The Ultimate 4L60E 3/4 Clutch ?

#1

Moderator

Thread Starter

As we all know, the 3/4 clutch is the Achilles heel of the 4L60E, with 3rd gear slippage one of the most common problems mentioned on this forum.

==============================

UPDATE from June 28, 2021 (8-1/2 years later): While the Sonnax drum documented here is still a go-to piece, a competing drum called the 4L79 is considered even better by some. (Google "4L79 drum").

In the following thread we reach possible consensus that the Borg Warner "Hi-Energy" frictions are the best choice for frictions in the 3/4 clutch, but MORE Importantly that clutch-friction brand/choice rarely causes 3/4 failure, but rather that leaks in the 3/4 hydraulic circuit is by far the most common reason for early failure on a rebuild. So concentrate on testing/repairing/modifying the 3/4 clutch circuit before spending money on fancy parts.

https://ls1tech.com/forums/automatic...-clutches.html

End of Update.

==============================

In my quest to experiment with various aftermarket parts, I discovered this new input drum kit from Sonnax that claims to finally solve the 3/4 clutch problems:

I just ordered it and the suggested parts to go with it. It doesn't come cheap at $360 for the drum kit without input shaft. (I added $275 for a billet input shaft and $95 for the Sonnax billet forward piston.)

Its claimed advantages include:

* Stronger input drum by using a reinforcing locking plate instead of a snap ring.

* Space for one additional friction and steel.

Sonnax recommends these combinations:

• Eight .067" frictions with seven .095" steels

-OR-

• Nine .062" frictions with eight .077" steels

Wanted - Suggestions for Frictions

I am open to suggestions on how many and what brand/model frictions and steels to use. Possibilities include:

* Borg Warner Hi Energy - recommended by several builders here

* Raybestos GPZ100 - Fairly new model that I have been using

* Alto Red - I haven't seen many good reviews of these

For steels, I would consider GM's stock steels for the .095 as they have a coating supposedly better than Kolene. I would consider .077 Kolene steels, but cannot find any. Some builders say that plain steel are just fine.

Wanted - Suggestions for Springs and Clearance

The Sonnax instructions recommend an older style cage for 10% more spring force and .050 to .060 clearance. The Transgo HD2 kit comes with very stiff springs for the 22-spring cage which I estimate triples the stiffness. (Therefore I have been using 16 HD2 springs to only double the stiffness.)

Any experience with the full 22-spring HD2 kit would be appreciated. I plan to also use the Sonnax supplied 3-4 clutch return springs as I think they help reduce drag in 1st and 2nd gears.

I have been aiming for a clearance more in the .030 range, typically by using one or two slightly thicker (.080) frictions of the same brand/model.

I will post pictures when the parts arrive and then measurements with different friction sets. I would appreciate the exact recommended model number for the best Borg Warner Hi Energy frictions. (I already have the others.)

Update: Jump forward to post #29 to see the pictures and measurements.

==============================

UPDATE from June 28, 2021 (8-1/2 years later): While the Sonnax drum documented here is still a go-to piece, a competing drum called the 4L79 is considered even better by some. (Google "4L79 drum").

In the following thread we reach possible consensus that the Borg Warner "Hi-Energy" frictions are the best choice for frictions in the 3/4 clutch, but MORE Importantly that clutch-friction brand/choice rarely causes 3/4 failure, but rather that leaks in the 3/4 hydraulic circuit is by far the most common reason for early failure on a rebuild. So concentrate on testing/repairing/modifying the 3/4 clutch circuit before spending money on fancy parts.

https://ls1tech.com/forums/automatic...-clutches.html

End of Update.

==============================

In my quest to experiment with various aftermarket parts, I discovered this new input drum kit from Sonnax that claims to finally solve the 3/4 clutch problems:

I just ordered it and the suggested parts to go with it. It doesn't come cheap at $360 for the drum kit without input shaft. (I added $275 for a billet input shaft and $95 for the Sonnax billet forward piston.)

Its claimed advantages include:

* Stronger input drum by using a reinforcing locking plate instead of a snap ring.

* Space for one additional friction and steel.

