To re-use the stock alt. bracket for relocation

#1

I am not by any means claming the to be my idea, there was another member in another thread that used it but he never elaborated on how he did it.

I wanted to share in minor detail how I am planning to do it, which is probably how he did it too. Smaller belt will be necessary.

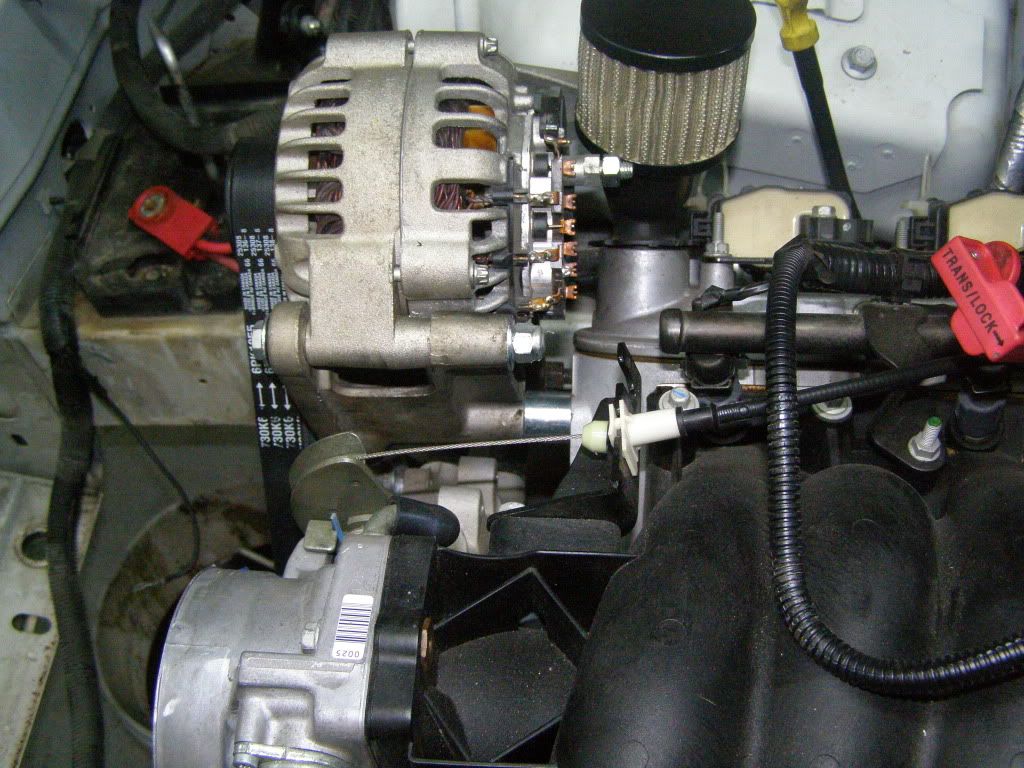

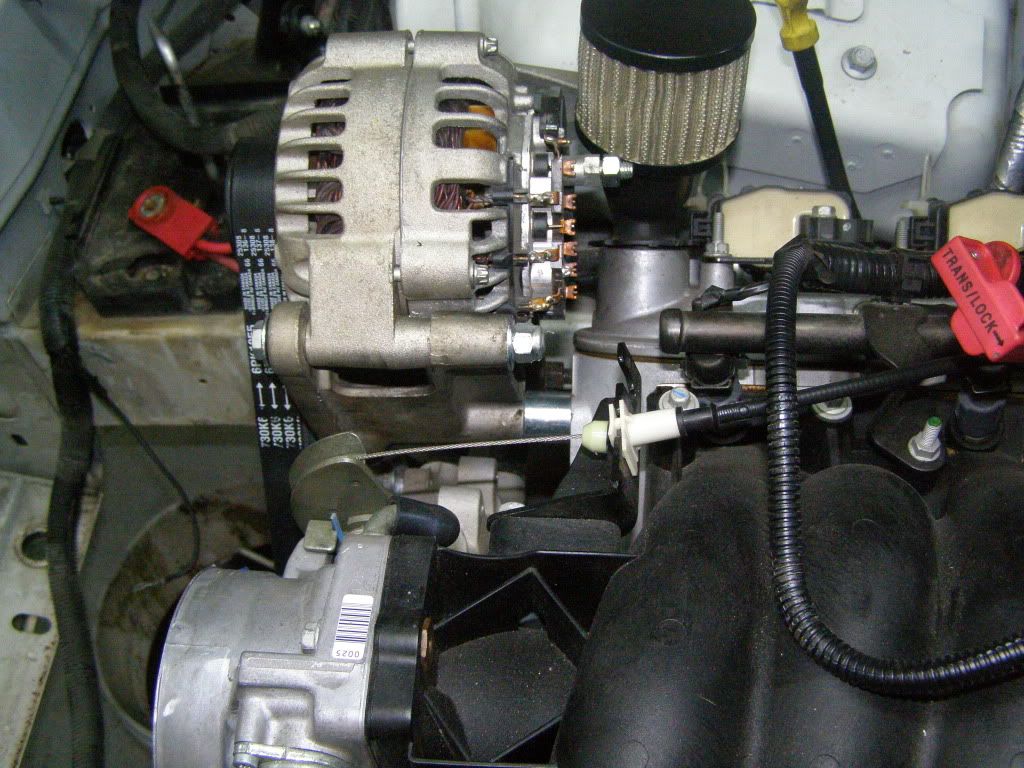

I did a quick mock-up and here are some pics.

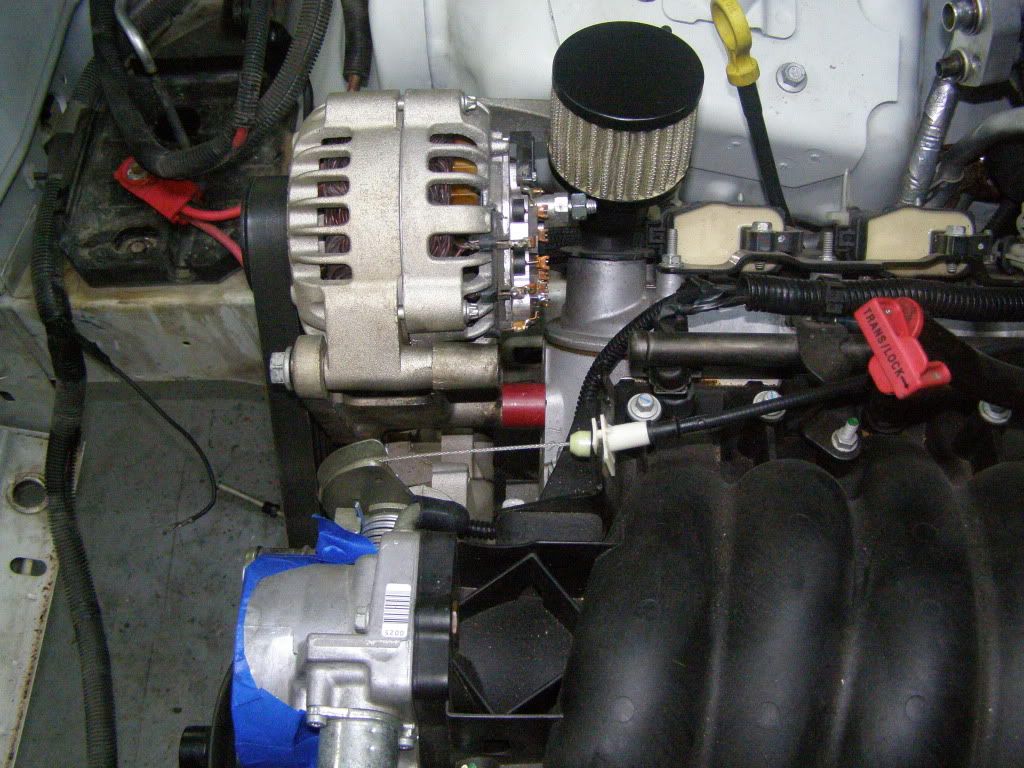

This gives you an idea of where it sits....doesn't look like aftermarket rails will work, but you might be able to rotate it left enough to get them in(I don't know).

