Hydraulic Coilover Thread

#1

PART 1

Some of you may know I've been looking at all sorts of adjustable ride height systems because they simply rock. Having the car sit on the ground when parked, lift up while driving and then raise way up for steep driveways and such. It's an ideal setup in my mind. The problem is how do you get all that while still having a corner carving vehicle?

I did a thread on air struts which will let you use your existing Koni or Bilstein shocks here:

Air Ride Using YOUR Front Shocks for $350

That's still a good setup, but I was concerned about the spring rates. It's just hard to say what you'll end up with. It may be fine, but I didn't want to take the chance.

I've also looked into the Roberuta Cup, but found it very expensive and doesn't have the travel I need.

A similar product is the kit from Umbrella Auto Design.

Both cup setups seem to run about $3000.

I also explored screw jacks, actuators and air cylinders. Maybe a few more things as well.

So what I came up with is a mix of lowrider hydraulic parts and high performance coilovers. I like this idea for several reasons.

One, it should be cheaper than an air setup.

Two, your spring rate will never change so you know your going to get the same great grip you have now (assuming you already have a good setup)

Three, I should be able to get more range of suspension travel.

Four, it takes up less space as you don't need a big air tank.

My idea is comprised of multiple sections.

First I will be selling my current Koni SA 8241-1139's and Ground Control setup on the front.

I'll replace it with the true coilover version Koni makes. I think the SA version will be fine along with 500lb springs. The advantage you get with these is it's much shorter so you have more room to work with. You can also order them in different stroke lengths so that your wheels don't drop wayyyy down when you jack up the car. I really hate that. It looks just like this, but with the aluminum body and no compression **** on the bottom.

They also have rod ends to mount them as they are a more universal style of shock over the 1139's which are a direct replacement.

Getting shorter shocks is kind of optional. I think I could continue using my current 1139 shocks and still have room for a 4" stroke cylinder which would lift the car 6.8" from full up to full down. That would probably be fine, but the 8216's are only about $300 each and with a shorter 3" stroke their total length wpould be about 13" fully extended. The stock shocks are about 18"-19" fully extended. With them I could fit a 6" stroke cylinder and get 10" of suspension travel assuming the A-arms and balljoints allow the car to go that far. Having more room is always good. I might be able to mount some 4" stroke cylinders completely under the wheel wells for a super stealth setup.

Here are some more of my thoughts on this and why I want to do it.

Some of you may know I've been looking at all sorts of adjustable ride height systems because they simply rock. Having the car sit on the ground when parked, lift up while driving and then raise way up for steep driveways and such. It's an ideal setup in my mind. The problem is how do you get all that while still having a corner carving vehicle?

I did a thread on air struts which will let you use your existing Koni or Bilstein shocks here:

Air Ride Using YOUR Front Shocks for $350

That's still a good setup, but I was concerned about the spring rates. It's just hard to say what you'll end up with. It may be fine, but I didn't want to take the chance.

I've also looked into the Roberuta Cup, but found it very expensive and doesn't have the travel I need.

A similar product is the kit from Umbrella Auto Design.

Both cup setups seem to run about $3000.

I also explored screw jacks, actuators and air cylinders. Maybe a few more things as well.

So what I came up with is a mix of lowrider hydraulic parts and high performance coilovers. I like this idea for several reasons.

One, it should be cheaper than an air setup.

Two, your spring rate will never change so you know your going to get the same great grip you have now (assuming you already have a good setup)

Three, I should be able to get more range of suspension travel.

Four, it takes up less space as you don't need a big air tank.

My idea is comprised of multiple sections.

First I will be selling my current Koni SA 8241-1139's and Ground Control setup on the front.

I'll replace it with the true coilover version Koni makes. I think the SA version will be fine along with 500lb springs. The advantage you get with these is it's much shorter so you have more room to work with. You can also order them in different stroke lengths so that your wheels don't drop wayyyy down when you jack up the car. I really hate that. It looks just like this, but with the aluminum body and no compression **** on the bottom.

They also have rod ends to mount them as they are a more universal style of shock over the 1139's which are a direct replacement.

