Converting Unibody 4th gen to Solid Frame?

#101

Staging Lane

iTrader: (1)

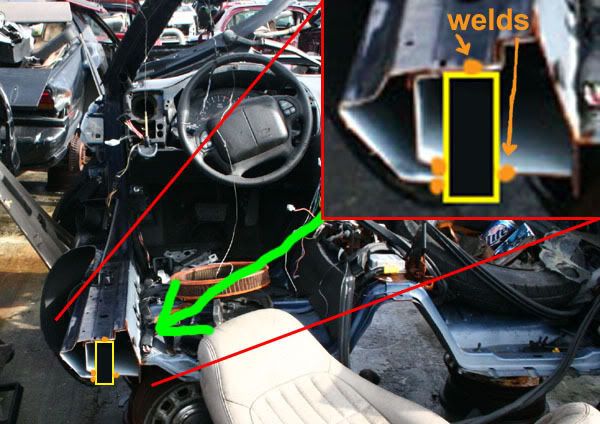

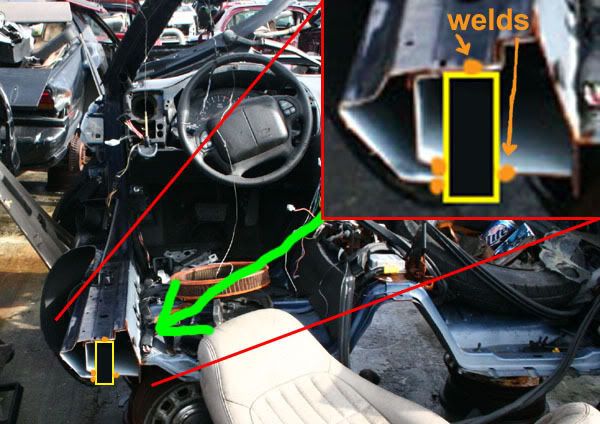

Sorry I didn't read the whole thread but I use to work for Griggs racing, they do mustangs, and the main chassis modification using tube steel would be to find where the sub frame is spot welded to to body from inside, then cut out the center and lay a tube inside and weld it up, usually from about the pedals to the bulk head of the body back by the rear seat, which we would then plate before welding the tube to it. This gave the cars awesome rigidity over a stock chassis. I'm sure something similar can be done with our cars, I just haven't bothered to try because my car cam with sub frame connectors and its just a street car. It looked like this http://www.teamvenomracing.com/image...griggsUSFC.jpg http://www.teamvenomracing.com/image...griggs-ufc.JPG

#102

The F-body doesn't use a subframe. The body is all stamped steel spotwelded together. Check out posts 45 and 46. I'd like to lay in some stiff tubing inside the factory rails. I think this is pretty much what your saying.

I mentioned maybe using this tubing as air tanks, but I've since learned that the rapid depressurization causes condensation to form. So I won't be using them for that.

I mentioned maybe using this tubing as air tanks, but I've since learned that the rapid depressurization causes condensation to form. So I won't be using them for that.

#103

TECH Fanatic

iTrader: (9)

The F-body doesn't use a subframe. The body is all stamped steel spotwelded together. Check out posts 45 and 46. I'd like to lay in some stiff tubing inside the factory rails. I think this is pretty much what your saying.

I mentioned maybe using this tubing as air tanks, but I've since learned that the rapid depressurization causes condensation to form. So I won't be using them for that.

I mentioned maybe using this tubing as air tanks, but I've since learned that the rapid depressurization causes condensation to form. So I won't be using them for that.

#104

Can anyone tell me how much structural stiffness the rear fenders are providing?

I basically would like the cut the rear fenders off and make them bolt on and off. I think the seams can be hidden in the door jamb and in the rear hatch groove. This will really pay off in the future as I'd like the widen the rear fender a few inches. I could even use the metal fenders to make a light weight fiberglass fender.

I'd like to move all the structural support in the rear from the unibody and into steel tubing. Then I can cut out the rear rails which wastes a like of space.

I basically would like the cut the rear fenders off and make them bolt on and off. I think the seams can be hidden in the door jamb and in the rear hatch groove. This will really pay off in the future as I'd like the widen the rear fender a few inches. I could even use the metal fenders to make a light weight fiberglass fender.

I'd like to move all the structural support in the rear from the unibody and into steel tubing. Then I can cut out the rear rails which wastes a like of space.

