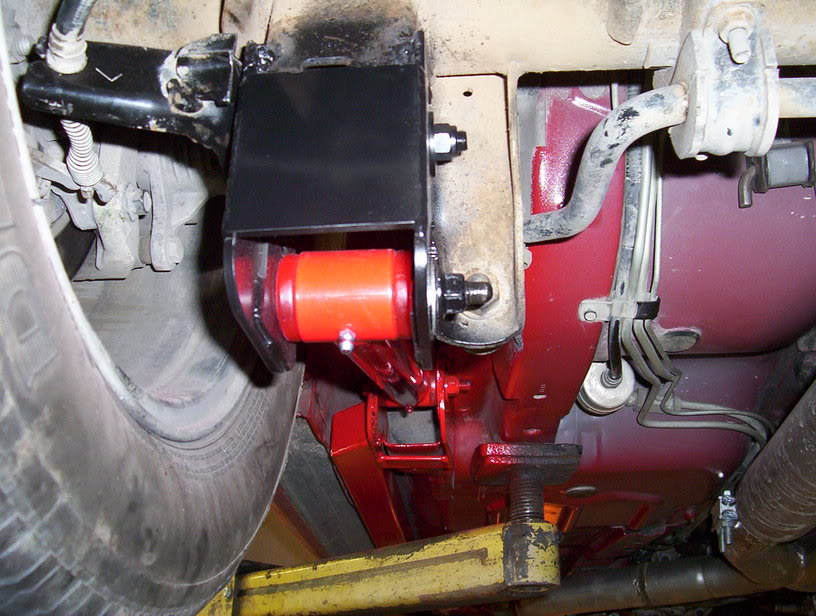

LCA relocation brackets

#1

9 Second Club

Thread Starter

iTrader: (30)

Join Date: Apr 2004

Posts: 1,419

Likes: 0

Received 0 Likes

on

0 Posts

I'm installing LCA's, LCA relocation brackets, & SFC's. (UMI) I have the relocation brackets set in place & ready to weld. It is possible to move these a little, so how do I know these are set completely correct before I weld. What I did was measure from the oval slot on the stock bracket & made sure that both sides were exactly the same height. So should this be OK? I have the new lca's hooked up on both sides. Does it matter that the car is on a lift without any weight on the rear wheels?

Last edited by code4; 01-23-2005 at 08:13 PM.

#2

You should only install one side at a time and weld one side at a time. The torque arm will hold the rear end from moving, however unbolting both control arms may cause the rear to shift slightly. Take one side and reinstall it back in the original location (stock). With that done now the other side you should be able to move the rear of the control arm up and down and see the arc and bolt pattern it should follow. My instructions where very detailed, if you read what I just wrote and follow the install instructions you should be able to get it.

#3

10 Second Club

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

You have 2 axis to consider, verticle & horizontal (front to back, disregard side to side for now). I think as long as the bolt holes for the LCAs are the same distance from the axle housing on both sides, you should be good to go vertically.

I think how to get the correct front to back position on the bracket before you weld it is the question. Having weight on wheels shouldn't affect the position of the LCA front to back. I'm thinking hanging a plumb bob (string with a bolt tied to it) from the top bolt of the bracket & then making the bottom bolt the exact same distance on both sides would work. This alignment is critical since it will determine if the rear tires are pointed / tracking straight.

Once those 2 axis are correct, you can adj the PHR to center the rear end side-to-side. And having weight on wheels is required for SFCs. You want the frame un-sprung when you attach them in place.

I think how to get the correct front to back position on the bracket before you weld it is the question. Having weight on wheels shouldn't affect the position of the LCA front to back. I'm thinking hanging a plumb bob (string with a bolt tied to it) from the top bolt of the bracket & then making the bottom bolt the exact same distance on both sides would work. This alignment is critical since it will determine if the rear tires are pointed / tracking straight.

Once those 2 axis are correct, you can adj the PHR to center the rear end side-to-side. And having weight on wheels is required for SFCs. You want the frame un-sprung when you attach them in place.

#4

I just swapped lca's on my car, and the torque arm doesn't keep the rear end in place, the lca's do... I did one side at a time, and I was able to move the rear end fore and aft to line up the bolt holes...