Getting shorter shocks is kind of optional. I think I could continue using my current 1139 shocks and still have room for a 4" stroke cylinder which would lift the car 6.8" from full up to full down. That would probably be fine, but the 8216's are only about $300 each and with a shorter 3" stroke their total length wpould be about 13" fully extended. The stock shocks are about 18"-19" fully extended. With them I could fit a 6" stroke cylinder and get 10" of suspension travel assuming the A-arms and balljoints allow the car to go that far. Having more room is always good. I might be able to mount some 4" stroke cylinders completely under the wheel wells for a super stealth setup.

Here are some more of my thoughts on this and why I want to do it.

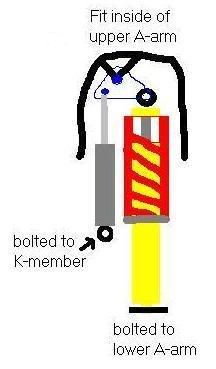

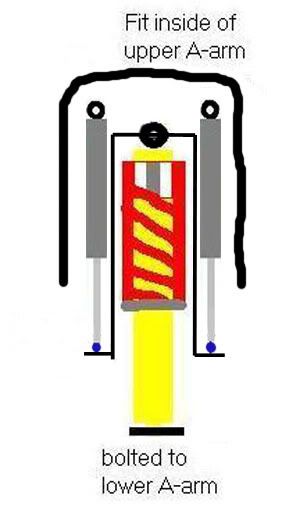

My idea is basically to run coilovers front and rear. The upper coilover mounts would be attached to the bottom of the hydraulic cylinder so I can raise and lower the mounting points. The reason for the hydraulics is that it will hold the mount nice and solid on both compression and rebound. The car will be running on coilovers due to their superior handling ability over air bags. The coilovers are also much shorter than the factory shocks so that will give me the room I need to install the cylinders on top.

So lets say I set the coilover to give me 4.5" of total wheel travel. 2.5" on the compression side and 2" on the extension side. Once that's set, it stays that way. I would be able to set a 3" ride height off the ground and the car would not bottom out. It would ride good as well due to the extra travel. (I only have 2" compression travel right now and it rides pretty good, but the car is way off the ground) So thanks to the front and rear wheel tubs I'd be tucking the tires way up there, riding way low and smoothly, too.

The best part is I can raise the car up for steep driveways and I might even be able to 3 wheel it. How sweet would it be to lift a flat tire off the ground without a jack to change the tire?

If I add a small computerized controller ($500) it can automatically set the car on the ground when I turn the engine off. Then raise it to ride height when I crank it back up. The controllers typically have 3 adjustable heights. On the ground, ride height and way up. If I pressed the 3rd button the car would lift up for steep driveways. Plus I'd have the manual switches for whatever I want. It's a lot of extra work, but it's so badass, you know? I mean, it does everything I wanted it to do. No more jacks, either. Just lift the car up, slide jack stands under the body and then lift all 4 wheels. I was thinking of seperate air jacks just for that purpose, but the hydraulics take care of it. It's just so sweet, I have to do it.

Even with all these extra parts and freaky looking setups, it won't lose it's handling ability, either. It will still carve the corners like a champ. The one stumbling block is I need to build some dropped spindles in order to prevent altering the suspension geometry. I'm working on a solution to that right now.

So lets say I set the coilover to give me 4.5" of total wheel travel. 2.5" on the compression side and 2" on the extension side. Once that's set, it stays that way. I would be able to set a 3" ride height off the ground and the car would not bottom out. It would ride good as well due to the extra travel. (I only have 2" compression travel right now and it rides pretty good, but the car is way off the ground) So thanks to the front and rear wheel tubs I'd be tucking the tires way up there, riding way low and smoothly, too.

The best part is I can raise the car up for steep driveways and I might even be able to 3 wheel it. How sweet would it be to lift a flat tire off the ground without a jack to change the tire?

If I add a small computerized controller ($500) it can automatically set the car on the ground when I turn the engine off. Then raise it to ride height when I crank it back up. The controllers typically have 3 adjustable heights. On the ground, ride height and way up. If I pressed the 3rd button the car would lift up for steep driveways. Plus I'd have the manual switches for whatever I want. It's a lot of extra work, but it's so badass, you know? I mean, it does everything I wanted it to do. No more jacks, either. Just lift the car up, slide jack stands under the body and then lift all 4 wheels. I was thinking of seperate air jacks just for that purpose, but the hydraulics take care of it. It's just so sweet, I have to do it.