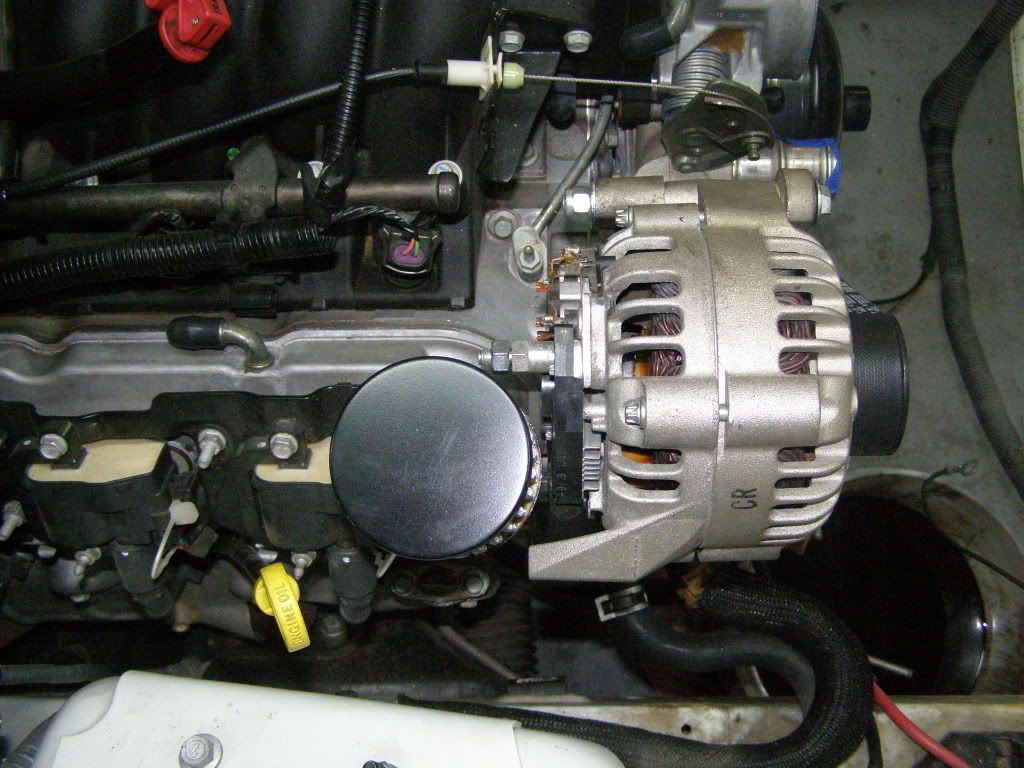

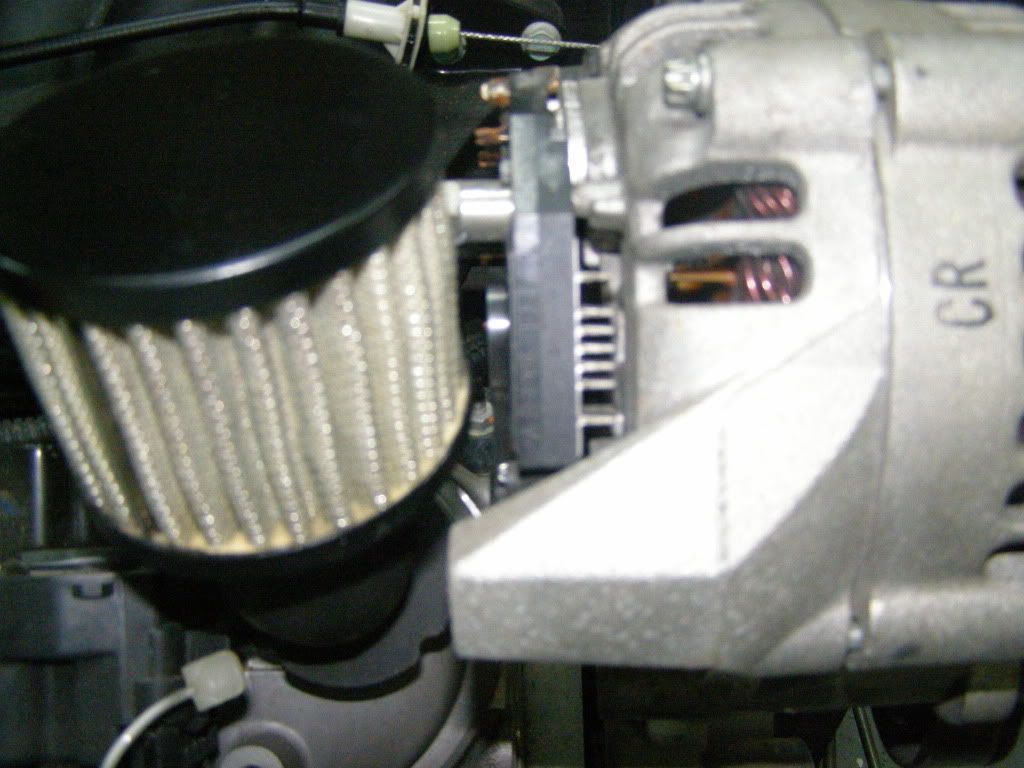

Here you can see the clearance I have away from my breather, should be quite a bit more room if you are keeping your pcv system.

I had a red spacer laying around and it's nearly perfect. Of course this will be a steel or aluminum spacer.