#105

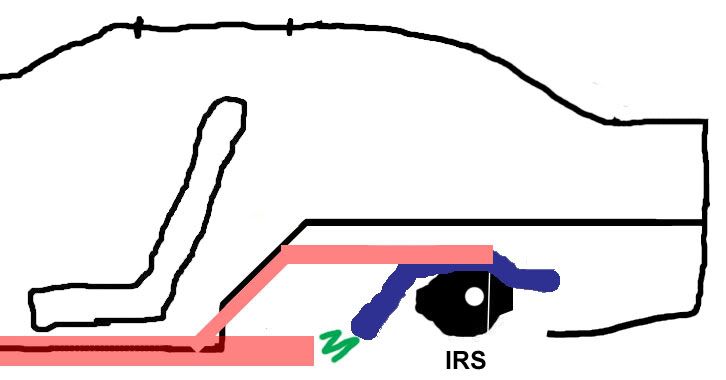

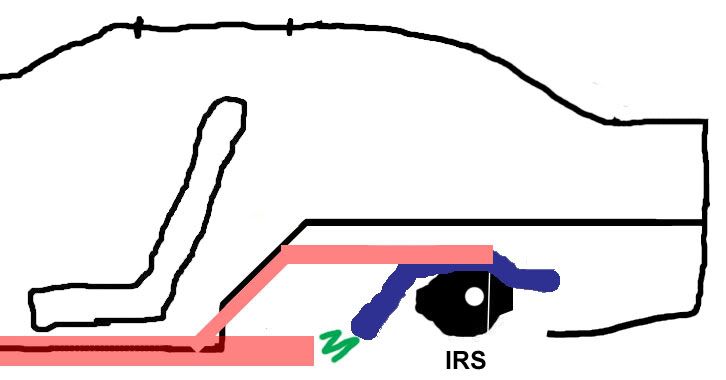

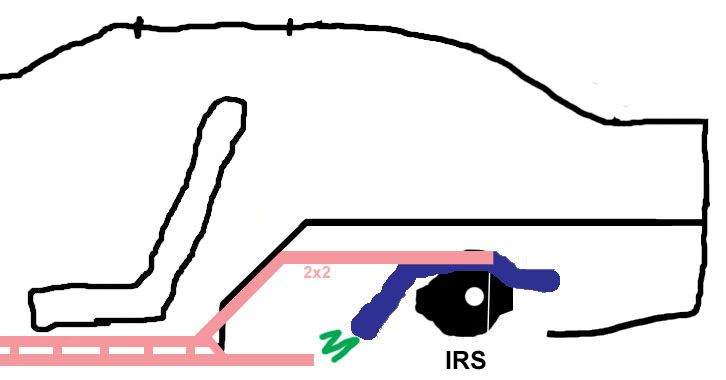

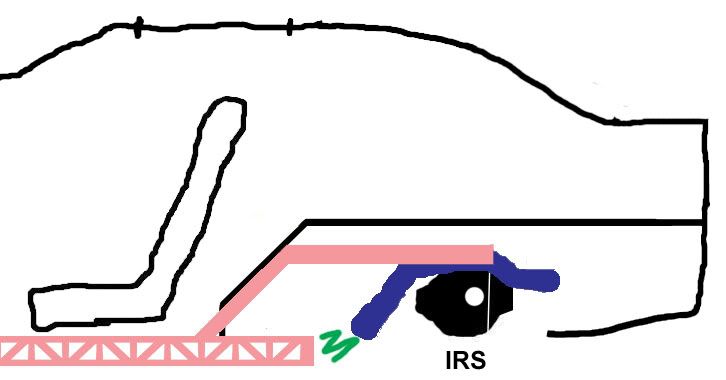

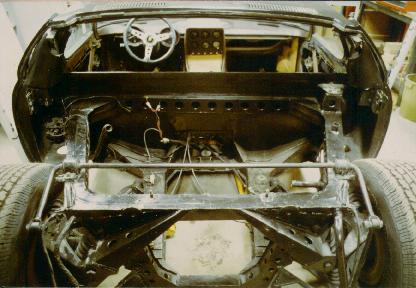

Here is the IRS I will be using. As you can see, it has it own small "subframe" and I would like to weld this in solid to the Trans Am's structure.