Sonnax recommends these combinations:

• Eight .067" frictions with seven .095" steels

-OR-

• Nine .062" frictions with eight .077" steels

Wanted - Suggestions for Frictions

I am open to suggestions on how many and what brand/model frictions and steels to use. Possibilities include:

* Borg Warner Hi Energy - recommended by several builders here

* Raybestos GPZ100 - Fairly new model that I have been using

* Alto Red - I haven't seen many good reviews of these

For steels, I would consider GM's stock steels for the .095 as they have a coating supposedly better than Kolene. I would consider .077 Kolene steels, but cannot find any. Some builders say that plain steel are just fine.

Wanted - Suggestions for Springs and Clearance

The Sonnax instructions recommend an older style cage for 10% more spring force and .050 to .060 clearance. The Transgo HD2 kit comes with very stiff springs for the 22-spring cage which I estimate triples the stiffness. (Therefore I have been using 16 HD2 springs to only double the stiffness.)

Any experience with the full 22-spring HD2 kit would be appreciated. I plan to also use the Sonnax supplied 3-4 clutch return springs as I think they help reduce drag in 1st and 2nd gears.

I have been aiming for a clearance more in the .030 range, typically by using one or two slightly thicker (.080) frictions of the same brand/model.

I will post pictures when the parts arrive and then measurements with different friction sets. I would appreciate the exact recommended model number for the best Borg Warner Hi Energy frictions. (I already have the others.)

Update: Jump forward to post #29 to see the pictures and measurements.

Last edited by mrvedit; 06-28-2021 at 08:18 PM.

#3

Moderator

Thread Starter

I am installing it into a trans I built this spring which is starting to flare the 2-3 shift after repeated (and numerous daily) WOT 4-2 and 2-3 shifts.

I started with a brand new 2010 4L60E and rebuilt it with:

* Sonnax Smart shell

* 5-pinion rear planetary

* 6-pinion front planetary with 2.84 1st gear ratio

* BW dual cage sprag

* Wider bushings

* Carbon wide band (Reverse drum was new)

* High-rpm pump spring and Transgo hardened rings

* Brand new 2006 Valve body (to work with 2002 PCM)

* Transgo HD2 shift kit including input drum springs and bleed

* Corvette servo (Sonnax "super-hold" 2nd servo is on order)

* Sonnax 2-3 shift valve

* Sonnax Servo release check valve

* A few other parts from the Sonnax performance pack

Other than a billet pump rotor and output shaft, I think this is about as crazy as you can go with a 4L65E. I built several 4L60E before it with slightly lesser parts and have dropped/swapped valve bodies numerous times to experiment with different Transgo and Sonnax shift kit combinations. I tune with Hp Tuners.

Still hope to discover the "magic sauce" of frictions and clearance to use in this Sonnax input drum. Thanks.

Ted.

#5

Adding clutches to the 3-4 pack helps but it's not the ultimate answer.

That clutch needs more apply area. The small 3-4 apply piston is a big part of why it doesn't live. A bigger apply piston would improve the transmission greatly. There just isn't enough real estate to go much bigger.

I would use the BW High Energy frictions.

That clutch needs more apply area. The small 3-4 apply piston is a big part of why it doesn't live. A bigger apply piston would improve the transmission greatly. There just isn't enough real estate to go much bigger.

I would use the BW High Energy frictions.

#6

Moderator

Thread Starter

Adding clutches to the 3-4 pack helps but it's not the ultimate answer.

That clutch needs more apply area. The small 3-4 apply piston is a big part of why it doesn't live. A bigger apply piston would improve the transmission greatly. There just isn't enough real estate to go much bigger.

I would use the BW High Energy frictions.

That clutch needs more apply area. The small 3-4 apply piston is a big part of why it doesn't live. A bigger apply piston would improve the transmission greatly. There just isn't enough real estate to go much bigger.

I would use the BW High Energy frictions.

The suggestion for BW High Energy frictions seems to be unanimous.

#7

The heavy springs purpose is to aid in a quicker release of the 3-4 clutches on a 3-2 or 4-2 downshift.

A clutch pack generally doesn't release as quickly/cleanly as a band.

One thing to remember about transmissions used in a street application is that we demand more of them than we do a pure racing application.

One of these demands is downshifting. Downshifts are not really designed to be the inherent strength. The idea is to design a transmission that will survive hundreds of WOT upshifts, and hundreds of part throttle downshifts at the OEM level.

