. It's possible that a coil could burn out, but they are usually turned on and them off so quick that heat shoulded be too big a deal.

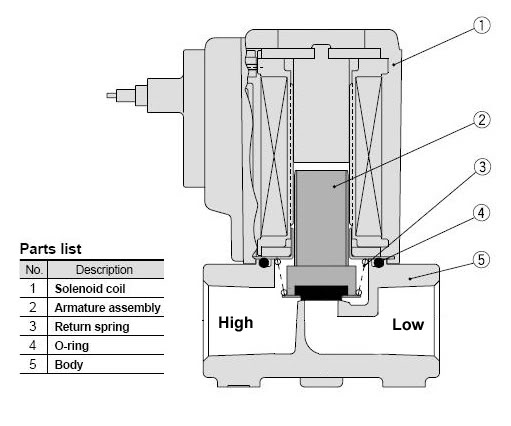

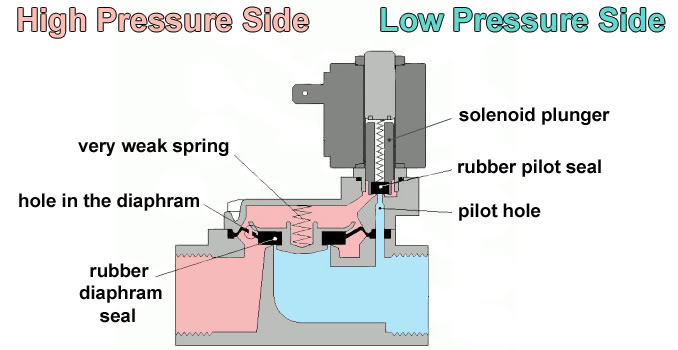

So here is how a pilot operated diaphram valve works:

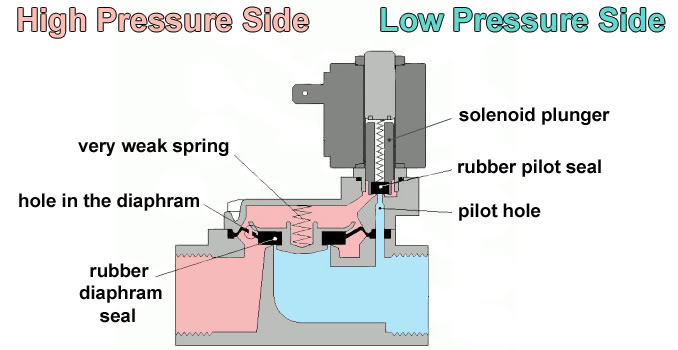

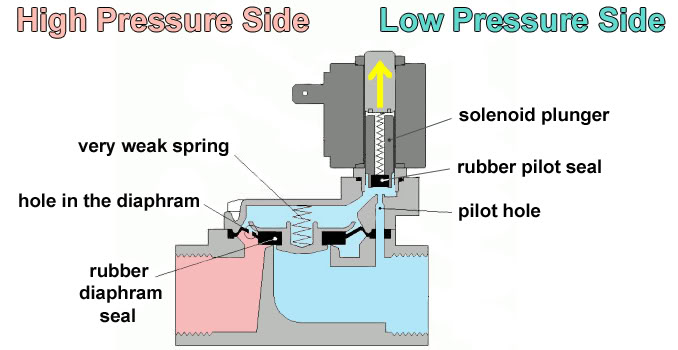

The law of Physics dictates that when 2 differing air pressures are combined, they will always try to equalize themselves. Pilot operated valves have a large diaphram for high air flow that seperates the high pressure side from the low pressure side. This is important, because these valves can only work in one direction.

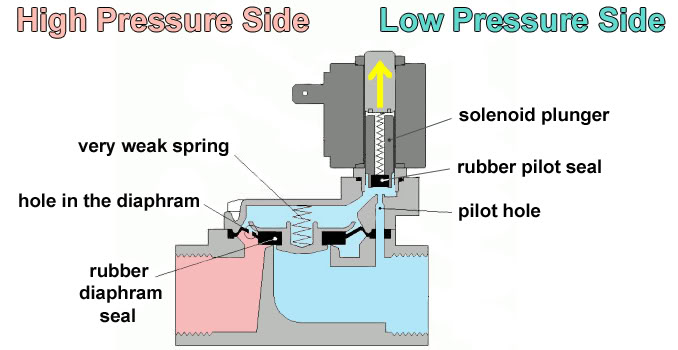

In a pilot operated design, the solenoid works against a fairly strong spring to expose the backside of the diaphram (high pressure) to the front side of of the diaphram (low pressure). This causes the diaphram to pop open and allow the high pressure air to travel to the other side.