Since I'd like to make the car a vert in the future I'm trying to build up the frame without going above the cars belt line. In fact, I'd like the have sort of a panel wagon design with the gas tank in the back seat area.

With this setup the rear subframe will be pushing forward directly in the stock boxed frame reails under the doors. That should be fine for now. If I cut the roof off then I'll probably redo the frame rails uder the doors to make them stronger.

Since I'd like to make the car a vert in the future I'm trying to build up the frame without going above the cars belt line. In fact, I'd like the have sort of a panel wagon design with the gas tank in the back seat area.

With this setup the rear subframe will be pushing forward directly in the stock boxed frame reails under the doors. That should be fine for now. If I cut the roof off then I'll probably redo the frame rails uder the doors to make them stronger.

#107

Banned

iTrader: (20)

Join Date: Apr 2009

Location: Inside Your Girlfriend

Posts: 1,120

Likes: 0

Received 0 Likes

on

0 Posts

Too bad you and I are not in the same state bro, lol, if so we could come up with some SICKLY EXTREEEM ****. How about a hubless wheel

Anyways, below is what I have planed out for my doors and like you, everyone has run the gambit on negitive **** to say. Your right, no one here has much vision past 600hp

Keep up the CRAZY Bro!!!

DM

Oh and as for your Crazy Convertible idea... I use to have 2 Camaros that were modded by a company called Autoform. They were a Simi-hardtop 2 seater convert. See the pics below. Anyways, this is another idea I am messing around with, but I am a little ahead of you since my T/A is a vert already.

Last edited by Devils Mentor; 08-30-2009 at 09:04 PM.

#108

Banned

iTrader: (20)

Join Date: Apr 2009

Location: Inside Your Girlfriend

Posts: 1,120

Likes: 0

Received 0 Likes

on

0 Posts

BTW - If you are still having issues on how to fit the exhaust, have you thought about useing something like what NASCAR uses; it is called a Boom Pipe Exhaust. I don't know much about them, but they seem like it would help with tight fitments.

DM

DM

#109

For right now I just want to focus on the frame and suspension. I can get a bit overloaded when I get too many ideas in my head.

The roof and doors are okay for the time being, but the chop top is still in the plans. It will look just like the stock hardtop, but be removable.

It's too early to worry about the exhaust as well. With the IRS I can easily run true duals under the driveshaft then there are a lot of ways to do it after that.

The roof and doors are okay for the time being, but the chop top is still in the plans. It will look just like the stock hardtop, but be removable.

It's too early to worry about the exhaust as well. With the IRS I can easily run true duals under the driveshaft then there are a lot of ways to do it after that.

