**RCC Twin Turbo Build Update**

#1

TECH Addict

Thread Starter

iTrader: (2)

Join Date: Jan 2002

Location: houston

Posts: 2,422

Likes: 0

Received 0 Likes

on

0 Posts

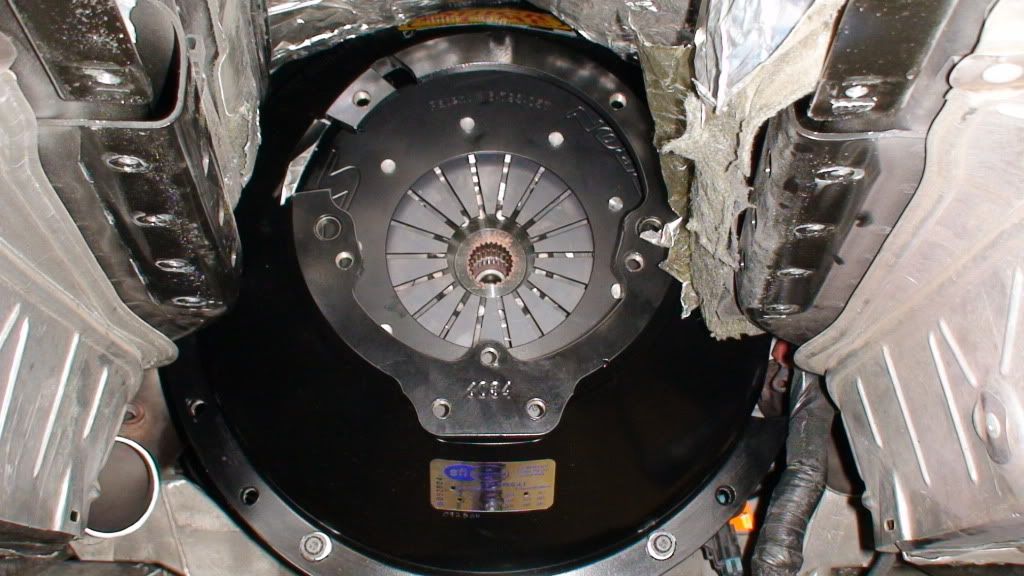

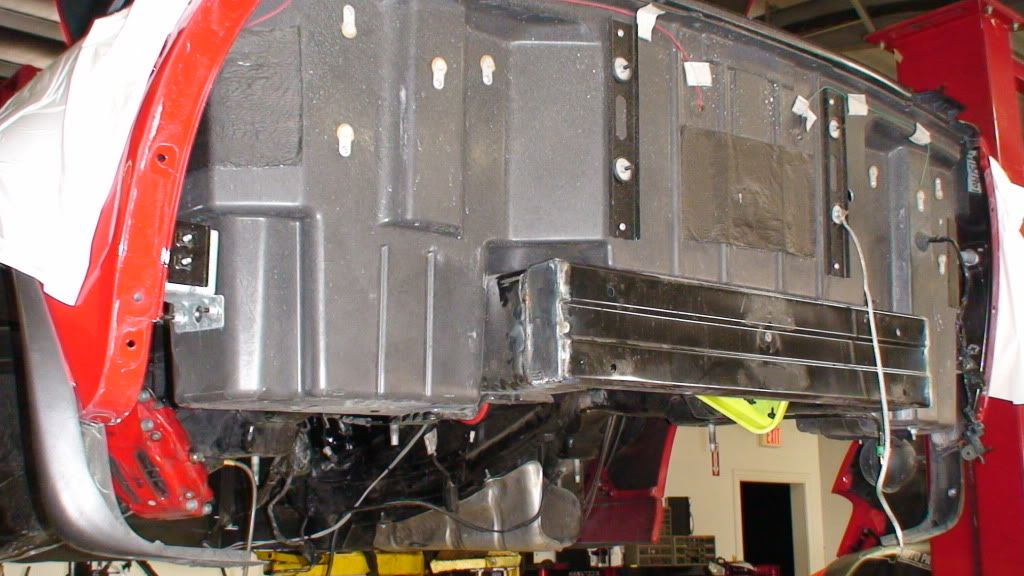

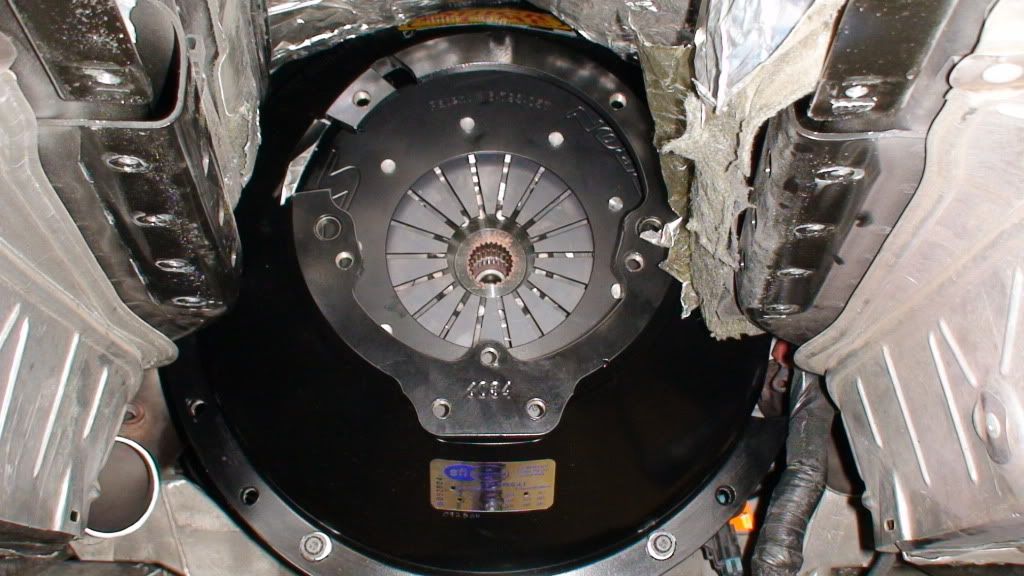

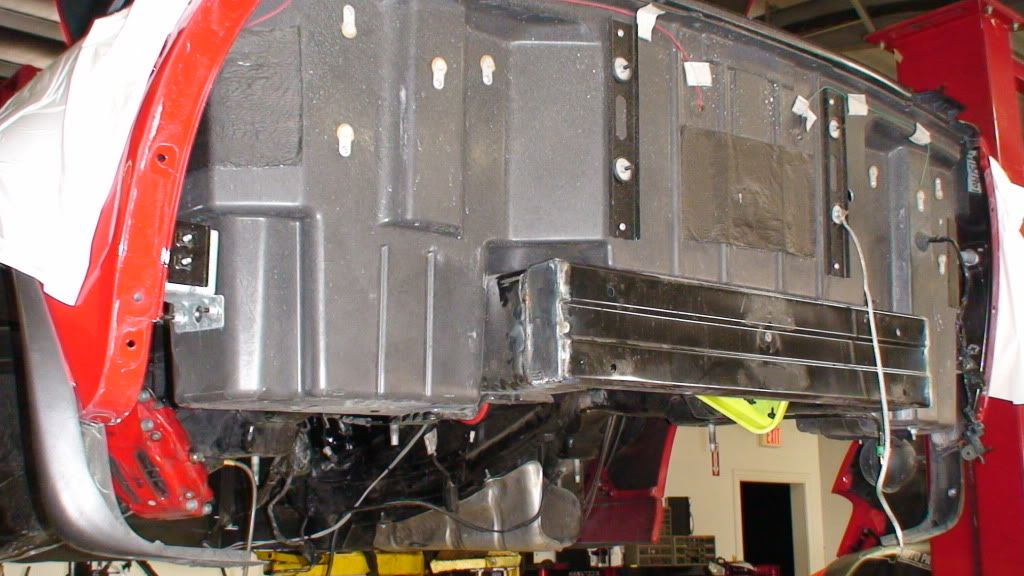

Finally some parts are starting to roll in so Josh began the new build. I will try and keep the pics coming weekly for you to view RC. Please let me know what yall think.

Updated pics from yesterday:

Updated pics from yesterday:

#6

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

amazing build, do you happen to have a flow chart for your oval pipe. Ive been curious for a long time about flow characteristics. I know its the cross sectional area that matters. But cant ever seem to find a flow chart for oval pipe. Have them all day for round, just not oval

And you guys are killing me. Making me wanna go live in a box so i can afford to make my car this sick. lol Great work, as always!!!!!!!

And you guys are killing me. Making me wanna go live in a box so i can afford to make my car this sick. lol Great work, as always!!!!!!!

