Gasket Matching an L76 intake

#1

I picked up some #823 L92 heads and an L76 rectangle port stock plastic intake manifold. The ports on the intake manifold are around 1/8" smaller than the ports in the heads! A huge port mismatch! There is a surprising amount of meat around the ports in the plastic intake. I really think that they could be matched well, an normally I'd just use an intake gasket to port match both the heads and intake. But I've heard from that the available paper gaskets have a uselessly large opening. Can anybody confirm this? Or measure a paper rectangular port gasket for me?

I'm hoping that a felpro or GMPP or whatever will actually closely line up with the head ports?

Per Anthony at LG Motorsports:

Intake ports have shown to be the same size and shape (roughly 1.25" wide x 2.53" tall) [on the LS3 vs L76 stock intake manifolds] The heads port or well over 1.35" wide.

http://www.digitalcorvettes.com/foru...ad.php?t=79686

I'm hoping that a felpro or GMPP or whatever will actually closely line up with the head ports?

Per Anthony at LG Motorsports:

Intake ports have shown to be the same size and shape (roughly 1.25" wide x 2.53" tall) [on the LS3 vs L76 stock intake manifolds] The heads port or well over 1.35" wide.

http://www.digitalcorvettes.com/foru...ad.php?t=79686

#3

Edelbrock ain't helpin

"Edelbrock Victor Jr. LS Series Gen IV Carbureted Manifold w/ L92 Cylinder Heads

Installation Notes: Uses LS1/LS6 style individual port o-ring seals GM PN12590125"

Here's a GMPP GM L92 Carb Intake Gasket 19172114 , only $25. Anybody know how wide these ports are?

Another option

http://www.scegaskets.com/Chevrolet/...-p6597835.html

only $16: Intake Gaskets for Gen 4 Chevrolet L92 6.2L with Aftermarket 4 Barrel Aluminum Manifolds (see also p/n 119103, 119105, 219103, 4119), Gasket Thickness: .032"; Port Size: 1.200" x 2.510" irregular rectangle; Package Contents: 1 Pair.

Smaller than the stock manifold???

"Edelbrock Victor Jr. LS Series Gen IV Carbureted Manifold w/ L92 Cylinder Heads

Installation Notes: Uses LS1/LS6 style individual port o-ring seals GM PN12590125"

Here's a GMPP GM L92 Carb Intake Gasket 19172114 , only $25. Anybody know how wide these ports are?

Another option

http://www.scegaskets.com/Chevrolet/...-p6597835.html

only $16: Intake Gaskets for Gen 4 Chevrolet L92 6.2L with Aftermarket 4 Barrel Aluminum Manifolds (see also p/n 119103, 119105, 219103, 4119), Gasket Thickness: .032"; Port Size: 1.200" x 2.510" irregular rectangle; Package Contents: 1 Pair.

Smaller than the stock manifold???

Last edited by GIGAPUNK; 01-26-2011 at 11:36 PM.

#5

I ordered the SCE intake gaskets. If they are actually smaller then that's a good thing. I'll post up the gaskets port dimensions when I get them. Now I need some Stainless 1.875" header flanges to use as a "gasket" for hogging out the exhaust ports. Any body know who makes some nice thick ones for not too much coin?

#6

I ordered the SCE intake gaskets. If they are actually smaller then that's a good thing. I'll post up the gaskets port dimensions when I get them. Now I need some Stainless 1.875" header flanges to use as a "gasket" for hogging out the exhaust ports. Any body know who makes some nice thick ones for not too much coin?

#7

Thanx for the tip. I found this great link to a pdf of the book you were refering too. Here's the relevant quote,

"We do not make an attempt to match the port

exit to the exhaust pipe. It is better to have a mismatch

at this point to reduce exhaust backflow. There

may be some slight gain, however, in raising the

centerline of the exhaust pipe above the centerline

of the head port. With the tube elevated some, the

activity near the roof of the port will exit more nearly

in line with the center of the header."

http://freeshopmanual.com/forum/view...p?thread_id=53

The question becomes how much mismatch is ideal? With step headers you usually step up 1/8" at a time. Which equates to only 1/16" of mismatch. That would still be quite a bit of hogging out to get just 1/16" mismatch between an LS3 exhaust port and a 1 7/8" header.

Here's a pic of WCCH ex port vs stock. They kick some *** in next months Hot Rod LS3 head shoot out. Notice how the stock D shape has been hogged out

"We do not make an attempt to match the port

exit to the exhaust pipe. It is better to have a mismatch

at this point to reduce exhaust backflow. There

may be some slight gain, however, in raising the

centerline of the exhaust pipe above the centerline

of the head port. With the tube elevated some, the

activity near the roof of the port will exit more nearly

in line with the center of the header."

http://freeshopmanual.com/forum/view...p?thread_id=53

The question becomes how much mismatch is ideal? With step headers you usually step up 1/8" at a time. Which equates to only 1/16" of mismatch. That would still be quite a bit of hogging out to get just 1/16" mismatch between an LS3 exhaust port and a 1 7/8" header.