Here is a Pilot Operated valve in the closed position.

Here is a Pilot Operated valve when the solenoid gets energized.

The pressure differential easily overcomes the diaphram spring and the air flows from the high pressure side to the low pressure side. It will continue to flow until you either close the valve or the tank and bag pressures equalize.

So here is how a pilot operated diaphram valve works:

The law of Physics dictates that when 2 differing air pressures are combined, they will always try to equalize themselves. Pilot operated valves have a large diaphram for high air flow that seperates the high pressure side from the low pressure side. This is important, because these valves can only work in one direction.

In a pilot operated design, the solenoid works against a fairly strong spring to expose the backside of the diaphram (high pressure) to the front side of of the diaphram (low pressure). This causes the diaphram to pop open and allow the high pressure air to travel to the other side.

Here is a Pilot Operated valve in the closed position.

Here is a Pilot Operated valve when the solenoid gets energized.

The pressure differential easily overcomes the diaphram spring and the air flows from the high pressure side to the low pressure side. It will continue to flow until you either close the valve or the tank and bag pressures equalize.

Last edited by JasonWW; 07-10-2009 at 02:56 AM.

#149

One small difference between the valve designs out there is that some companies use a small hole in the outer part of the diaphram and other companies will bore a hole through the body. SMC uses both designs.

If you want to see more pics of the above valve, just click here:

http://www.s10forum.com/smc-valve-cleaning-how-to

.

If you want to see more pics of the above valve, just click here:

http://www.s10forum.com/smc-valve-cleaning-how-to

.

Last edited by JasonWW; 07-10-2009 at 12:55 AM.

#151

Here is a very interesting document which gives you a better understanding of flow rates. This isn't gospel, nor have I verified any of this, so take it with a grain of salt.

Just because a valve has a 1/2" pipe thread on it's inlet and outlet doesn't mean it will flow more than a valve with 3/8" threads. That is just the external size and both of those threads are plenty big. The key to good flow is the size of the smallest restriction in the valve. From the 2 valve styles I've posted you can clearly see that a diaphram valve will flow a lot more than a direct valve. One of the key differences between a direct valve and a diaphram valve has to do with water in freezing temperatures. Now if water collects in the tiny air passage of a diaphram valve and then freezes, the solenoid part of the valve can open and close like normal, but the diaphram will not open. The same if a piece of debris get's in there. So direct valves are considered to be more reliable, but they don't flow as much.

For my personal use, I don't have much preference. 1/4" air line seems fast enough for my needs. I do need to know what material all the rubber parts are made of and it would be nice if diaphrams or any other special rubber parts could be bought seperately in case they degrade over time or whatever. So far, all these valve retailers are super secret about who makes what and has virtually no details about the valves. It's like a conspiracy or something.

.

Just because a valve has a 1/2" pipe thread on it's inlet and outlet doesn't mean it will flow more than a valve with 3/8" threads. That is just the external size and both of those threads are plenty big. The key to good flow is the size of the smallest restriction in the valve. From the 2 valve styles I've posted you can clearly see that a diaphram valve will flow a lot more than a direct valve. One of the key differences between a direct valve and a diaphram valve has to do with water in freezing temperatures. Now if water collects in the tiny air passage of a diaphram valve and then freezes, the solenoid part of the valve can open and close like normal, but the diaphram will not open. The same if a piece of debris get's in there. So direct valves are considered to be more reliable, but they don't flow as much.

There is some confusion between port size, valve size, fittings and airline.

For example a 3/8 port on a tank is referring to the thread size.

The inside diameter of a 3/8 port is 14.5mm or 9/16”.

The inside diameter of the 3/8 spool where the air travels around the spool to get to the port is equivalent to 6mm.

The size of the Orifice, which the air travels through on a 3/8 2-position valve, is 9mm

3/8 DOT air fitting inside diameter is 5.4mm

3/8 DOT airline refers to the outside diameter.

The actual size of the hole it passes through is 6.5mm

Sound confusing.

