Power Steering Rack Bolt... wtf...

#1

Thread Starter

Joined: Nov 2005

Posts: 59

Likes: 0

From: Somewhere boring...

Ok, so my power steering rack has been leaking from the input shaft for a while so I decided to fix it. I pulled everything apart today and started to remove the rack. I got everything disconnected with no issues and thought this was going to be a piece of cake.... apparently I was wrong. Either that or I'm completely retarded.

So basically, I can't get the power steering rack bolt out on the driver's side because it hits the oil pan before it even comes close to making it out of the hole(s) Has anyone else had this happen before? I figured they surely would have made this easier to replace. I'm guessing I'm either going to have to cut the bolt or pull the motor mount bolt out on the driver's side and hope I can raise the engine up enough to get the bolt out. I wish I would have known about this when I did one of my five engine swaps, it would have taken me 5 minutes and there would have been no issues. I've twisted, pryed, pulled, punched, and turned everything I can every way I can and nothing. Not even close. The bolt won't come out far enough for the threads to show on the top side and will barely tilt at an angle (think like 3 degrees at the most)

I wish I would have known about this when I did one of my five engine swaps, it would have taken me 5 minutes and there would have been no issues. I've twisted, pryed, pulled, punched, and turned everything I can every way I can and nothing. Not even close. The bolt won't come out far enough for the threads to show on the top side and will barely tilt at an angle (think like 3 degrees at the most)

Driver's side of the engine looking toward the rear of the car:

Driver's side of the car looking toward the front of the car (Subframe's all gunky from the leaking fluid):

Length of the bolt's twin from the passengers side:

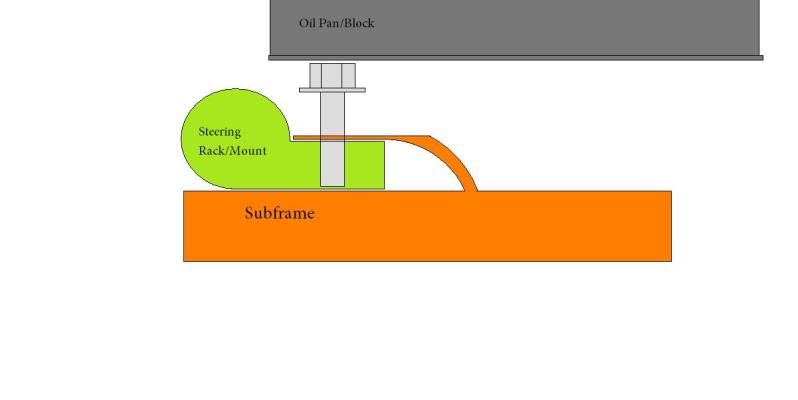

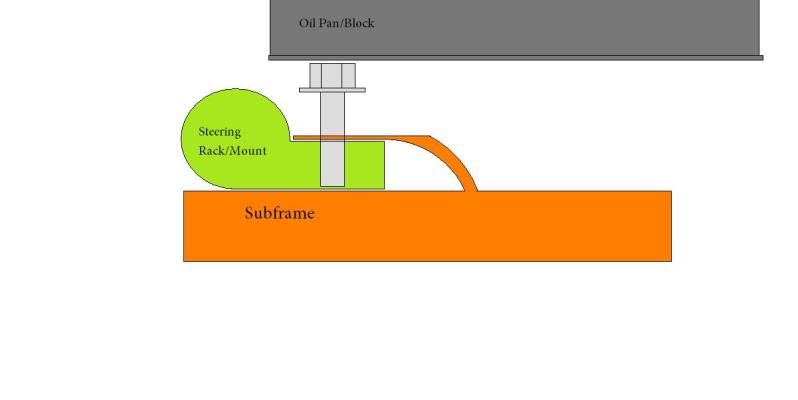

A quick diagram I made showing what exactly is going on here.

