Post your best welds!

#42

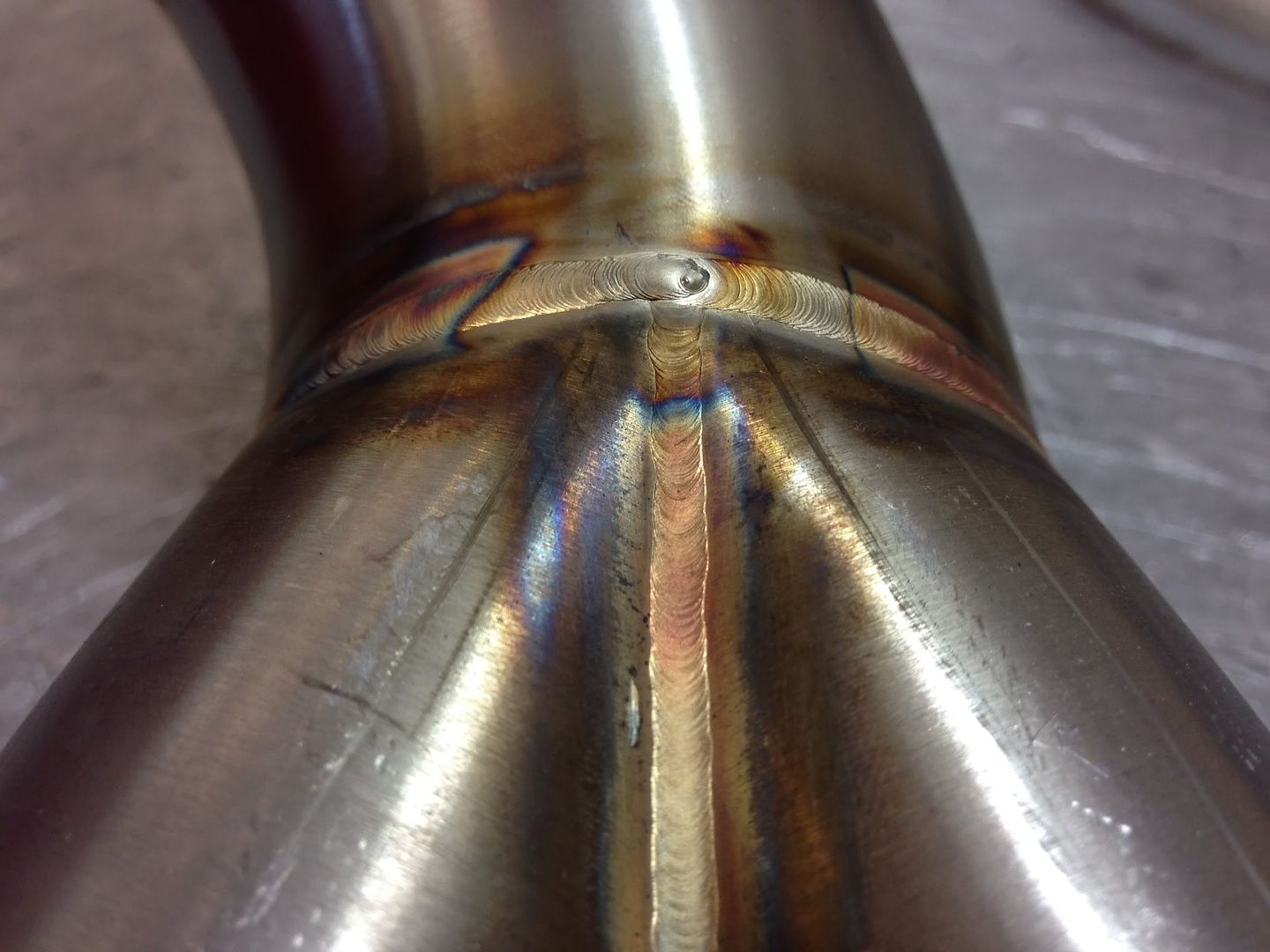

Unobtainium,

Damn dude. Awsome welds.

Damn dude. Awsome welds.