When considering the speed of the system you want you should be looking at the type of valves you are running and how they are mounted.

This will have the biggest impact on the speed of your system.

Some companies try to make their product sound good by selling ½” lines and fittings with all their 3/8 valve kits. Especially if they use spool or direct valves.

This is done to make you believe it will make them faster when infect it will have very little impact compared to up sizing to ½” valves with an 11.6mm diameter hole. When the ½” DOT push to connect fitting themselves have a inside diameter of 8.6mm

The inside diameter of ½” line is 9.6mm.

If you really want to get the most out of your air system running ½” valves with a 11.6mm hole and try using ¾” line which has a inside diameter of 14.5mm and the ¾ fittings have and inside diameter of 13mm.

From this chart above you should be able to see that a ½” side ported tank running 3/8 2 position valves and ½” lines and fitting will give you a much less restrictive system than using 3/8 spool valves with ½” lines and fittings.

For speed and reliability 2 position valves are the BEST CHOICE

Another thing to consider is the fitting of larger lines can be very difficult.

The bigger you go in air line diameter the larger the bend radius.

This means you will need more space to be able to run the line through the car.

The bend radius of 3/8, 1/2 and ¾ lines are 38mm, 50mm and 75mm respectively.

For example a 3/8 port on a tank is referring to the thread size.

The inside diameter of a 3/8 port is 14.5mm or 9/16”.

The inside diameter of the 3/8 spool where the air travels around the spool to get to the port is equivalent to 6mm.

The size of the Orifice, which the air travels through on a 3/8 2-position valve, is 9mm

3/8 DOT air fitting inside diameter is 5.4mm

3/8 DOT airline refers to the outside diameter.

The actual size of the hole it passes through is 6.5mm

Sound confusing.

When considering the speed of the system you want you should be looking at the type of valves you are running and how they are mounted.

This will have the biggest impact on the speed of your system.

Some companies try to make their product sound good by selling ½” lines and fittings with all their 3/8 valve kits. Especially if they use spool or direct valves.

This is done to make you believe it will make them faster when infect it will have very little impact compared to up sizing to ½” valves with an 11.6mm diameter hole. When the ½” DOT push to connect fitting themselves have a inside diameter of 8.6mm

The inside diameter of ½” line is 9.6mm.

If you really want to get the most out of your air system running ½” valves with a 11.6mm hole and try using ¾” line which has a inside diameter of 14.5mm and the ¾ fittings have and inside diameter of 13mm.

From this chart above you should be able to see that a ½” side ported tank running 3/8 2 position valves and ½” lines and fitting will give you a much less restrictive system than using 3/8 spool valves with ½” lines and fittings.

For speed and reliability 2 position valves are the BEST CHOICE

Another thing to consider is the fitting of larger lines can be very difficult.

The bigger you go in air line diameter the larger the bend radius.

This means you will need more space to be able to run the line through the car.

The bend radius of 3/8, 1/2 and ¾ lines are 38mm, 50mm and 75mm respectively.

.

Last edited by JasonWW; 07-10-2009 at 05:40 PM.

#152

Here's a kickass page on air tanks. They show some pics of non-SAE J10 compliance tanks that have exploded. It's cool.

http://www.tubularsuspensionsystems.com/tanks.htm

Here is also a neat article from the same website talking about cloned air bags and how to spot them. A really good read.

http://www.tubularsuspensionsystems.com/faq_bags.htm

I know that the F-body has no need for air cylinders, but I just ran across something totally new to me. A cylinder that has a built in shock! Cool.

http://www.tubularsuspensionsystems...._cylinders.htm

Did you guys know that the Dakota Digital base system uses VDO Pressure senders and these senders have a stated accuracy of + or - 8 psi as stated by the manufacturer? Wow, that is not very accurate at all.

http://www.tubularsuspensionsystems.com/tanks.htm

All air reservoirs for air brake applications are tested to SAE J10. Since there is no standard specifically relating to air suspensions, this standard has been adopted.

http://www.tubularsuspensionsystems.com/faq_bags.htm

I know that the F-body has no need for air cylinders, but I just ran across something totally new to me. A cylinder that has a built in shock! Cool.

http://www.tubularsuspensionsystems...._cylinders.htm

Did you guys know that the Dakota Digital base system uses VDO Pressure senders and these senders have a stated accuracy of + or - 8 psi as stated by the manufacturer? Wow, that is not very accurate at all.