The rack has never been off of the car before to my knowledge and looks original. Just wanted to share my frustration

So basically, I can't get the power steering rack bolt out on the driver's side because it hits the oil pan before it even comes close to making it out of the hole(s) Has anyone else had this happen before? I figured they surely would have made this easier to replace. I'm guessing I'm either going to have to cut the bolt or pull the motor mount bolt out on the driver's side and hope I can raise the engine up enough to get the bolt out.

I wish I would have known about this when I did one of my five engine swaps, it would have taken me 5 minutes and there would have been no issues. I've twisted, pryed, pulled, punched, and turned everything I can every way I can and nothing. Not even close. The bolt won't come out far enough for the threads to show on the top side and will barely tilt at an angle (think like 3 degrees at the most)

I wish I would have known about this when I did one of my five engine swaps, it would have taken me 5 minutes and there would have been no issues. I've twisted, pryed, pulled, punched, and turned everything I can every way I can and nothing. Not even close. The bolt won't come out far enough for the threads to show on the top side and will barely tilt at an angle (think like 3 degrees at the most)Driver's side of the engine looking toward the rear of the car:

Driver's side of the car looking toward the front of the car (Subframe's all gunky from the leaking fluid):

Length of the bolt's twin from the passengers side:

A quick diagram I made showing what exactly is going on here.

The rack has never been off of the car before to my knowledge and looks original. Just wanted to share my frustration

Last edited by Sage282; 05-02-2011 at 10:33 PM.

#3

welcome to the club.......there is a reason i have a new sawzall now.......and now both my NEW bolts are installed upside down

Last edited by sjsingle1; 03-16-2011 at 10:32 PM.

#5

Oh yea.. forgot to tell you.. thats not a normal size bolt. The OD size is odd but I cant remember exactly what it was. 1/2" was too big and 7/16 was sloppy. It has to fit perfectly in the racks hole or it WILL have play.. I went to Autozone, Oreillys, Napa, Home Depot and Lowes.. NO ONE HAD IT... Go find one in a junk yard first. I got one from a guy local who parts them out...

#6

i got my bolts at lowes.....forget the size.....but they were metric of course.....on another note.....heard the power steering pump whine the other day.....pull over......the reservoir was low...WTF.....where was the leak? it had better not be my RP which is only a 1yr old.....get the car in the air and look underneath......the damm high pressure side hose was leaking at the compression fitting.....lucky for me pep boys could get me 1 in a few hrs

Trending Topics

#8

There are no standard bolts on your car. The bolt is a 12MM

Oh yea.. forgot to tell you.. thats not a normal size bolt. The OD size is odd but I cant remember exactly what it was. 1/2" was too big and 7/16 was sloppy. It has to fit perfectly in the racks hole or it WILL have play.. I went to Autozone, Oreillys, Napa, Home Depot and Lowes.. NO ONE HAD IT... Go find one in a junk yard first. I got one from a guy local who parts them out...

#11

Just my $0.02 worth.....From the stadpoint of the "home mechanic", or car enthusiast who does his own work, this orientation is a royal PITA, just like the torque arm bolts, which also go in from the top, and require dropping the axle WAY down, when removing the bolt.

However, there's a least one good reason for them being that way, possibly two. Number one, it's a safety thing, because in case the nut works loose, in either situation, the rack won't just flop around, and cause a complete loss of steering control, or the torque arm won't fall out of place, and cause the rear axle to rotate and twist the shocks all to hell, break the brake lines, maybe cut a fuel line, causing a loss of control of the car and possibly a fire.

Reason number two isn't so complicated...Sometimes in "sub-assembling" car components, things are upside down, in a fixture, and the bolt goes in from the "bottom" so it doesn't fall out while the assembler is installing the nut........

However, there's a least one good reason for them being that way, possibly two. Number one, it's a safety thing, because in case the nut works loose, in either situation, the rack won't just flop around, and cause a complete loss of steering control, or the torque arm won't fall out of place, and cause the rear axle to rotate and twist the shocks all to hell, break the brake lines, maybe cut a fuel line, causing a loss of control of the car and possibly a fire.