Trending Topics

#8

TECH Fanatic

iTrader: (13)

amazing build, do you happen to have a flow chart for your oval pipe. Ive been curious for a long time about flow characteristics. I know its the cross sectional area that matters. But cant ever seem to find a flow chart for oval pipe. Have them all day for round, just not oval

And you guys are killing me. Making me wanna go live in a box so i can afford to make my car this sick. lol Great work, as always!!!!!!!

And you guys are killing me. Making me wanna go live in a box so i can afford to make my car this sick. lol Great work, as always!!!!!!!

Spintech sells everything!!! Up to a 6in Oval.

#11

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

i was almost 100% positive that round flows better then oval. Kind of the same deal with two smaller pipes not being the same as a larger. ie. two 2" pipes together dont flow as well as one 4" pipe.

#12

On The Tree

Join Date: Jan 2009

Location: Willis Texas

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

#14

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Im not saying your method is flawed. It would help to know what the flow of the oval pipe is. IE. Pressure drop/friction loss. Since i dont have a chart i cannot tell you. other information to know would be, the velocity in which your exhaust is moving.

But i cant tell you that a 5" pipe that is flowing 100 cfm has a friction loss of .2 and that a 10" pipe flowing 100 cfm has a friction loss of around .05 which is much better. Now i used 5" and 10" at 100 cfm because it was round numbers.

but the same does and will hold true for smaller size pipes. Now, If i had an oval chart, i could figure out what size it would take to be equivalent.

maybe ill try this formula on for size. lol

de = 1.55 (π b2 / 4 + a b - b2)0.625/(π b + 2 a - 2 b)0.25

http://www.engineeringtoolbox.com/eq...ter-d_205.html

Found at bottom of page, last equation.

give me a second, and ill figure this out. lol

But i cant tell you that a 5" pipe that is flowing 100 cfm has a friction loss of .2 and that a 10" pipe flowing 100 cfm has a friction loss of around .05 which is much better. Now i used 5" and 10" at 100 cfm because it was round numbers.

but the same does and will hold true for smaller size pipes. Now, If i had an oval chart, i could figure out what size it would take to be equivalent.

maybe ill try this formula on for size. lol

de = 1.55 (π b2 / 4 + a b - b2)0.625/(π b + 2 a - 2 b)0.25

http://www.engineeringtoolbox.com/eq...ter-d_205.html

Found at bottom of page, last equation.

give me a second, and ill figure this out. lol

Last edited by JAX04; 07-22-2010 at 01:23 PM.

#15

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Now unless i completely botched that formula and the math. Your 5" oval is about the same as a 4.25" diameter Round pipe. Assuming the flow characteristics are similar. Which i have not determined yet.

assuming that 3.25=B and 6=A which is the numbers used from spintechs' drawing. Height and Width.

Im no math wizz, and haven't done a compound math problem in over 10 years. i hope i did it right

Im going to do it again, probably two more times, it was fun. Not having even looked at an equation like that in years. lol

EDIT: Did it again, and did it somewhat differently, i thought i made a previous mistake, and still got 4.247

assuming that 3.25=B and 6=A which is the numbers used from spintechs' drawing. Height and Width.

Im no math wizz, and haven't done a compound math problem in over 10 years. i hope i did it right

Im going to do it again, probably two more times, it was fun. Not having even looked at an equation like that in years. lol

EDIT: Did it again, and did it somewhat differently, i thought i made a previous mistake, and still got 4.247

Last edited by JAX04; 07-22-2010 at 02:10 PM.

#16

9 Second Club

iTrader: (27)

Join Date: Apr 2003

Location: HOUSTON-TX

Posts: 3,685

Likes: 0

Received 0 Likes

on

0 Posts

right on, good move. It must keep equal hydraulic radius in order to not affect flow. Its not as simple as equal areas because of friction losses of the fluid against the walls of the tubing as well as friction between the fluid itself, although this maybe negligible in some cases.

#17

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

right on, good move. It must keep equal hydraulic radius in order to not affect flow. Its not as simple as equal areas because of friction losses of the fluid against the walls of the tubing as well as friction between the fluid itself, although this maybe negligible in some cases.

higher head pressure would result in a higher reynolds number. And a lower pressure drop would result in a more laminar flow

still trying to find the formula for hydraulic radius of oval tubing

Either way, going from two pipes of a diameter of 3.5" to a single 5" oval will result in a higher pressure at that point and cause a more turbulent flow. Which is not what we want.

Last edited by JAX04; 07-22-2010 at 03:13 PM.

.jpg)