Even with all these extra parts and freaky looking setups, it won't lose it's handling ability, either. It will still carve the corners like a champ. The one stumbling block is I need to build some dropped spindles in order to prevent altering the suspension geometry. I'm working on a solution to that right now.

Last edited by JasonWW; 12-03-2007 at 11:55 PM.

#2

PART 2

I came up with my design before seeing the CozyTech unit. I'm still not sure what all it's components look like, but I assume it's very similar to what I have in mind. The link below is the one and only video I can find of this unique hydraulic coilover suspension. It was made by a company called CozyTech in around '02 or '03 for Hyundai GK and XD cars like the Hyundai Elantra and now seems to be out of business. Their system is pretty slow because it uses a very small pump mounted under the hood. I posted some pics of the CozyTech unit further down.

CozyTech hydraulic coilover suspension video

Now that you've seen what it can do I'll explain a little about how hydraulics work.

Here is a typical lowrider kit you can buy for $750.

Here's another kit:

The 2 big chrome parts are pumps and each one consists of a motor on one side, a chrome fluid reservoir on the other side and a pump block in the middle. Inside the reservoir is the pump itself. These big unit are pretty much overkill for my needs. A single smaller pump should be fine. Something like that would cost under $150. Cylinders are maybe $90pr.

Motor:

.jpg)

Reservoir tank:

.jpg)

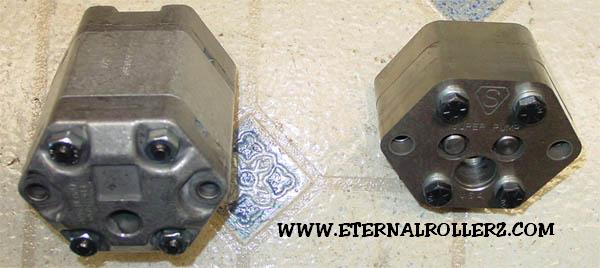

Pump block:

.jpg)

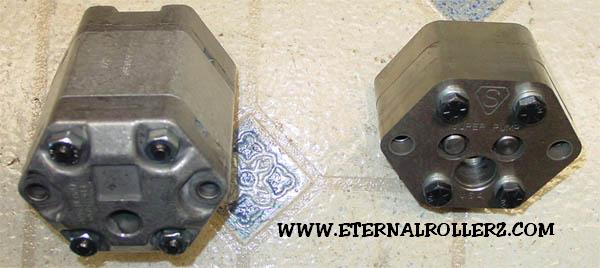

Pumps:

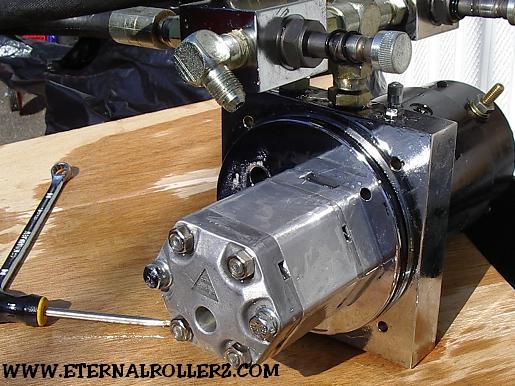

Pump attached to a pumpblock with the reservoir removed:

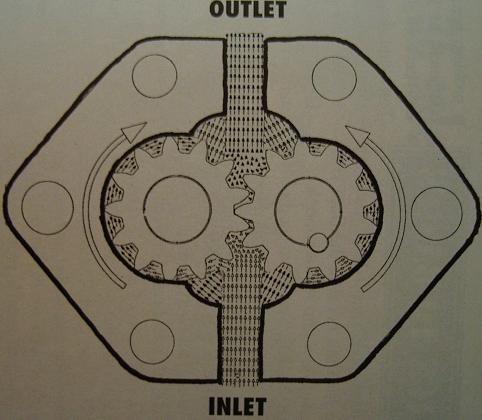

The pump uses gears much like an oil pump in an engine. You spin the gears, feed it oil and it will push the oil out at high pressure.