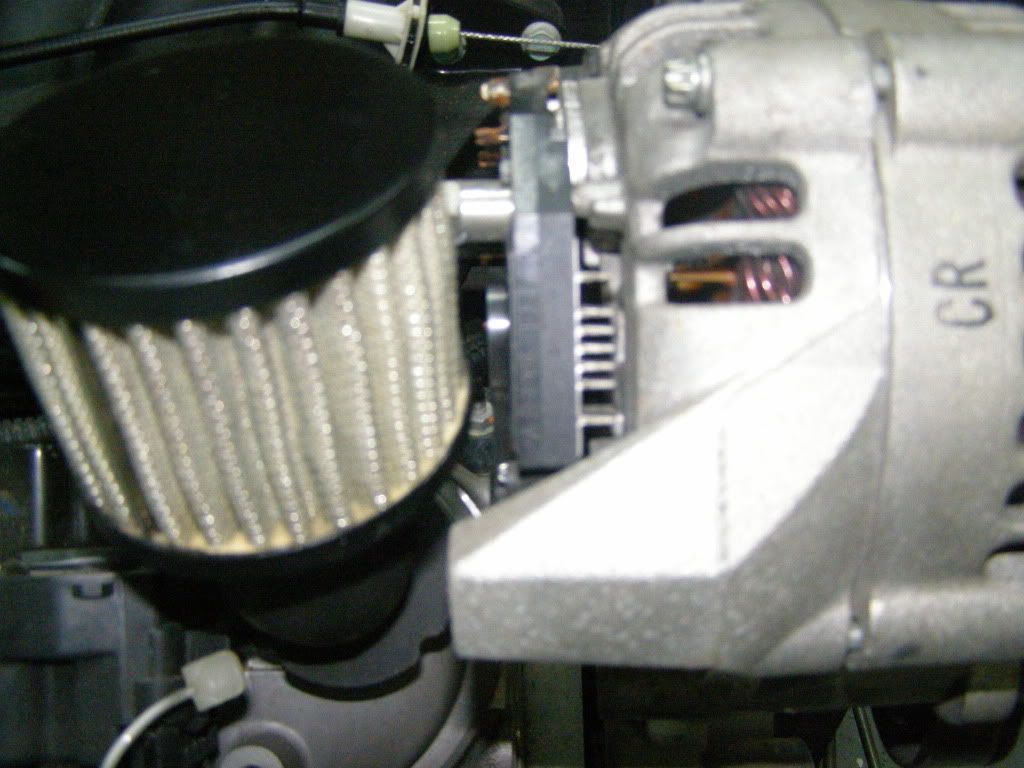

I used the stock bolts in this picture simply for visual purposes. The yellow dots indicate the two bolts the flatstock will connect. I will use a similar spacer against the head for this part minus the thickness of the flatstock you will see in the next picture.