When the typical aftermarket modifies an auto for drag racing or performance use, almost everything we do is detrimental to doing WOT downshifts, because we are trying to achieve better WOT upshifts and clutch life.

A clutch pack generally doesn't release as quickly/cleanly as a band.

One thing to remember about transmissions used in a street application is that we demand more of them than we do a pure racing application.

One of these demands is downshifting. Downshifts are not really designed to be the inherent strength. The idea is to design a transmission that will survive hundreds of WOT upshifts, and hundreds of part throttle downshifts at the OEM level.

When the typical aftermarket modifies an auto for drag racing or performance use, almost everything we do is detrimental to doing WOT downshifts, because we are trying to achieve better WOT upshifts and clutch life.

Trending Topics

#8

TECH Fanatic

iTrader: (20)

Cool, any info on what frictions (make and part#) and clearance you used would be appreciated! I have gotten recommendations for Borg Warner Hi-Energy, but suspect there might be different models of that.

I am installing it into a trans I built this spring which is starting to flare the 2-3 shift after repeated (and numerous daily) WOT 4-2 and 2-3 shifts.

I started with a brand new 2010 4L60E and rebuilt it with:

* Sonnax Smart shell

* 5-pinion rear planetary

* 6-pinion front planetary with 2.84 1st gear ratio

* BW dual cage sprag

* Wider bushings

* Carbon wide band (Reverse drum was new)

* High-rpm pump spring and Transgo hardened rings

* Brand new 2006 Valve body (to work with 2002 PCM)

* Transgo HD2 shift kit including input drum springs and bleed

* Corvette servo (Sonnax "super-hold" 2nd servo is on order)

* Sonnax 2-3 shift valve

* Sonnax Servo release check valve

* A few other parts from the Sonnax performance pack

Other than a billet pump rotor and output shaft, I think this is about as crazy as you can go with a 4L65E. I built several 4L60E before it with slightly lesser parts and have dropped/swapped valve bodies numerous times to experiment with different Transgo and Sonnax shift kit combinations. I tune with Hp Tuners.

Still hope to discover the "magic sauce" of frictions and clearance to use in this Sonnax input drum. Thanks.

Ted.

I am installing it into a trans I built this spring which is starting to flare the 2-3 shift after repeated (and numerous daily) WOT 4-2 and 2-3 shifts.

I started with a brand new 2010 4L60E and rebuilt it with:

* Sonnax Smart shell

* 5-pinion rear planetary

* 6-pinion front planetary with 2.84 1st gear ratio

* BW dual cage sprag

* Wider bushings

* Carbon wide band (Reverse drum was new)

* High-rpm pump spring and Transgo hardened rings

* Brand new 2006 Valve body (to work with 2002 PCM)

* Transgo HD2 shift kit including input drum springs and bleed

* Corvette servo (Sonnax "super-hold" 2nd servo is on order)

* Sonnax 2-3 shift valve

* Sonnax Servo release check valve

* A few other parts from the Sonnax performance pack

Other than a billet pump rotor and output shaft, I think this is about as crazy as you can go with a 4L65E. I built several 4L60E before it with slightly lesser parts and have dropped/swapped valve bodies numerous times to experiment with different Transgo and Sonnax shift kit combinations. I tune with Hp Tuners.

Still hope to discover the "magic sauce" of frictions and clearance to use in this Sonnax input drum. Thanks.

Ted.

16 Z-pack clutchs at .050 will be fine...First few years my car was in the 10's I had the "Noraml" 14 clutch Z-pack that if installed only is usually .075'' never had one burn on me great clutch design...set one up at .050 add 2 clutchs, hello 9's capability

, just MAKE SURE to start with an outside spline clutch if you use this setup,

, just MAKE SURE to start with an outside spline clutch if you use this setup, Good Luck!