#5

9 Second Club

Thread Starter

iTrader: (30)

Join Date: Apr 2004

Posts: 1,419

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by WAHUSKER

You have 2 axis to consider, verticle & horizontal (front to back, disregard side to side for now). I think as long as the bolt holes for the LCAs are the same distance from the axle housing on both sides, you should be good to go vertically.

I think how to get the correct front to back position on the bracket before you weld it is the question. Having weight on wheels shouldn't affect the position of the LCA front to back. I'm thinking hanging a plumb bob (string with a bolt tied to it) from the top bolt of the bracket & then making the bottom bolt the exact same distance on both sides would work. This alignment is critical since it will determine if the rear tires are pointed / tracking straight.

Once those 2 axis are correct, you can adj the PHR to center the rear end side-to-side. And having weight on wheels is required for SFCs. You want the frame un-sprung when you attach them in place.

I think how to get the correct front to back position on the bracket before you weld it is the question. Having weight on wheels shouldn't affect the position of the LCA front to back. I'm thinking hanging a plumb bob (string with a bolt tied to it) from the top bolt of the bracket & then making the bottom bolt the exact same distance on both sides would work. This alignment is critical since it will determine if the rear tires are pointed / tracking straight.

Once those 2 axis are correct, you can adj the PHR to center the rear end side-to-side. And having weight on wheels is required for SFCs. You want the frame un-sprung when you attach them in place.

On the SFC's I am thinking I will set the car down on it's suspension and weld a short bead in a few locations to hold them in place then lift again so I can finish it on the lift.

#6

Originally Posted by kemmert

I just swapped lca's on my car, and the torque arm doesn't keep the rear end in place, the lca's do... I did one side at a time, and I was able to move the rear end fore and aft to line up the bolt holes...

#7

Originally Posted by 2w0s060

When I installed mine, by only unbolting one control arm at a time the axle did not move at all. I was able to swing the control arm in and out of the rear mounting point and have the hole still line up perfect. Now if you unbolt both the axle will move, however the torque arm has better hold then the old style GM upper control arms that allowed the rear to roll foward.

When I changed mine by unbolting one arm at a time, the bolt hole in the rear end's bracket didn't realign perfectly, I needed to use an alignment punch to align the holes. The rear end moved, not much, but it did move.....

Trending Topics

#8

9 Second Club

Thread Starter

iTrader: (30)

Join Date: Apr 2004

Posts: 1,419

Likes: 0

Received 0 Likes

on

0 Posts

OK I'm done welding them in. Here is what I did for piece of mind, I reinstalled the stock LCA in the stock hole on one side as recommended. Now I measured the center of the front and rear mounting bolt of the stock lca. Then measured the other side and made sure they were the same. Now once this was done to perfection the relocation bracket still had play up & down, I picked somewhere in the middle & welded the shiot out of it. Then used the same measurement on the other side for center to center of the stock lca mounting holes and the same height using the slot in the back as a reference point. Now they are dead nuts accurate & I am very happy. Now on to the SFC's tomorrow. Thanks for the advice.

#9

On The Tree

Join Date: Jan 2002

Location: Germantown, MD

Posts: 105

Likes: 0

Received 0 Likes

on

0 Posts

sounds like you got your LCA re-lo brackets in OK. you'll feel that difference the first time you pull off the line or out of a turn.

for the SFC's, though, be sure your suspension is loaded, as if the car was on the road. There is significant movement in the entire car, specifically the front clip, when left to hang.

for the SFC's, though, be sure your suspension is loaded, as if the car was on the road. There is significant movement in the entire car, specifically the front clip, when left to hang.

#10

9 Second Club

Thread Starter

iTrader: (30)

Join Date: Apr 2004

Posts: 1,419

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 99HOSS

sounds like you got your LCA re-lo brackets in OK. you'll feel that difference the first time you pull off the line or out of a turn.

for the SFC's, though, be sure your suspension is loaded, as if the car was on the road. There is significant movement in the entire car, specifically the front clip, when left to hang.

for the SFC's, though, be sure your suspension is loaded, as if the car was on the road. There is significant movement in the entire car, specifically the front clip, when left to hang.

#11

Originally Posted by code4

Will do, I am going to weld them in tonight. Going to set it down and weld a good bead on the areas that I can reach, then lift it again & finish up.