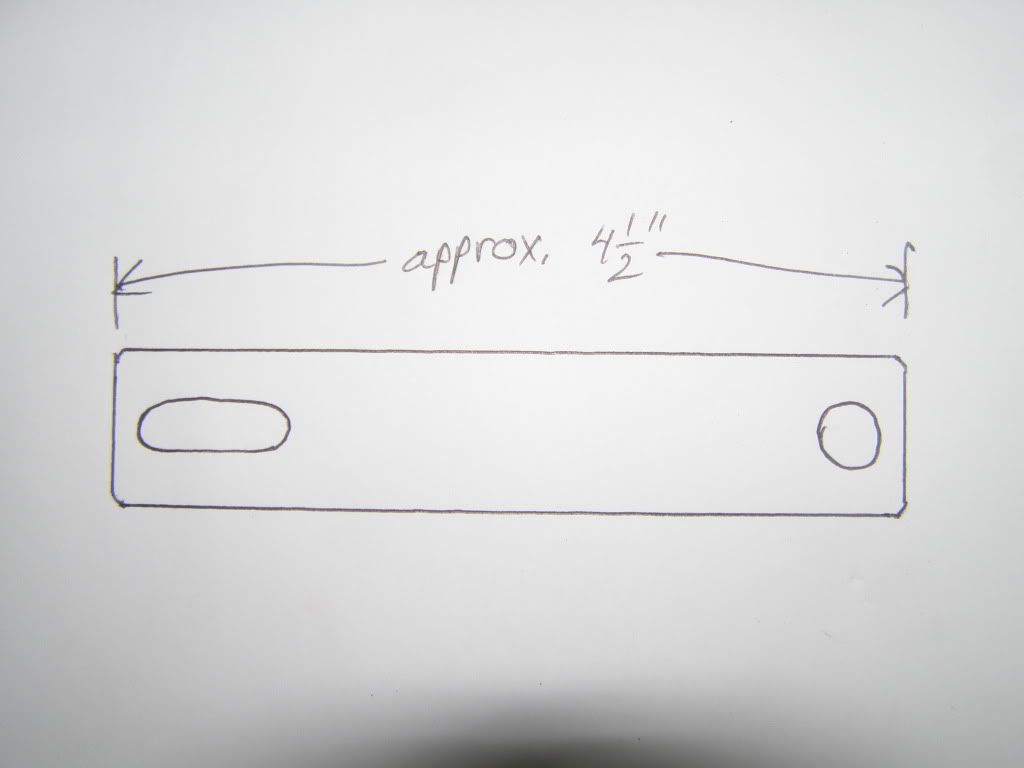

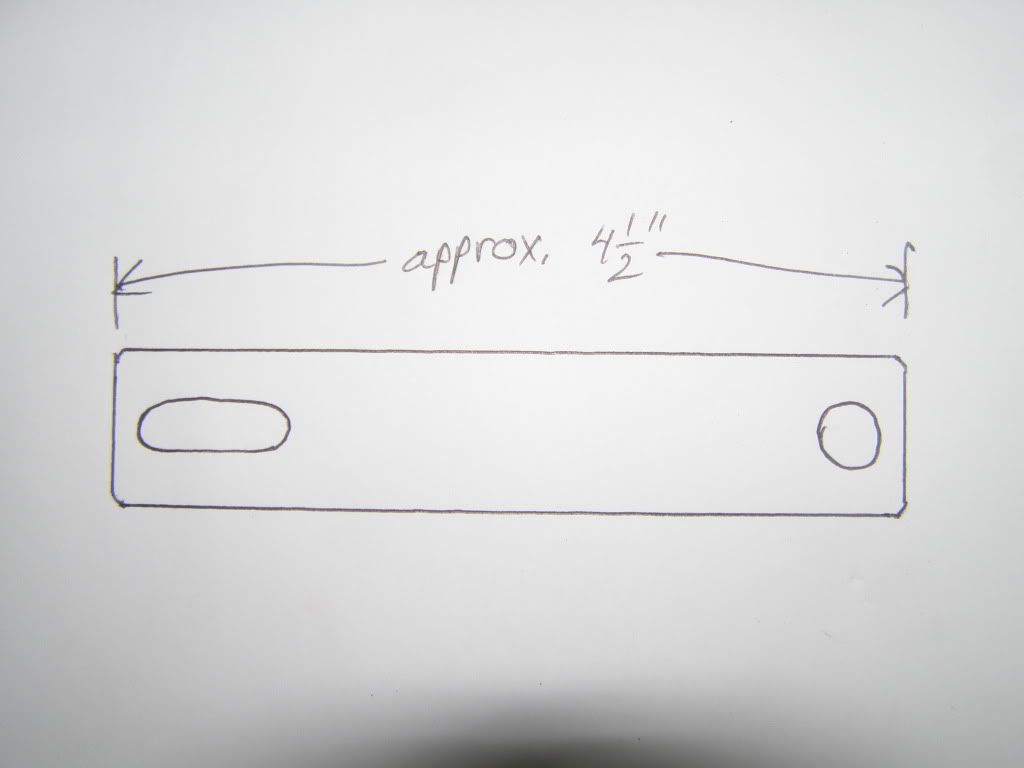

This is a very rough sketch of what I plan to use as a stabilizer/tensioner and will be made of steel flat stock. I will either use a spacer and keep it flat or make bends at either bolt mounting point for a slight "S" shape to it.