Here's a pic of WCCH ex port vs stock. They kick some *** in next months Hot Rod LS3 head shoot out. Notice how the stock D shape has been hogged out

Trending Topics

#8

Youre on the right track but I believe youre thinking the mis-match is with the primary diameter.

The exhaust, itself, doesn't travel down the center of the exhaust port. It rides the top or the "long turn".

Grumpy was saying to have the primary pipe center, be raised in comparison to the exhaust port center. How much? I'm not sure. Thats what grumpy was all about.

How else did he get 600hp out of a 327 SBC with dual carbs back in the 70's with STOCK ported heads? Thats still unheard of.

The exhaust, itself, doesn't travel down the center of the exhaust port. It rides the top or the "long turn".

Grumpy was saying to have the primary pipe center, be raised in comparison to the exhaust port center. How much? I'm not sure. Thats what grumpy was all about.

How else did he get 600hp out of a 327 SBC with dual carbs back in the 70's with STOCK ported heads? Thats still unheard of.

#11

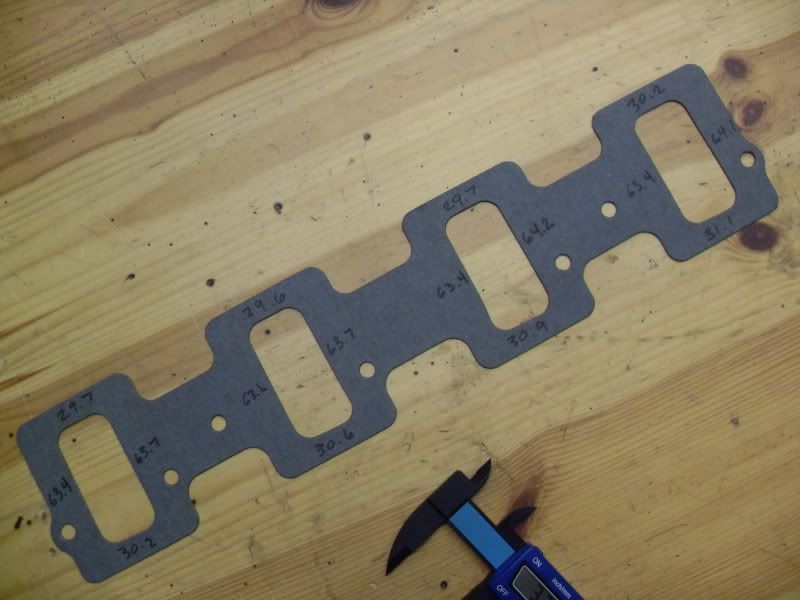

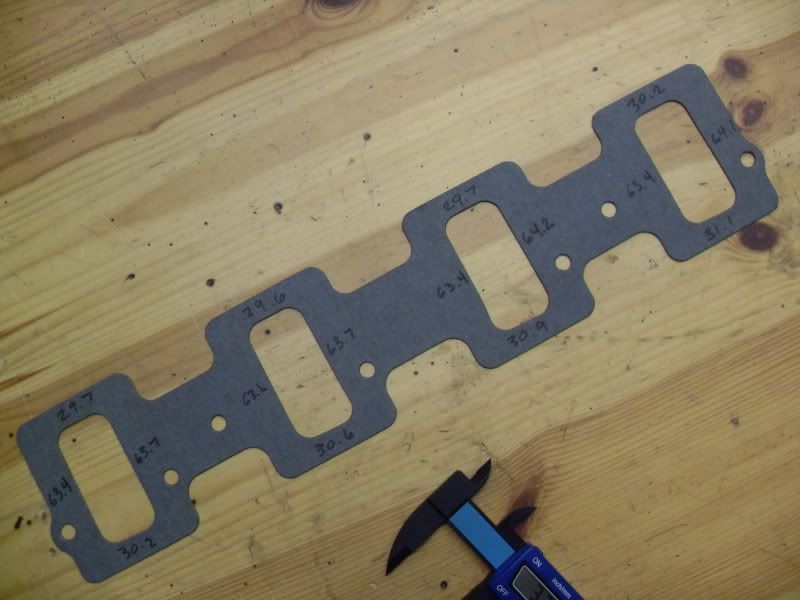

Got the SCE gasket in the mail yesterday. It's ports weren't perfectly square but they were smaller than both the head and intake ports for the most part.