#110

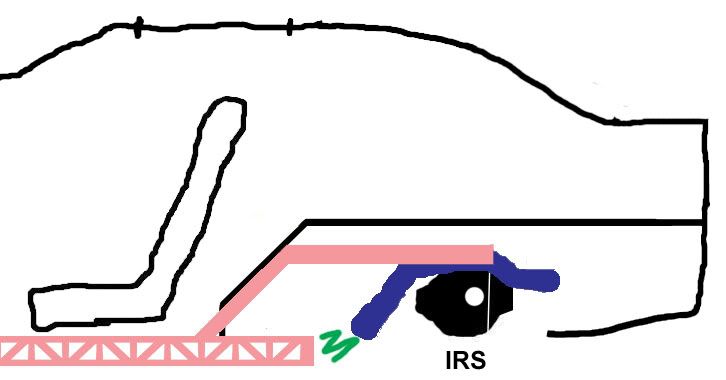

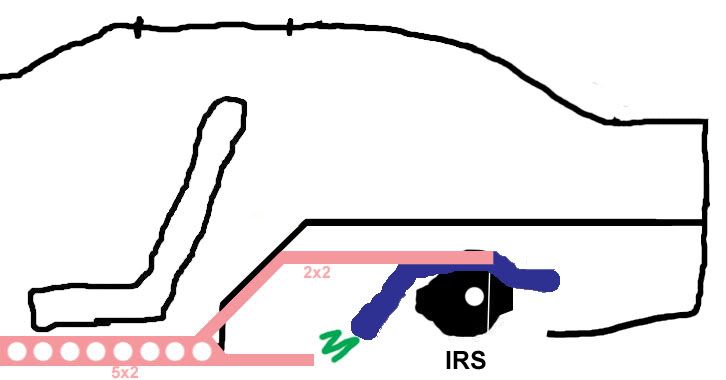

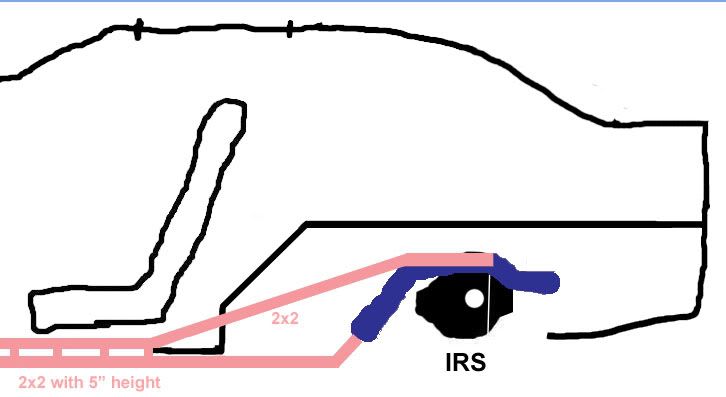

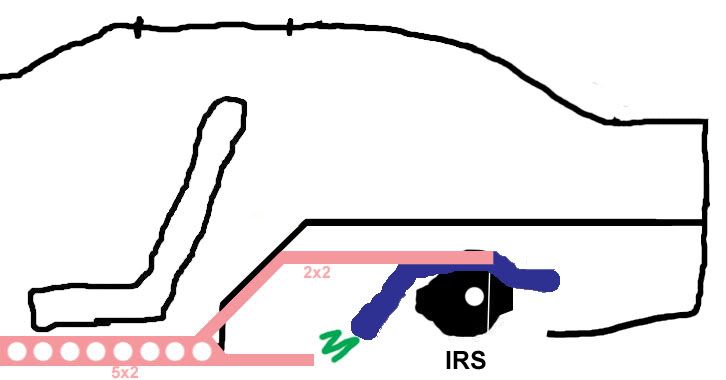

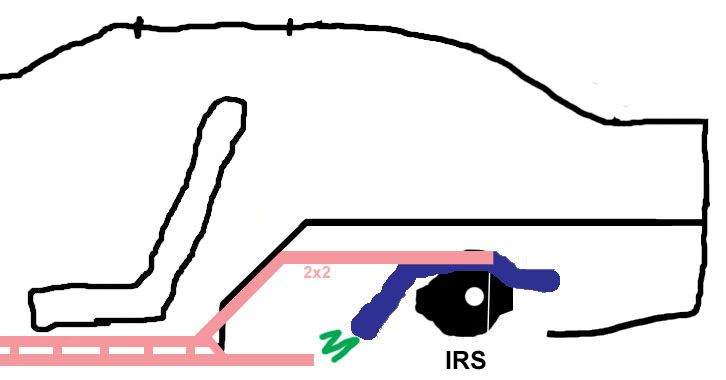

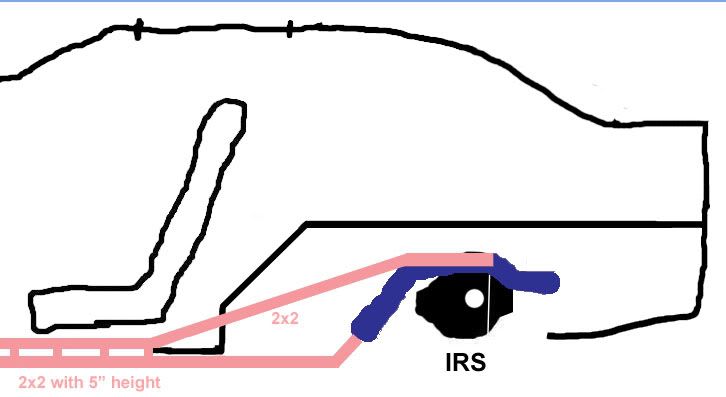

A few more ideas:

2x5 main rails with lots of material cut out with plasma torch.

A variation of the above.

2x2 main rails welded together for a 5" height.

A variation of the above.

I don't see any reason to make the frame rails any higher than the rails of the IRS, unless I want them for roll over protection.

I also don't want the rails any higher than 5" until they are out of the way behind the seat.