I will be trying to put this together tomorrow, but unless I've missed something this should work and be very cheap to make. The only problem I could see is it putting too much stress on the one bolt holding it to the head....Have an idea of how to counter act that but we'll see. Just thought I would share this info....have to see if it works like I think it will though.

I wanted to share in minor detail how I am planning to do it, which is probably how he did it too. Smaller belt will be necessary.

I did a quick mock-up and here are some pics.

This gives you an idea of where it sits....doesn't look like aftermarket rails will work, but you might be able to rotate it left enough to get them in(I don't know).

Here you can see the clearance I have away from my breather, should be quite a bit more room if you are keeping your pcv system.

I had a red spacer laying around and it's nearly perfect. Of course this will be a steel or aluminum spacer.

I used the stock bolts in this picture simply for visual purposes. The yellow dots indicate the two bolts the flatstock will connect. I will use a similar spacer against the head for this part minus the thickness of the flatstock you will see in the next picture.

This is a very rough sketch of what I plan to use as a stabilizer/tensioner and will be made of steel flat stock. I will either use a spacer and keep it flat or make bends at either bolt mounting point for a slight "S" shape to it.

I will be trying to put this together tomorrow, but unless I've missed something this should work and be very cheap to make. The only problem I could see is it putting too much stress on the one bolt holding it to the head....Have an idea of how to counter act that but we'll see. Just thought I would share this info....have to see if it works like I think it will though.

Last edited by Dr. Jeckel; 08-06-2009 at 08:32 PM.

#7

Your concerns are warranted but it's the same principal as old school setups and the Speed Inc. setup....the alternator pulled tight creates tension....you just have to make sure it's good and tight

Problem is that I won't really be able to test it's street worthiness for about 6 months when I finish the kit....but hopefully someone else that's done with theirs or near done can try it in the real world and not just the theoretical as I am doing.

If it doesn't work I will be out about $10 in materials.

Problem is that I won't really be able to test it's street worthiness for about 6 months when I finish the kit....but hopefully someone else that's done with theirs or near done can try it in the real world and not just the theoretical as I am doing.

If it doesn't work I will be out about $10 in materials.

