Who has over spun their D1? I've talked to 3 techs at Procharger w/3 different answer

#1

I've talked to 3 tech guys at Procharger and they each gave me a different answer.

Tech Guy 1: "I would not recommend it"

Tech Guy 2: "You shouldn't have a problem at 65000, but I wouldn't go more than that"

Tech Guy 3: "Its a crap shoot, I've seen them fail at 62500 and I've seen guys spinning them 68000 for years with no problems"

So what is your take on this? Is the benefit going from 62000 to 65000 worth the risk? Will it actually make a significant amount of extra power, besides the boost coming in quicker?

Tech Guy 1: "I would not recommend it"

Tech Guy 2: "You shouldn't have a problem at 65000, but I wouldn't go more than that"

Tech Guy 3: "Its a crap shoot, I've seen them fail at 62500 and I've seen guys spinning them 68000 for years with no problems"

So what is your take on this? Is the benefit going from 62000 to 65000 worth the risk? Will it actually make a significant amount of extra power, besides the boost coming in quicker?

#4

Launching!

iTrader: (14)

Join Date: Jan 2005

Location: Belton, Tx

Posts: 246

Likes: 0

Received 0 Likes

on

0 Posts

I've seen several guys over spin their smaller blowers with great results. I know Mr. Big overspun the crap out of his P1 and made somewhere around 780rw. Doug at ECS is overspinning his novi 2000 with no issue as well.

I know i've seen someone swap the bearings out in their blower to some with higher tolerences in order to take on the extra rpm that is required.

I know i've seen someone swap the bearings out in their blower to some with higher tolerences in order to take on the extra rpm that is required.

#6

TECH Veteran

iTrader: (32)

from what iv read its the wheel that gets effected and not soo much the bearings. at the higher rpms the wheel gets deflection/expands and rubs the housing of the charger and thats why the "better" blowers have a thicker wheel on them. Dont quote me on it as it is just what iv read.

Trending Topics

#8

I actually measured my pulleys today and was a little suprised with the results. The crank pulley, which is supposed to be 8.25" actually measured out a 8.13". My RR blower pulley, which is stamped 3.5" actually measured out a 3.54". I measured them by wraping a taylor's tape around the pulley to get a circumference measurement and dividing by pi. This is the most accurate way I can figure to measure a pulley as just sticking a ruler across it only ballparks the measurement due to the outside lip being taller. Is there a proper way to measure a pulley. How do any of the pulley manufacturers do it? I measured some other pulleys I had from procharger and they are off a significant amount as well. It's kind of like measureing the circumference of slicks. I've yet to see one that was per the manufacturers specs.

Anyway, I'm gonna give the pulley combo a shot. I shift at 6900 and the motor will generally flash to about 7050 for a split second before the rpms drop. This should put me about 64970 impeller speed at the shift. It's a little higher than I wanted it, but I can't find a 3.6 or 3.7 RR pulley in 8-rib anywere, and RR is not answering my emails. I sure hope I've got one of those D1's that doesn't go boom from spinning it a little higher than recommended. We'll see. Maybe I'll turn the shift point down to 6800 at first and see what happens.

Anyway, I'm gonna give the pulley combo a shot. I shift at 6900 and the motor will generally flash to about 7050 for a split second before the rpms drop. This should put me about 64970 impeller speed at the shift. It's a little higher than I wanted it, but I can't find a 3.6 or 3.7 RR pulley in 8-rib anywere, and RR is not answering my emails. I sure hope I've got one of those D1's that doesn't go boom from spinning it a little higher than recommended. We'll see. Maybe I'll turn the shift point down to 6800 at first and see what happens.

#11

Make sure you are using a larger than supplied air filter with your D-1SC when cranking up the boost. We have picked up two psi of boost just be swapping to a larger air filter.

More than likely you would pick up more power by swapping to an F-1A, even if you kept the boost at the same level that the D-1SC is producing. Check this build out. http://www.exoticperformanceplus.com...Car.php?car=29 Bob

More than likely you would pick up more power by swapping to an F-1A, even if you kept the boost at the same level that the D-1SC is producing. Check this build out. http://www.exoticperformanceplus.com...Car.php?car=29 Bob

#12

Make sure you are using a larger than supplied air filter with your D-1SC when cranking up the boost. We have picked up two psi of boost just be swapping to a larger air filter.

More than likely you would pick up more power by swapping to an F-1A, even if you kept the boost at the same level that the D-1SC is producing. Check this build out. http://www.exoticperformanceplus.com...Car.php?car=29 Bob

More than likely you would pick up more power by swapping to an F-1A, even if you kept the boost at the same level that the D-1SC is producing. Check this build out. http://www.exoticperformanceplus.com...Car.php?car=29 Bob

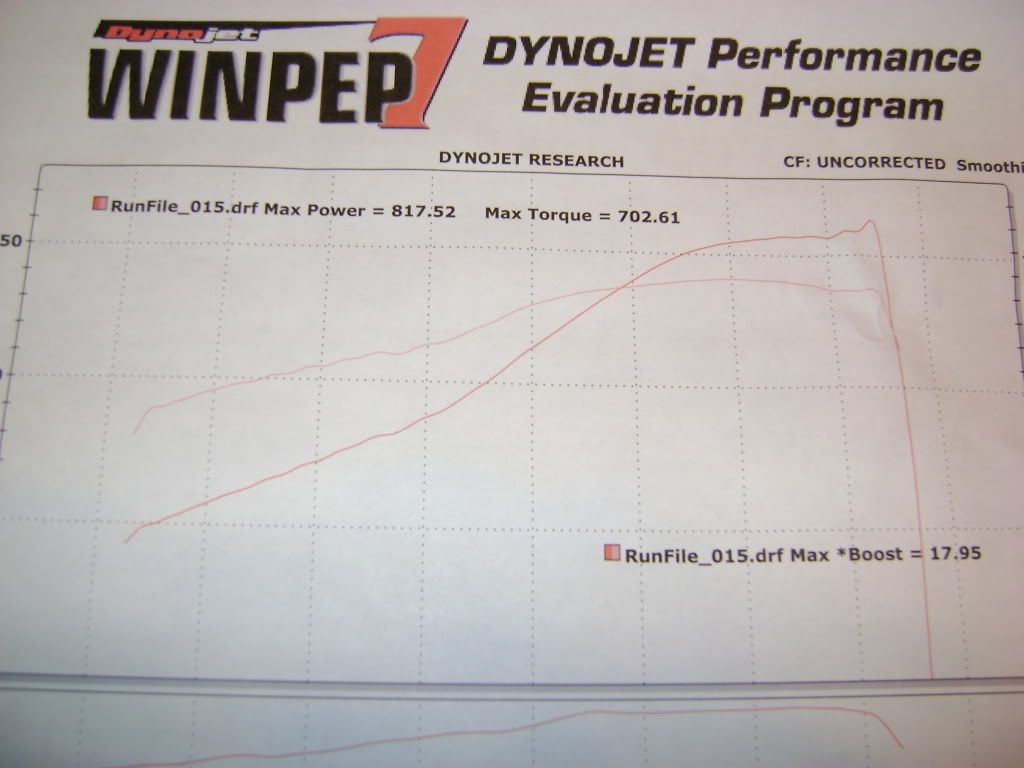

I really don't know what to expect by adding this much blower rpm. I'm basically going from spinning the D1 86% and running 10.90's at 126 mph to spinning the D1 106%. I'm hoping to at least go 130. Any guesses on how much power this thing will pick up with the additional 10600 rpm?