#9

Moderator

Thread Starter

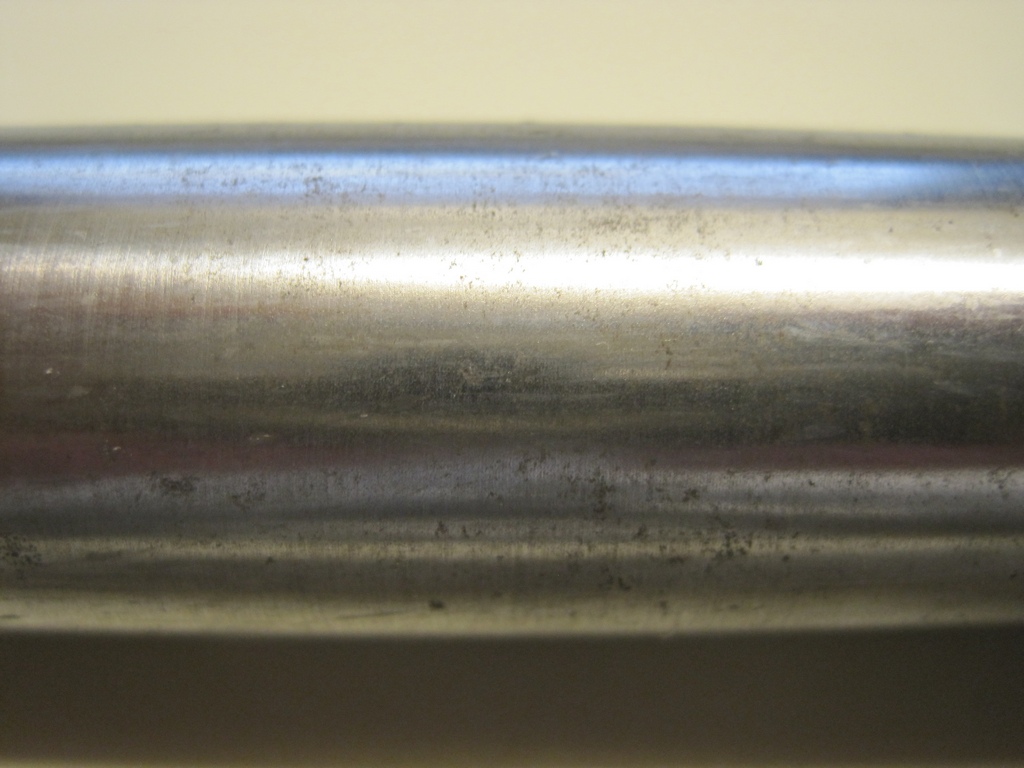

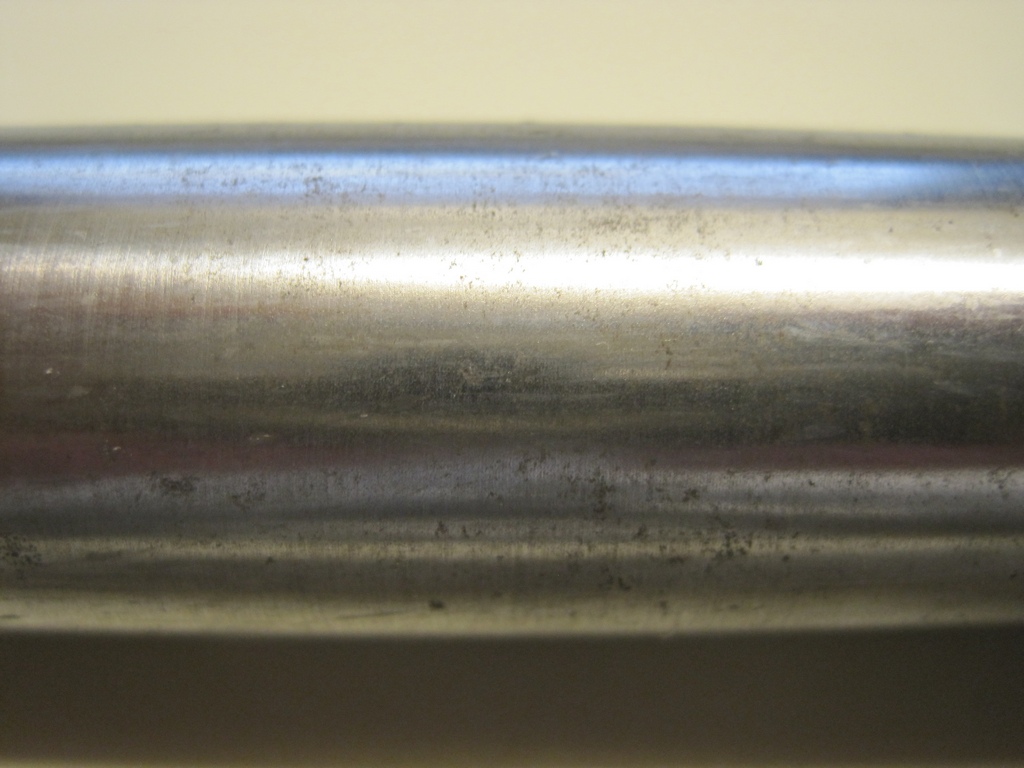

I ordered and received the Billet input shaft from ebay seller "boundlessv" for $275:

http://www.ebay.com/itm/GM-4L60E-4L6...-/261132044684

It is supposedly made from "M300 Steel" (not to be confused with its 300mm size).