I'm trying to balance the material cost with labor time as well as weight versus strength.

2x5 main rails with lots of material cut out with plasma torch.

A variation of the above.

2x2 main rails welded together for a 5" height.

A variation of the above.

I don't see any reason to make the frame rails any higher than the rails of the IRS, unless I want them for roll over protection.

I also don't want the rails any higher than 5" until they are out of the way behind the seat.

I'm trying to balance the material cost with labor time as well as weight versus strength.

Last edited by JasonWW; 08-31-2009 at 08:08 PM.

#111

Just to remind everyone, these 36 inches are the critical area that need to be stiffened up.

That's why I was suggesting using such stiff materials like a 2x5 .125 tubing.

Or even 5" .125 round tubing. Yeah it's heavy, but the strength is really needed.

I think if I used 2x2 square tubing with the 1" gap, then I could use a lighter gauge tube. I'm not sure it would save any weight, though.

The 2x5 is 5.7lbs/ft, so 3 feet would be 17lbs per side.

That's why I was suggesting using such stiff materials like a 2x5 .125 tubing.

Or even 5" .125 round tubing. Yeah it's heavy, but the strength is really needed.

I think if I used 2x2 square tubing with the 1" gap, then I could use a lighter gauge tube. I'm not sure it would save any weight, though.

The 2x5 is 5.7lbs/ft, so 3 feet would be 17lbs per side.

Last edited by JasonWW; 08-31-2009 at 08:52 PM.

#117

Hi,I found this thread while searching for info regarding building Unibody projects.

What you are proposing is completely wrong and will make a whole lot of work.

The full chassis idea,while it has it's merits ( you could go the easy route and use a C10 frame.. .) a lot of the full chassis i see on various sites belong in the 1970's. Cars have progressed a real long way since the days of SBC's in a sqaure tube frame with a body on top.

.) a lot of the full chassis i see on various sites belong in the 1970's. Cars have progressed a real long way since the days of SBC's in a sqaure tube frame with a body on top.

I like your idea of the IRS but instead of a big bulky Ford item,why not go to a mercedes Benz W124 or W201 Rear end?

Nice and light ,they incorporate the springs and you will never build an engine with enough horses to break one. And you can pick up a whole mercedes 300E or 420 E for next to nothing (thanks to goldman sachs) .

GM late model Automatics use a rubber flex disc and drive shafts which bolt right up to the mercedes diff.

if you look around you can find one with ABS sensors. i have a friend who has even used one and incorporated air suspension ,ABS and ESP from an AMG Mercedes.

You said earlier you wanted Mid engine. It's not so hard , look for the Front wheel drive guts from a caddy.Use the trans and drive shafts and adapt the Chev engine in place of the North star.

Then,you can properly plan a frame to :1/ hold the engine in place behind the seats ,It will sit sideways ala Lambo Miura. 2/ Act as rear chassis to secure the body tub to the rear frame .

Your idea of the 5" tube won't work. You mentioned the old cobras,having driven a real 427 SC back in my youth I can promise you that they were really flexible and only the mad horsepower is what let them win sports car races.

What you need is to do is reinforce the exisiting structure by building a central tube frame which connects the rear chassis to the front of the car.

Again ,in the same manner as a Lamborghini Miura. Although they are over 40 years old,even Lambo hasn't built a chassis as beautiful as the Miura and so simple too.

Here is Fellow Kiwi Enginner Bob Wallace on the right with a Miura chassis . nice and light,super strong and handle like a true racer.

Now,can you see what I am saying ? ,the front suspension mounts on the frames on the front,this was connected to the frames on the rear where the engine sits sideways above the trans .(not such a hot idea but this was the 1960's!.i have a customer who wants me to install a BMW V12 in his to keep it on the road and reliable)

Here is a better pic.

As you can see,the whole shebang is very simple and if you think about it,it's easier to do it this way than spend time and money hacking around a perfectly nice body shape and fitting in big pieces of pipe which will nothing but take up your time and add weight.

Miura rear without engine.

here is the first chassis built(1965..!!) .

If you were to incorporate a tube center section with long rectangle of four tubes (1.5-2" OD ) running though the centerline of your cars body tieing the front and rear ends , acting as the tunnel,keep the rocker sections and still keep the really attractive lines of the body but have an insanely great handling car. Then the need for a ultrahigh performance engine wouldn't matter so much because in the twisty bits no one could catch you.

have a look at Ford GT40's from the same era,although the engine was mounted North /south the simple frame to hold everything in the back was a common idea back then.