A diagram:

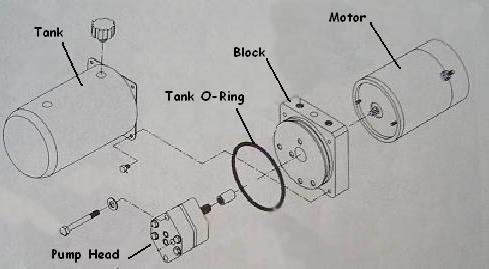

Here are the 4 parts together:

These 4 pieces are usually combined for simplicities sake.

The other main part is the cylinders that mount by each wheel. Here are some fully collapsed.

%20Competition%20Cylinders.jpg)

Here is one seperated:

It's a very simple device. It has an outer sleeve and an inner shaft. When you pump fluid into the end of it, it pushes the shaft out. The vehicles weight will push the fluid back out when you release the pressure.

There are also check valves, dump valves, relays, fittings, lines, etc... Basically a lot of small parts we don't need to get into here. Hopefully that's enough for you to get the basic idea. Now I don't plan on running 2 of the motor/pumps as I don't need to make the car hop or anything. Using one pump should work fine and cut the costs way down. It will just make the cylinders move a bit slower. I've figured out a way a single pump can give me FBSS (front, back, side to side) a fancy way of saying 4 wheel control, instead of just lifting the front or back as a pair. It will be able to send pressure to and remove pressure from each individual wheel through the use of 8 dump valves. I'll talk about the plumbing and control wiring in Part 3.

Since I plan to mount all these parts out of site I may be able to buy second hand components or ones not chromed and maybe put it together for under $400. An electronic controller is an add-on device and can jack the price up another $500 or more, but hey, you'd want it for an air system also.

Here is a brief explanation of how the hydraulic plumbing works with a simple diagram for those interested:

http://www.layitlow.com/tech/oilflow_2dumps.shtml

If your wondering why so many lowriders use a large bank of batteries, it's because they can be wired to 24v, 36v, 48v, 60v, 72v, 84v or even 96v(!) to the motors so that they spin up quick and produce lots of power for hopping. In my case I plan to use the single battery I have under the hood. 12v should be fine for my needs and I don't want to add any extra weight if it can be helped.

BTW, hopping lowriders typically use huge 3 and 4 ton springs under the cylinders for bouncing and I will obviously not be using those either.

Now keep in mind that the Cozy Tech setup used a very small motor and pump. So small it mounted under the hood. Here is a pic.

The reservoir was remote mounted nearby:

It used a simple switch box like this:

Links if you want to learn more:

Hydraulics in lowriders history lesson, all about the 2 main styles of pump heads, plus a whole lot more. Did you know aircraft hydraulic parts were first fitted to cars back in the 50's?

http://www.eternalrollerz.com/TechArticles/techpage.htm

Also keep in mind some lowriders just like cruising. Others may be into hopping. There are several different subcultures just like here with some people into drag racing, some into autocross and some into car shows, etc.... I just like riding low and always have as can be seen from my sig pic.

I came up with my design before seeing the CozyTech unit. I'm still not sure what all it's components look like, but I assume it's very similar to what I have in mind. The link below is the one and only video I can find of this unique hydraulic coilover suspension. It was made by a company called CozyTech in around '02 or '03 for Hyundai GK and XD cars like the Hyundai Elantra and now seems to be out of business. Their system is pretty slow because it uses a very small pump mounted under the hood. I posted some pics of the CozyTech unit further down.

CozyTech hydraulic coilover suspension video

Now that you've seen what it can do I'll explain a little about how hydraulics work.

Here is a typical lowrider kit you can buy for $750.

Here's another kit:

The 2 big chrome parts are pumps and each one consists of a motor on one side, a chrome fluid reservoir on the other side and a pump block in the middle. Inside the reservoir is the pump itself. These big unit are pretty much overkill for my needs. A single smaller pump should be fine. Something like that would cost under $150. Cylinders are maybe $90pr.