Reason number two isn't so complicated...Sometimes in "sub-assembling" car components, things are upside down, in a fixture, and the bolt goes in from the "bottom" so it doesn't fall out while the assembler is installing the nut........

#12

^ I thought about the same thing when I did mine and put the bolt in from the bottom. I used two Neoprene lock nuts on it.. i thought about drilling the end and putting a clip through the bolt just in case. Either way, that bolt can be a bitch if you let it. Just score the shoulder to weaken it, then put an impact on it from the bottom and a backup wrench on top. Break the head clean off and let it drop out.

#13

However, there's a least one good reason for them being that way, possibly two. Number one, it's a safety thing, because in case the nut works loose, in either situation, the rack won't just flop around, and cause a complete loss of steering control, or the torque arm won't fall out of place, and cause the rear axle to rotate and twist the shocks all to hell, break the brake lines, maybe cut a fuel line, causing a loss of control of the car and possibly a fire.

#14

^ The passenger side is still going in from the top. With the steering knuckle and the passenger side bolt in place, that rack would only get sloppy and not "fall out" if that upside down bolt should ever come completely loose and fall out.

As far as the torque arm goes, Ive always put the bolts back in from the top cause all you have to do is take off the ebrake and that rear just pivots when the DS is dropped.

Now having said all that, the correct way would be to lift the motor and put them in as they were originally but, doing it the "upside down" way, in this instance, is just as good as far as I'm concerned. The chances of that bolt falling completely out is extremely unlikely. Use a lock nut and you will never have a problem.

As far as the torque arm goes, Ive always put the bolts back in from the top cause all you have to do is take off the ebrake and that rear just pivots when the DS is dropped.

Now having said all that, the correct way would be to lift the motor and put them in as they were originally but, doing it the "upside down" way, in this instance, is just as good as far as I'm concerned. The chances of that bolt falling completely out is extremely unlikely. Use a lock nut and you will never have a problem.

#15

Very true, but when dealing with new cars, the manufacturer has to keep its azz covered, just in case a bolt doesn't get tightened properly. A "sloppy" steering rack most certainly wind up in court with a million dollar lawsuit attached to it.

#17

Just a thought ...

What if you supported the trans with a jack, yanked the 4 trans mount bolts and then lowered the jack.

The motor would pivot on the motor mounts and give some more room.

What if you supported the trans with a jack, yanked the 4 trans mount bolts and then lowered the jack.

The motor would pivot on the motor mounts and give some more room.

#20

Went through this process this weekend, PITA. Bolt is a 12mm, use a 15mm for the head and an 18mm for the nut(deep socket would make it easier).

I decided to go the "easy" route and cut the driver side bolt. I read some other threads on here that you could get it with a hacksaw, HAA! I'm pretty strong and all I did was polish the bolt. Road trip to harbor freight and got their $30 sawzall replica. That worked somewhat but I ran throught the 5 "heavy duty metal" blades pretty quickly and only made it about 40% through the bolt.

So I went to home depot and picked up some of the nasty steel cutting blades made to cut 1/2" industrial steel. Those worked well and I ripped through using only 1.

After that bolt was out everything went pretty smooth, here's a pic of some of the carnage.

This is what my bellows looked like after they started filling with fluid!

You can see my grinding marks where that bolt was and the red that came off from my sick nasty blade.

I decided to go the "easy" route and cut the driver side bolt. I read some other threads on here that you could get it with a hacksaw, HAA! I'm pretty strong and all I did was polish the bolt. Road trip to harbor freight and got their $30 sawzall replica. That worked somewhat but I ran throught the 5 "heavy duty metal" blades pretty quickly and only made it about 40% through the bolt.

So I went to home depot and picked up some of the nasty steel cutting blades made to cut 1/2" industrial steel. Those worked well and I ripped through using only 1.

After that bolt was out everything went pretty smooth, here's a pic of some of the carnage.

This is what my bellows looked like after they started filling with fluid!

You can see my grinding marks where that bolt was and the red that came off from my sick nasty blade.