gear pattern check please

#1

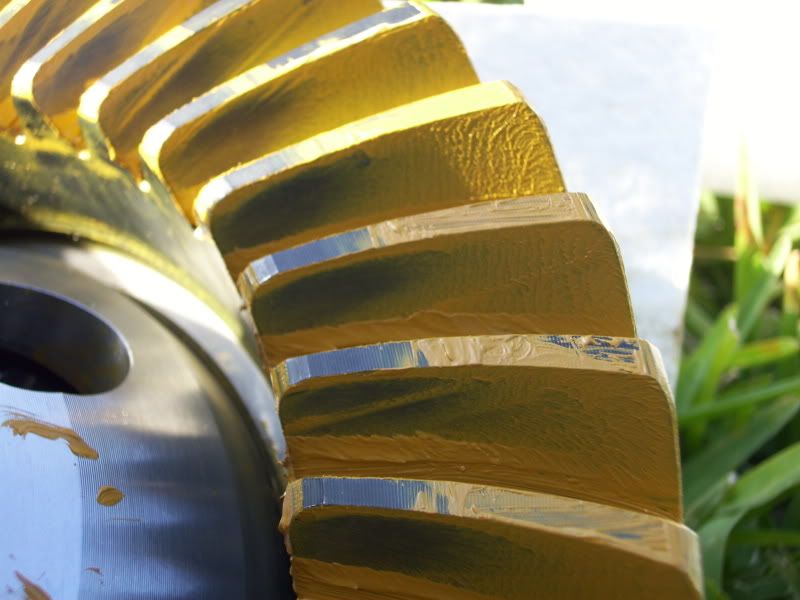

Trying to set up my 9" third member, got the backlash set right at .009". Here are my drive and coast patterns.

Drive

Coast

thanks,

pete

Drive

Coast

thanks,

pete

Last edited by vettett15; 04-28-2009 at 06:44 PM.

#3

you mean like it could move to the right in the first pic (sorry forgot the terminology)?

Would that mean I need to add shims on the pinion support to housing interface. Thanks for the response

Would that mean I need to add shims on the pinion support to housing interface. Thanks for the response

#4

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

basically move the ring gear in closer to the pinion to get the pattern a little deeper on the ring gear tooth, it seems to be pretty close to the edge. i may be wrong though as im still learning wipe patterns.

Trending Topics

#8

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 81 Likes

on

72 Posts

i was looking again and there does seem to be a line on the drive side where its not going to the edge of the tooth, just like the coast, except the coast is more defined. maybe you didnt load it as good on the drive side. set your backlash within spec and gives us some fresh pics...

#10

Yeah my plan is to tighten up the backlash a little more and then put some new compound on the gears and see what the pattern looks like. I'm pretty sure I need to add just a touch thicker shim between the pinion support and housing. I just want to get this thing together. Appreciate the responses so far.

#15

mikey,

I have the preloaders pretty tight when i'm checking the backlash but i'm not apply any load to the actualy preloaders themselves with like a clamp or bar or something. Also when doing the gear pattern check do you spin the pinion both ways?

I have the preloaders pretty tight when i'm checking the backlash but i'm not apply any load to the actualy preloaders themselves with like a clamp or bar or something. Also when doing the gear pattern check do you spin the pinion both ways?

#16

FormerVendor

iTrader: (2)

Join Date: Dec 2007

Location: Sacramento, California

Posts: 761

Likes: 0

Received 0 Likes

on

0 Posts

Those patterns are a bit unclear. Put a little oil on the ring gear teeth and make sure you have carrier preload, rotate the ring gear back and forth 3 or 4 times then take more pics so we have a better picture of the contact pattern.

Jeff

Jeff

#18

11 Second Club

iTrader: (37)

I put at a minimum,,, 75lb/ft of torque on the side adjusters. This preloads the caps so they won't spread/move apart under a hard launch and f*(K up your settings.

Also, you should be applying resistance to the ring gear while spinning the pinion when doing your pattern check. Sometimes people forget that part lol...

I've never actually had a pattern turn out like yours before, with the drive side so far out on the heel, and the coast side so far into the toe.

Mike

#19

FormerVendor

iTrader: (2)

Join Date: Dec 2007

Location: Sacramento, California

Posts: 761

Likes: 0

Received 0 Likes

on

0 Posts

Heel to Toe makes no difference if the pattern is centered from face to flank or top to bottom. If the housing was machined high or low you will get the heel/toe combo like shown above. Make sure your backlash is out to .010" and button it up.

Jeff

Jeff