Last edited by JasonWW; 07-11-2009 at 08:26 PM.

#153

I found some wicked cool videos that shows how these valves works.

First is a pilot type valve. The end is the best.

http://www.youtube.com/watch?v=e5434dDB-7w

Another one.

http://www.youtube.com/watch?v=K3oCsiECK1M

Here is a direct acting valve animation.

http://www.youtube.com/watch?v=SwqM8zpmAD8

Here's a 10 min one, but is super informative.

http://www.youtube.com/watch?v=RPVNnVEq7Lk

Same guy, but 5 min showing how to clean a valve.

http://www.youtube.com/watch?v=yPEsntRlpQE

First is a pilot type valve. The end is the best.

http://www.youtube.com/watch?v=e5434dDB-7w

Another one.

http://www.youtube.com/watch?v=K3oCsiECK1M

Here is a direct acting valve animation.

http://www.youtube.com/watch?v=SwqM8zpmAD8

Here's a 10 min one, but is super informative.

http://www.youtube.com/watch?v=RPVNnVEq7Lk

Same guy, but 5 min showing how to clean a valve.

http://www.youtube.com/watch?v=yPEsntRlpQE

#154

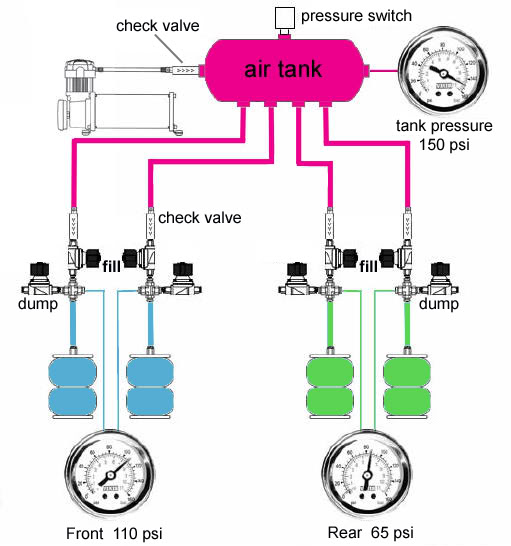

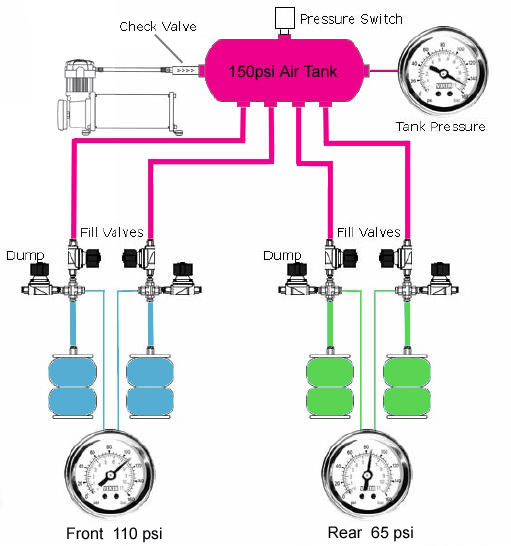

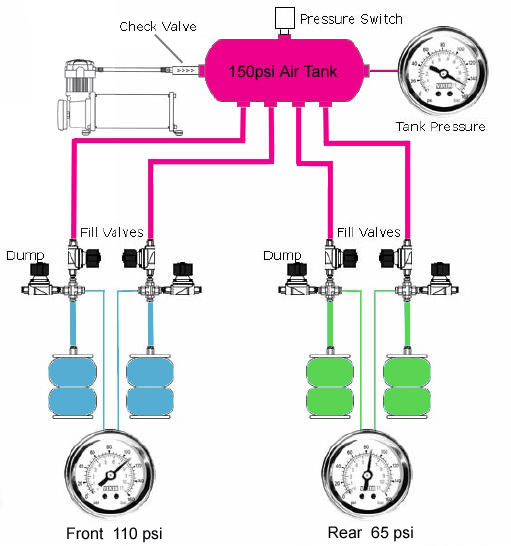

I learned something unsettling about the typical air setup such as this:

I always assumed that the lines from the bags to the valves were the ones in most need of protecting. Obviously a leak there would cause that particular bag to go down. I've now learned that due to the way the valves work, if the storage tank or any lines connected to it (pink) should burst or rub through or lose pressure for any reason, you end up with an even worse problem. The loss of head pressure on the fill valves will cause them to open and all FOUR bags will deflate, dropping the car and possibly leading to an accident.