Doing it this way,the body could be built very low,allowing for a full suspension movement with the need for bags .No need for power steering either as the weight would near to the center of the car,not over the front wheels. just a few thoughts! Cheers!

What you are proposing is completely wrong and will make a whole lot of work.

The full chassis idea,while it has it's merits ( you could go the easy route and use a C10 frame..

.) a lot of the full chassis i see on various sites belong in the 1970's. Cars have progressed a real long way since the days of SBC's in a sqaure tube frame with a body on top.

.) a lot of the full chassis i see on various sites belong in the 1970's. Cars have progressed a real long way since the days of SBC's in a sqaure tube frame with a body on top.I like your idea of the IRS but instead of a big bulky Ford item,why not go to a mercedes Benz W124 or W201 Rear end?

Nice and light ,they incorporate the springs and you will never build an engine with enough horses to break one. And you can pick up a whole mercedes 300E or 420 E for next to nothing (thanks to goldman sachs) .

GM late model Automatics use a rubber flex disc and drive shafts which bolt right up to the mercedes diff.

if you look around you can find one with ABS sensors. i have a friend who has even used one and incorporated air suspension ,ABS and ESP from an AMG Mercedes.

You said earlier you wanted Mid engine. It's not so hard , look for the Front wheel drive guts from a caddy.Use the trans and drive shafts and adapt the Chev engine in place of the North star.

Then,you can properly plan a frame to :1/ hold the engine in place behind the seats ,It will sit sideways ala Lambo Miura. 2/ Act as rear chassis to secure the body tub to the rear frame .

Your idea of the 5" tube won't work. You mentioned the old cobras,having driven a real 427 SC back in my youth I can promise you that they were really flexible and only the mad horsepower is what let them win sports car races.

What you need is to do is reinforce the exisiting structure by building a central tube frame which connects the rear chassis to the front of the car.

Again ,in the same manner as a Lamborghini Miura. Although they are over 40 years old,even Lambo hasn't built a chassis as beautiful as the Miura and so simple too.

Here is Fellow Kiwi Enginner Bob Wallace on the right with a Miura chassis . nice and light,super strong and handle like a true racer.

Now,can you see what I am saying ? ,the front suspension mounts on the frames on the front,this was connected to the frames on the rear where the engine sits sideways above the trans .(not such a hot idea but this was the 1960's!.i have a customer who wants me to install a BMW V12 in his to keep it on the road and reliable)

Here is a better pic.

As you can see,the whole shebang is very simple and if you think about it,it's easier to do it this way than spend time and money hacking around a perfectly nice body shape and fitting in big pieces of pipe which will nothing but take up your time and add weight.

Miura rear without engine.

here is the first chassis built(1965..!!) .

If you were to incorporate a tube center section with long rectangle of four tubes (1.5-2" OD ) running though the centerline of your cars body tieing the front and rear ends , acting as the tunnel,keep the rocker sections and still keep the really attractive lines of the body but have an insanely great handling car. Then the need for a ultrahigh performance engine wouldn't matter so much because in the twisty bits no one could catch you.

have a look at Ford GT40's from the same era,although the engine was mounted North /south the simple frame to hold everything in the back was a common idea back then.

Doing it this way,the body could be built very low,allowing for a full suspension movement with the need for bags .No need for power steering either as the weight would near to the center of the car,not over the front wheels. just a few thoughts! Cheers!