Trending Topics

#8

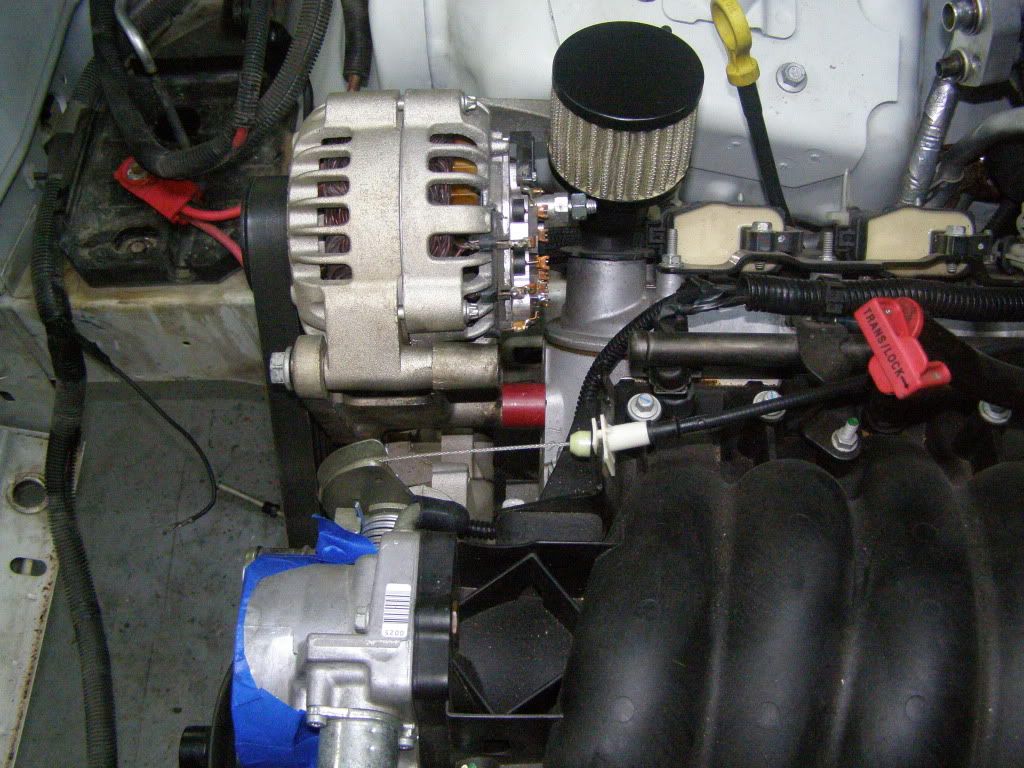

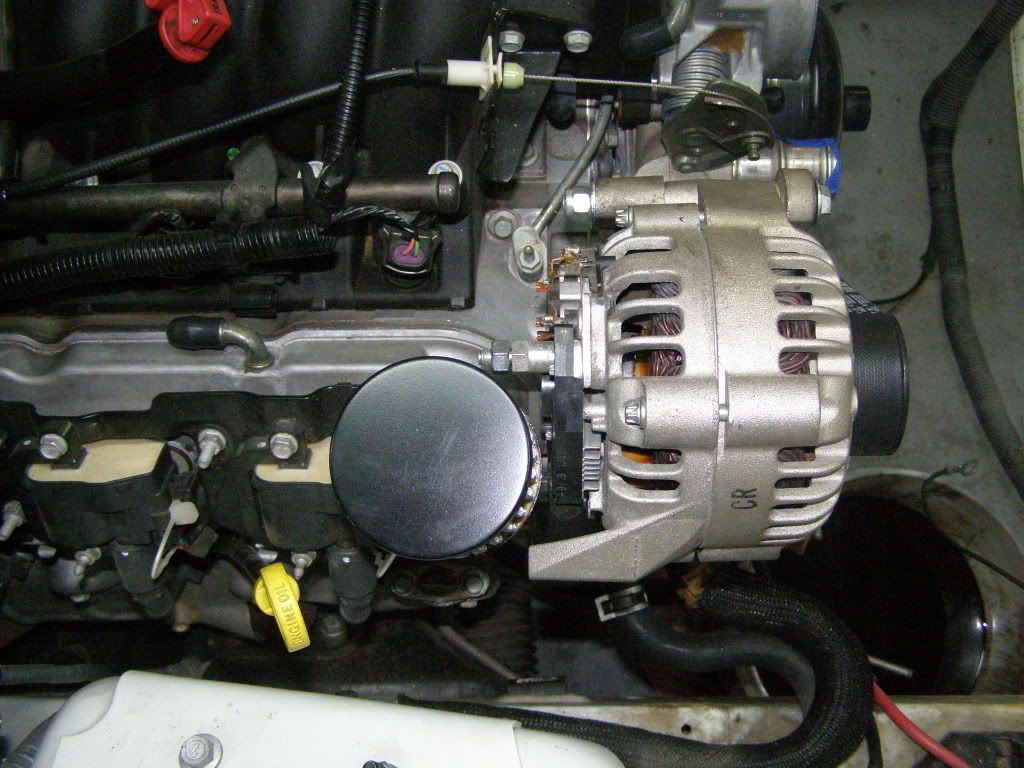

I got it on. Used a 73in belt, the 72.5" was just way to tight. I wish I could go out and test it. I know it's not worth much, but I turned over the engine by hand a few revolutions to see if the belt tracked ok and it did, but like I said, that don't mean much. There is an extremely small amount of play in the alternator...maybe 1/64". Like I said, i wish I could take it out and test it at 6k rpm, but sadly this is not the case.

Perhaps someone else will try this out and verify if it actually holds up.

Here are some pics.

Perhaps someone else will try this out and verify if it actually holds up.

Here are some pics.