Motor:

.jpg)

Reservoir tank:

.jpg)

Pump block:

.jpg)

Pumps:

Pump attached to a pumpblock with the reservoir removed:

The pump uses gears much like an oil pump in an engine. You spin the gears, feed it oil and it will push the oil out at high pressure.

A diagram:

Here are the 4 parts together:

These 4 pieces are usually combined for simplicities sake.

The other main part is the cylinders that mount by each wheel. Here are some fully collapsed.

%20Competition%20Cylinders.jpg)

Here is one seperated:

It's a very simple device. It has an outer sleeve and an inner shaft. When you pump fluid into the end of it, it pushes the shaft out. The vehicles weight will push the fluid back out when you release the pressure.

There are also check valves, dump valves, relays, fittings, lines, etc... Basically a lot of small parts we don't need to get into here. Hopefully that's enough for you to get the basic idea. Now I don't plan on running 2 of the motor/pumps as I don't need to make the car hop or anything. Using one pump should work fine and cut the costs way down. It will just make the cylinders move a bit slower. I've figured out a way a single pump can give me FBSS (front, back, side to side) a fancy way of saying 4 wheel control, instead of just lifting the front or back as a pair. It will be able to send pressure to and remove pressure from each individual wheel through the use of 8 dump valves. I'll talk about the plumbing and control wiring in Part 3.

Since I plan to mount all these parts out of site I may be able to buy second hand components or ones not chromed and maybe put it together for under $400. An electronic controller is an add-on device and can jack the price up another $500 or more, but hey, you'd want it for an air system also.

Here is a brief explanation of how the hydraulic plumbing works with a simple diagram for those interested:

http://www.layitlow.com/tech/oilflow_2dumps.shtml

If your wondering why so many lowriders use a large bank of batteries, it's because they can be wired to 24v, 36v, 48v, 60v, 72v, 84v or even 96v(!) to the motors so that they spin up quick and produce lots of power for hopping. In my case I plan to use the single battery I have under the hood. 12v should be fine for my needs and I don't want to add any extra weight if it can be helped.

BTW, hopping lowriders typically use huge 3 and 4 ton springs under the cylinders for bouncing and I will obviously not be using those either.

Now keep in mind that the Cozy Tech setup used a very small motor and pump. So small it mounted under the hood. Here is a pic.

The reservoir was remote mounted nearby:

It used a simple switch box like this:

Links if you want to learn more:

Hydraulics in lowriders history lesson, all about the 2 main styles of pump heads, plus a whole lot more. Did you know aircraft hydraulic parts were first fitted to cars back in the 50's?

http://www.eternalrollerz.com/TechArticles/techpage.htm

Also keep in mind some lowriders just like cruising. Others may be into hopping. There are several different subcultures just like here with some people into drag racing, some into autocross and some into car shows, etc.... I just like riding low and always have as can be seen from my sig pic.

Last edited by JasonWW; 12-03-2007 at 12:21 AM.

