How many of you dowl or pin your mains?

#1

Launching!

Thread Starter

iTrader: (17)

Join Date: May 2006

Location: MN

Posts: 278

Likes: 0

Received 0 Likes

on

0 Posts

This seems to be pretty common in high hp and fi app so I hope I'm in the right forum?

At what power level is it recommended?

I have had my mains machined already. Is it to late?

Could anyone shed some light on this procedure?

At what power level is it recommended?

I have had my mains machined already. Is it to late?

Could anyone shed some light on this procedure?

#2

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

anything over 800 hp and I'd considering them. I think it has to be done before a line hone incase anything moves...

I know my block had the mains moving a considerable amount at 1200 RWHP

I know my block had the mains moving a considerable amount at 1200 RWHP

#5

Staging Lane

iTrader: (3)

Join Date: Jul 2004

Location: SS Indianapolis,In.

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Also interested in this,any picks,write up on it. I plan on running iron 6.0 short filled and anything else that could help it I will do. Sure my engine builder knows what it is,but can someone give us guy that dont know some insite.

Trending Topics

#10

TECH Apprentice

looking good shawn..

i was actually thinking of something simular,

in the heavy diesel world, they have the 'sleeves' or dowels . that are hollow , and the bolt hole is inside the dowel

you know what i mean?

for the 7/16 sbc main stud, the sleeve is say 5/8 , and hollow, and the stud thread is inside the sleeve / dowel

how would this work ??

ash

i was actually thinking of something simular,

in the heavy diesel world, they have the 'sleeves' or dowels . that are hollow , and the bolt hole is inside the dowel

you know what i mean?

for the 7/16 sbc main stud, the sleeve is say 5/8 , and hollow, and the stud thread is inside the sleeve / dowel

how would this work ??

ash

#11

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

looking good shawn..

i was actually thinking of something simular,

in the heavy diesel world, they have the 'sleeves' or dowels . that are hollow , and the bolt hole is inside the dowel

you know what i mean?

for the 7/16 sbc main stud, the sleeve is say 5/8 , and hollow, and the stud thread is inside the sleeve / dowel

how would this work ??

ash

i was actually thinking of something simular,

in the heavy diesel world, they have the 'sleeves' or dowels . that are hollow , and the bolt hole is inside the dowel

you know what i mean?

for the 7/16 sbc main stud, the sleeve is say 5/8 , and hollow, and the stud thread is inside the sleeve / dowel

how would this work ??

ash

#12

Staging Lane

iTrader: (3)

Join Date: Jul 2004

Location: SS Indianapolis,In.

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

This may sound dumb,but how are they drilled?Is it with the caps on? I know you said the mains may get recut but with it be a machine fit and no room for error. Sorry I'm not a machinest and the procedure info would be great.

Thanks again

Thanks again

#18

FormerVendor

iTrader: (3)

Join Date: Jun 2007

Location: Virginia Beach,Virginia

Posts: 2,991

Likes: 0

Received 2 Likes

on

2 Posts

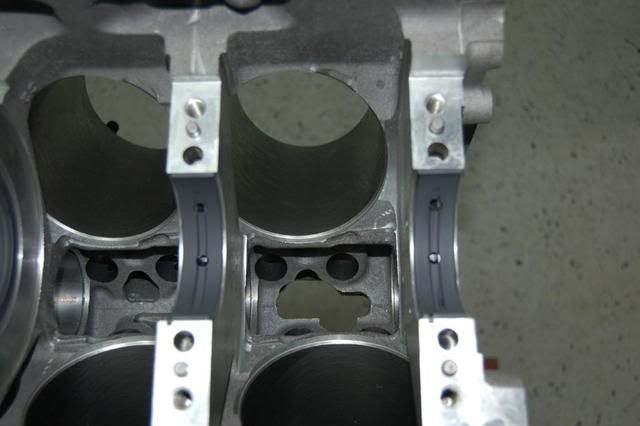

yes,i machine the hole in the block and caps with the cnc,accuracy really needs to be greater than .001,you could probably do it in a std mill but it would be very time consuming.i'll post some pics later

as far as the caps being porous and brittle,they are much better than cast iron,i dont think you will be able to push air or water through them,they are actually a very strong piece,Brian's motor made 1400+ on stock caps with no issues other than cap walk.

as far as the caps being porous and brittle,they are much better than cast iron,i dont think you will be able to push air or water through them,they are actually a very strong piece,Brian's motor made 1400+ on stock caps with no issues other than cap walk.