Why am I just learning this now? It seems kinda important, don't cha think?

I always assumed that the lines from the bags to the valves were the ones in most need of protecting. Obviously a leak there would cause that particular bag to go down. I've now learned that due to the way the valves work, if the storage tank or any lines connected to it (pink) should burst or rub through or lose pressure for any reason, you end up with an even worse problem. The loss of head pressure on the fill valves will cause them to open and all FOUR bags will deflate, dropping the car and possibly leading to an accident.

Why am I just learning this now? It seems kinda important, don't cha think?

Last edited by JasonWW; 07-11-2009 at 08:30 PM.

#156

Hey guys, I've been playing around with the red valves some more (taking it apart and such) and I think with a simple mod or 2 these suckers will work just fine.

The main issue was high pressure air going from the side ports to the bottom port. It would sometimes push the o-ring to the point it would catch on the edge when closing and require another push to fix it. I don't think that will actually happen in reality. First of all it won't do it at 120 psi, only 140 and higher. So you have to have at least a 140 psi differential. Going from a 150 psi tank to an empty bag won't count because once the bag gets 20 psi in it the air has slowed down and there's no chance the o-ring will catch. So I think it's a non-issue.

Next problem was the toggle was too sensitive. A slight bump would cause the valve to open a bit. I fixed that by unscrewing the stainless top plate and adding a thin gasket made from universal gasket material. What that does is make the 2 brass spool valves sit about 1mm. higher. It works and feels much better now.

Drew, I finally got those rear plates back from Ekstensive this Sat. They look good. I just need to bend them properly. Do you have an electric drill? The one thing your gonna have to do is drill a hole for this side bolt:

The main issue was high pressure air going from the side ports to the bottom port. It would sometimes push the o-ring to the point it would catch on the edge when closing and require another push to fix it. I don't think that will actually happen in reality. First of all it won't do it at 120 psi, only 140 and higher. So you have to have at least a 140 psi differential. Going from a 150 psi tank to an empty bag won't count because once the bag gets 20 psi in it the air has slowed down and there's no chance the o-ring will catch. So I think it's a non-issue.

Next problem was the toggle was too sensitive. A slight bump would cause the valve to open a bit. I fixed that by unscrewing the stainless top plate and adding a thin gasket made from universal gasket material. What that does is make the 2 brass spool valves sit about 1mm. higher. It works and feels much better now.

Drew, I finally got those rear plates back from Ekstensive this Sat. They look good. I just need to bend them properly. Do you have an electric drill? The one thing your gonna have to do is drill a hole for this side bolt:

Last edited by JasonWW; 07-21-2009 at 03:54 AM.

#158

Man, I'm so excited. I'm going to pick up a 97 Thunderbird today and I'll be swapping it's indepandant rear suspension into my black Trans Am.

Much like so:

No torque arm means I can tuck a true dual exhaust in the trans tunnel.

No rear lower control arms mean I can run the exhaust out the side just in front of the tire without it hanging low.

Much like so:

No torque arm means I can tuck a true dual exhaust in the trans tunnel.

No rear lower control arms mean I can run the exhaust out the side just in front of the tire without it hanging low.

Last edited by JasonWW; 07-31-2009 at 03:05 PM.

#160

Teching In

iTrader: (1)

Join Date: Dec 2007

Location: Houston

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Do you mean the toggle valve or the adjustable ride height? You don't like the way air springs ride? Even I haven't had a good test drive yet as I'm working on the rest of the car. You mention taste, so do you mean the overall look of the car? It's pretty stock looking except for the bigger rims. You've got me a little confused. What exactly are you talking about?

It is sharp looking. The stem is machined stainless steel. It would look real good installed in the gray center console.

Can anyone make a few suggestions on high quality soleniod valves? So far I've heard these where good:

Danz

Blitzluft

SMC

Parker

It is sharp looking. The stem is machined stainless steel. It would look real good installed in the gray center console.

Can anyone make a few suggestions on high quality soleniod valves? So far I've heard these where good:

Danz

Blitzluft

SMC

Parker