#3

PART 3

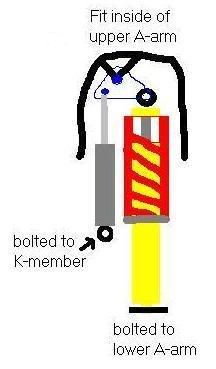

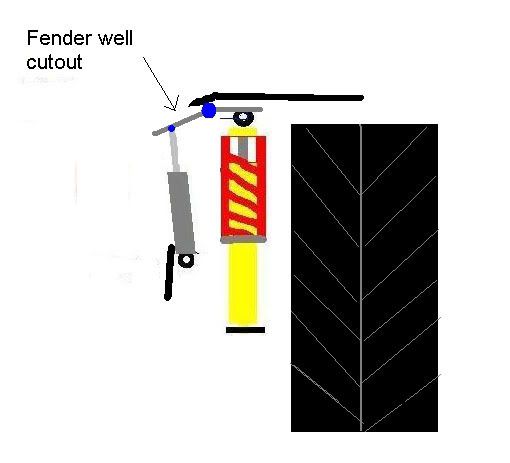

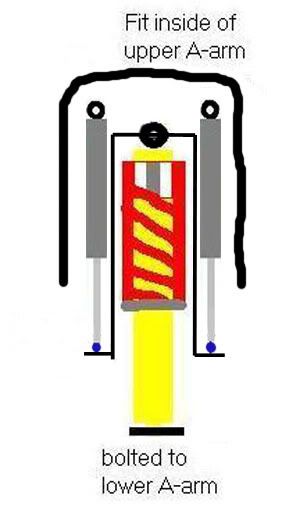

I think that covers the 2 main parts. Now here I will explain how I want to mount the cylinder to the shock tower so I can raise and lower the shock mount. I have several different designs in mind. By far the simplist and most straight forward way is to mount a short cylinder right above a coilover shock in the TA. The cylinder will be mounted rigidly and there will be a swivel joint in between them to allow for the angle changes the shocks go through when expanding and compressing. I think a 4" stroke cylinder will fit and not poke the hood.

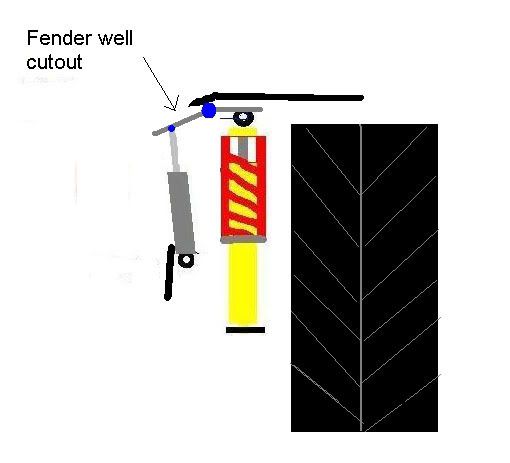

If I switched over to the shorter coilovers I could easily fit a 4" stroke cylinder and probably a 6" if I wanted. There may even be room to mount the 4" cylinder completely under the fenderwell for a stealth install.

[IMG] [/IMG]

[/IMG]

If I did not have room for the cylinder right on top of the shock I would run some sort of rocker to mount the cylinder to the side. Here are some of the designs:

or:

Here is one sneaky7980 drew up:

Here is a new thought for doing the front using the existing shocks. Cylinders are only about $45 each. Using 4 up front is not going to cost much more and may make it easier for others to install this setup.

I'll keep updating this section until I decide on a good design.

I think that covers the 2 main parts. Now here I will explain how I want to mount the cylinder to the shock tower so I can raise and lower the shock mount. I have several different designs in mind. By far the simplist and most straight forward way is to mount a short cylinder right above a coilover shock in the TA. The cylinder will be mounted rigidly and there will be a swivel joint in between them to allow for the angle changes the shocks go through when expanding and compressing. I think a 4" stroke cylinder will fit and not poke the hood.

If I switched over to the shorter coilovers I could easily fit a 4" stroke cylinder and probably a 6" if I wanted. There may even be room to mount the 4" cylinder completely under the fenderwell for a stealth install.

[IMG]

[/IMG]

[/IMG]If I did not have room for the cylinder right on top of the shock I would run some sort of rocker to mount the cylinder to the side. Here are some of the designs:

or:

Here is one sneaky7980 drew up:

Here is a new thought for doing the front using the existing shocks. Cylinders are only about $45 each. Using 4 up front is not going to cost much more and may make it easier for others to install this setup.

I'll keep updating this section until I decide on a good design.

Last edited by JasonWW; 12-04-2007 at 07:48 AM.

#4

PART 4

Here I will show how the computerized ride height controllers will work. I will basically adapt an automatic control system from an air bag company to control the hydraulics. It will give me one touch "slammed", "ride height" and then "4x4 mode". Automatic drop on engine off, automatic ride height on engine crank, etc... Technically they refer to it as having 3 preset ride heights, but I like my names "slammed" for sitting on the ground, "ride height" for the height the alignment will be set and what the car will be driven at and "4x4 mode" which will only be for steep driveways and such.

So far the Dakota Digital system looks like it will work.

Here is what a ride height sensor looks like:

They come with little linkage assemblies that connect to the A-arm while the body attaches to the frame or body.

Here is an example of how it would mount.