The LS3 head port dimensions

Gasket Overlay

Overlay on Intake (with intake dimension measurements upright)

The LS3 head port dimensions

Gasket Overlay

Overlay on Intake (with intake dimension measurements upright)

#12

What do you guys think of this idea

alittle1 from near Nome, Alaska suggested the following

http://www.hotrodders.com/forum/port...old-30804.html

For perfect port match, do the following:

1. Coat the intake port flange side with Dykem machine shop ink. (Dark blue ink)

2. Place the heads (with valve assembly removed) on the engine with gaskets, place intake manifold with gaskets on top of lifter valley, bolt together firmly.

3. Remove head bolts, lift off bolted heads and intake manifold assembly.

4. Place sandblaster nozzle in each valve port and give it a 2 -3 second blast while aiming nozzle towards towards intake ports.

5. Disassemble heads from intake manifold and you should have a perfect impression of the head port area on your intake manifold. The sandblasting removes the Dykem ink from the intake port flanges, leaving a clear sharp edge to port to.

Note! you can reverse the procedure if intakes are larger than head ports.

Been doing this for port matching for twenty-five years or more, works slick as snot.

My only two concerns are that it's going to be a bitch to clean the sand 100% out of an LSX one piece plastic manifold, and two, that the sand blasting won't be clearly visible on the black plastic, because using Dykum is a waste of time on black plastic. Maybe a dusting of white spray paint instead of Dykum?

alittle1 from near Nome, Alaska suggested the following

http://www.hotrodders.com/forum/port...old-30804.html

For perfect port match, do the following:

1. Coat the intake port flange side with Dykem machine shop ink. (Dark blue ink)

2. Place the heads (with valve assembly removed) on the engine with gaskets, place intake manifold with gaskets on top of lifter valley, bolt together firmly.

3. Remove head bolts, lift off bolted heads and intake manifold assembly.

4. Place sandblaster nozzle in each valve port and give it a 2 -3 second blast while aiming nozzle towards towards intake ports.

5. Disassemble heads from intake manifold and you should have a perfect impression of the head port area on your intake manifold. The sandblasting removes the Dykem ink from the intake port flanges, leaving a clear sharp edge to port to.

Note! you can reverse the procedure if intakes are larger than head ports.

Been doing this for port matching for twenty-five years or more, works slick as snot.

My only two concerns are that it's going to be a bitch to clean the sand 100% out of an LSX one piece plastic manifold, and two, that the sand blasting won't be clearly visible on the black plastic, because using Dykum is a waste of time on black plastic. Maybe a dusting of white spray paint instead of Dykum?

#13

What do you guys think of this idea

alittle1 from near Nome, Alaska suggested the following

http://www.hotrodders.com/forum/port...old-30804.html

For perfect port match, do the following:

1. Coat the intake port flange side with Dykem machine shop ink. (Dark blue ink)

2. Place the heads (with valve assembly removed) on the engine with gaskets, place intake manifold with gaskets on top of lifter valley, bolt together firmly.

3. Remove head bolts, lift off bolted heads and intake manifold assembly.

4. Place sandblaster nozzle in each valve port and give it a 2 -3 second blast while aiming nozzle towards towards intake ports.

5. Disassemble heads from intake manifold and you should have a perfect impression of the head port area on your intake manifold. The sandblasting removes the Dykem ink from the intake port flanges, leaving a clear sharp edge to port to.

Note! you can reverse the procedure if intakes are larger than head ports.

Been doing this for port matching for twenty-five years or more, works slick as snot.

My only two concerns are that it's going to be a bitch to clean the sand 100% out of an LSX one piece plastic manifold, and two, that the sand blasting won't be clearly visible on the black plastic, because using Dykum is a waste of time on black plastic. Maybe a dusting of white spray paint instead of Dykum?

alittle1 from near Nome, Alaska suggested the following

http://www.hotrodders.com/forum/port...old-30804.html

For perfect port match, do the following:

1. Coat the intake port flange side with Dykem machine shop ink. (Dark blue ink)

2. Place the heads (with valve assembly removed) on the engine with gaskets, place intake manifold with gaskets on top of lifter valley, bolt together firmly.

3. Remove head bolts, lift off bolted heads and intake manifold assembly.

4. Place sandblaster nozzle in each valve port and give it a 2 -3 second blast while aiming nozzle towards towards intake ports.

5. Disassemble heads from intake manifold and you should have a perfect impression of the head port area on your intake manifold. The sandblasting removes the Dykem ink from the intake port flanges, leaving a clear sharp edge to port to.

Note! you can reverse the procedure if intakes are larger than head ports.

Been doing this for port matching for twenty-five years or more, works slick as snot.

My only two concerns are that it's going to be a bitch to clean the sand 100% out of an LSX one piece plastic manifold, and two, that the sand blasting won't be clearly visible on the black plastic, because using Dykum is a waste of time on black plastic. Maybe a dusting of white spray paint instead of Dykum?

the port match looks really good for factory parts. I would just leave it alone if it were me.