#118

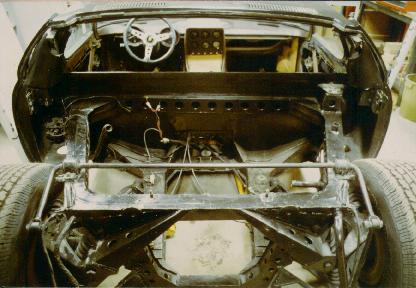

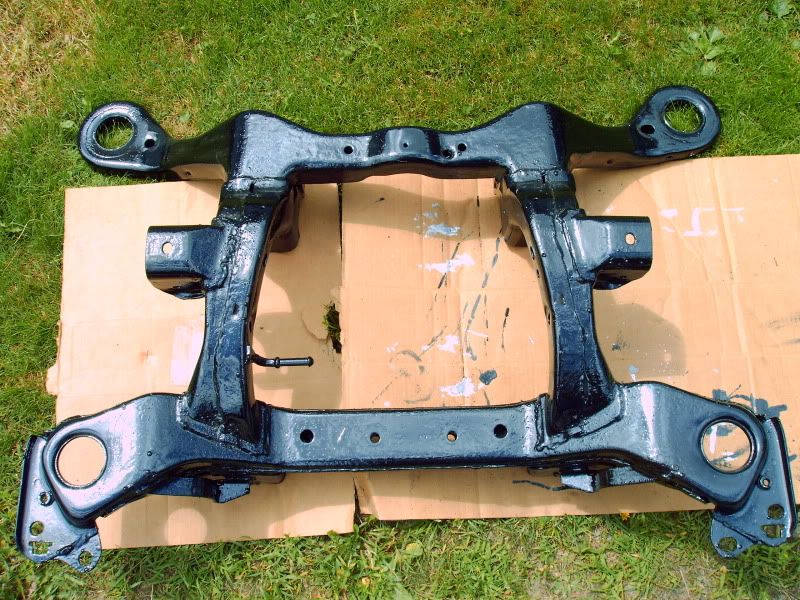

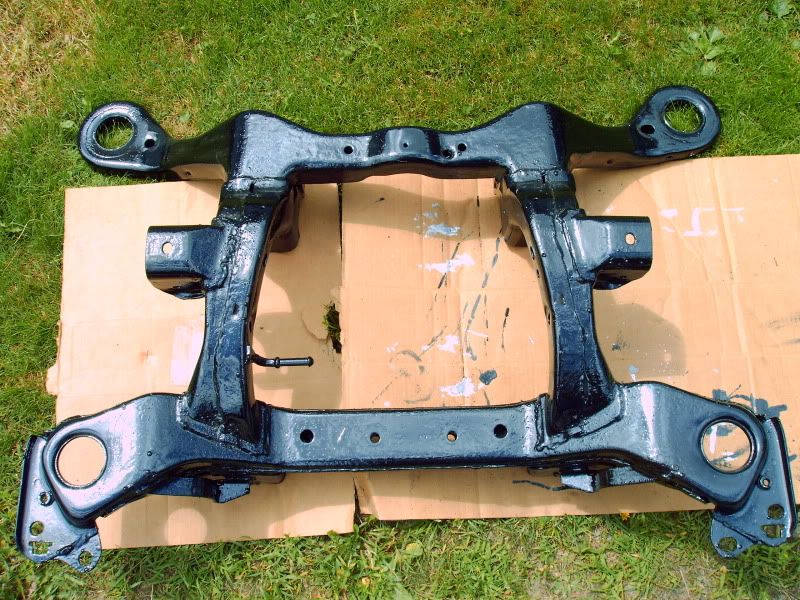

I just saw this thread. Figured id add some info about the Tbird/Cougar/Mark VIII subframe. The whole complete unit is HEAVYYYY. I wish I weighed it when I had my tbirds IRS out. The frame its self must be 100+lbs, the lower control arms are like 20-25lbs each. The Mark VIII has aluminum LCA's and aluminum gear case which would lose some weight.

Also some v6 Tbirds/Cougars had a 7.5 inch differential vs the normal 8.8.

Some pics of mine just for reference:

Also some v6 Tbirds/Cougars had a 7.5 inch differential vs the normal 8.8.

Some pics of mine just for reference:

#119

TECH Resident

iTrader: (13)

Join Date: Jan 2004

Location: South Carolina

Posts: 992

Likes: 0

Received 0 Likes

on

0 Posts

This is an exercise in adding weight where it isn't needed. To do it the correct way would be to build a "chromoloy" tube frame and modify the body to fit it, not hack up a uni-body and add stuff to it. The only advantage I can gleam from adding boxed frame rails is torsional rigidity and you're car is far from needing such. That's more of a complete road race build, one that when your car becomes that rigid you wouldn't want to drive it on the street without some kidney protection, otherwise with a much softer street-friendly suspension you're basically wasting much of that rigidity (meaning it's "nice" to say you have it but you just don't need it." It would handle/work better with more real world mods. I enjoy some of your ideas for mods, no matter how far out some of them are but I can't help to think poor f-body...