Simple, huh? The Dakota unit expects to see a pressure reading from the tank to work, but I'm pretty sure I can figure out what voltage is good for it to see and just rig the sensor to always see that. Here is a PDF file for the Dakota Digital system.

It shows inputs and outputs consisting of:

constant +

switched +

ground

park/nuetral switch (to prevent full drop while in gear)

display dimmer - to headlight signal

tank pressure - I'll have to rig it

4 height sensors

optional remote control antenna - cool stuff

8 outputs to the 8 solenoids - 4 to lift, 4 to lower

So far this system looks like a winner for controlling the hydraulics. As you'll see in the next section I'm working on the plumbing so that the 8 electrical signals provide pressure and remove pressure to each of the 4 corners completely independantly. Typical lowriders can't do that.

Here I will show how the computerized ride height controllers will work. I will basically adapt an automatic control system from an air bag company to control the hydraulics. It will give me one touch "slammed", "ride height" and then "4x4 mode". Automatic drop on engine off, automatic ride height on engine crank, etc... Technically they refer to it as having 3 preset ride heights, but I like my names "slammed" for sitting on the ground, "ride height" for the height the alignment will be set and what the car will be driven at and "4x4 mode" which will only be for steep driveways and such.

I need to list a few different ones here to figure out the best one.

Auto Pilot Digital Controller from Air Lift $476 - won't work (uses pressure sensors only)

Air Ride LevelPro leveling system $1300 - might work (uses pressure sensors and load level)

Some new system from this AU company $850 - http://users.bigpond.net.au/burnin/G...ontrollers.htm (unknown)

Dakota Digital DHC-2100 $800 - should work (uses load sensors only)

Auto Pilot Digital Controller from Air Lift $476 - won't work (uses pressure sensors only)

Air Ride LevelPro leveling system $1300 - might work (uses pressure sensors and load level)

Some new system from this AU company $850 - http://users.bigpond.net.au/burnin/G...ontrollers.htm (unknown)

Dakota Digital DHC-2100 $800 - should work (uses load sensors only)

Here is what a ride height sensor looks like:

They come with little linkage assemblies that connect to the A-arm while the body attaches to the frame or body.

Here is an example of how it would mount.

Simple, huh? The Dakota unit expects to see a pressure reading from the tank to work, but I'm pretty sure I can figure out what voltage is good for it to see and just rig the sensor to always see that. Here is a PDF file for the Dakota Digital system.

It shows inputs and outputs consisting of:

constant +

switched +

ground

park/nuetral switch (to prevent full drop while in gear)

display dimmer - to headlight signal

tank pressure - I'll have to rig it

4 height sensors

optional remote control antenna - cool stuff

8 outputs to the 8 solenoids - 4 to lift, 4 to lower

So far this system looks like a winner for controlling the hydraulics. As you'll see in the next section I'm working on the plumbing so that the 8 electrical signals provide pressure and remove pressure to each of the 4 corners completely independantly. Typical lowriders can't do that.

Last edited by JasonWW; 12-03-2007 at 08:58 AM.

#5

Part 5

Here I will show how the lines will be plumbed for the hydraulics and interfaced with the controller.

Since lowriders don't do the things I want to do I have to come up with my own unique setup. I can use existing manifold blocks, dump valves, fittings, etc... just in a different way. Where as the typical lowrider with FBSS control uses 2 pumps and 4 dump valves I could use a single pump and 8 dump valves. This is just like an air system that uses a single pump and 8 solenoids. 4 solenoids to let air into each of the 4 bags and then 4 solenoids to let air out of each of the bags. Since I'm adapting an air bag controller to work with the hydraulic system it needs to have the same inputs and outputs for the controller to control. So far I think I have it figured out. I may have a way to do it using only 4 dumps as they can be expensive at $50ea.

Check these 5 posts often as I'm constantly updating them. Once I think I'm finally finished, I'll do a new post to let you guys know.

Here I will show how the lines will be plumbed for the hydraulics and interfaced with the controller.