Here are pics:

There is some porosity in the metal, unlike a billet camshaft, but perhaps that is irrelevant. The seller only sells billet parts he makes himself and has a 100% satisfaction rate.

Does it look good enough to try?

http://www.ebay.com/itm/GM-4L60E-4L6...-/261132044684

It is supposedly made from "M300 Steel" (not to be confused with its 300mm size).

Here are pics:

There is some porosity in the metal, unlike a billet camshaft, but perhaps that is irrelevant. The seller only sells billet parts he makes himself and has a 100% satisfaction rate.

Does it look good enough to try?

Last edited by mrvedit; 12-02-2012 at 02:59 PM. Reason: Moved image links

#10

I know who makes that shaft and he's not in Colorado.

It does appear to be 300M and it's a good piece. I could have saved you some money on it.

The porosity appearance happens in heat treat.

It does appear to be 300M and it's a good piece. I could have saved you some money on it.

The porosity appearance happens in heat treat.

#11

Moderator

Thread Starter

Thank you for the information Jake.

If you can sell it for less than $275, you might get some takers.

I feel much more comfortable using it now.

Any advice on whether the TCC checkball is needed?

If you can sell it for less than $275, you might get some takers.

I feel much more comfortable using it now.

Any advice on whether the TCC checkball is needed?

#13

Moderator

Thread Starter

#14

I spent some time with a former sponsor who has been using the new smart drum on higher end builds.

Was setting these up using all the transgo springs as well as the helper springs that go in the drum. Was using 8 borg warner clutches since the new drum allows for the thicker steels than the stock drum.

My previous thread searches showed most builders using .077 steels or similar for an 8 clutch setup. As you have realized the new drum allows the thickest .095 steels with 8 clutches.

Now thinking about this it would seem to me that if the new drum really elimintes the flex problem and reinforces the end retainer by eliminating the snap ring that this may allow for further experimenting. I think feed holes could be enlarged without fear of blowing snap rings or excessive pressure causing flex and coning. It may also be possible to increase clutch count to 10 or more and use thinner steels without fear of coning.

Was setting these up using all the transgo springs as well as the helper springs that go in the drum. Was using 8 borg warner clutches since the new drum allows for the thicker steels than the stock drum.

My previous thread searches showed most builders using .077 steels or similar for an 8 clutch setup. As you have realized the new drum allows the thickest .095 steels with 8 clutches.

Now thinking about this it would seem to me that if the new drum really elimintes the flex problem and reinforces the end retainer by eliminating the snap ring that this may allow for further experimenting. I think feed holes could be enlarged without fear of blowing snap rings or excessive pressure causing flex and coning. It may also be possible to increase clutch count to 10 or more and use thinner steels without fear of coning.

#15

Moderator

Thread Starter

Thanks for the additional input HighMileageC4. I currently have sets of all the different thickness frictions and steels with which to experiment. BorgWarner, Raybestos, Alto, got them all.

I will aim for 9 frictions, but will document the combos that fit.

This drum is a fairly new part; hopefully we will know by next summer whether it really solves the 3/4 clutch problem.

I will aim for 9 frictions, but will document the combos that fit.

This drum is a fairly new part; hopefully we will know by next summer whether it really solves the 3/4 clutch problem.

#16

I have not used the the drum but, that anchor plate looks like a good idea. As far as the 3-4 clutch goes you are still left with the same common stack up of 7,8,or 9 that has been commonly used. On the Chevy full size 2500 vans with the 5.7L we use Raybestos stage1 frictions from a th350. I had special steels and pressure plates made and do some machine work on the 3-4 clutch hub and the input drum. It gave us a some good results.

The following users liked this post:

headsup9550 (08-31-2021)