#46

Very nice looking work. Probably the best example is the Ti weld. Looks like it might have been a little better if a trailing cup were used (I may be wrong but looks like a little trash in there, usually get that when the Ti cools without purge, so you use a trailing cup).

And I see some can walk the cup. Very nice freehand stuff too, assuming nobody cheated and dry washed!

One note. Per AWS, 6G is a position using pipe. It is a butt weld on a fixed 45. Most around here cut coupons ~1 foot long, prep the joint, tack one to a fixture on a 45, tack the other coupon to the fixed one, then weld it out. It is used to qualify welders and is not limited to stick. It can be other processes like TIG.

Welders are the most tested craft out there in the PetroChem industry. They test to prove they can weld then have a minimum of 5% of their work tested after they have passed the test. (assuming they work on fixed equipment - tanks, pressure vessels, pipe).

In another life, I worked as a millwright, then as a welder. Then I decided to try working on the other side. I would be the guy that pisses welders off, especially when they didn't do something right.

And I see some can walk the cup. Very nice freehand stuff too, assuming nobody cheated and dry washed!

One note. Per AWS, 6G is a position using pipe. It is a butt weld on a fixed 45. Most around here cut coupons ~1 foot long, prep the joint, tack one to a fixture on a 45, tack the other coupon to the fixed one, then weld it out. It is used to qualify welders and is not limited to stick. It can be other processes like TIG.

Welders are the most tested craft out there in the PetroChem industry. They test to prove they can weld then have a minimum of 5% of their work tested after they have passed the test. (assuming they work on fixed equipment - tanks, pressure vessels, pipe).

In another life, I worked as a millwright, then as a welder. Then I decided to try working on the other side. I would be the guy that pisses welders off, especially when they didn't do something right.

#48

#51

Launching!

iTrader: (2)

Some great craftsmanship in here. One thing I have noticed is probably too much heat, too fast TS, or not enough wire on some of these welds. The concavity/throat under fill and undercut will lead to weld cracking on some applications. No reason to run that much heat input on such thin material. If you wanted penetration, TIG wouldn't be the first choice anyways. I'm being nit picky  all welds look impressive.

all welds look impressive.

all welds look impressive.

all welds look impressive.

#60

Very nice looking work. Probably the best example is the Ti weld. Looks like it might have been a little better if a trailing cup were used (I may be wrong but looks like a little trash in there, usually get that when the Ti cools without purge, so you use a trailing cup).

And I see some can walk the cup. Very nice freehand stuff too, assuming nobody cheated and dry washed!

One note. Per AWS, 6G is a position using pipe. It is a butt weld on a fixed 45. Most around here cut coupons ~1 foot long, prep the joint, tack one to a fixture on a 45, tack the other coupon to the fixed one, then weld it out. It is used to qualify welders and is not limited to stick. It can be other processes like TIG.

Welders are the most tested craft out there in the PetroChem industry. They test to prove they can weld then have a minimum of 5% of their work tested after they have passed the test. (assuming they work on fixed equipment - tanks, pressure vessels, pipe).

In another life, I worked as a millwright, then as a welder. Then I decided to try working on the other side. I would be the guy that pisses welders off, especially when they didn't do something right.

And I see some can walk the cup. Very nice freehand stuff too, assuming nobody cheated and dry washed!

One note. Per AWS, 6G is a position using pipe. It is a butt weld on a fixed 45. Most around here cut coupons ~1 foot long, prep the joint, tack one to a fixture on a 45, tack the other coupon to the fixed one, then weld it out. It is used to qualify welders and is not limited to stick. It can be other processes like TIG.

Welders are the most tested craft out there in the PetroChem industry. They test to prove they can weld then have a minimum of 5% of their work tested after they have passed the test. (assuming they work on fixed equipment - tanks, pressure vessels, pipe).

In another life, I worked as a millwright, then as a welder. Then I decided to try working on the other side. I would be the guy that pisses welders off, especially when they didn't do something right.

Welding is the most tested trade, no doubt. If you can't handle pressure, it's not a good choice.

I'll post a few more pics shortly.

[/URL]

[/URL]