Bumpstop Spring Rates Inside

#41

TECH Senior Member

iTrader: (35)

I've got exactly what he needs right here:

Starting back row from left: ERS 8" 600lbs/in. pr. NEW, ERS 10" 550lbs./in. pr. NEW, ERS 12" 625lbs./in. pr. USED.

Starting middle row from left: Kenny Brown Hypercoil frt. springs USED, Eibach LT1 pro kit frt. springs USED, ERS 10" 550lbs./in. pr. USED, Hypercoil 12" 550lbs./in. pr. Slightly used.

Front row from left: GlobalWest rear control arm relocation brackets (weld in)pr. NEW, GlobalWest rear ride height adjustable spring seats USED, Ground Control front adjustible upper and lower spring seats pr. USED with slight surface rust.

Starting back row from left: ERS 8" 600lbs/in. pr. NEW, ERS 10" 550lbs./in. pr. NEW, ERS 12" 625lbs./in. pr. USED.

Starting middle row from left: Kenny Brown Hypercoil frt. springs USED, Eibach LT1 pro kit frt. springs USED, ERS 10" 550lbs./in. pr. USED, Hypercoil 12" 550lbs./in. pr. Slightly used.

Front row from left: GlobalWest rear control arm relocation brackets (weld in)pr. NEW, GlobalWest rear ride height adjustable spring seats USED, Ground Control front adjustible upper and lower spring seats pr. USED with slight surface rust.

Last edited by 99Bluz28; 10-18-2008 at 05:35 PM.

#42

TECH Senior Member

iTrader: (35)

Here's some Energy Suspension bump stops I came across that look like they would fit in the rear with little , or no modification.

http://www.energysuspensionparts.com...sp?prod=9.9137

http://www.energysuspensionparts.com...sp?prod=9.9137

#43

I have a feeling these are going to be much stiffer than we want. Polyurethane can be made in numerous levels of hardness. Even if they make these really soft, it's still going to be too rubbery. You want long and progressive bumpstops, not these.

Last edited by JasonWW; 10-18-2008 at 07:45 PM.

#44

TECH Senior Member

iTrader: (35)

For stock ride height, and drag racing I think the E.S. bump stops would work fine.

#46

No, when fully compressed they become like a block of metal and can withstand many thousands of pounds because there is no give left in them. When you run out of bumpstop travel and the wheel wants to keep compressing, then things like the A-arm and chassis flex as well as the tire compressing more until something catastrophic happens, like the tire gets pinched between the ground and the rim or a suspension piece breaks (shock, shock mount, a-arm etc...)

#48

Here's a quick correction:

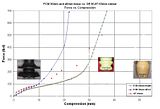

(click on thumbnail)

Once you squish all the air out of the bumpstop, it acts like a solid and the rates jump through the roof. With a well designed suspension you will slow the compression down before the bumpstop is fully compressed. Because once the rates go sky high the suspension no longer suspends, it becomes solid and things can start breaking.

Last edited by JasonWW; 12-22-2009 at 08:19 PM.

#50

They were not graphed correctly in your link, but I made a correction.

In response to your original post, it's not the actual pounds per inch numbers that are most important. It's the rate in which it compresses. You want a smooth progressive ramp up over the longest amount of travel you can get, combined with a good material that does not want to rebound. Rubber rebounds badly and they make for a bumpy ride. The cellular polyurethene (or microcellular urethane ) used by Koni and other aftermarket companies rebounds very slowly, which means it is not pushing the car up after full compression. It is merely absorbing the compression forces. A rubber bumpstop will compress and then release that energy back with force which is not good for the ride or handling.

BTW, if your fully compressing your bumpstops, it's a sign that either your spring rates are not high enough or your compression travel is too short.

In response to your original post, it's not the actual pounds per inch numbers that are most important. It's the rate in which it compresses. You want a smooth progressive ramp up over the longest amount of travel you can get, combined with a good material that does not want to rebound. Rubber rebounds badly and they make for a bumpy ride. The cellular polyurethene (or microcellular urethane ) used by Koni and other aftermarket companies rebounds very slowly, which means it is not pushing the car up after full compression. It is merely absorbing the compression forces. A rubber bumpstop will compress and then release that energy back with force which is not good for the ride or handling.

BTW, if your fully compressing your bumpstops, it's a sign that either your spring rates are not high enough or your compression travel is too short.

Last edited by JasonWW; 12-22-2009 at 08:32 PM.

#51

TECH Junkie

iTrader: (7)

Join Date: Jul 2005

Location: MA

Posts: 3,934

Likes: 0

Received 0 Likes

on

0 Posts

So do you think the square SS/WS6 bumpstops would be easier on your back than the poly bumpstops?

If a particular bumpstop is extremely stiff, does that kind of ruin the point of the bumpstop? Since your not allowing any cushioning, wouldn't that be hurting the mounting point area?

If a particular bumpstop is extremely stiff, does that kind of ruin the point of the bumpstop? Since your not allowing any cushioning, wouldn't that be hurting the mounting point area?