Since lowriders don't do the things I want to do I have to come up with my own unique setup. I can use existing manifold blocks, dump valves, fittings, etc... just in a different way. Where as the typical lowrider with FBSS control uses 2 pumps and 4 dump valves I could use a single pump and 8 dump valves. This is just like an air system that uses a single pump and 8 solenoids. 4 solenoids to let air into each of the 4 bags and then 4 solenoids to let air out of each of the bags. Since I'm adapting an air bag controller to work with the hydraulic system it needs to have the same inputs and outputs for the controller to control. So far I think I have it figured out. I may have a way to do it using only 4 dumps as they can be expensive at $50ea.

Check these 5 posts often as I'm constantly updating them. Once I think I'm finally finished, I'll do a new post to let you guys know.

Last edited by JasonWW; 12-04-2007 at 07:51 AM.

#6

So far this thread has hit a snag. I under estimated the electrical requirements to power the pumps. After talking to some lowrider builders it seems you'd need to run 2 dedicated batteries to provide 24v to the pump and it's quite possible you'd need to run 2 pumps. One for the front and one for the rear. Since the alternator won't be able to charge them, you'd either have to run a 24v battery charger at home to maintain them or get a "street charger" which is about $400 All this just seems unacceptable as far as I'm concerned.

Now I did learn a few more things about the Cozytech unit. It consists of special coilovers with cylinders, a larger PS reservoir and a block with check valves and 2 dump solenoids. That's it. What actually provides the hydraulic pressure is the power steering pump. The whole hydraulic system uses PS fluid so everything is compatible.

So now I'm going to explore a engine driven pump as it would save lots of weight and complexity. I see 2 basic paths:

One is a larger PS pump capable of increased flow and pressure with a restricted down output for the PS rack and the higher pressure output for the cylinders. The other is a 2nd pump added to the engine. Since we have a few pulleys that spin backward due to the serpintine belt, it may be possible to mount a pump on the front of the engine facing it. A backwards facing pump combined with a backward running pulley will mean it's turning in the proper direction.

I'm going to be looking into tractor equipment as they use engine driven pumps to run their hydraulics all the time. When I learn more I'll report back.

Now I did learn a few more things about the Cozytech unit. It consists of special coilovers with cylinders, a larger PS reservoir and a block with check valves and 2 dump solenoids. That's it. What actually provides the hydraulic pressure is the power steering pump. The whole hydraulic system uses PS fluid so everything is compatible.

So now I'm going to explore a engine driven pump as it would save lots of weight and complexity. I see 2 basic paths:

One is a larger PS pump capable of increased flow and pressure with a restricted down output for the PS rack and the higher pressure output for the cylinders. The other is a 2nd pump added to the engine. Since we have a few pulleys that spin backward due to the serpintine belt, it may be possible to mount a pump on the front of the engine facing it. A backwards facing pump combined with a backward running pulley will mean it's turning in the proper direction.

I'm going to be looking into tractor equipment as they use engine driven pumps to run their hydraulics all the time. When I learn more I'll report back.

Last edited by JasonWW; 12-06-2007 at 11:06 PM.

#7

This is starting to not be fun anymore.

The reasons I switched from an air system to hydraulic:

One, it should be cheaper than an air setup. (I'm not so sure about this anymore. I'm also not looking so hard at the bottom dollar. I want something that will work well and meet my goals. Price is not a high priority anymore)

Two, your spring rate will never change so you know your going to get the same great grip you have now. (I think I found a solution to this problem if you run 2 bags up front with an adjustable ride height threaded sleeve and collar)

Three, I should be able to get more range of suspension travel. (The dual bag setup should give me the range I need)

Four, it takes up less space as you don't need a big air tank. (The hydraulic setup was getting bigger and bigger. The air setup may actaully take less space)

The reasons I switched from an air system to hydraulic:

One, it should be cheaper than an air setup. (I'm not so sure about this anymore. I'm also not looking so hard at the bottom dollar. I want something that will work well and meet my goals. Price is not a high priority anymore)

Two, your spring rate will never change so you know your going to get the same great grip you have now. (I think I found a solution to this problem if you run 2 bags up front with an adjustable ride height threaded sleeve and collar)

Three, I should be able to get more range of suspension travel. (The dual bag setup should give me the range I need)

Four, it takes up less space as you don't need a big air tank. (The hydraulic setup was getting bigger and bigger. The air setup may actaully take less space)